Hydraulic shearing machines utilize the powerful thrust generated by hydraulic cylinders to cut sheet metal into desired shapes and sizes. They boast advantages such as large shearing force, high efficiency, convenient operation, and high safety, making them indispensable equipment in modern sheet metal processing.

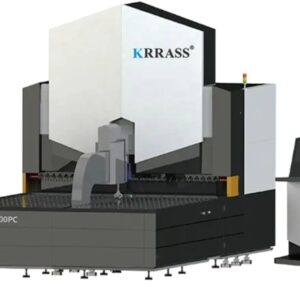

1.Introduction to hydraulic shearing machine

Hydraulic shearing machines utilize the powerful thrust generated by hydraulic cylinders to cut sheet metal into desired shapes and sizes. They boast advantages such as large shearing force, high efficiency, convenient operation, and high safety, making them indispensable equipment in modern sheet metal processing.

2. Working Principle of Hydraulic Shearing Machines

The fundamental working principle of hydraulic shearing machines is as follows:

- The hydraulic pump pressurizes the hydraulic oil.

- The pressurized hydraulic oil enters the hydraulic cylinder through the hydraulic control valve.

- The hydraulic cylinder drives the blades to move, completing the shearing of the sheet metal.

2.1 Composition of Hydraulic System

The hydraulic system of a hydraulic shearing machine primarily consists of the following components:

- Hydraulic pump: Converts mechanical energy into hydraulic energy, providing power for the hydraulic system. Common hydraulic pump types include gear pumps, vane pumps, and plunger pumps.

- Hydraulic cylinder: Converts hydraulic energy into mechanical energy, driving the blades to move. The cylinder diameter and stroke determine the magnitude of the shearing force and the length of the shearing stroke.

- Hydraulic control valve: Controls the direction and speed of the hydraulic cylinder movement. Common hydraulic control valves include directional control valves, pressure control valves, and flow control valves.

- Hydraulic oil tank: Stores hydraulic oil and dissipates heat. The capacity of the hydraulic oil tank should be sufficiently large to ensure the normal operation of the hydraulic system.

2.2 Working Process

- The operator starts the hydraulic pump to pressurize the hydraulic oil.

- The pressurized hydraulic oil flows into the hydraulic cylinder through the hydraulic control valve.

- The hydraulic cylinder drives the blades to move, completing the shearing of the sheet metal.

- After the shearing is completed, the hydraulic oil flows back to the hydraulic oil tank through the hydraulic control valve.

3. Maintenance of Hydraulic Shearing Machines

Regular maintenance is necessary to ensure the normal operation and prolong the service life of hydraulic shearing machines.

3.1 Daily Maintenance

- Check the hydraulic oil level in the tank and ensure it is within the specified range. Insufficient hydraulic oil can lead to abnormal operation of the hydraulic system.

- Inspect the color and clarity of the hydraulic oil. If it becomes discolored or cloudy, replace the hydraulic oil promptly. Deteriorated hydraulic oil will accelerate the wear of the components in the hydraulic system.

- Examine all connections in the hydraulic system for any leaks. Hydraulic system leaks can cause a drop in hydraulic oil pressure, affecting the shearing force.

- Clean the exterior of the hydraulic shearing machine to keep it clean. Dust and dirt can accelerate the corrosion of components in the hydraulic system.

3.2 Regular Maintenance

- Replace the hydraulic oil filter. The hydraulic oil filter can remove impurities from the hydraulic oil, protecting the components in the hydraulic system.

- Inspect all components in the hydraulic system. If any wear or damage is found, repair or replace them promptly. Worn or damaged components can lead to abnormal operation of the hydraulic system.

- Debug the hydraulic system to ensure its normal operation. Debugging includes checking the hydraulic oil pressure, adjusting the hydraulic control valves, etc.

4. Troubleshooting of Hydraulic Shearing Machines

Hydraulic shearing machines may encounter some problems during operation. Here are common troubleshooting methods for common problems:

- Insufficient Shearing Force:

- Check if the hydraulic oil level is sufficient.

- Inspect if the hydraulic oil pressure is normal.

- Examine the hydraulic cylinder seal rings for damage.

- Check if the blades are sharp.

5. Conclusion

Hydraulic shearing machines are crucial sheet metal processing equipment. Understanding their working principles, hydraulic system composition, and maintenance methods is vital for maximizing their efficiency and lifespan. This knowledge also equips users with the ability to troubleshoot common issues, ensuring smooth operation and maintaining optimal performance.