Discover how KRRASS’s Bending technology can help you optimize your production

More productive sheet metal machines, new customized solutions, and easy-to-use option suites are designed to meet the customer’s real needs.

KRRASS is Industry 4.0

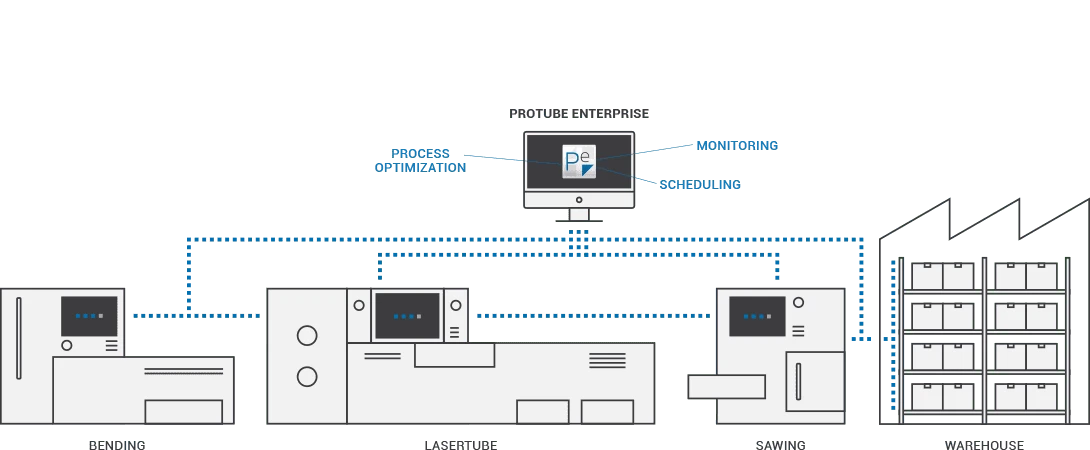

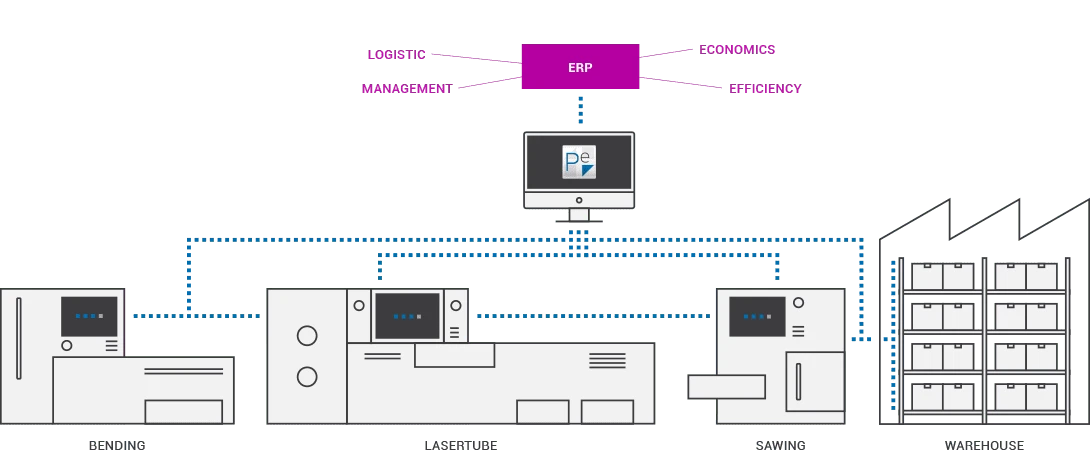

KRRASS machines and software form a productive ecosystem with a constant exchange of digital information. The key to all this is the availability of information with which you can constantly monitor your work and streamline the work flow from design to production.

Priceless

All information at your fingertips

Quotes, part programs, technology options, reports: everything you need to know about your productions is available in real-time and in digital format.

Track every single part

Don’t lose your bearings. Keep track of the history of each of your finished products. The KRRASS system automatically associates traceability codes with your processes, so you can monitor your production process at all times.

React immediately to the unexpected

The intelligence of the system reconfigures the production processes following unexpected events. With Active Job technology, machine and software will always be synchronized.

