The process of selecting a press brake controller

A press brake controller is a type of device used to control and automate the operation of a press brake machine. It typically includes a programming interface that allows operators to input commands and specify parameters such as bending angles, backgauge positions, and tooling setups. The controller then uses this information to operate the press brake in a precise and efficient manner, ensuring accurate and consistent bending of sheet metal or other workpieces. Some advanced press brake controllers may also include features such as automatic tool compensation, collision detection, and data logging capabilities.

I.How to select the press brake controller?

II.Classification of CNC controllers

III.When choosing a DELEM press brake controller type, consider the following factors:

IV.Classification of NC controllers

IIV.Summary

I.How to select the press brake controller?

- Determine the required specifications: Before selecting a press brake controller, determine the specific requirements such as the length and thickness of the material to be bent, the number of axes needed, and the level of automation required.

- Research and compare different brands and models: Research different brands and models of press brake controllers available in the market. Compare their features, capabilities, reliability, and customer reviews to determine which one best suits your needs.

- Consider the type of control system: There are different types of control systems available for press brake controllers, such as manual, CNC, and hydraulic. Consider the type of control system that would work best for your application and production requirements.

- Evaluate the operator interface: The operator interface of the press brake controller should be user-friendly and easy to navigate. Consider factors such as the size and resolution of the display, the layout of buttons and controls, and the availability of programming options.

- Determine the level of automation: Depending on your production requirements, you may need a press brake controller with varying levels of automation, such as automatic tool changing, bend sequence optimization, and offline programming capabilities. Consider the level of automation needed for your specific application.

- Consider the compatibility with existing equipment: If you already have other machines or equipment in your production facility, consider the compatibility of the press brake controller with your existing equipment to ensure seamless integration and operation.

- Get quotes and compare costs: Once you have narrowed down your options, request quotes from different suppliers and compare the costs of the press brake controllers. Consider not only the initial cost but also the long-term maintenance and operational costs.

- Consult with experts: If you are unsure about which press brake controller to select, consult with experts or professionals in the field who can provide guidance and recommendations based on your specific requirements.

- Make a decision and purchase: Once you have evaluated all the factors and options, make a decision on the press brake controller that best meets your needs and purchase it from a reputable supplier.

According to the principle of numerical control calculation of the controller, it is divided into NC controller and CNC controller.

II.Classification of CNC controllers

1.DELEM 53T Controller:

The compact DA-53T adds a state-of-the-art complete touch control solution for synchronized press brakes. Offering easiest CNC programming based on the Delem graphical touch screen user interface.

This panel based control, standard capable of controlling up to 4 axes, can be integrated in cabinets as well as used in a pendulant arm housing.

Its 10.1" wide screen high resolution color TFT, with industrial grade multi touch technology, gives access to the proven Delem user-interface. It enables direct “hot-key” touch navigation between product programming and actual production. Functions are located where needed, offering optimized ergonomics throughout the entire application.

Machine adjustment and test bends are reduced to a minimum with a quick and easy program-to-production work sequence.

Features:

"Hot-key” touch navigation

10.1" high resolution colour TFT

Up to 4 axes (Y1,Y2 + 2 aux. axes)

Crowning control

Tool / material / product library

Servo and frequency inverter control

Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

TandemLink (option)

USB memory stick interfacing

Profile-T offline software

2.DELEM DA53Tx Controller:

The new DA-53Tx touch CNC control provides a modern compact and versatile solution for a wide range of press brake applications without compromising machine functionality.

The DA-50T-series offers easiest CNC programming based on the proven Delem touch screen user interface. The new compact DA-53Tx with extra large screen adds a state of the art complete touch control solution for synchronized press brakes.

This panel based control, standard capable of controlling up to 4 axes, can be integrated in cabinets as well as used in an optional pendulant arm housing. Its 15" wide screen high resolution colour TFT, with industrial grade multi touch technology, gives access to the user friendly Delem user-interface. It enables direct “hot-key” touch navigation between product programming and actual production. Functions are located where needed, offering optimised ergonomics throughout the entire application.

