Welcome to our comprehensive guide on Press Brake Operation Basics, an essential resource for anyone involved in metal fabrication. Whether you’re new to the field or looking to refine your expertise, this article covers everything from the fundamentals of press brake operation to advanced bending techniques and safety measures. Dive into the world of press brakes with us, as we explore the types, applications, and best practices that define excellence in metal bending.

1.Basics of Press Brake Operation

Diving into the world of manufacturing, specifically the realm where metal bending reigns supreme, the press brake emerges as an indispensable protagonist. This powerhouse tool is pivotal for bending sheets and plates of various metals with precision and ease. But what makes it tick? Let’s peel back the layers.

At its core, the press brake is a marvel of engineering designed to transform flat sheets of metal into specific shapes and angles. This transformation is achieved through the application of significant force, courtesy of a punch and die setup. Imagine the punch as the dynamic force that pushes the metal into the die, which is essentially a stationary block that molds the metal into the desired shape.

Operationally, the press brake can be categorized into manual, hydraulic, electric, and hybrid types, each with its unique benefits and applications. The choice between these types often boils down to the specific requirements of the task at hand, such as the material thickness, the complexity of the bend, and the production volume.

Key to mastering press brake operation is understanding its parameters and controls. Factors like bend angle, bend radius, and the material’s properties play a critical role in achieving the perfect bend. Adjustments and settings are meticulously managed to ensure the metal bends without cracking or compromising its integrity.

In the quest to achieve bending perfection, operators must be versed in reading and interpreting technical drawings and specifications. This knowledge allows them to set up the machine accurately, select the appropriate tools, and execute the bending process with precision.

As we delve deeper into the nuances of press brake operation, remember that safety is paramount. The immense force and potential for injury necessitate strict adherence to safety protocols, ensuring operators are well-trained and equipped with the necessary protective gear.

2.Types of Press Brakes

As we delve deeper into the intricate world of press brakes, it becomes evident that not all press brakes are created equal. The diversity in types caters to various industrial needs, ranging from simple bending operations to complex and precise metal forming processes. Let’s explore the primary types of press brakes that have become staples in the manufacturing industry.

Manual Press Brake

The manual press brake stands as the most basic form of the machine. Relying on manual force applied by the operator through a lever or handle, this type is best suited for small-scale operations or workshops where precision is not the highest priority. Its simplicity and cost-effectiveness make it an excellent entry point for newcomers to the metal fabrication field.

Hydraulic Press Brake

Hydraulic press brakes represent a significant step up in both capability and complexity. Utilizing hydraulic cylinders to apply force to the punch, these machines offer greater power and control. This allows for bending thicker materials with higher precision. The adjustability and consistency of pressure make hydraulic press brakes a favorite among medium to large-scale operations that demand reliability and flexibility.

CNC Press Brake

At the pinnacle of press brake technology lies the CNC (Computer Numerically Controlled) press brake. This marvel of modern engineering integrates computer controls to automate the bending process, delivering unmatched precision and efficiency. CNC press brakes can precisely control parameters such as angle, pressure, and depth, making them ideal for complex and repetitive tasks. Their ability to produce consistent and high-quality results with minimal human intervention has made CNC press brakes indispensable in high-volume, precision-oriented manufacturing environments.

3.Working Principle of Press Brake

To truly master the art of metal bending with a press brake, one must first understand the foundational principles that govern its operation. At the heart of this powerful machine lies a simple yet profound mechanism that facilitates the transformation of raw metal sheets into precise shapes and angles. Let’s break down the working principle of the press brake and the pivotal roles of its core components.

