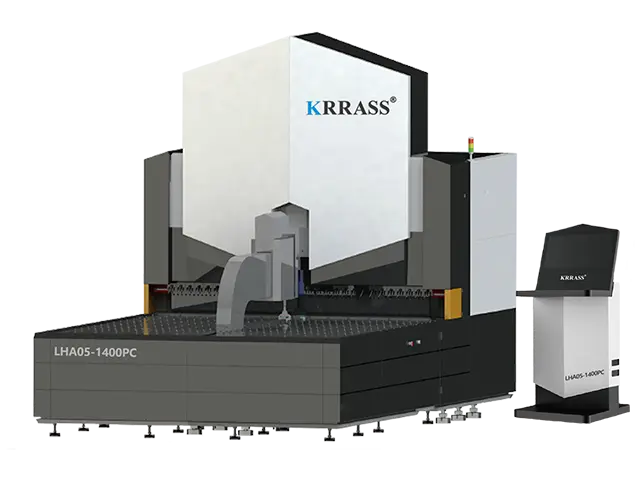

Panel Bender

As the leading panel bender manufacturer in China, KRRASS always provide the best panel bender machine to manufacturers around the world. A panel bender machine is a piece of equipment used in the manufacturing and fabrication industries to bend and shape sheet metal or other flat materials into various shapes and configurations.

We equip the machine with a suction cup design that enables sheet metal fabrication with a maximum bending size of 2000mm x 2000mm. Its remarkable bending speed of only 0.2 seconds per bend significantly enhances productivity and helps reduce labor expenses.

Inquire Now

What is Panel Bender?

1.The panel bender can bend a wide variety of items, achieving bends that cannot be made on any other bending machine. Its integrated adaptive technologies make the system intelligent and able to automatically adapt to changes in the material and the external environment, eliminating waste and corrections, and extending the range of products that can be made.

2.The compact electric panel bender natively combines productivity, with its automatic bending and handling cycles, and flexibility, with its universal bending tools. It doesn't require re-tooling and the set-up has minimal impact on productivity. It is also equipped with the ABA automatic blankholder, which automatically adapts the length of the tool according to the size of the part to be produced without the need for machine downtime or manual re-tooling

3.The panel bender is 100% electric, minimizing consumption. It adopts only electric actuators, thus removing the hydraulics and guaranteeing maximum consumption of 3kW. The technical solutions adopted, including the use of only pneumatic and electric actuators, allow it to respect both people and the environment without reducing productivity

Panel Bender

Panel Bender

The compact electric panel bender is truly a game-changer in the world of bending machines. With its automatic bending and handling cycles, it offers unparalleled productivity and flexibility.

Customer Case

FAQ

What are the advantages of KRRASS Panel Bender's Control System?

The entire control system of KRRASS panel bender is designed according to the platform, which has good stability and scalability; its self-driven robotic arm and multi-axis linkage cutting machine tool have good scalability. It is easy to extend to other fields.

However, most competitors’ control systems are temporarily assembled or improved based on turret punching machines, which need better stability and scalability.

How does KRRASS panel bender load and unload automatically?

KRRASS panel bender can directly mount the self-driven robotic arm, which is effectively combined with the bending center, with high efficiency and muscular flexibility. It is also convenient to replace the workpiece; the movement of the self-driven robotic arm of the panel bender is automatically generated according to the bending action, so the user does not need to maintain the automated arm program, and the operation is simple and convenient.

Most competitors’ panel bender robotic arms cannot be directly driven but can only be docked with the mechanical arm system, resulting in users needing to maintain two systems. Changing workpieces requires repeated debugging between the two systems very inconvenient during the bending process.

What about the concurrent linking of the KRRASS panel bender?

The underlying driver of the KRRASS panel bender is developed using a hardware description language, which can realize absolute multi-axis concurrent linkage control, coordinate movement between axes without time difference, and efficiently complete various complex action combinations.

However, most of the panel benders of other manufacturers use the bus control method, not accurate concurrent linkage, which leads to more axes of the machine, more significant time difference, and poorer association, so it can only complete some relatively simple actions. The overall efficiency could be higher.

Reviewed by 10 users

any uograde for the panel bender? waiting

The panel bender machine I got from KRRASS really works well.I am quite satisfied

Fuimos a la fábrica a ver esta máquina de doblado panel y decidimos comprarla, tiene muy buena calidad.

El doblador de Panel llegó a tiempo, con la calidad esperada KRASS RAS-2000. El gerente de ventas fue muy atento y servicial.

I ordered the RAS- 2500, fabulous!!