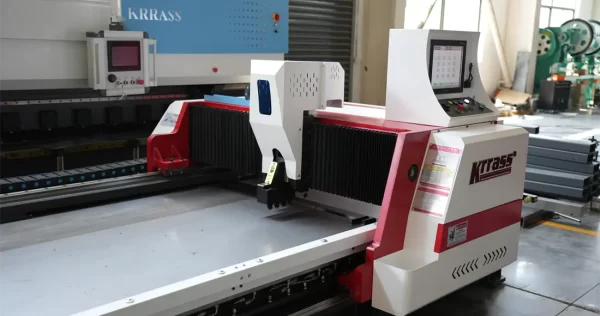

A vertical V grooving machine is a machine used to cut V-shaped grooves in sheet metal. It consists of a vertical tool holder and a horizontal workbench. The knife holder has a head with a V-shaped blade. The sheet metal is placed on the table and the carriage moves down to cut the V-shaped groove.

We will teach you how to properly operate and use a vertical V grooving machine in this article:

Video Tutorial

If you don’t want to watch video tutorials, you can also check out the graphic tutorials below:

Graphic Tutorial

Preparation

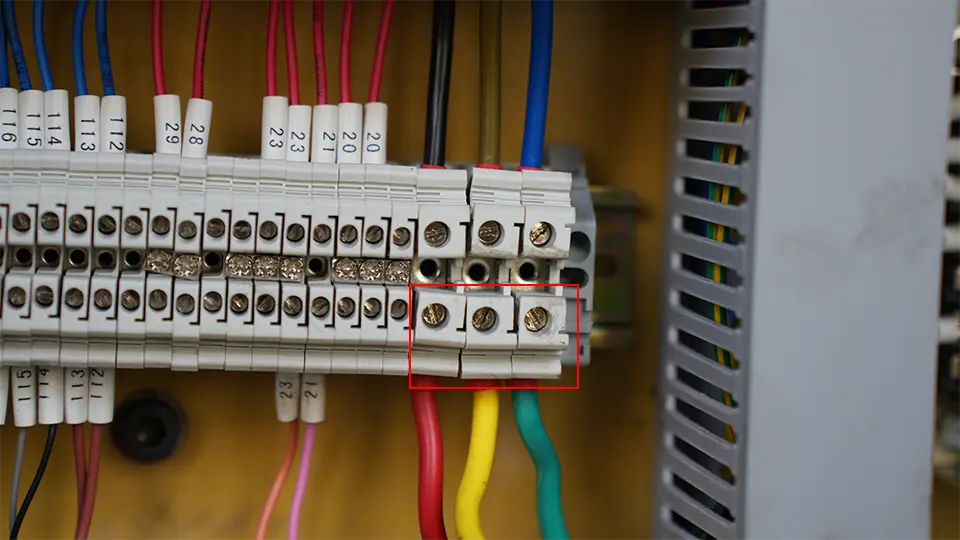

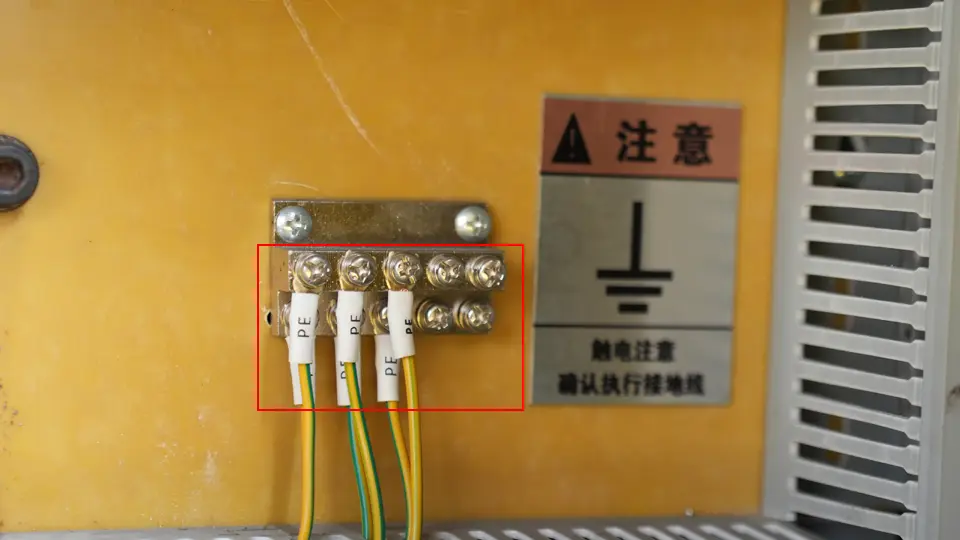

1. Before using the vertical V grooving machine, we need to connect the main power cable;

Note: The ground wire should also be connected.