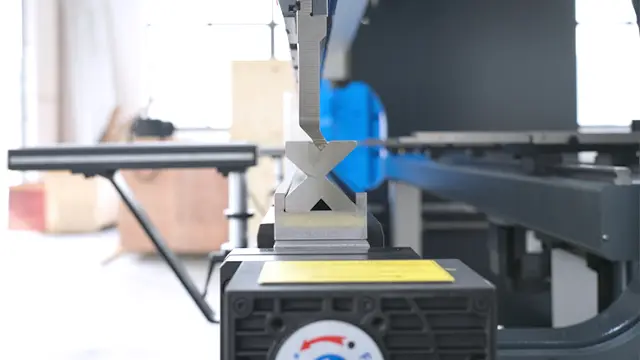

Role of Punch and Die

The dynamic duo of the punch and die is where the magic happens in a press brake. The punch, a hard metal tool, is mounted on the upper part of the press brake and moves downward with force. The die, situated on the lower part, serves as the mold that shapes the metal sheet. As the punch presses the metal into the die, the specific angle and shape desired are achieved. This interaction is a delicate balance of force, precision, and material properties, all working in harmony to bend metal without damaging it. The versatility of the press brake comes from the ability to interchange punches and dies, allowing for an array of bends and shapes.

Tonnage

Tonnage, in the context of press brakes, refers to the maximum force that the machine can apply during the bending process. It’s a crucial factor that determines the thickness and type of material that can be bent. Calculating the required tonnage for a specific job involves considering the material’s yield strength, the length of the bend, and the V-width of the die. Underestimating the tonnage can lead to incomplete bends, while overestimating can damage the machine, the tooling, or the workpiece. Therefore, understanding and accurately calculating tonnage is essential for efficient and safe press brake operation.

4.Bending Processes and Techniques

Within the domain of press brake operation, bending processes and techniques are the alchemists’ spells, transforming metal sheets into functional and aesthetic components. Each technique has its unique characteristics, advantages, and applications, making the selection process as critical as the operation itself. Let’s explore three fundamental bending processes: coining, air bending, and bottom bending, shedding light on their intricacies and when to use them.

Coining

Coining is a high-precision bending technique where the punch and die exert enough force to embed the metal entirely within the die, creating a permanent deformation that mirrors the die’s shape. This process is characterized by its ability to achieve sharp, accurate bends with minimal springback, making it ideal for projects requiring high levels of precision. However, coining requires significantly more tonnage than other bending methods, making it less energy-efficient and more suitable for smaller, detailed work where accuracy is paramount.

Air Bending

Air bending, the most common and versatile technique, involves the punch pressing the metal into the die with a gap remaining between the two, allowing the metal to spring back slightly after bending. This method requires less force than coining, making it more energy-efficient and adaptable to a wider range of material types and thicknesses. The flexibility of air bending, coupled with its lower tonnage requirement, allows for quick adjustments and is ideal for operations that demand versatility and efficiency.

Bottom Bending

Bottom bending is a technique that strikes a balance between coining and air bending. It involves the metal being pressed firmly against the die, with the punch and die making full contact but without the extreme force used in coining. This method offers more control over the angle and springback compared to air bending, providing a higher level of precision without the high tonnage requirements of coining. Bottom bending is particularly useful for medium to high volume production runs where consistency and accuracy are desired.

5.Factors Influencing the Choice of Bending Techniques

The selection of a bending technique is not a decision to be taken lightly. It’s a strategic choice that can significantly impact the efficiency, quality, and cost-effectiveness of production. Several critical factors come into play when deciding on the most suitable bending method for a specific application. Understanding these factors can help ensure that the chosen process aligns with the project’s requirements and goals. Let’s examine the key elements that influence the choice of bending techniques.

Material Type and Thickness

The type and thickness of the material being bent are paramount in determining the appropriate bending technique. Different materials exhibit varying degrees of ductility and strength, which can affect their ability to be formed without cracking or breaking. Thicker materials may require more force, pushing the preference towards techniques like coining or bottom bending, while thinner materials might be more suited to air bending due to its lower tonnage requirements.

Desired Precision and Finish

The level of precision and the quality of finish required for the final product also play a critical role. Coining, for instance, offers high precision and a smooth finish but at the cost of higher tonnage and reduced efficiency. For projects where these aspects are crucial, the increased cost and time may be justified. Conversely, air bending might be preferred for less critical applications where slight variations in angle or finish are acceptable.

Production Volume

The volume of production influences the choice of bending technique as well. High-volume runs may benefit from the efficiency and speed of air bending, where the setup and operation times are shorter. On the other hand, for low-volume, high-precision tasks, coining or bottom bending might be more appropriate despite their longer setup times and slower operation speeds, due to the consistency and accuracy they offer.