More efficiency and productivity with Industrial IoT

Don’t waste time. Don’t waste material. Don’t keep the machine stopped. Take advantage of the Industrial Internet of Things (IIoT) to maximize the efficiency of your line and increase the quality and quantity of your production.

For your production

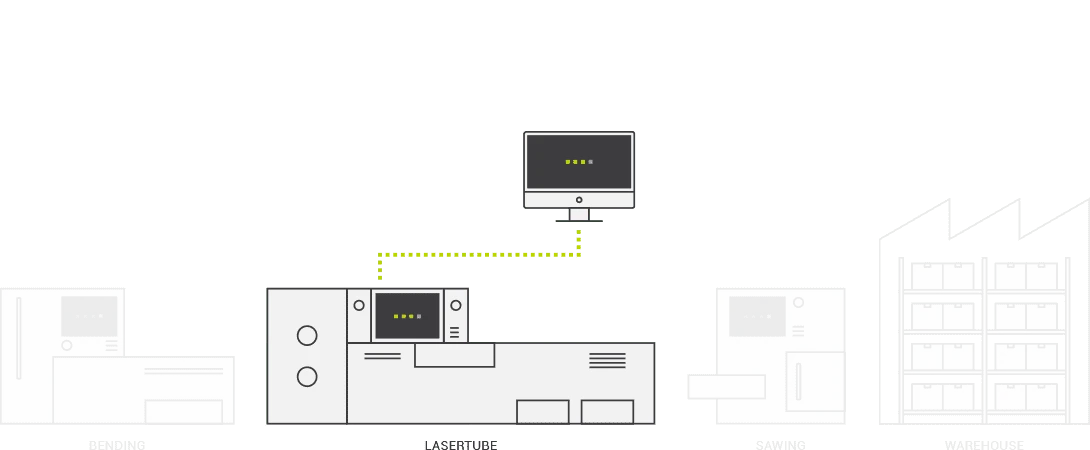

1. Monitor your machine

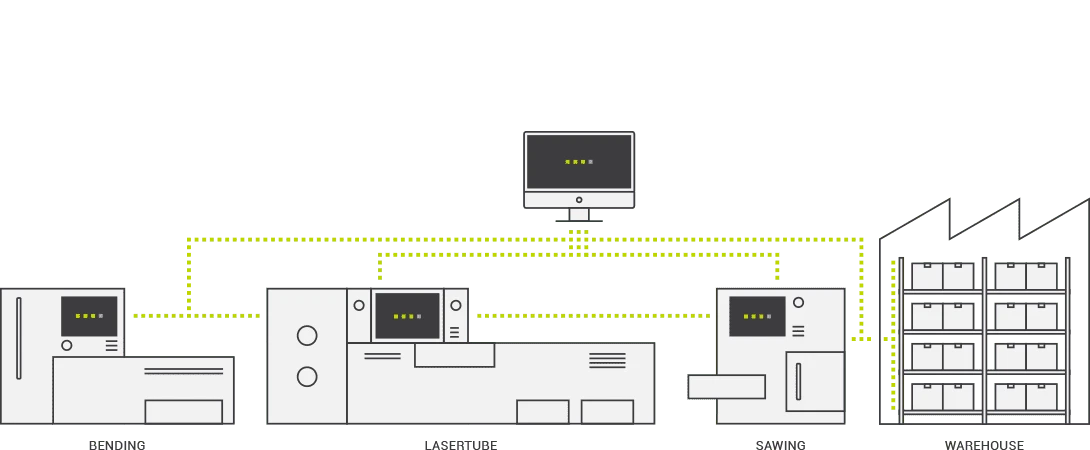

2. Leverage interconnections

3. Integrate programming and planning

4. Integrate the corporate information system

For your support

Continuous remote support

In the event of critical issues, KRRASS Service Department can securely connect to your machine for immediate troubleshooting and resolution.

Our professionalism is always at your service.

Easier with augmented reality

Active Eye is your augmented reality 4.0 remote support that you can use to contact the KRRASS Service Department via smartphone, tablet or PC.

100% predictive, 0% unexpected

Analyze machine performance data and recommended maintenance actions to prevent unexpected failures. You have maximum system availability at all times.