Looking for the best large format laser cutter? Here are the top 7 cutting lasers every professional should know:

- KRRASS Fiber Laser Cutting Machine: Cuts metal fast and very accurately for big jobs.

- xTool D1 Pro: This is the best portable laser. It has a big work area and is easy to use.

- Sculpfun S30 Pro Max: This is great for home crafting and laser engraving.

- Kern OptiFlex: Cuts large pieces and is very reliable.

- OneLaser Hydra: Works well with different materials and has good automation.

- Han’s Laser HG: This is the best laser for home businesses and saves money.

- Trotec Speedy 1000: This is the best high-end laser for home business and small production.

The right laser cutter can make a big difference. You need a machine that matches your material, how much you make, and how exact you need to be. Some machines are best for automation. Others are good for being flexible or saving money.

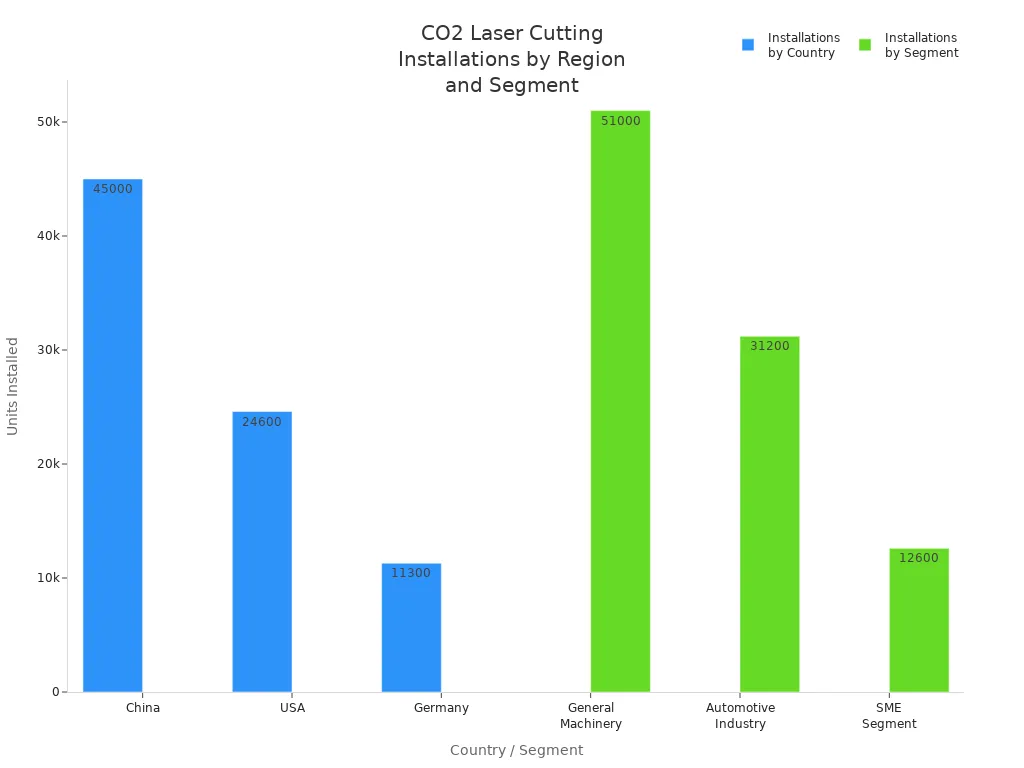

| Statistic | Value |

|---|---|

| Total CO2 laser cutting machines installed | 132,800 units |

| Asia-Pacific market share | 49% (65,800 units) |

| Leading country installations | China: 45,000 units |

| USA: 24,600 units | |

| Germany: 11,300 units | |

| High-power CO2 units above 2,000 W | 56% |

| Productivity improvement with automation | +28% |

| Downtime reduction with automation | -17% |

More companies now use fiber lasers because they work better. If you have a busy shop or want to do more laser engraving and crafting, these machines have something for everyone.

Table of Contents

Key Takeaways

- Pick the best laser cutter for your material. Some machines work better with metal, wood, or mixed materials.

- Think about how big the work area is. A bigger bed lets you cut larger sheets. You can also cut more pieces at the same time.

- Find machines with automation features. Automation helps save time and lowers mistakes. It makes your work easier and faster.

- Check the laser’s power and how exact it is. You need more power to cut thick materials. Precision helps make clean and neat cuts.

- Look at the list of materials the machine can cut. Not every laser can cut all materials. Make sure the machine fits your project.

- Know why maintenance is important. Cleaning and checking your machine often keeps it working well. This also helps it last longer.

- Look for options that do not cost too much. Many good laser cutters are cheaper. This helps small businesses and hobbyists buy them.

- Read about and compare different models. Use tables to compare and find the best laser cutter for your needs and budget.

Best Large Laser Cutters: Quick Overview

Top 7 Cutting Lasers Summary

If you want a great large laser cutter, look for power, size, and how well it works. Here are the top seven cutting lasers you should know:

- KRRASS Fiber Laser Cutting Machine: This machine cuts metal fast and very accurately. It is good for big jobs in factories.

- xTool D1 Pro: It has a big work area and is easy to set up. Both new users and experts can use it.

- Sculpfun S30 Pro Max: This one is good for home crafts and laser engraving. It is simple to use.

- Kern OptiFlex: It can cut large sheets and gives the same good results every time.

- OneLaser Hydra: It works with many materials and has smart automation. This helps busy shops.

- Han’s Laser HG: This is great for home businesses. It works well and does not cost too much.

- Trotec Speedy 1000: This is a top choice for small production and advanced engraving.

Each large laser cutter has something special. Some are fast and strong. Others are easy to use or flexible. You can find the best one by looking at what each model does best.

Selection Criteria

Picking the best large laser cutter is about more than just the brand. You need a machine that fits your space and can handle your materials. It should also keep up with your work. Here are the main things professionals think about before buying:

- Tube type and size

- Cutting precision and speed

- Overall cutting capacity

- Laser brand and power

- Level of automation

- Control system and software capabilities

- Main configurations

- Machine footprint and workshop space

- Power supply and voltage

- Energy consumption and operating costs

Tip: Always check the working area and what materials the machine supports before you buy. Some machines are better for metal. Others are best for wood, acrylic, or mixed materials.

When you pick the right features for your needs, you get a machine that helps you do more work. The best large laser cutters make your job easier, faster, and more exact. If you want to cut metal, wood, or both, there is a perfect machine for you.

KRRASS Fiber Laser Cutting Machine

Specifications

The KRRASS Fiber Laser Cutting Machine is made for professionals. It is fast, strong, and very exact. You can choose from many laser power levels. This helps you pick the right one for your job. The machine can cut many metals like carbon steel and copper. It works with thick and thin pieces. Your cuts will look smooth and clean. Most of the time, you do not need to do extra work after cutting.