Tooling Availability and Cost

The availability of specific tools and the associated costs can also influence the choice of bending technique. Specialized tooling required for certain bending processes might not be readily available or could be cost-prohibitive, especially for one-off projects or small batches. In such cases, opting for a bending technique that utilizes more common or affordable tooling might be the more pragmatic choice.

6.Applications of Press Brakes

The versatility and precision of press brakes have made them indispensable tools in numerous industries. These machines play a pivotal role in the fabrication and production of a wide array of products, from simple metal brackets to complex components used in aerospace and automotive industries. Let’s explore some of the key applications of press brakes, highlighting the diversity of their utility and the impact they have on manufacturing processes.

Automotive Industry

In the automotive sector, press brakes are used to shape metal parts for cars, trucks, and other vehicles. Components such as door frames, chassis, and brackets are formed with precision to meet strict industry standards. The ability of press brakes to produce consistent, high-quality bends is crucial for ensuring the safety and performance of automotive products.

Aerospace Industry

The aerospace industry demands the highest levels of precision and quality. Press brakes are utilized to fabricate components for aircraft and spacecraft, where even the slightest deviation can have significant implications. The versatility of press brakes, especially CNC models, allows for the creation of parts with complex geometries that meet the rigorous standards of the aerospace industry.

Construction and Infrastructure

Press brakes find extensive application in the construction and infrastructure sectors, shaping metal components used in buildings, bridges, and other structures. From steel beams to architectural elements, the ability to bend large and thick plates is essential for constructing durable and aesthetically pleasing structures.

Metal Furniture and Decorative Items

The flexibility of press brakes extends to the production of metal furniture and decorative items. This includes everything from industrial shelving units to intricate sculptures and artwork. The adaptability to various materials and thicknesses allows manufacturers to explore creative designs and finishes.

Electronics and Appliance Manufacturing

In the realm of electronics and appliances, press brakes are key to fabricating metal casings, brackets, and components that require precise dimensions and smooth finishes. The precision and efficiency of CNC press brakes, in particular, support the rapid production of components that fit seamlessly into complex electronic assemblies.

7.Press Brake Components and Operation

Understanding the components of a press brake and how they operate together to achieve precise metal bending is fundamental for anyone involved in the manufacturing process. This knowledge not only aids in the effective use of the machine but also in troubleshooting and maintenance. Let’s take a closer look at the key components of press brakes and their roles in operation.

Main Frame

The main frame of the press brake is its backbone, providing the necessary rigidity and stability for the bending process. Made of high-strength steel, it supports all other components and withstands the forces exerted during metal bending. The frame’s design is crucial for maintaining precision and preventing deflection under load.

Hydraulic System

For hydraulic press brakes, the hydraulic system is the heart that powers the machine. It consists of hydraulic cylinders, pumps, and valves that generate and control the force applied by the punch. The system’s efficiency and reliability are key to achieving consistent bending results.

CNC Controller

In CNC press brakes, the controller is the brain of the operation. It interprets CAD drawings and programming inputs to precisely control the movement and pressure of the punch and die. The CNC controller enables automated adjustments for bend angles, allowing for high-precision and repeatable bends.

Punch and Die

The punch and die are the tools that actually perform the bending. The punch, mounted on the ram, moves downward to press the metal into the die, which is fixed on the bed of the machine. The shapes and dimensions of the punch and die determine the angle, radius, and type of bend produced. Interchangeable tools increase the versatility of the press brake, enabling it to perform a wide range of bends.

Back Gauge

The back gauge is an adjustable stop that positions the workpiece accurately for bending. It moves along several axes to accommodate different bend locations and dimensions. The precision of the back gauge is crucial for achieving consistent bending results, especially in complex parts with multiple bends.

Operating a press brake involves setting up the machine with the correct tools, adjusting the parameters according to the material and desired bend, positioning the workpiece against the back gauge, and executing the bend. The interplay between these components and the operator’s expertise are what lead to successful and precise metal forming.

