Fiber laser cutting machines has surpassed traditional laser cutting machines and is quickly becoming a mainstream choice in the manufacturing industry. Its excellent precision, efficiency and processing capabilities enable it to handle more complex tasks and help companies achieve higher levels of production.

This guide is designed to provide you with a comprehensive introduction to fiber laser cutting machines, covering their features, benefits, application scenarios, and maintenance requirements. Whether you're a business owner, an engineer, or a casual reader curious about the technology, you'll gain the knowledge in this guide to help you understand and make the most of the transformative power of fiber laser cutting machines.

Table of contents

I. What is a fiber laser cutting machine?

II. How does fiber laser cutting machine work?

III. Using Fiber Laser cutting machines on an Industrial scale

IV. Small-scale manufacturing using fiber laser cutting machines

V. Factors affecting fiber laser cutting machines

VI. CO2 VS fiber laser cutting machine

VII. Metal cutting machine VS fiber laser cutting machine

VIII. CNC cutting machine VS fiber laser cutting machine

IX. Advantages of IX fiber laser cutting machine

X. Factors to consider before choosing a fiber laser cutting machine

XI. KRRASS fiber laser cutting machine

I. What is a fiber laser cutting machine?

Fiber laser cutting machine is an industrial laser cutting equipment that uses high-power fiber laser to cut various materials with high precision and efficiency. This equipment is suitable for metal sheets and pipes of various thicknesses, including thin, soft and thick metal materials. Especially excellent in cutting stainless steel and non-ferrous metal materials. Equipped with more than 500 watts of laser power, the fiber laser cutting machine can easily handle materials of various thicknesses.

II. How does fiber laser cutting machine work?

The working principle of fiber laser cutting machine is to use high-power laser beam to cut various materials.

- The device uses a fiber laser source to generate a high-intensity laser beam that passes through the machine's optical path.

- A lens is then used to focus the laser beam onto the material to be cut, concentrating the laser's energy into a small area.

- The focused laser beam heats and vaporizes the material, creating a narrow cut.

- The laser beam is guided along the desired cutting path via the machine's computer-controlled positioning system.

- During the cutting process, the laser beam melts and vaporizes the material, while the high-pressure gas jet blows the molten material away from the cut, leaving a clean, precise cut edge.

III. Using Fiber Laser Cutting Machines on an Industrial Scale

Fiber laser cutting machines are widely used in many industries, including but not limited to:

Metal processing:

In the fields of metal manufacturing, sheet metal processing, and metal processing, fiber laser cutting machines are used to cut, engrave, and mark various metals, such as stainless steel, aluminum, copper, brass, etc.

Automobile manufacturing:

In the automotive industry, fiber laser cutting machines are used to cut various parts such as body parts, frames, exhaust systems, etc.

Aerospace:

In the aerospace industry, fiber laser cutting machines are used to cut a variety of materials such as titanium, aluminum, and composites to produce aircraft parts.

Electronics Manufacturing:

In the electronics industry, fiber laser cutting machines are used to cut, drill, and mark various components such as circuit boards, connectors, and sensors.

Medical field:

In the medical industry, fiber laser cutting machines are used to cut and mark a variety of materials, such as surgical instruments, implants, and medical devices.

Jewelry Industry:

In the jewelry industry, fiber laser cutting machines are used to cut, engrave and mark precious metals and gemstones.

IV. Small-scale manufacturing using fiber laser cutting machines

Some of the applications for using fiber laser cutting machines for small-scale manufacturing include:

Jewelry production:

Fiber laser cutting machines can be used to cut metal jewelry with high precision and speed to achieve complex designs.

Signage production:

Fiber laser cutting machines can cut precise shapes and text to create signs. This is great for small businesses and local stores that need custom signage.

Model Making:

Fiber laser cutting machines can cut and engrave a variety of wood, plastic, and acrylic materials to create accurate models and prototypes.

Craft making:

Fiber laser cutting machines are great for small craft businesses that need to cut intricate designs on a variety of materials, including paper, cardboard, and fabric.

V. Factors affecting fiber laser cutting machines

There are several factors that affect the performance of fiber laser cutting machines. Here are some of the most important ones:

Laser Power:

The laser power used during cutting can significantly affect cut speed and quality. Generally speaking, higher laser power results in faster, smoother cuts, but also increases the cost of the machine.