Here’s a quick look at the main specs:

| Specification | Details |

|---|---|

| Laser Power | 1.5kw, 2kw, 3kw, 6kw, 12kw, 20kw |

| Cutting Materials | Carbon steel, stainless steel, electrical steel, tool steel, galvanized steel, mild steel, aluminum zinc plate, aluminum alloy, aluminum, titanium alloy, brass, copper, iron, and more metals |

| Cutting Thickness | Handles different thicknesses based on material |

| Cutting Speed | Fast, with smooth and flat cuts that usually need no extra processing |

| Precision | High, with a narrow slit (0.1mm~0.3mm) and a small heat-affected zone |

| CNC Programming | Lets you cut any shape or plan, even large formats, without needing a mold |

| Advantages | High machining accuracy, good repeatability, no damage to the surface, and low processing cost |

This machine can do big jobs and small details. You can use CNC programming to make any shape. You do not need molds or extra steps.

Pros

The KRRASS Fiber Laser Cutting Machine is very reliable and exact. If you have a busy shop, you want every piece to match. This machine makes sure each cut is the same. It does not touch the metal, so your tools last longer. You will not need to fix or replace them as much. This saves you time and money. You also have less downtime, so your work stays on schedule.

Here are some of the top benefits:

| Feature | Benefit |

|---|---|

| Repeatability | You get the same results every time, even in large production runs. |

| Durability of Tools | Non-contact cutting reduces wear, so you save on maintenance and replacement costs. |

| Minimized Material Deformation | Less heat means your metal stays flat and true, which is important for accuracy. |

| Complex Cut Geometries | You can create detailed shapes and fine designs that other machines cannot match. |

You can trust this machine for easy or hard cuts. It is also good for laser engraving. You can add logos or small details to metal parts.

Cons

The KRRASS Fiber Laser Cutting Machine is made for high performance and flexibility. It meets world standards and has models for many needs. You can use it for simple jobs or fast production.

Note: If you want a machine that grows with your business, KRRASS has options for sheet and tube cutting. It also has automatic typesetting to help you save material.

Ideal Applications

You need a machine that does hard work and helps your business. The KRRASS Fiber Laser Cutting Machine is used in many fields. If you work with metal, this machine is helpful in many ways.

Here are some top places to use the KRRASS Fiber Laser Cutting Machine:

- Metal Fabrication Shops

You can cut carbon steel, stainless steel, and aluminum. This machine helps you make parts for cars, machines, or furniture. You get smooth edges and finish big orders fast. - Automotive Industry

If you make car parts, you need strong and exact cuts. The KRRASS machine lets you make frames, panels, and special parts. You can also use it for small details and custom designs. - Aerospace Manufacturing

Planes and rockets need parts that fit just right. You can use this machine to cut titanium, aluminum, and other metals. It is very exact, so every piece matches your plans. - Electronics and Electrical Enclosures

You can make cases, brackets, and panels for electronics. The machine cuts thin and thick metals for many projects. You also get smooth edges, which keeps things safe. - Medical Device Production

Hospitals and labs need tools that are safe and clean. The KRRASS machine helps you cut parts for medical devices. It is very exact, even for tiny pieces. - Signage and Decorative Metalwork

Want to make custom signs or art? You can cut letters, shapes, and patterns easily. The machine also does laser engraving, so you can add logos or text. - Tube and Pipe Cutting

Some jobs need you to cut round or square tubes. The KRRASS machine has models for sheets and tubes. You can switch between different jobs easily.

Tip: Use the automatic typesetting feature to save material. It arranges your shapes to use all the metal, so you waste less and save money.

You can use the KRRASS Fiber Laser Cutting Machine for small jobs or big orders. It works well in busy factories, small shops, and design studios. If you want a machine that grows with your business, this one lets you take on new and bigger jobs.

Kern OptiFlex Laser Cutter

Specifications

If you need to work on big projects, this laser cutter is a good choice. The Kern OptiFlex Laser Cutter has a large work area. You can cut or engrave big sheets without moving them. It uses a strong CO2 laser. You can cut wood, acrylic, plastics, textiles, and some metals if you set it up right. The OptiFlex has a fast motion system. Your cuts will be smooth.

Here’s a quick look at the main specs:

| Specification | Details |

|---|---|

| Work Area | Up to 100″ x 52″ (custom sizes available) |

| Laser Power | 100W to 650W CO2 laser |

| Supported Materials | Wood, acrylic, plastics, textiles, foam, thin metals (with special setup) |

| Max Cutting Speed | Up to 1500 mm/sec |

| Precision | High accuracy with repeatable results |

| Automation | Optional conveyor and camera systems |

| Software | Compatible with popular design programs |

You can pick the power level you need. The machine works with many design programs. You can use your favorite software.

Pros

The Kern OptiFlex is reliable and flexible. It has a huge work area. You can cut big signs or many small parts at once. The motion system keeps cuts straight and curves smooth. You can use it for cutting and engraving. There are extra features like a conveyor system. This helps you load and unload materials faster.

Here are some reasons to like the Kern OptiFlex:

- You can cut and engrave many materials.

- The big work area saves time. You do not need to move your material.

- The machine is very accurate. Your parts fit together well.

- You can add automation to work faster.

- It works with most design software. You do not need to learn new programs.

Tip: If your shop is busy or you make many of the same part, automation can help you work faster.

Cons

The Kern OptiFlex is a large machine. You need a lot of space in your workshop. Some materials need special ventilation. High power models cost more, especially with automation. If you want to cut thick metals, you may need a fiber laser. It can be hard to learn if you have never used a big laser before.

Note: Check your shop’s power and space before you buy. This machine works best in a big, professional workshop.

Ideal Applications

You need a laser cutter for big jobs and many materials. The Kern OptiFlex Laser Cutter works well in busy shops, schools, and art studios. If you use large sheets or cut many pieces, this machine helps a lot.

Here are some top ways to use the Kern OptiFlex:

- Sign Making and Display Production

You can cut big signs, letters, and panels. The large work area lets you finish big projects fast. You do not need to move your material much. Your signs will look neat and professional. - Custom Furniture and Interior Design

Do you make furniture or design rooms? The OptiFlex cuts wood, acrylic, and some metals. You can make cool patterns and fancy panels. Your work will stand out and impress people. - Educational and Maker Spaces

Schools and labs like this machine. Students can learn with real tools. The big table is good for group work. Students can cut models, test ideas, or make art. - Packaging and Prototyping

If you make packaging samples or test products, the OptiFlex is fast and exact. You can cut foam, cardboard, and plastic. Your samples will look like the real thing. - Textile and Fashion Industry

The OptiFlex cuts fabric, leather, and felt. You can make custom clothes, bags, or art. The fast speed helps you finish orders on time. - Laser Engraving and Personalization

You can add logos, names, or art to many things. The OptiFlex does laser engraving easily. You can make gifts, awards, or special products.

Tip: Use the conveyor system to save time. It helps you load and unload fast. You can finish more jobs in less time.

- Industrial Parts and Gaskets

You can cut exact parts for machines or electronics. The high accuracy means your parts fit right every time. - Event and Stage Production

Need props or stage decorations? The OptiFlex cuts big pieces quickly. You can make custom shapes for any event.

The Kern OptiFlex gives you lots of choices. If you run a sign shop, school lab, or factory, this laser cutter helps you do more. You can take bigger jobs, offer new things, and keep your customers happy.

Han’s Laser HG Series

Specifications

If you want a strong machine, this one is a good choice. The Han’s Laser HG Series is safe and works hard. It uses new technology but is not too big. The motors are fast and powerful. The system is closed in, so it keeps you safe. The laser glass windows protect your eyes. They also block noise and smoke. You can cut big sheets and lift heavy things easily. The dust suction system keeps your shop clean. You save money because it uses less nitrogen gas.

Here are some things that make the Han’s Laser HG Series special:

| Feature/Technology | Description |

|---|---|

| High-productivity Laser Cutting Machine | Made to save money and work well. It uses parts that are very exact. |

| Laser Safety | The whole machine is closed in. The laser glass windows keep you safe and block noise and smoke. |

| Extremely Fast | The motors are strong and the design helps it move quickly. |

| Compact Design | The machine is easy to set up and take care of. It does not take up much space or cost a lot to ship. |

| Work Environment Friendly | The dust suction system has many zones. It keeps your shop clean. |

| Larger Cutting Area | You can cut bigger sheets measured in inches. |

| Ultra-High Power Suitable | It can use up to 60kW power. This keeps it working well and stops heat problems. |

| Heavy Load Capacity | You can add a hydraulic table. This helps you lift and move heavy sheets. |

| Lower Gas Consumption | It uses low nitrogen pressure. This makes cutting faster and saves gas. |

| Mix-M Device | The special gas mixing cabinet helps you cut better and keeps your work exact. |

You can use this machine for laser engraving and cutting. The gas mixing cabinet helps you get good results and keeps your cuts neat.

Pros

The Han’s Laser HG Series has many good points. It works fast and can handle big jobs. The motors help you finish work quickly. The closed system keeps you safe and makes your shop quiet. You do not have to worry about dust or smoke. The dust suction system takes care of it. You save money because it uses less nitrogen gas.

Here are some reasons you might like this machine:

- Every cut is very exact.

- It works with big sheets and heavy things.

- The closed design and laser glass windows keep you safe.

- You spend less on gas.

- The compact design makes it easy to set up and fix.

- The dust suction system keeps your shop clean.

- The hydraulic table helps you move heavy sheets fast.

Tip: If you want your shop to be faster and safer, this machine can help.

Cons

There are some things to think about before you buy the Han’s Laser HG Series. The machine is big, so you need enough space. Your team may need training to use all the features. The high power models cost more at first. You might need extra ventilation for some materials.

Note: Always check your shop’s space and power before you buy a large format laser cutter.

Ideal Applications

You need a laser cutter that works for your business. The Han’s Laser HG Series gives you many choices. This machine is good for lots of industries. You can use it for big or small jobs. Here are some top ways to use this machine:

- Industrial Manufacturing

You can cut big metal sheets for machines or buildings. The strong motors help you finish fast. Your cuts are always clean and exact. - Automotive Parts Production

If you make car parts, you need a tough machine. The Han’s Laser HG Series cuts frames and panels. You can also add logos with laser engraving. - Aerospace Components

Planes and rockets need perfect parts. You can cut titanium and aluminum. The machine keeps your cuts smooth and strong. - Sheet Metal Fabrication

You can make cabinets and panels. The closed design keeps your shop safe and clean. You do not have to worry about dust or smoke. - Signage and Decorative Work

Want to make signs or art? You can cut letters and shapes. The machine helps you make cool designs that stand out. - Medical Device Manufacturing

Hospitals need safe and exact tools. You can cut small parts for medical devices. The machine gives you the precision you need. - Heavy Equipment and Machinery

If you build big machines, you need to cut thick plates. The Han’s Laser HG Series handles heavy loads easily. The hydraulic table helps you move large sheets.

Tip: To save time and money, use the gas mixing cabinet. It helps you get better cuts and lowers your gas costs.

Here is a table to show where this machine works best:

| Industry | Example Uses |

|---|---|

| Automotive | Frames, panels, custom parts |

| Aerospace | Precision components, brackets |

| Manufacturing | Machine parts, enclosures |

| Medical Devices | Small, detailed metal parts |

| Signage & Art | Custom signs, decorative panels |

| Heavy Equipment | Thick plates, structural parts |

You can use the Han’s Laser HG Series for many jobs. If you want speed, safety, and clean work, this machine is a smart pick. You can take more projects and help your business grow.

OneLaser Hydra Series

Specifications

The OneLaser Hydra Series brings a lot to your workshop. You get a machine that can handle both big and small projects. This series stands out because it uses a dual-laser system. You can switch between a CO2 laser and an RF laser during the same job. This feature saves you time and helps you work faster. The work area is large, so you can cut or engrave big sheets without stopping to move them. The Hydra Series works with many materials, like wood, acrylic, plastics, and even some metals. You can use it for cutting, marking, or laser engraving.

You control the machine with a touchscreen. The interface is simple, so you do not need to be an expert to get started. The Hydra Series also has an integrated camera system. This camera gives you a bird’s-eye view of your work area. You can check your design’s position before you start cutting. This helps you avoid mistakes and saves material.

Here’s a quick look at some key features:

| Feature | Description |

|---|---|

| Dual-Laser System | Switch between CO2 and RF lasers for different materials and tasks. |

| Work Area | Large enough for big sheets and batch jobs. |

| Touchscreen Interface | Easy to use, even if you are new to laser cutters. |

| Integrated Camera System | Lets you see your design’s position for better setup and fewer errors. |

| Supported Materials | Wood, acrylic, plastics, leather, paper, some metals (with proper settings) |

Pros

You will notice right away how easy the Hydra Series makes your work. The dual-laser system means you do not have to stop and change machines for different materials. You just switch lasers and keep going. The touchscreen interface feels like using a tablet. You tap, drag, and select options with your finger. This makes setup quick and simple.

The camera system is a big help. You can line up your design perfectly before you start. This boosts your accuracy and cuts down on wasted material. If you run a busy shop, you will love how the Hydra Series speeds up your workflow. You can handle more jobs in less time.

Here’s a table that shows what makes the Hydra Series easy to use:

| Feature | How It Helps You |

|---|---|

| Dual-Laser System | No need to stop for material changes. |

| Touchscreen Interface | Simple controls, less training needed. |

| Integrated Camera System | Confirms design placement, reduces mistakes. |

You can use the Hydra Series for detailed laser engraving, cutting, or marking. The machine gives you clean lines and sharp details every time.

Cons

The Hydra Series does a lot, but you should know a few things before you buy. The machine is large, so you need enough space in your shop. If you want to cut thick metals, you may need a more powerful fiber laser. The price is higher than some basic models because of the advanced features. You might need a little time to learn all the options, especially if you have never used a dual-laser system before.

Note: Make sure your workspace has enough room and power for the Hydra Series. Take time to learn the touchscreen and camera features so you get the best results.

Ideal Applications

You need a laser cutter that can do many jobs. The OneLaser Hydra Series is flexible for different tasks. You can use it in busy shops or creative studios. This machine works for both big and small projects.

Here are some ways to use the Hydra Series:

- Custom Sign Making

You can cut letters, logos, and shapes from wood, acrylic, or plastic. The big work area lets you make large signs without moving your material. If you have a sign shop, you will finish orders faster. - Prototyping and Product Design

You can test new ideas quickly. The Hydra Series lets you cut and engrave many materials. You can make models, parts, or samples for your next project. - Batch Production

You can work on many pieces at once. The dual-laser system lets you switch between materials fast. If you have lots of orders, this saves you time. - Educational Labs and Maker Spaces

Students and makers like this machine. The touchscreen and camera system are easy to use. You can cut, mark, or try laser engraving on many materials. It is safe and fun for group projects. - Personalized Gifts and Crafts

You can make custom gifts, awards, or decorations. The Hydra Series gives you sharp details and clean cuts. You can add names, dates, or designs to make each item special. - Architectural Models

You can build detailed models for buildings or landscapes. The machine cuts thin sheets with high accuracy. You can show your ideas with professional results. - Packaging and Branding

You can cut boxes, inserts, or branded tags. The camera system helps you line up your designs. Your packaging will look neat and stand out.

Here’s a table to help you see where the Hydra Series fits best:

| Application Area | What You Can Do |

|---|---|

| Sign Making | Cut letters, logos, and shapes |

| Prototyping | Make models and test parts |

| Batch Production | Handle many pieces at once |

| Education | Teach cutting and laser engraving |

| Gifts & Crafts | Personalize and decorate items |

| Architecture | Build detailed scale models |

| Packaging | Create custom boxes and tags |

Tip: If you want to try new materials or switch between cutting and laser engraving, the Hydra Series makes it easy. You do not need to stop and change machines.

You can use the Hydra Series in many industries. If you work in design, education, or manufacturing, this machine helps you do more. You get speed, accuracy, and flexibility all in one machine.

Trotec Speedy 1000 Laser Cutter

Specifications

The Trotec Speedy 1000 can handle big projects. It has a large work area for cutting or engraving big sheets. You can pick a CO2 laser power from 60W to 120W. The machine works with wood, acrylic, plastics, textiles, and coated metals. You can switch between cutting and laser engraving using the touchscreen.

Here’s a table with the main specs:

| Specification | Details |

|---|---|

| Work Area | 39.4″ x 24″ (expandable) |

| Laser Power | 60W, 80W, 100W, 120W CO2 |

| Supported Materials | Wood, acrylic, plastics, textiles, coated metals |

| Max Speed | Up to 355 ips (inches per second) |

| Precision | High accuracy for detailed work |

| Software | Trotec Ruby, compatible with major design programs |

| Features | Autofocus, camera positioning, air assist |

The autofocus helps you get good results every time. The camera system lets you line up your designs fast. Air assist keeps cuts clean and reduces smoke.

Pros

The Trotec Speedy 1000 is easy to use. The touchscreen makes it simple, even for beginners. You can load your design, set your material, and start quickly. Autofocus and the camera system save time and help you avoid mistakes.

Here are some reasons to like this machine:

- It cuts and engraves fast for big or small jobs.

- The large work area lets you finish more pieces at once.

- Autofocus and the camera system make your work more accurate.

- You can switch materials without changing machines.

- The software works with popular design programs.

Tip: Clean the mirrors and lenses often. This helps your machine last longer and keeps results sharp.

You can trust the Speedy 1000 for laser engraving, custom signs, and batch jobs. It gives you smooth edges and crisp details every time.

- Regular cleaning keeps your machine working well.

- Cleaning optical parts stops failures and helps them last longer.

- You can check parts easily and find problems early.

Cons

Think about a few things before picking the Trotec Speedy 1000. The machine is big, so you need enough space in your shop. High-power models cost more, especially with extra features. You may need training to use all the advanced options. Mirrors and lenses wear out over time. Clean and check them often to avoid problems.

Note: Plan for regular cleaning and maintenance. This helps you avoid downtime and keeps your machine working well.

If you want to cut thick metals, you may need a fiber laser. The Speedy 1000 works best with wood, acrylic, and coated metals.

Ideal Applications

You want a laser cutter that helps your business grow. The Trotec Speedy 1000 gives you lots of choices. This machine works in many different industries. You can use it for cutting and engraving. Let’s see where this laser cutter is most useful.

1. Sign Making and Display Production

You can make big signs, letters, and panels. The large work area lets you cut or engrave full sheets. You can use acrylic, wood, or plastic. You finish projects faster because you do not need to move your material. Your signs always look neat and professional.

2. Custom Gifts and Personalization

Do you want to make custom gifts? The Speedy 1000 makes this simple. You can engrave names, logos, or designs on many materials. Use wood, acrylic, or coated metals. People like items made just for them. You can make awards, trophies, or keepsakes that are special.

3. Prototyping and Product Design

If you design new products, you need to test ideas fast. The Speedy 1000 lets you cut and engrave many materials for prototypes. You can make models, parts, or packaging samples. This helps you find problems early and fix your designs.

4. Batch Production and Small Manufacturing

You can handle small production runs easily. The large bed lets you cut many pieces at once. This saves time and keeps your work moving. If you have a small business, this machine helps you fill orders quickly.

5. Educational Labs and Maker Spaces

Schools and maker spaces like the Speedy 1000. Students can learn by doing real projects. The machine is safe and easy to use. You can cut, engrave, or mark many materials. This helps students learn new skills and try their ideas.

6. Architectural Models and Crafts

You can build detailed models for buildings or landscapes. The Speedy 1000 cuts thin sheets with high accuracy. You can show your ideas with clean, professional results. Crafters use this machine to make decorations, ornaments, and art.

Tip: Use the camera and autofocus features to line up your designs. This saves material and gives you better results.

Here’s a table to help you see where the Trotec Speedy 1000 works best:

| Application Area | What You Can Do |

|---|---|

| Sign Making | Cut and engrave large signs, displays |

| Custom Gifts | Personalize awards, trophies, keepsakes |

| Prototyping | Create models, parts, packaging samples |

| Batch Production | Cut multiple pieces at once |

| Education | Teach laser cutting and engraving |

| Architecture & Crafts | Build models, make art and decorations |

You can use the Trotec Speedy 1000 in many ways. If you want to grow your business, teach new skills, or make custom products, this machine gives you what you need.

xTool D1 Pro Large Laser Cutter

Specifications

You want a laser cutter that works fast and gives you sharp results. The xTool D1 Pro Large Laser Cutter stands out because of its speed and precision. You can engrave at speeds up to 600 mm per second. That means you finish projects quickly, even when you need small details. The machine keeps its accuracy at high speeds. You do not see much wobble, so your engravings look clean.

You can adjust the speed from 1200 to 3000 mm per minute. This helps you match the settings to the thickness of your material. The xTool D1 Pro works best with wood and acrylic. You get crisp lines and smooth edges every time. The laser dot stays square, which helps you get even cuts and sharp corners.

Here’s a quick look at what you get:

- Engraving speed up to 600 mm/s for fast jobs

- Adjustable speed settings for different materials

- Consistent laser dot shape for clean cuts

- High precision, even at top speed

- Best results on wood and acrylic

Pros

You will notice the benefits of the xTool D1 Pro right away. The machine gives you high-quality results without slowing down. You can finish more projects in less time. The laser cutter keeps its precision, so you do not need to redo your work. You get clean cuts and sharp engravings every time.

Users say the xTool D1 Pro offers great value for money. You get a powerful machine that works well for small businesses or serious hobbyists. The quality of the output stands out. You can trust the machine to deliver strong performance on every job.

Here’s what users like most:

| Feature | User Feedback |

|---|---|

| Value for Money | Users find the xTool D1 Pro to offer good value, especially for serious users or small to medium scale businesses. |

| Performance | The machine is noted for its powerful performance and speed. |

| Quality | High-quality output is consistently mentioned as a significant advantage. |

Tip: If you want a machine that helps you grow your business, the xTool D1 Pro gives you speed, accuracy, and reliability.

Cons

You should know a few things before you choose the xTool D1 Pro. The machine works best with wood and acrylic. You may not get the same results with thick metals or other materials. The work area is large, but it may not fit every workshop. You need to check your space before you buy.

Some users say the learning curve is a bit steep at first. You need to spend time with the software and settings to get the best results. The machine does not have built-in air assist, so you may need to add that for cleaner cuts.

Note: Make sure you have enough room for the machine. Try out the software before you start big projects. You can add accessories to improve your results.

Ideal Applications

You want a laser cutter that fits your projects and helps you work smarter. The xTool D1 Pro Large Laser Cutter shines in many settings. You can use it for business, school, or creative hobbies. Let’s look at where this machine really stands out.

1. Small Business Production

You run a small shop or online store. You need to make products fast and keep quality high. The xTool D1 Pro helps you cut and engrave wood, acrylic, and more. You can make signs, ornaments, jewelry, and custom gifts. The large work area lets you finish many pieces in one run. You save time and boost your output.

2. Personalized Gifts and Crafts

You love making unique gifts. The xTool D1 Pro lets you engrave names, dates, and designs on wood or acrylic. You can create keychains, awards, puzzles, or home décor. Your projects look sharp and professional. People love getting something made just for them.

3. Prototyping and Product Design

You have ideas for new products. You want to test them before selling. The xTool D1 Pro helps you cut models and parts with high precision. You can see what works and fix problems fast. This machine makes it easy to try new shapes and designs.

4. Education and STEM Learning

You teach students about design and technology. The xTool D1 Pro is safe and easy to use. Students can cut and engrave projects for science fairs, art classes, or engineering clubs. They learn real skills and see their ideas come to life.

5. Home Workshop and DIY Projects

You enjoy building things at home. The xTool D1 Pro fits in your workshop. You can make storage boxes, wall art, or custom tools. The machine handles detailed cuts and engravings. Your projects look neat and well-made.

Tip: Try batch processing if you have lots of orders. Place several designs on one sheet. The xTool D1 Pro will cut them all at once. You save time and materials.

Here’s a quick table to help you see where the xTool D1 Pro works best:

| Application Area | What You Can Make |

|---|---|

| Small Business | Signs, gifts, jewelry, décor |

| Personalization | Awards, keychains, custom crafts |

| Prototyping | Models, parts, product samples |

| Education | STEM projects, art, learning kits |

| Home Workshop | DIY crafts, storage, home improvements |

You can use the xTool D1 Pro for many jobs. If you want speed, accuracy, and flexibility, this machine gives you the tools to grow your skills or business.

Sculpfun S30 Pro Max Laser Cutter

Specifications

You want a laser cutter that works hard and gives you clean results. The Sculpfun S30 Pro Max packs a lot of power and smart features into a sturdy frame. You can use it for wood, plastic, and even some metals. The machine cuts fast and keeps your workspace neat with its strong airflow. You control the air pump right from the LightBurn software, so you get smooth cuts and sharp engravings every time.

Check out the main features in this table:

| Feature | Description |

|---|---|

| Pneumatic Metal Nozzle | Blows strong air (30 l/min) to keep cuts clean and boost efficiency. |

| Automatic Air Supply | Lets you control the air pump with software for quick, tidy results. |

| High Speed Cutting Efficiency | Cuts faster than many other machines, so you finish jobs quickly. |

| Wide Material Compatibility | Handles wood, plastic, and metals for lots of different projects. |

| Industrial-Grade Precision | X-axis guide rail keeps the machine steady and accurate, so engravings look sharp. |

| Sturdy and Durable Frame | Made from tough aluminum alloy, supports up to 50kg for long-lasting use. |

| Accurate Tick Marks | Scale marks on X and Y axes help you measure and line up your work easily. |

You get a machine that feels solid and works well for professional jobs. The guide rail and tick marks help you set up your projects fast. You can trust the Sculpfun S30 Pro Max to handle big pieces and detailed designs.

Pros

You will notice how easy it is to use this laser cutter. The automatic air supply keeps your cuts clean, so you spend less time cleaning up. The strong frame means you can work with heavy materials without worrying about damage. The guide rail gives you sharp engravings and smooth lines. You can switch between different materials and still get great results.

Here are some things you will like:

- Fast cutting saves you time on big jobs.

- The machine works with wood, plastic, and metals, so you can take on more projects.

- The sturdy frame supports heavy pieces and keeps everything steady.

- Accurate tick marks help you measure and set up your work quickly.

- The air nozzle keeps your workspace clean and your cuts sharp.

Tip: Use the LightBurn software to control the air pump. You get better results and less mess.

Cons

You should know about a few common problems before you choose this machine. Some users say the cutter does not always follow the file exactly, so you might see small mistakes in your cuts. Mechanical issues can pop up, like jumps or lost steps, especially if you use the machine a lot. Wiring can be tricky, too. If you have a wide frame, cables might move around and cause bad contacts.

Here’s a quick list of things to watch for:

- Cutting files sometimes come out imprecise, which can affect your finished product.

- Mechanical jumps and lost steps may happen, often because of the machine’s moving parts.

- Wiring problems can show up, especially with wider frames, leading to bad connections.

Note: Check your cables and moving parts often. Regular maintenance helps you avoid most problems.

Ideal Applications

You want a laser cutter that fits your projects and helps you work smarter. The Sculpfun S30 Pro Max gives you lots of options. You can use it in a workshop, classroom, or even at home. This machine works well for many types of jobs. Let’s look at where you can get the most out of it.

1. Small Business Production

You run a small shop or online store. You need to make products fast and keep quality high. The Sculpfun S30 Pro Max helps you cut and engrave wood, acrylic, and even some metals. You can make signs, ornaments, jewelry, and custom gifts. The sturdy frame lets you handle big orders without worry. You finish more pieces in less time.

2. Personalized Gifts and Crafts

You love making unique gifts. This laser cutter lets you engrave names, dates, and designs on wood or plastic. You can create keychains, awards, puzzles, or home décor. Your projects look sharp and professional. People enjoy getting something made just for them.

3. Prototyping and Product Design

You have ideas for new products. You want to test them before selling. The Sculpfun S30 Pro Max helps you cut models and parts with high precision. You can see what works and fix problems fast. This machine makes it easy to try new shapes and designs.

4. Education and STEM Learning

You teach students about design and technology. The Sculpfun S30 Pro Max is safe and easy to use. Students can cut and engrave projects for science fairs, art classes, or engineering clubs. They learn real skills and see their ideas come to life.

5. Home Workshop and DIY Projects

You enjoy building things at home. The Sculpfun S30 Pro Max fits in your workshop. You can make storage boxes, wall art, or custom tools. The machine handles detailed cuts and engravings. Your projects look neat and well-made.

Tip: Try batch processing if you have lots of orders. Place several designs on one sheet. The Sculpfun S30 Pro Max will cut them all at once. You save time and materials.

Here’s a quick table to help you see where the Sculpfun S30 Pro Max works best:

| Application Area | What You Can Make |

|---|---|

| Small Business | Signs, gifts, jewelry, décor |

| Personalization | Awards, keychains, custom crafts |

| Prototyping | Models, parts, product samples |

| Education | STEM projects, art, learning kits |

| Home Workshop | DIY crafts, storage, home improvements |

You can use the Sculpfun S30 Pro Max for many jobs. If you want speed, accuracy, and flexibility, this machine gives you the tools to grow your skills or business.

Laser Cutters and Engravers: Comparison Table

If you want to see how large laser cutters compare, this is the right place. You can check each machine’s work area, power, materials, precision, automation, and price. The table helps you choose the best cutting lasers for your shop, classroom, or business.

Tip: Look at the table below to find the laser cutters and engravers that fit your needs. You will see the differences fast.

| Model | Work Area (W × D) | Laser Power | Supported Materials | Precision | Automation Features | Price Range |

|---|---|---|---|---|---|---|

| KRRASS Fiber Laser Cutting Machine | Up to 157″ × 79″ (customizable) | 1.5kW – 20kW Fiber | Metals (steel, aluminum, brass, copper, titanium) | High (0.1–0.3mm slit) | CNC, auto typesetting, exchange platform | $60,000 – $250,000+ |

| Kern OptiFlex | Up to 100″ × 52″ | 100W – 650W CO2 | Wood, acrylic, plastics, textiles, thin metals | High | Conveyor, camera, software integration | $70,000 – $150,000 |

| Han’s Laser HG Series | Up to 157″ × 79″ | Up to 60kW Fiber | Metals (steel, aluminum, titanium, copper) | Ultra-high | Closed system, dust suction, hydraulic table | $80,000 – $300,000+ |

| OneLaser Hydra Series | Up to 51″ × 35″ | Dual CO2/RF (up to 150W) | Wood, acrylic, plastics, leather, thin metals | High | Touchscreen, camera, dual-laser switching | $35,000 – $80,000 |

| Trotec Speedy 1000 | 39.4″ × 24″ (expandable) | 60W – 120W CO2 | Wood, acrylic, plastics, textiles, coated metals | High | Autofocus, camera, air assist | $30,000 – $60,000 |

| xTool D1 Pro | 16.93″ × 15.35″ | 10W – 20W Diode | Wood, acrylic, paper, leather | High | Software control, batch processing | $700 – $1,500 |

| Sculpfun S30 Pro Max | 15.75″ × 15.75″ | 20W Diode | Wood, plastic, some metals | Industrial-grade | Air pump control, LightBurn integration | $800 – $1,200 |

Some large laser cutters have big work areas and lots of power. Others are easy to use or flexible. If you need to cut thick metal, look at fiber cutting lasers like KRRASS or Han’s Laser HG. If you want a machine for crafts or small jobs, xTool D1 Pro and Sculpfun S30 Pro Max are good choices.

Here are things to check when you compare laser cutters and engravers:

- Work Area: Bigger work areas help you cut large sheets or do batch jobs.

- Laser Power: More power lets you cut thicker materials and work faster.

- Supported Materials: Some cutting lasers only work with metals. Others can cut wood, acrylic, or mixed materials.

- Precision: If you want fine details, look at slit width and engraving accuracy.

- Automation: Features like CNC, camera systems, and auto typesetting save time and lower mistakes.

- Price Range: You can find models under $1,000 for beginners and over $250,000 for big factories.

If you want to grow your business or do bigger projects, large laser cutters with automation and high power help you work faster. For schools or makers, smaller laser cutters and engravers are flexible and easy to set up.

You do not have to guess which cutting lasers are right for you. Use this table to compare, pick, and get the best machine for your next big project.