8.Safety and Efficiency in Press Brake Operation

Safety and efficiency are two pillars of press brake operation that cannot be overlooked. Ensuring the well-being of operators and maximizing the productivity of the machine go hand in hand. Adopting best practices and understanding the safety mechanisms of press brakes can significantly reduce the risk of accidents and enhance operational efficiency. Let’s discuss how to achieve a safe and efficient working environment in the context of press brake operation.

Adhering to Safety Protocols

The first step towards safe operation is strict adherence to established safety protocols. This includes wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses, and understanding the machine’s safety features, like light curtains and emergency stops. Regular training and refreshers on safety procedures ensure that operators are always aware of the best practices and the latest safety innovations.

Regular Maintenance and Inspections

A well-maintained press brake is a safer and more efficient press brake. Regular maintenance and inspections help identify and rectify potential hazards before they lead to accidents. Keeping hydraulic systems, electrical components, and mechanical parts in optimal condition also prevents downtime and maintains productivity.

Efficient Workflow and Ergonomics

Designing an efficient workflow minimizes unnecessary movements and reduces the risk of injury. Ergonomic considerations, such as adjustable workstations and the strategic placement of controls and material, can significantly reduce operator fatigue and increase efficiency. Implementing lean manufacturing principles can also streamline operations, reducing waste and improving overall safety and productivity.

Utilizing Advanced Technology

Embracing advanced technology, such as CNC controls and automated bending systems, can enhance both safety and efficiency. These technologies reduce the need for manual adjustments and handling, minimizing the risk of accidents. Furthermore, they allow for precise and repeatable bends, increasing the quality of output and reducing material waste.

9.FAQs: Press Brake Operation Insights

Press brakes are versatile machines, but like any specialized equipment, there are common questions about their capabilities, maintenance, and operation. Here are answers to some frequently asked questions that can help demystify aspects of press brake usage.

What materials cannot be processed with a press brake?

Press brakes are designed for bending metal sheets and plates. However, they are not suitable for processing brittle materials like glass or certain plastics, which cannot withstand the bending process without cracking or breaking. Additionally, extremely hard or thick materials that exceed the machine’s tonnage capacity may also be unsuitable for bending with a press brake.

How often should maintenance be performed on a press brake?

Regular maintenance is crucial for the longevity and efficiency of press brakes. It’s recommended to perform routine inspections and maintenance tasks according to the manufacturer’s guidelines, which typically suggest monthly, quarterly, and annual check-ups. However, the frequency can vary based on the machine’s usage intensity and the operational environment.

Can press brake operations be automated?

Yes, press brake operations can be automated, especially with CNC press brakes. These machines use computer programming to control bending operations, reducing manual input and increasing precision and productivity. Automation can also include the use of robotic arms for loading and unloading materials, further enhancing efficiency and safety.

What are the key factors affecting bending accuracy?

Bending accuracy on a press brake is influenced by several factors, including material properties (such as thickness, type, and grain direction), tool condition, machine condition, and operator skill. Precise control of bending parameters and the use of appropriate tooling also play critical roles in achieving accurate bends.

How to choose the right type of press brake for my needs?

Choosing the right press brake depends on several factors: the material type and thickness you plan to bend, the complexity of the bending operations, production volume, and desired level of precision. Manual press brakes are suitable for low-volume, simple tasks; hydraulic press brakes offer versatility for a range of materials and thicknesses; CNC press brakes are ideal for high precision and high-volume production. Assessing your specific requirements and consulting with manufacturers can help in selecting the most appropriate press brake.

Empowering Your Fabrication with Krrass

As we conclude our journey through the essentials of press brake operation, we hope you’ve gained valuable insights and skills to enhance your metal fabrication projects. Whether you’re implementing the basics of press brake operation, exploring the various bending techniques, or adhering to safety and efficiency standards, knowledge is your most powerful tool. For those seeking the pinnacle of press brake manufacturing and services, look no further than Krrass. As a leading press brake manufacturer and service provider, Krrass offers innovative solutions tailored to your fabrication needs. Discover the difference that quality and precision can make at https://www.krrass.com/. Join us in shaping the future of metal fabrication, where excellence and expertise meet to create unparalleled results.

Read More: