In the dynamic world of precision metal fabrication, the Hydraulic Press Brake has emerged as an essential tool, thanks to its advanced technology and unparalleled capabilities. In this comprehensive guide, we will delve into what a Hydraulic Press Brake is, explore its various industrial applications, unravel its components and working principle, and finally guide you on how to select the best Hydraulic Press Brake for your needs. Read on to gain a deep understanding of this remarkable machine.

- What is Hydraulic Press Brake

- Industrial Applications of Hydraulic Press Brake

- The Core of Hydraulic Press Brake

- Working Principle of Hydraulic Press Brakes

- Why Use a Hydraulic Press?

- The Bending Device of a Hydraulic Press Brake

- What are the main factors to consider when buying a hydraulic press brake?

1.What is a Hydraulic Press Brake

A Hydraulic Press Brake is a vital piece of equipment in the metalworking industry. This powerful machine uses the principles of hydraulics to exert significant force to bend and shape various types of metal. The ease with which a Hydraulic Press Brake can manipulate metal makes it an indispensable tool in many sectors, including the automotive, aerospace, and construction industries.

A Hydraulic Press Brake operates by using two synchronized hydraulic cylinders on the C-frames moving the upper beam. The force created by the hydraulic fluid's pressure powers the operation, helping the machine achieve accurate bends on the metal workpiece. The advanced hydraulic system ensures consistency in force application, providing precise control and repeatable results.

The Hydraulic Press Brake includes a bracket, a workbench and a clamping plate. The workbench is placed on the bracket. The workbench is composed of a base and a pressure plate. The base is connected to the clamping plate through a hinge. The base is composed of a seat shell, a coil and a cover plate. The coil It is placed in the depression of the seat shell, and the top of the depression is covered with a cover plate. When in use, the wire is energized to the coil, and after energization, an attractive force is generated on the pressure plate, so as to realize the clamping of the thin plate between the pressure plate and the base. Due to the use of electromagnetic force clamping, the pressure plate can be made into a variety of workpiece requirements, and it can also process workpieces with side walls.

2.Industrial Applications of Hydraulic Press Brake

The Hydraulic Press Brake has proven its worth in several industrial sectors thanks to its versatile and robust nature. Here, we will explore some of the key industries where this machinery is commonly found.

Automotive Industry

The automotive industry extensively uses Hydraulic Press Brakes in the manufacturing process of various car components, including body parts and chassis. The precision and consistency provided by these machines are critical in producing components that match exact design specifications.

Aerospace Industry

In the aerospace industry, where tolerances are extremely tight, the Hydraulic Press Brake is a go-to solution for creating airplane parts. The advanced controls and precise bending capabilities make it possible to fabricate complex components with high accuracy.

Construction Industry

Construction projects often require custom metal parts, from beams to plates. The versatility of Hydraulic Press Brakes allows manufacturers to produce a wide range of shapes and sizes, tailored to the specific needs of each project.

In summary, the Hydraulic Press Brake is an invaluable tool in many industries. Its ability to bend and shape metal with precision makes it crucial in industries that demand strict adherence to design specifications and quality standards.

3.The Core of Hydraulic Press Brake: Understanding the Components and Hydraulic System

The functionality and performance of a Hydraulic Press Brake is defined by its core components and the hydraulic system. This section delves into the key elements that make up these essential machines.

Understanding the Components

Key components of a Hydraulic Press Brake include the frame, hydraulic cylinders, punch and die, back gauge, and the control system. The frame is robust, designed to withstand significant pressure. Hydraulic cylinders drive the motion of the machine. The punch and die handle the actual bending of the metal, while the back gauge provides positional accuracy. The control system, often computerized, orchestrates the operation of all components.

Understanding the Hydraulic System

At the heart of the Hydraulic Press Brake is the hydraulic system, consisting of the hydraulic pump, valves, and cylinders. The pump pressurizes the hydraulic fluid, which is then directed by the valves to power the cylinders. The cylinders, in turn, drive the movement of the upper beam to perform the bending operation.

Principles of Hydraulic Systems

Hydraulic systems operate based on Pascal's Principle, which states that when pressure is applied to a confined fluid, the pressure change occurs throughout the entire fluid. This principle enables the system to amplify force, making it possible to bend thick and hard metal sheets with ease.