Material Type and Thickness:

Different materials have different properties that affect how fiber lasers cut. For example, thicker materials may require higher laser power to cut through, while some materials may reflect the laser beam, requiring additional measures to ensure a successful cut.

Cutting speed:

The speed at which the fiber laser generator moves over the material can affect the quality of the cut, especially when cutting thicker materials. Slower speeds may increase cutting efficiency, but also increase production time and cost.

Focus Position:

The position of the laser focus relative to the material being cut affects the quality and accuracy of the cut. Improper focus position can lead to uneven cuts or even damage to the material.

Gas pressure and type:

The type and pressure of gas used during cutting affects cut quality and speed. Oxygen and nitrogen are commonly used gases in fiber laser cutting, and the pressure of these gases can be adjusted to optimize cutting performance.

VI.CO2 VS fiber laser cutting machine

CO2 laser cutters are another popular laser machine used in various industries. While both types of machines use lasers to cut materials, there are some key differences between them.

- CO2 laser cutting machines use a mixture of gases composed of carbon dioxide to produce a laser beam. These machines typically cut non-metallic materials such as plastic, wood, fabric, and thin metal sheets.

- Fiber laser cutting machines, on the other hand, use a solid-state laser source, often made from fiber optic cables doped with rare earth elements. These machines are ideal for cutting a variety of materials, including metals, ceramics, plastics and composites.

- Fiber laser cutters are generally faster and more precise than CO2 laser cutters. This is because fiber lasers have shorter wavelengths than CO2 lasers, which allows for greater accuracy and faster cutting speeds. Fiber lasers are also more energy efficient, generating less heat and using less power than CO2 lasers.

- In terms of cost, CO2 laser cutting machines are generally cheaper than fiber laser cutting machines, especially for lower power models. However, fiber laser cutting machines offer greater long-term cost savings due to their energy efficiency and lower maintenance requirements.

- Ultimately, choosing a CO2 laser cutting machine or a fiber laser cutting machine will depend on the specific needs and requirements of the user.

VII. Metal cutting machine VS fiber laser cutting machine

Metal cutting machines and fiber laser cutting machines are both used to cut metal, but they use different technologies and each has its own advantages and disadvantages.

- Metal cutting machines use mechanical force and cutting tools such as saws, drills, and milling machines to remove material from metal workpieces. These machines are generally slower and require more maintenance than laser cutters, but they can be more cost-effective for certain jobs and materials.

- Fiber laser cutting machines, on the other hand, use a high-power laser beam to melt and vaporize material on the workpiece. The process is faster and more precise than mechanical cutting and can be used on a wider range of materials, including metals, plastics and composites. Fiber laser cutting machines also have lower maintenance requirements and can be more energy efficient.

- When deciding between metal and fiber laser cutters, it's important to consider the specific needs of the job. For smaller or simpler jobs, a metal cutter may be sufficient and more cost-effective. However, fiber laser cutters may be better suited for larger or more complex jobs that require greater precision and a wider range of materials.

VIII.CNC cutting machine VS fiber laser cutting machine

CNC laser cutting machines (Computer Numerical Control System) can also accurately cut a variety of materials, but their underlying technology and applications are different.

CNC machines are used in various industries from woodworking to metalworking. They work by following a set of programmed instructions to control the movement of a cutting tool, such as a drill, router or saw blade.

The cutting tool is mounted on a movable platform and can be moved in multiple directions, allowing complex cuts and shapes to be made. CNC machines are versatile and can process a variety of materials, including metal, wood, plastic and composites.

Fiber laser cutting machines, on the other hand, are specialized tools primarily used for cutting metal surfaces. They use high-power fiber lasers to melt and vaporize metal, creating clean and precise cuts. Fiber lasers can cut thick metal quickly and accurately, making them ideal for industrial applications such as metal processing and manufacturing.

Fiber laser cutting machines offer several advantages over CNC machines, including faster cutting speeds, greater accuracy, and lower maintenance requirements. They also produce less waste material and can be used to cut a wider range of metals.

However, fiber laser cutting machines are more expensive and less versatile than CNC machines. They also require specialized training and safety precautions to operate. Ultimately, choosing between a CNC machine or a fiber laser cutting machine will depend on the user's specific needs and the materials they are working with.

IX.Advantages of IX fiber laser cutting machine

Here are some advantages of fiber laser cutting machines:

- Speed: Fiber laser cutting machines are much faster than CO2 laser cutting machines. This is because fiber lasers have higher power density and can cut thicker materials faster.

- Precise: Fiber laser cutting machines are precise and can cut shapes and designs with high precision. This is due to their small laser cutting head, spot size, and ability to maintain focus over long distances.

- Great value for money: Fiber laser cutting machines are more cost-effective than CO2 laser cutting machines because they consume less energy, require less maintenance, and last longer.

- Versatility: Fiber laser cutting machines can cut a variety of materials, including metal, plastic, carbon steel, and ceramics, making them a versatile choice for many applications.

- Automation: Fiber laser cutting machines can be fully automated, allowing for continuous, uninterrupted production. They can also be integrated with other manufacturing processes such as welding and bending.

- Environmentally friendly: Compared to traditional CO2 laser cutting machines, fiber laser cutting machines produce less waste and consume less energy, making them more environmentally friendly.

Overall, the advantages of fiber laser cutting machines make them a popular choice for a variety of metal cutting applications, from small prototyping to large-scale industrial production.

X. Factors to consider before choosing a fiber laser cutting machine

Here are a few factors to consider when choosing a fiber laser cutting machine.

Cutting material

The most important thing to consider is what material you need to cut. Fiber lasers are suitable for cutting hard materials such as steel and stainless steel.

Cutting ability

Another thing to consider is the cutting capabilities of the machine. You need to make sure the machine can handle the cutting thickness and size of the material you plan to cut. A common misconception is that high power is a good solution for all thicknesses.

Power

Laser cutting power is also an important consideration. Higher powered machines can cut thicker materials at faster speeds. Laser power settings allow you to adjust the power used to cut materials. Cutting thin materials at very high power may produce poor cutting results.

Cutting speed

The appropriate cutting speed of your machine will affect your production efficiency. Choose a machine with cutting speeds that match your production needs.

Maintain

Maintenance is an important consideration, so choose a machine that is easy to maintain and low-maintenance.

Price

Finally, you need to consider the price of the machine. Determine your budget and choose a machine that offers the features you need at a price you can afford.

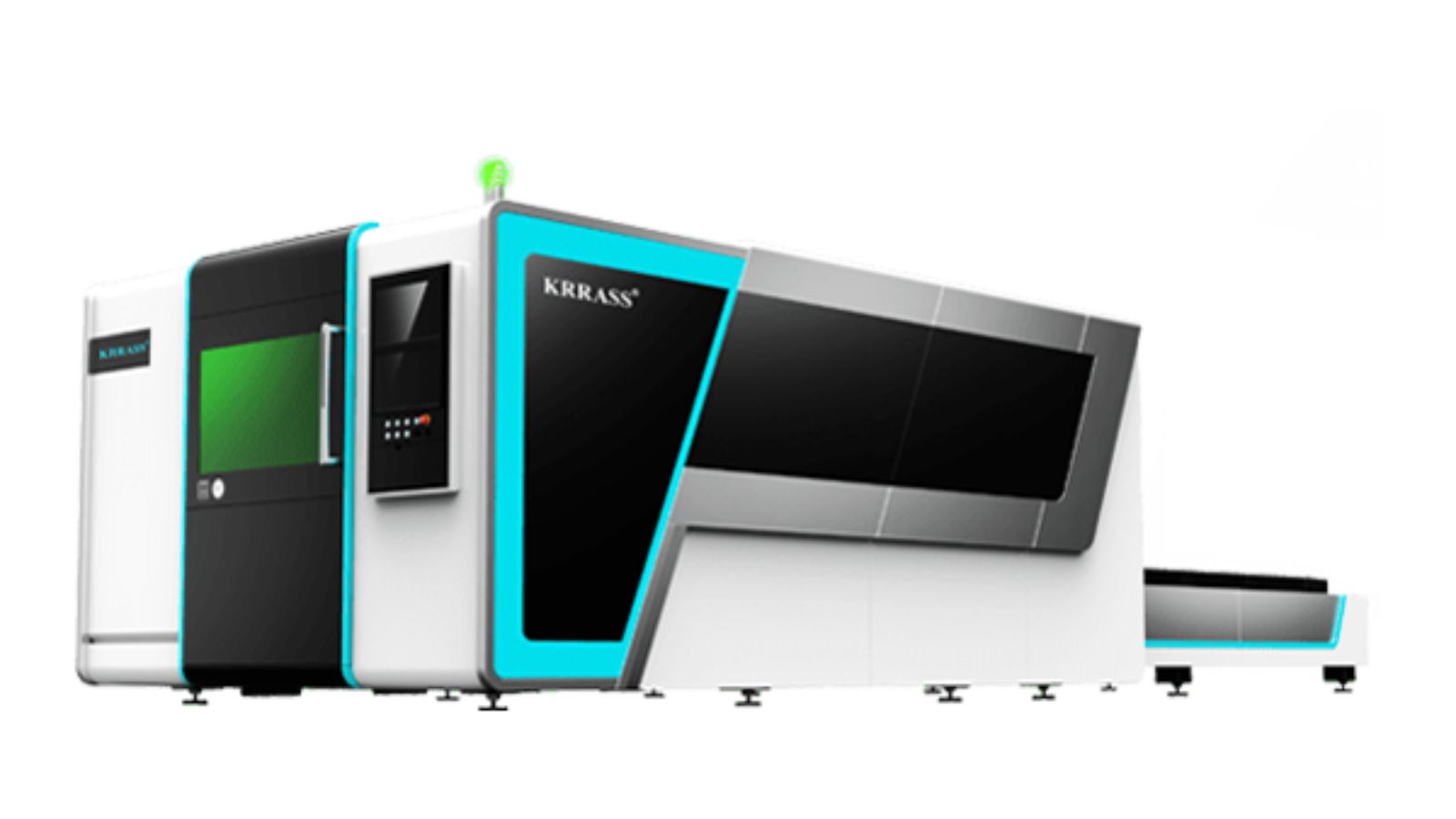

XI.KRRASS fiber laser cutting machine

KRRASS is committed to providing high-quality industrial-grade fiber laser cutting machines. Our machines are suitable for applications of all sizes, from small operations to large production. Targeting small, medium and large manufacturers, we offer state-of-the-art fiber laser cutting machine equipment.

Our product line includes fiber laser cutting machines for sheet and multi-purpose applications that can cut a wide range of sheet and tube thicknesses. Utilizing cutting-edge technology, our machines are able to accurately cut a wide range of materials, including steel, aluminum alloys, copper and brass, and more.

The KRRASS fiber laser cutting machine is designed with user-friendliness, efficiency and reliability in mind, making it an ideal choice for any manufacturing company that wants to improve production efficiency and reduce costs. We are committed to providing our customers with excellent support and service, ensuring they get the most out of our equipment and achieve their production goals.

XII. Conclusion

In conclusion, fiber laser cutting machines have revolutionized manufacturing by providing faster, more efficient and cost-effective solutions for cutting and engraving a variety of materials. Their advanced technology and high precision make them ideal for a variety of applications, from automotive and aerospace to electronics and medical equipment.

Additionally, their energy efficiency and low maintenance requirements make them an eco-friendly option that can significantly reduce energy costs and carbon emissions.

As fiber laser cutting machines continue to develop and improve, we expect wider adoption across industries and increased innovation in their capabilities. Whether you are a small business owner or a large manufacturing company, investing in a fiber laser cutting machine can help you stay ahead of the competition and meet the needs of your customers.

Upgrade your manufacturing process with our fiber laser cutting machines

Want to streamline your manufacturing process and increase efficiency? Our fiber laser cutting machine is your best choice. With leading technology and precision, our equipment is designed to deliver high-quality results, taking on even the most complex projects with ease.

From metal fabrication to automotive manufacturing, our fiber laser cutting machines are used in a wide range of applications and can handle a variety of materials and applications. With faster cutting speeds and less downtime, our equipment will help you save time and money while increasing productivity.

Contact us to get a quote and learn more about how our fiber laser cutting machines can improve your business. If you're not sure which laser system is best for your needs, feel free to request a free evaluation at +86-189-5208-7956.

Reviewed by 1 user

I was impressed by the detailed and practical advice given on selecting a fiber laser machine. The tips provided were easy to understand and covered all the essential aspects I should consider before making a purchase. highly informative and beneficial in guiding me toward choosing the right fiber laser machine.