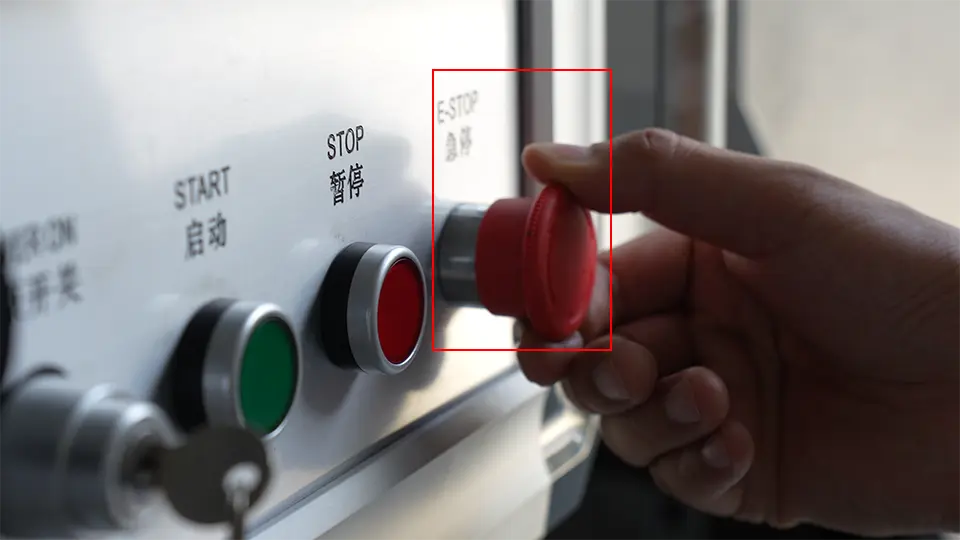

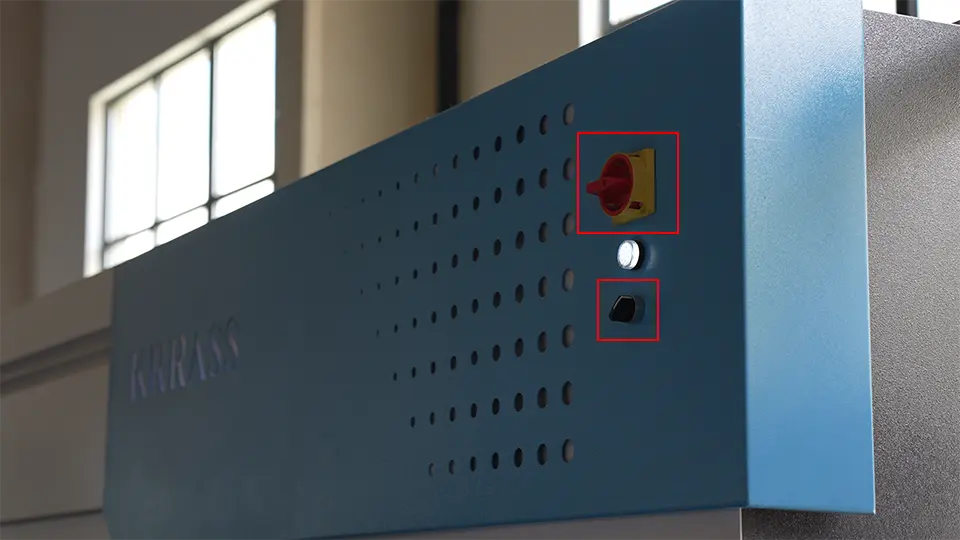

2. Check and reset all emergency stop buttons on airframe and controller;

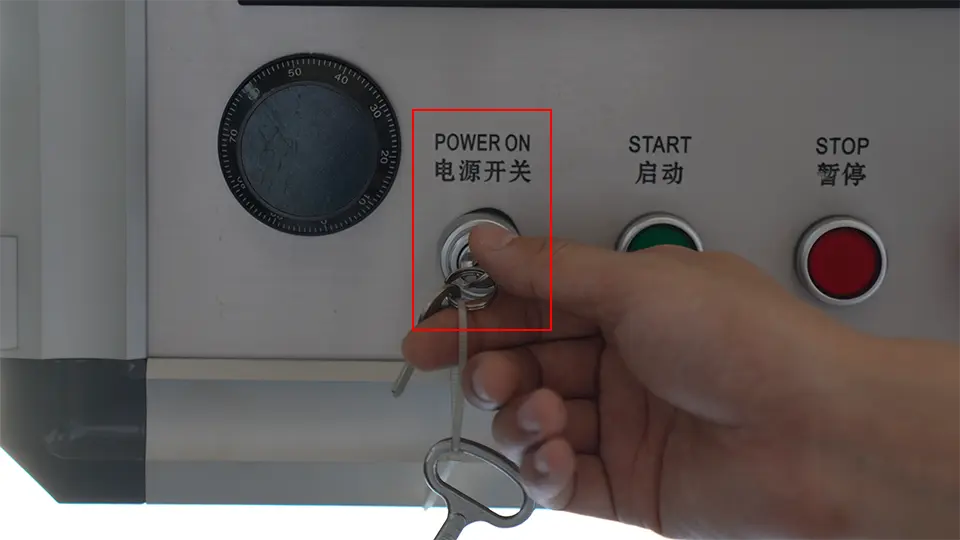

3. Turn on the power switches on the controller and the host panel in turn;

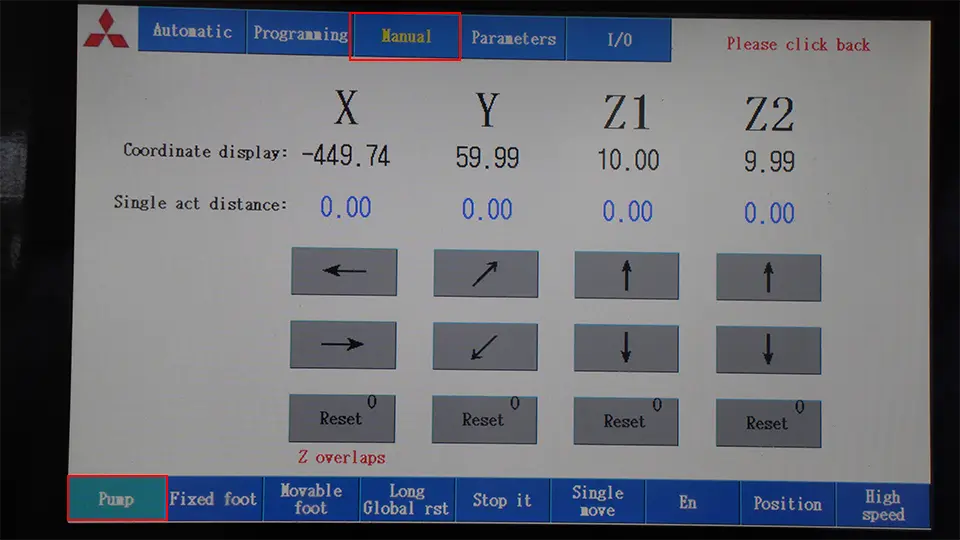

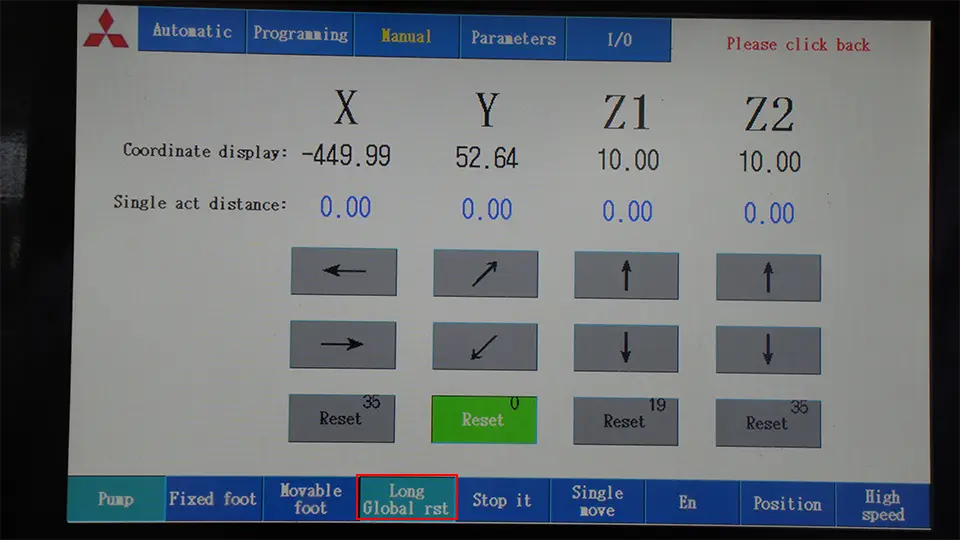

4. Switch the controller operation interface to the manual page, start the oil pump, press and hold the reset button, and return to the reference point;

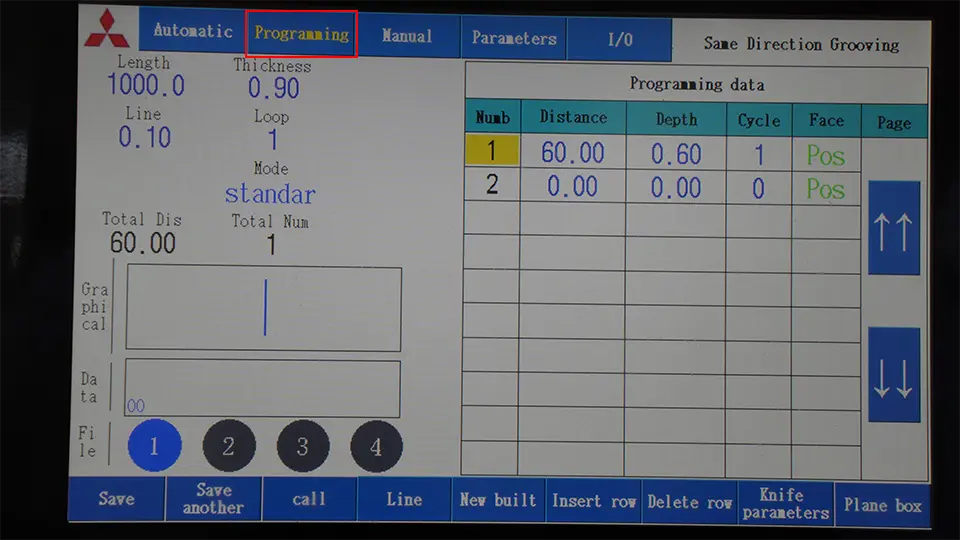

Programming

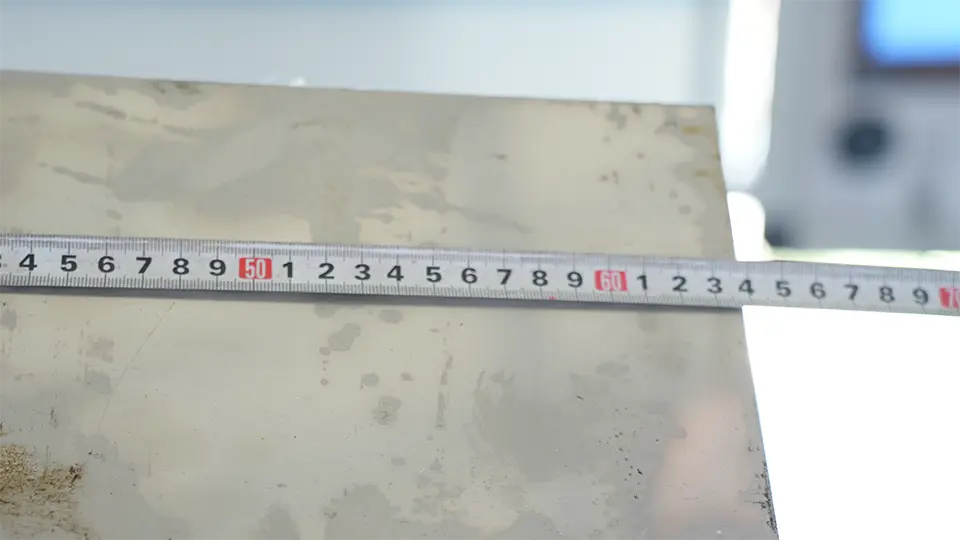

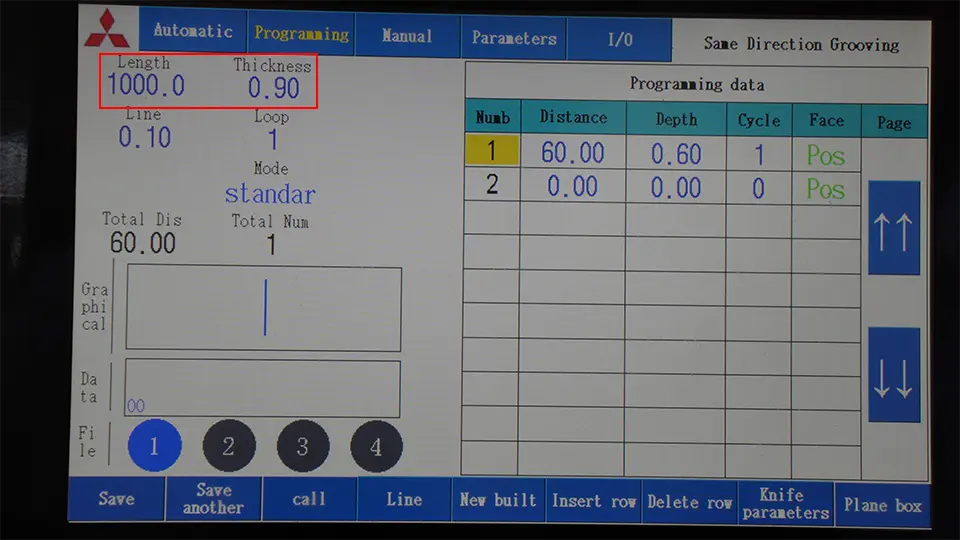

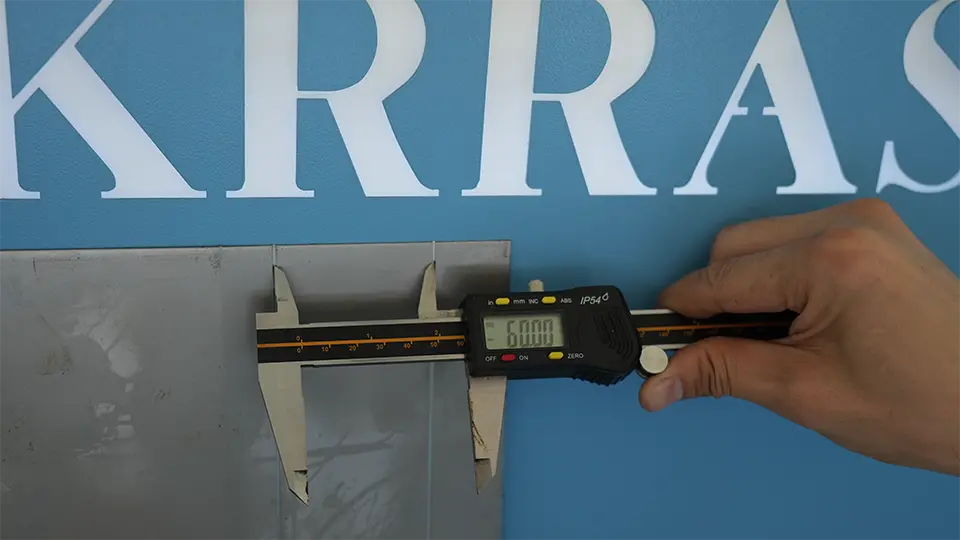

5. Measure the length and thickness of the metal plate that needs to be slotted;

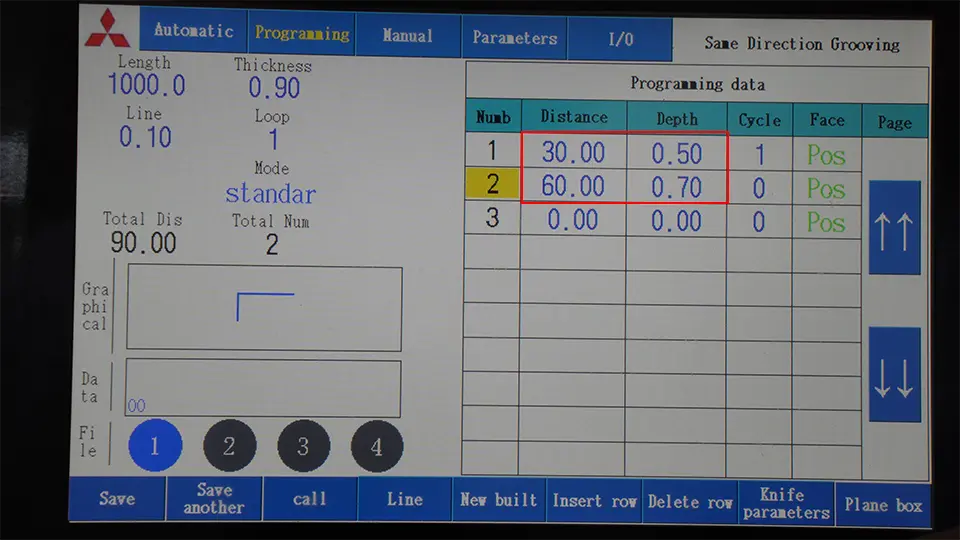

6. Switch the controller operation interface to the Programming page, and set the length and thickness of the metal plate to be slotted in turn;

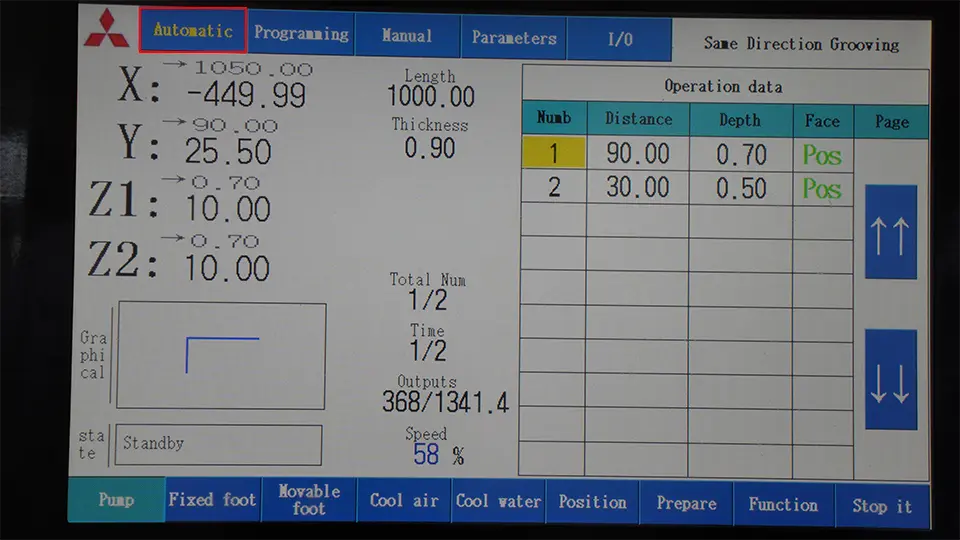

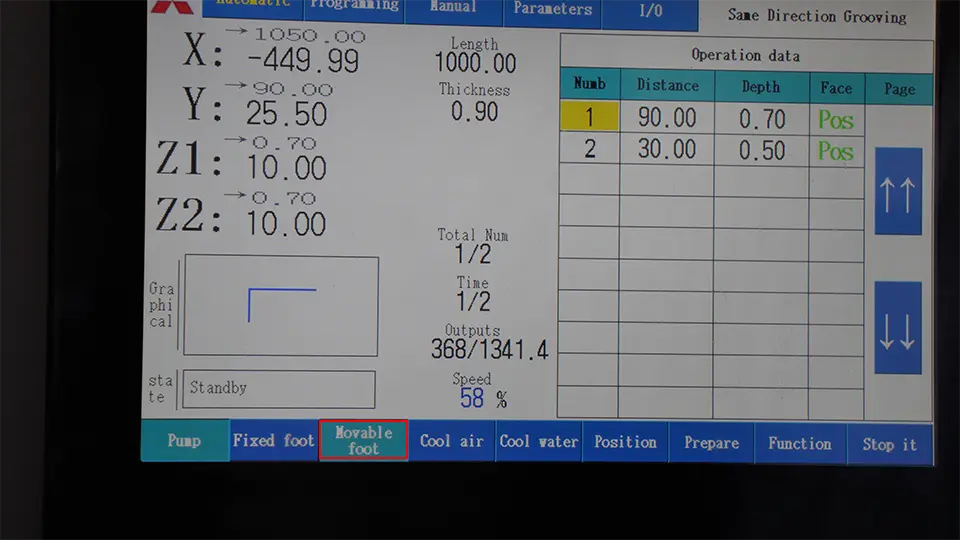

7. In the controller operation interface, set the interval distance and slotting depth of each working step in turn, after the setting is complete, switch to the Automatic tab interface;

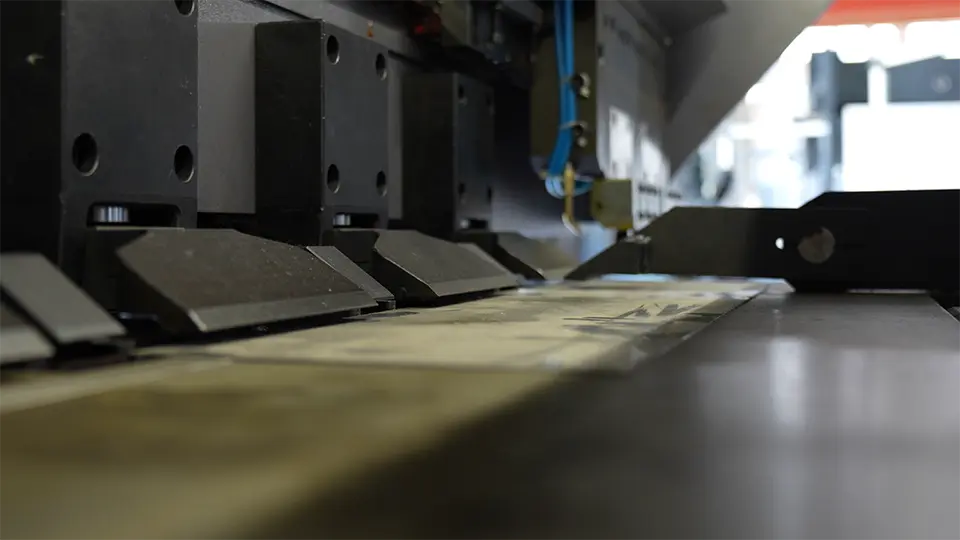

08. Place the metal plate that needs to be grooved on the working table of the vertical V grooving machine, and cling to the rear support material;

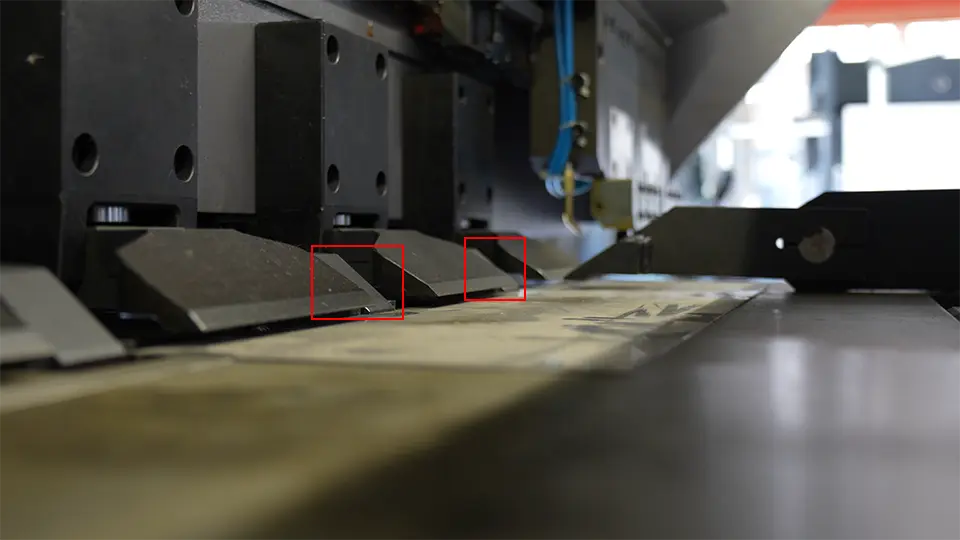

09. Press the movable foot button to clamp the metal plate;

Grooving

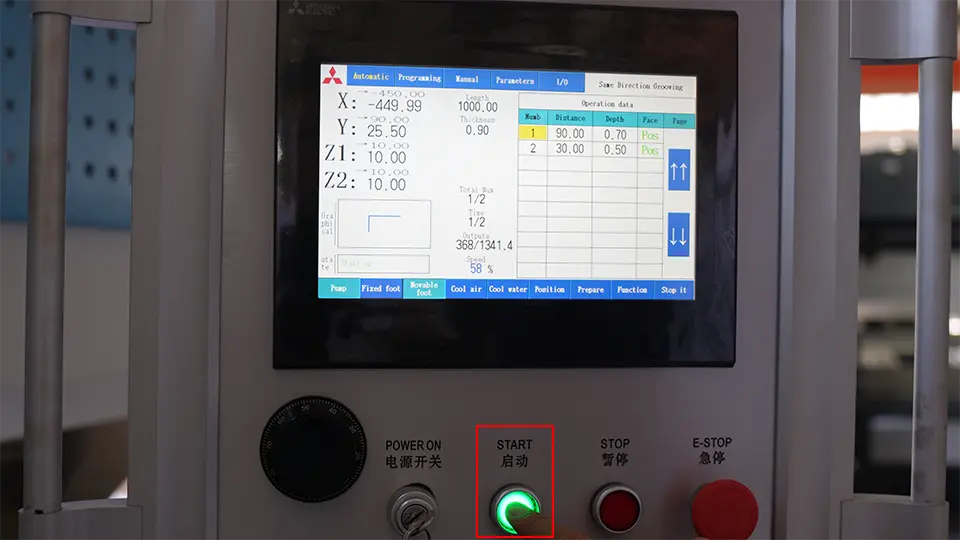

10. Press the start button on the controller panel, the vertical V grooving machine starts to do the grooving work;

Measurement

11. Measure whether the data of each working step meets the requirements.

The above are the related tutorials on how to use the KRRASS vertical V grooving machine. If you have just purchased our vertical V grooving machine and don’t know how to install and use it, you can read this article first:

Reviewed by 1 user

V grooving machine

Very good metal grooving machine.