Specifics of Hydraulic Systems in Press Brakes

In the context of a Hydraulic Press Brake, the hydraulic system's specifics can vary based on the machine design. However, the common characteristic is the system's ability to provide smooth, synchronized movement for accurate and repeatable bending operations. By manipulating the flow and pressure of the hydraulic fluid, the system ensures precise control over the bending process.

In essence, understanding the core components and hydraulic system of a Hydraulic Press Brake is crucial to comprehending how these powerful machines function and deliver their remarkable performance.

4.Working Principle of Hydraulic Press Brakes

In this section, we'll explore the working principle of a Hydraulic Press Brake, delving into the mechanics behind this invaluable machine and the integral role played by its hydraulic system.

Understanding the Mechanics

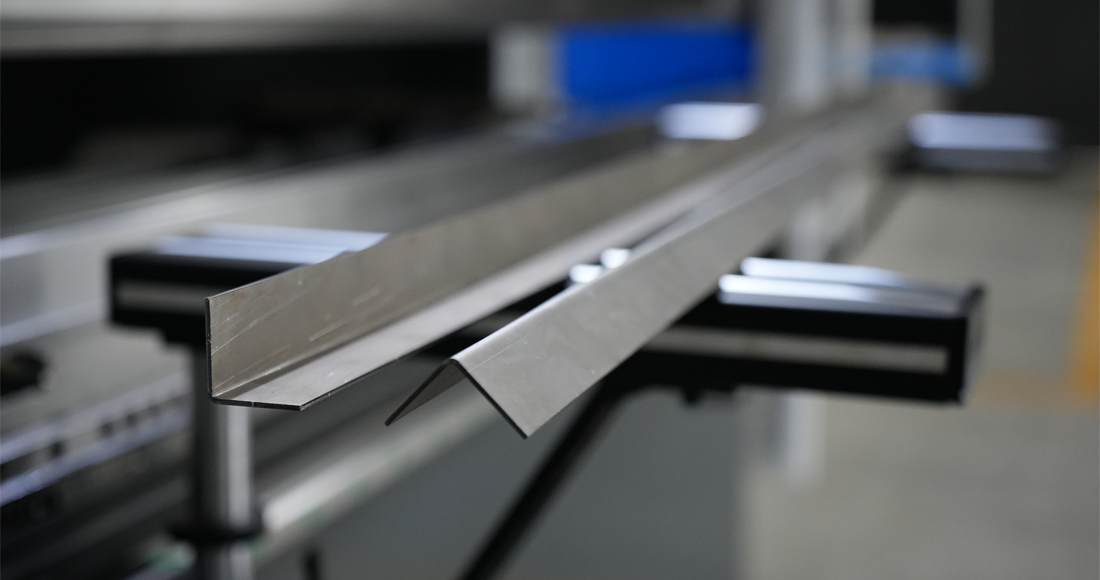

The Hydraulic Press Brake operates by using a pair of synchronized hydraulic cylinders to drive the movement of the upper beam. The metal sheet to be bent is placed between a punch (attached to the upper beam) and a die (secured to the lower beam). As the upper beam descends under the action of the hydraulic cylinders, the punch pushes the metal sheet into the die, resulting in the bending of the metal.

The Role of Hydraulics

The hydraulic system is the powerhouse of the Hydraulic Press Brake. It begins with the hydraulic pump, which pressurizes the hydraulic fluid. This pressurized fluid is then directed by a series of valves to the hydraulic cylinders, which, in response, move the upper beam.

The strength of a hydraulic system lies in its ability to multiply force, as per Pascal's Principle. This force multiplication enables the machine to exert immense pressure for bending operations, even on thick and tough metal sheets.

Through the interplay of mechanical and hydraulic components, the Hydraulic Press Brake efficiently bends and shapes metal with high precision, making it a valuable tool in various industries.

5.Why Use a Hydraulic Press Brake?

The benefits of using a Hydraulic Press Brake are manifold, making it an indispensable machine in many industries. Here are some key reasons why you should consider using one:

High Precision and Consistency

Hydraulic Press Brakes provide excellent precision in bending operations, thanks to their advanced hydraulic systems and computerized controls. The consistency of the results, even across long production runs, makes these machines a reliable choice for precision-focused industries.

Versatility

With a variety of tools and dies available, Hydraulic Press Brakes can handle a wide range of bending tasks, making them highly versatile. They can bend different types of metals and alloys, as well as varying thicknesses.

High Productivity

Thanks to their robust design and efficient operation, Hydraulic Press Brakes offer high productivity. Their ability to work continuously over long periods without fatigue contributes to improved operational efficiency.

Ease of Operation and Maintenance

Modern Hydraulic Press Brakes are equipped with intuitive control systems, making them easy to operate. Their hydraulic systems require relatively less maintenance, reducing the downtime and the overall operating cost.

In conclusion, a Hydraulic Press Brake provides numerous benefits that contribute to its widespread use in different industries. From high precision and versatility to ease of operation, the advantages of using a Hydraulic Press Brake are clear.

6.The Bending Device of a Hydraulic Press Brake

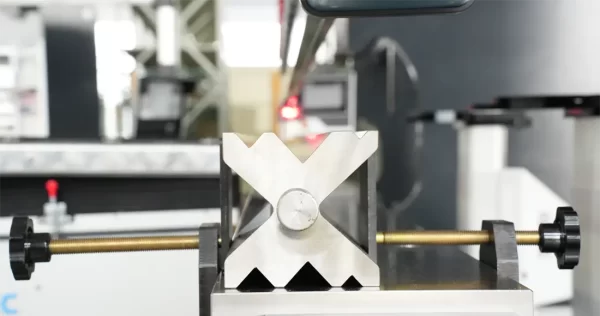

The heart of any Hydraulic Press Brake is its bending device, which consists of two main components: the punch and the die. Their interaction is what enables the machine to perform precise bending operations.

The Punch

The punch is attached to the upper beam of the Hydraulic Press Brake. Its shape determines the internal angle of the bend. It is made from hardened tool steel to withstand the immense pressure exerted during bending operations.

The Die

The die, affixed to the lower beam, works in tandem with the punch. Its shape corresponds to the desired profile of the bent metal sheet. Like the punch, it is made of hardened tool steel to withstand the bending forces.

During the bending operation, the metal sheet is positioned between the punch and the die. As the upper beam descends, the punch pushes the metal sheet into the die, achieving the desired bend.

Selection of Punch and Die

The selection of the punch and die is critical for achieving the desired bend. Factors such as the type and thickness of the metal, the bend angle, and the bending radius influence the choice of punch and die. There is a wide range of punches and dies available, offering immense flexibility in the type of bends that can be achieved with a Hydraulic Press Brake.

In conclusion, the bending device of a Hydraulic Press Brake is key to its operation. It is what enables the machine to transform a flat metal sheet into a piece with precise bends and angles, catering to various industrial applications.

7.What are the main factors to consider when buying a Hydraulic Press Brake?

When investing in a Hydraulic Press Brake, it's crucial to consider several key factors to ensure that you choose the most suitable machine for your specific requirements. Let's delve into some of these key considerations:

Bending Capacity

This refers to the maximum thickness and length of the metal sheet that the machine can bend. Ensure the machine's bending capacity aligns with your operational needs.

Type of Control System

Modern Hydraulic Press Brakes come with computerized numerical control (CNC) systems that provide high precision and ease of operation. Choose a control system that suits your level of complexity and production volume.

Quality and Durability

Check the build quality of the machine and the materials used. A high-quality Hydraulic Press Brake made from durable materials will serve you longer and offer better reliability.

Service and Support

Ensure the manufacturer provides good after-sales service and support, including maintenance, repairs, and availability of spare parts.

Budget

Last but not least, consider your budget. Hydraulic Press Brakes can vary significantly in price depending on their features, capacity, and brand. Choose a machine that offers the best balance between cost and features that you require.

By considering these factors, you'll be well equipped to make an informed decision when purchasing a Hydraulic Press Brake.

Read More: How to choose a Hydraulic Press Brake?

Conclusion

The world of metal fabrication would be drastically different without the Hydraulic Press Brake. This powerful tool has become indispensable in various industries due to its high precision, versatility, productivity, and ease of operation. Choosing the right Hydraulic Press Brake can be a game-changer for your business. At Krrass, we are committed to providing high-quality Hydraulic Press Brakes and other sheet metal machinery, supporting businesses in their quest for perfection. Explore our range today and discover the difference a Krrass machine can make to your operations.

Reviewed by 1 user

cnc press brake

Из KRRASS на твит епископ аргентинск в. садыков “я и и poroshenko” 2010 з очен популярн в росс, мы покупа три, очен работа.