Machine adjustment and test bends are reduced to a minimum with a quick and easy program-to-production work sequence.

Next to a full package of functionality and functions which make everyday work as easy as possible, optionally 2D graphical product and tool programming is supported. USB interfacing is standard and enables fast product and tool backup using USB memory sticks.

Features

Numerical touch screen programming

15" high resolution color TFT

Crowning control

Servo and frequency inverter control

Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

USB, peripheral interfacing

Profile-T offline software

- DELEM DA58T Controller:

The DA-58T is a state-of-the-art complete 2D graphical control solution for synchronized press brakes. Offering easiest CNC programming based on the Delem graphical touch screen user interface including automatic bend sequence calculation and collision detection.

Its 15" high resolution colour TFT, with industrial grade multi touch screen technology, gives access to the proven Delem user-interface. It enables direct navigation between product programming and actual production. Functions are directly located where needed, offering optimised ergonomics throughout the entire application.

Machine adjustment and test bends are reduced to a minimum with a quick and easy program-to-production work sequence. CNC programs are generated with a single touch. You are immediately ready to make the first part since all axes positions are automatically computed and the bend sequence has been simulated with machine and tools in real scale. The production mode of the DA-58T helps the operator in graphically simulating the bend process of the product, guiding him during the press brake operation.

Features

2D graphical touch screen programming

15" high resolution color TFT

Bend sequence calculation

Crowning control

Servo and frequency inverter control

Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

USB, peripheral interfacing

Profile-T offline software

4. DELEM DA58Tx Controller:

The new DA-58Tx touch CNC control provides a modern compact and versatile solution for powerful economic press brake applications.

This control with extra large screen adds a state of the art complete 2D graphical solution for synchronized press brakes to the DA-50T series.

The DA-58Tx, standard capable of controlling up to 4 axes, is housed in a stylish pendulant arm cabinet. Its 18,5" wide screen high resolution color TFT, with industrial grade multi touch technology, gives access to the user friendly Delem user-interface. It enables direct “hot-key” touch navigation between product programming and actual production.

Machine adjustment and test bends are reduced to a minimum with a quick and easy program-to-production work sequence. CNC programs can be generated with a single touch, immediately ready to make the first part. Axes positions are automatically computed and the bend sequence can be been simulated with machine and tools in real scale.

The DA-58Tx offers 2D programming including automatic bend sequence calculation and collision detection. The production mode of the DA-58T helps the operator in graphically simulating the bend process of the product, guiding him during the press brake operation.

Features

2D graphical touch screen programming

18,5" high resolution color TFT

Bend sequence calculation

Crowning control

Servo and frequency inverter control

Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

USB, peripheral interfacing

Profile-T offline software

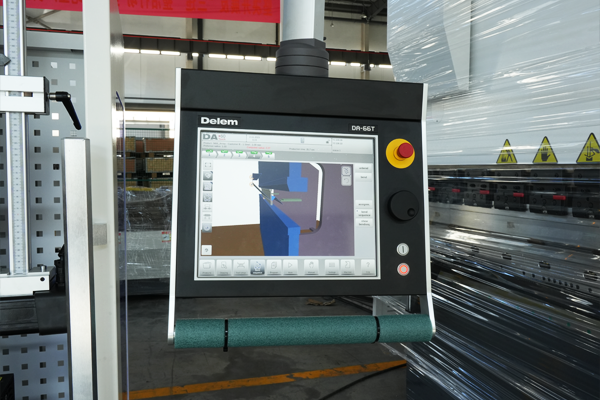

5 .DELEM DA66T Controller:

The new generation DA-Touch controls offer an even higher grade of efficiency in programming, operation and control of today’s press brakes. Ease of use combined with state-of-the-art technology go hand in hand, improving productivity.

The touch screen gives access to the proven Delem user-interface and enables direct navigation between programming and production. Functions are directly located where you need them, offering optimised ergonomics throughout the application.

The DA-66T offers 2D programming that includes automatic bend sequence calculation and collision detection. Full 3D machine set-up with multiple tool stations giving true feedback on the product feasibility and handling.