Professional Buying Guide for Cutting Lasers

Work Area & Material Compatibility

When you pick a laser cutter, the work area matters a lot. You want a machine that fits your biggest projects. If you plan to cut large sheets or batch many small pieces, check the bed size first. Some machines, like the best portable laser, give you a big workspace in a small package. Others have huge beds for industrial jobs.

Think about what materials you use most. Not every laser can handle every material. Some work best with wood and acrylic. Others cut metal, leather, or even glass. If you love crafting or run a shop, make sure your machine matches your favorite materials. The best home crafting laser cutter will let you switch between wood, plastic, and more without trouble.

Tip: Always check the manufacturer’s list of supported materials. This helps you avoid mistakes and keeps your projects running smoothly.

Power & Precision

Power and accuracy go hand in hand. You need enough power to cut through your thickest material. If you work with metal, look for a fiber laser with high wattage. For wood or acrylic, a lower-powered CO2 or diode laser might be enough.

Accuracy is just as important. You want every cut to match your design. A good laser cutter gives you sharp lines and smooth edges. If you make detailed models or custom gifts, look for a machine with a narrow slit width and high repeatability. The best laser for home business will balance power and accuracy, so you get clean results every time.

Here’s a quick table to help you compare:

| Material | Suggested Power | Precision Needed |

|---|---|---|

| Wood/Acrylic | 10W–100W | High |

| Metals | 1.5kW+ | Ultra-high |

| Plastics | 20W–100W | Medium-High |

| Fabrics/Textiles | 40W–100W | Medium |

Note: If you want the best premium laser for home business, look for models that offer both high power and fine accuracy.

Automation & Ease of Use

Automation can save you time and reduce mistakes. Some laser cutters come with features like automatic focusing, camera alignment, or material sensors. These tools help you set up jobs faster and keep your cuts consistent. If you run a busy shop, automation lets you handle more orders with less effort.

Ease of use matters too. You want a machine with simple controls and clear software. Touchscreens, easy-to-read menus, and good support make a big difference. If you’re new to laser cutting, pick a model with helpful guides and tutorials. The best portable laser often shines here, giving you pro features without a steep learning curve.

Tip: Try out the software before you buy. A user-friendly interface can save you hours of frustration.

If you want to keep your machine running well, remember these maintenance tips:

- Clean the inside and outside of your machine often.

- Check and clean the fan unit to keep airflow strong.

- Lubricate moving parts so everything runs smoothly.

- Make sure the air-assist compressor works right for clean cuts.

- Inspect and clean the optics to keep your cut quality high.

- Monitor and clean the chiller to cool the laser tube.

A little care goes a long way. You get better results and your laser cutter lasts longer.

Price & Value

When you shop for a large format cutting laser, price matters. You want to get the most for your money. Some machines cost less but offer fewer features. Others have a higher price tag because they include advanced technology and automation. You need to decide what fits your budget and your business goals.

Here’s a simple way to compare price and value:

| Feature | Entry-Level Models | Professional Models | Industrial Models |

|---|---|---|---|

| Price Range | $700 – $2,000 | $30,000 – $80,000 | $60,000 – $300,000+ |

| Work Area | Small | Medium to Large | Large to Extra Large |

| Power | Low | Medium to High | High to Ultra-High |

| Automation | Basic | Some automation | Full automation |

| Supported Materials | Wood, acrylic, paper | Plastics, metals, wood | Metals, thick materials |

| Accuracy | Good | High | Ultra-high |

You should think about how often you use the machine. If you run a busy shop, a higher-priced laser might save you money in the long run. It works faster and lasts longer. If you only do small projects, a budget-friendly model could be enough.

Tip: Always check what comes with the machine. Some brands include software, training, or extra parts. These add value and help you get started faster.

Ask yourself these questions:

- How much can you spend now?

- Will the machine help you grow your business?

- Does it save you time and materials?

- Can you upgrade it later?

A good laser cutter is an investment. You want a machine that fits your needs and helps you work smarter.

Support & Maintenance

Support and maintenance keep your laser cutter running well. You want help when something goes wrong. Good support means you get answers fast and avoid long downtimes. Some brands offer phone support, online guides, or even on-site service.

Maintenance is important. You need to clean the machine, check the optics, and replace worn parts. Regular care keeps your cuts sharp and your machine safe. If you ignore maintenance, you might see problems like bad cuts or machine errors.

Here are some things to look for:

- Warranty: Does the brand offer a warranty? How long does it last?

- Training: Will you get help learning to use the machine?

- Parts Availability: Can you order spare parts easily?

- Service Network: Is there a local technician who can help?

- Online Resources: Are there videos or manuals you can use?

Note: Make a simple checklist for maintenance. Clean the optics, check the fans, and inspect the moving parts every week. This helps you avoid trouble and keeps your machine working like new.

If you choose a machine with strong support and easy maintenance, you save time and money. You also keep your projects on track and your customers happy.

Best CO2 Laser Cutter: When to Choose

CO2 vs. Fiber vs. Diode

You might ask which laser cutter is right for you. CO2, fiber, and diode lasers all have special strengths. Each type works best for certain jobs. If you compare them, you will see clear differences.

Here’s a table to help you see how they match up:

| Laser Type | Material Compatibility | Cost Range |

|---|---|---|

| CO2 | Fabrics, Paper, Wood, Acrylic, Plastics | $500 – $4,000 |

| Diode | Fabrics, Paper, Wood, Acrylic | $300 – $1,000 |

| Fiber | Metals | N/A |

CO2 lasers are great for cutting and engraving many non-metal materials. You can use them on wood, acrylic, plastics, and fabric. Diode lasers also work with wood and acrylic, but they are not as strong. Fiber lasers are made for metals like steel, aluminum, and brass.

If you want the best co2 laser cutter, think about what materials you use most. CO2 lasers give you good power and a fair price. They cost less than fiber lasers. They work on more materials than diode lasers. Many people choose CO2 lasers because they are strong, flexible, and simple to use.

Ideal Use Cases for CO2 Lasers

CO2 lasers are found in lots of shops and studios. They are best for cutting or engraving non-metal materials with fine detail. The best co2 laser cutter helps you finish projects with smooth edges and neat lines.

Here are some top ways to use CO2 lasers:

- Cut and engrave wood, acrylic, and plastics with precision

- Make detailed designs for crafts and art

- Engrave names or logos on items for promotion

- Cut fabric for clothes or decorations

- Create custom packaging and labels

- Engrave glass and leather for gifts or décor

Let’s see how different industries use CO2 lasers:

| Industry | Applications |

|---|---|

| Woodworking | Cutting and engraving detailed designs on wood |

| Textiles | Cutting and engraving fabric |

| Crafts | Making designs on many materials |

| Advertising | Engraving items for promotion |

| Packaging | Cutting and engraving packaging |

| Decoration | Engraving glass and leather |

New CO2 laser technology makes these machines even better and easier to use. You can find the best co2 laser cutter for work or home. These machines let you do many projects, from small crafts to big signs.

Tip: If you want sharp details and a machine that works with lots of materials, a CO2 laser is a smart pick. You get great results and save money.

Choosing the best co2 laser cutter helps you create new things, customize your work, and grow your business.

Recommendations: Best Large Laser Cutters by Need

High-Volume Production

If your shop is busy, you need a strong laser cutter. These machines work fast and can handle big jobs every day. Some models are made for high-volume work.

- The P-Series is great for shops that need to make a lot. It works all day and does not break down easily.

- Big lasers like the PS36 and PS48 have wide beds over 24 inches. They also have strong power from 90W to 150W. You can cut large sheets or many pieces at once.

- These machines cut stainless steel, carbon steel, and aluminum easily. Your cuts will be strong and look smooth.

- You can use these machines for testing ideas or making lots of parts. You do not need to change machines to switch jobs.

Pick a laser cutter with a strong motor, a wide bed, and automation. These features help you finish big orders on time. Your business will keep moving and growing.

Tip: Pick a machine that matches what you cut most. If you cut metal, choose a fiber laser. For mixed jobs, a CO2 laser with a big bed is a good choice.

Precision & Prototyping

If you need sharp cuts and fine details, laser cutters help a lot. You can make prototypes that look just like your designs. Laser cutting gives you smooth edges and saves time. You do not have to watch the machine the whole time. This means fewer mistakes and lower costs.

Here’s why laser cutters are good for precision and prototyping:

| Advantage | Description |

|---|---|

| Precision | You get very accurate cuts and engravings. |

| Speed | You can make many test pieces quickly. |

| Versatility | One machine can cut wood, plastic, and metal. |

| Cost-efficiency | Prices are lower now, so more people can use them. |

| Sustainability | Laser cutting makes less waste, which is better for the planet. |

You can send your CAD designs right to the machine. Once it starts, you do not need to watch it. This helps you avoid mistakes and finish faster. If you want a home crafting laser cutter for detailed work, pick one that is accurate and easy to set up.

Mixed-Material Work

If you use many materials, you need a flexible laser cutter. Some machines let you cut wood, plastic, and metal without stopping. This helps you do more jobs and offer more to your customers.

- Dual-laser systems let you cut and engrave different materials in one go.

- You can use these machines for crafts, signs, packaging, and custom gifts.

- The best portable laser is easy to move. You can take it where you need and work on many projects.

If you want a laser cutter for mixed jobs, look for easy controls and support for many materials. This helps you try new ideas and grow your business without buying more machines.

Note: Always check what materials the machine can cut before you buy. Some machines work better with certain materials than others.

Budget-Friendly Choices

Looking for a large format laser cutter that won’t break the bank? You have some great options. You don’t need to spend a fortune to get a machine that works well for your projects. Many brands now offer powerful cutters at prices that fit small businesses, schools, or even home workshops.

Here are some top picks if you want to save money:

- xTool D1 Pro: This machine gives you a big work area and sharp results. You can cut and engrave wood, acrylic, and more. It’s easy to set up and use. Many small business owners and hobbyists love it.

- Sculpfun S30 Pro Max: You get strong cutting power and a sturdy frame. The air assist keeps your cuts clean. You can work with wood, plastic, and some metals. It’s a smart choice for crafts or small shops.

- Trotec Speedy 1000 (Entry Models): If you want a pro brand but need to watch your budget, look at the lower-power Speedy 1000 models. You still get a large work area and good software support.

Tip: Always check what comes in the box. Some budget models need extra parts, like air assist or safety covers. Make sure you know what you’re getting.

Here’s a quick table to help you compare:

| Model | Price Range | Best For | Key Features |

|---|---|---|---|

| xTool D1 Pro | $700–$1,500 | Home, small business | Big work area, easy to use |

| Sculpfun S30 Pro Max | $800–$1,200 | Crafts, classrooms | Strong air assist, sturdy |

| Trotec Speedy 1000 | $30,000+ | Pro shops, schools | Pro software, large bed |

You can stretch your budget by looking for sales or refurbished machines. Some brands offer payment plans or bundles with software and training. If you’re just starting out, try a diode laser. These cost less and still handle many jobs.

Note: Think about your main projects. If you mostly cut wood or acrylic, a diode laser works well. For metal, you may need to save up for a fiber laser.

You don’t have to settle for less. With the right research, you can find a laser cutter that fits your wallet and your workshop. Start small, learn the basics, and upgrade as your needs grow. That way, you get the best value for your money and build your skills at the same time.

You have many choices when it comes to large format cutting lasers. Some machines work best for metal, while others shine with wood or mixed materials. If you want speed and accuracy, high-power fiber lasers help you finish tough jobs and take on bigger projects. These machines boost your efficiency, cut down on waste, and help you win more contracts.

- They give you fast, precise, and consistent results.

- You save money over time because they use less energy and need less labor.

- Automation features make your work easier and help your business grow.

Think about what you need most. Reach out to manufacturers for a demo or quote. The right laser cutter is a smart investment for your future.

FAQ

What materials can I cut with a large format laser cutter?

You can cut metals, wood, acrylic, plastics, textiles, and more. Each machine supports different materials. Always check your laser cutter’s manual for a full list.

How do I choose the right laser power?

Think about what you want to cut. Thicker metals need more power. For wood or acrylic, lower power works fine. Match the laser power to your main projects.

Is laser cutting safe for beginners?

Yes, most machines have safety features. Always wear safety glasses and follow the instructions. Keep your workspace clean. If you’re new, start with simple projects.

How often should I maintain my laser cutter?

Clean your machine after every use. Check the optics and moving parts weekly. Regular maintenance keeps your laser cutter working well and helps you avoid problems.

Can I use my own designs with these machines?

Absolutely! You can upload your own files. Most laser cutters work with popular design software. Just make sure your file format matches what your machine supports.

What is the difference between CO2, fiber, and diode lasers?

CO2 lasers cut wood, acrylic, and plastics. Fiber lasers work best for metals. Diode lasers handle light materials like wood and paper. Pick the type that fits your main jobs.

Do I need special ventilation for my laser cutter?

Yes, you do. Laser cutting creates smoke and fumes. Use a good exhaust system or air filter. This keeps your workspace safe and clean.

Can I upgrade my laser cutter later?

Some machines let you add features like air assist, cameras, or stronger lasers. Check with your manufacturer before you buy if upgrades matter to you.