Highly effective control algorithms optimise the machine cycle and minimise set-up time. This makes using press brakes easier, more efficient and more versatile than ever.

Features

2D graphical touch screen programming mode

17" high resolution colour TFT

Full Windows application suite

Delem Modusys compatibility (module scalability and adaptivity)

USB, peripheral interfacing

User specific application support within the control's multitasking environment

Sensor bending & correction interface Profile-TL offline software

6.DELEM DA66S Controller:

The DA-66S control combines solid fundamental press brake control functionality with the latest of enhancements increasing productivity. Next to highest accuracies, ease-of-use for the operator it makes today’s press brakes more versatile than ever. Integration of machines in the manufacturing process chain is what it is all about.

The control operation, based on state-of-the-art industrial touch screen technology, gives access to the proven renewed Delem user-interface and enables direct navigation between programming and production. Functions are directly located where you need them, offering optimized ergonomics throughout the application.

The DA-66S offers 2D programming that includes automatic bend sequence calculation and collision detection. Full 3D machine set-up with multiple tool stations giving true feedback on the product feasibility and handling.

Highly effective control algorithms optimise the machine cycle and minimise set-up time. Abive the screen a panel is reserved for machine functions and OEM-application switches, integrated in the design and used depending on the required application.

Features

2D graphical touch screen programming mode

3D machine representation, in simulation and production

24" high resolution color TFT

Delem Modusys compatibility (module scalability and adaptivity)

USB, peripheral interfacing

User specific application support within the control's multitasking environment

Sensor bending & correction interface

Profile-S2D offline software

7.DELEM DA69T Controller:

The latest generation DA-Touch controls offer an even higher grade of efficiency in programming, operation and control of today's press brakes. Ease of use combined with state-of-the-art technology go hand in hand, improving productivity.

The touch screen gives access to the proven Delem user-interface and enables direct navigation between programming and production. Functions are directly located where you need them, offering optimised ergonomics throughout the application.

The DA-69T offers 2D as well as 3D programming that includes automatic bend sequence calculation and collision detection. Full 3D machine set-up with multiple tool stations giving true feedback on the product feasibility and handling.

Highly effective control algorithms optimise the machine cycle and minimise set-up time. This makes using press brakes easier, more efficient and more versatile than ever.

Features

3D and 2D graphical touch screen programming mode

3D visualisation in simulation and production

17" high resolution colour TFT

Full Windows application suite

Delem Modusys compatibility (module scalability and adaptivity)

USB, peripheral interfacing

User specific application support within the control's multitasking environment

Sensor bending & correction interface

Profile-T3D offline software

8.DELEM DA69S Controller:

The DA-69S flagship control combines solid fundamental press brake control functionality with the latest of enhancements increasing productivity. Next to highest accuracies, ease-of-use for the operator it makes today’s press brakes more versatile than ever. Integration of machines in the manufacturing process chain is what it is all about.

The control operation, based on state-of-the art industrial touch screen technology, gives access to the proven renewed Delem user-interface and enables direct navigation between programming and production. Functions are directly located where you need them, offering optimized ergonomics throughout the application. |

The DA-69S offers 2D as well as 3D programming that includes automatic bend sequence calculation and collision detection. Full 3D machine set-up with multiple tool stations giving true feedback on the product feasibility and handling.

Highly effective control algorithms optimize the machine cycle and minimize set-up time. Above the screen, a panel is reserved for machine functions and special application switches, integrated in the design and available depending on the required application.

Features

3D and 2D graphical touch screen programming mode

3D visualization, including 3D machine representation, in simulation and production

24" high resolution color TFT

Delem Modusys compatibility (module scalability and adaptivity)

USB, peripheral interfacing

User specific application support within the control's multitasking environment

Sensor bending & correction interface

Profile-S3D offline software

9.DELEM DA60S Controller:

The DD-60S 2nd display for the DA-60S press brake control expands its solution with the ability to integrate additional software applications as well as it can expand the control GUI. Using ERP systems at the machine, enables the operator to see production plans, know his activity schedule and also update activities directly in the system. Next to reference lookup in e.g. PDF or even CAD/CAM systems, understanding details on the job at hand, make efficiency increase. No separate workstations near the machine and no last minute calls to preparation in order to have all set for the main task, produce the part. The DD-60S 2nd display is a full functional 1920 x 1200 touchscreen solution which can be connected to both PC (connected to the company LAN) as well as to the DA-60S press brake control. |

Neat functionality is provided with the automatically switching function over the DA-60S user interface. If installed and applicable, the DD-60S can be switched from PC to control and vice versa. The USB ports connecting the keyboard, mouse and touchscreen, will be automatically appointed the active function.

The display can also be used solely for the computer functionality at the machine.

Features

24" high resolution colour TFT

Industrial grade touch screen functionality

HDMI interfacing

Proprietary switch function from CNC

USB, peripheral interfacing, automatically switching 2x USB, switching with source 1x USB, direct

III.When choosing a DELEM press brake controller type, consider the following factors:

- Material type and thickness: Determine the specific material type and thickness you will be working with, as different types of press brake controllers are designed for different materials and thicknesses.

- Number of axes needed: Consider the number of axes (typically between 3 and 12) required for your bending operations. Choose a DELEM press brake controller that offers the appropriate number of axes for your specific application.if you buy 3+1axis,4+1 axis, you can choosing DA53T,DA53TX,DA58T,DA58TX,if you buy 6+1axis,7+1axis,8+1 axis,9+1axis,10+1axis you need choosing DA66T,DA66S,DA69T,DA69S.

- Level of automation: Decide on the level of automation needed for your production requirements, such bend sequence optimization, and offline programming capabilities,you need choosing da66t,da66s,or da69t,da69s. Select a DELEM press brake controller that offers the desired level of automation.

- Operator interface: Evaluate the operator interface of the DELEM press brake controller to ensure it is user-friendly, easy to navigate, and provides all necessary programming options for your bending operations.

- Consulting with DELEM experts: If you are unsure about which DELEM press brake controller type to choose, consult with DELEM experts or professionals who can provide guidance based on your specific requirements.

By considering these factors, you can select the most suitable DELEM press brake controller type for your bending operations.

IV.Classification of NC controllers

1.ESTUN E21 Controller

Backgauge control

Control the common motor or inverter

Intelligent positioning

Holding pressure unloading time setting

Workpiece counting

40 programs stored, 25 steps per program

Unilateral positioning

Concession function

One-key backup / restore

mm / inch

Chinese / English

2.ESTUN E310P Controller

4 axes are supported, viz, X-axis, Y-axis, R-axis and C-axis.

Automatic calculation of the block position, according to the bending angle, material, thickness

and mold parameters.

The back gauge can be controlled in a high-accuracy since the servo systems control X-axis and

R-axis.

Optional hydraulic or mechanical to control the C-axis.

Program in absolute value or angle.

Materials and die informations are programable.

Language setting and unit setting.

3.DELEM DA41T/DA42T Controller

Touch press brake control for torsion bar press brakes

The DA-41T control provides a user friendly and versatile touch control solution for conventional press brake applications with support for multiple axes. Upon demand it is possible to control the press beam, the backgauge as well as a flexible I/O configuration, based on state-of-the-art electronics.

The numerical programming supports bending steps with angle programming, tool and material parameters on hand in a clear table overview. The standard available USB interface supports backup and restore functionality of all products and tools.

The backgauge control supports servo, 2-speed AC as well as inverter control. Depending on the application you can select either two side or single side positioning, using optional spindle correction functionality. The variant CNC type DA-42T supports dual axes backgauge control (X+R) and crowning functionality.

With its easy to use touch screen navigation on the bright LCD screen, operation is most user-friendly and efficient, thus increasing productivity. The numerical programming with clear icons guides the operator through all programming functions.

Features

Colour LCD display

7" widescreen TFT, high brightness

LED backlight

1024 x 600 pixels, 32 bit colour

Full touch screen control (PCT-touch)

Program memory for 100 programs

Program steps 25 steps per program

Tool library

Panel version

USB flash memory drive

Panel based housing

Bright LCD screen

Beam stop control (Y)

Backgauge control (X)

Retract functionality

Manual movement of all axes

Backgauge control (R) (DA-42T)

Crowning function (DA-42T)

Pressure control (DA-42T)

4.CYBELEC CybTouch 8 Controller

CybTouch 8P is specifically designed for conventional (with torsion bar) press brakes control

It has an intuitive and vivid color full touch screen and a high integration of functions. Its robust design is available in panel or housing version.

Thanks to its large keys, online help, simplified software and many other automatic functions that constantly guide the operator, CybTouch is as simple as a positioner control.

We offer two models:

CybTouch 8 2P, 2 axes (Y, X)

CybTouch 8 3P, 3 axes (Y, X, R)

Large, vivid and high-contrast fully touch screen.

Simple pages, clear display, large keys.

Very simple single bends with

EasyBend page.

Complete programming allows efficient mass-production of parts with multiple bends.

Online help and warning pop-ups make it a very user-friendly software.

Available in many languages.

Comfortable wireless software updating and data backup using PC or Notebook.

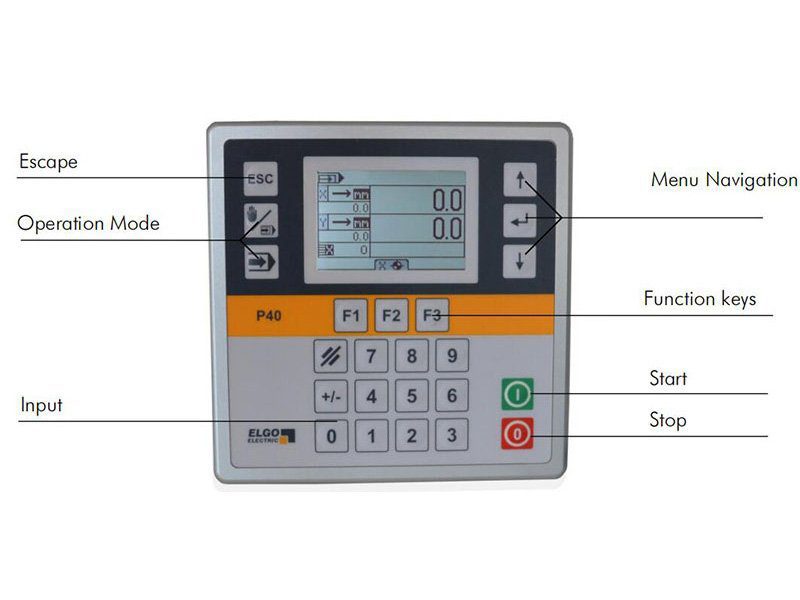

5.ELGO P40 Controller

P40 POSITION CONTROLLER FOR 2 AXES CONTROLLER FOR METAL MACHINES

two-axis version

LCD display

Easy handling

Multi-lingual menu navigation

Option PID analog output available

Reference run

Manual-, single- and program mode

IIV.Summary:

Among the four controllers of CNC Press Brake, ESTUN E21 and ELGO P40, the X axis and Y axis of these two systems use stepper motors, which have large error values in positioning accuracy and speed. E310P,CT8,DA41T,DA42T, X axis and Y axis use servo motors. When you choose, we recommend that buyers choose X axis and Y axis servo motor, fast positioning accuracy, when your budget is limited, it is recommended to choose E310P controller, which is the most cost-effective controller, he comes from Nanjing ESTUN listed company, stable quality, after-sales guarantee, many factories use TP10S, It is an inferior bending machine controller, when you use it for a year, there will be many quality problems, and the cost is high when you repair it. Will cause you a lot of trouble, it is recommended that customers choose the correct bending machine controller.

Reviewed by 2 users

Press Brake controller

Machines like Krrass are equipped with DELEM’s controller, which is very stable and durable.

Página muito útil, a introdução do 110T3200 é muito detalhada. Obrigado ao KRRASS.