China has emerged as a global leader in manufacturing, particularly in the production of high-quality fiber laser cutting machines. Known for their precision, efficiency, and cost-effectiveness, these machines are highly sought after by industries worldwide. Understanding the China fiber laser cutting machine price is essential for businesses looking to invest in this technology. This article explores the various factors influencing the price of fiber laser cutting machines in China, providing valuable insights for potential buyers to make well-informed purchasing decisions.

Undertanding Fiber Laser Cutting Machine

What Is A Fiber Laser Cutting Machine

This type of machine uses a fiber laser source to generate a high-intensity laser beam. It is known for its high cutting speed, precision, and efficiency. laser metal cutting machines are commonly used for cutting metal materials. Most plates with a thickness of more than 2 mm use laser metal cutting machines. Many experts agree that in the next 30 years -40 years is the golden age of laser processing technology development.

It is recommended to use a cnc fiber laser cutting machine for cutting metal materials such as carbon steel plates within 12mm and stainless steel plates within 10mm. There are many factors to consider when purchasing a cnc laser metal cutting machine. In addition to considering the maximum size and material of the currently processed workpiece, the maximum thickness that needs to be cut, and the size of the raw material, you also need to consider the future development direction, such as the quality of the products you make.

The maximum size of the workpiece to be processed after the technical modification, the format of the materials provided by the steel market, which one is the most economical for your product, the loading and unloading time, etc.

How Does the Fiber Laser Cutting Machine Work?

Fiber laser technology uses powerful laser beams to cut materials. The laser beam is created by a laser diode and amplified through a fiber optic cable. When the laser beam hits the material, it heats up and melts the surface. To keep the cutting area clean, a strong airflow blows away any melted material.To start cutting, the laser beam needs to make a hole in the material. This hole lasts for about ten seconds for a twelve-millimeter sheet of stainless steel. At the same time, the airflow removes any debris, so you can see the cut clearly.

A fiber laser cutting machine is controlled by a computer and can receive cutting instructions from a design workstation. This allows for precise control over the cutting process, so you can create specific patterns or designs. The laser cutting machine also has platforms that make it easy to load and unload materials. This speeds up the cutting process without sacrificing accuracy.

Maintenance of a fiber laser machine is straightforward because the parts don't need to be replaced or tuned up often, saving time and money. Using nitrogen in the cutting process makes the cuts faster, more precise, and cleaner.

Why Choose China Fiber Laser Cutting Machine

Cost-Effectiveness

Chinese manufacturers offer fiber laser cutting machines at highly competitive prices compared to their Western counterparts, making high-quality equipment more accessible to a broader range of businesses. This affordability is largely due to lower production and labor costs in China. Furthermore, Chinese fiber laser cutting machines often incorporate advanced features and technologies at a fraction of the cost found elsewhere, providing exceptional value for money.

Advanced Technology and Innovatione

Many Chinese manufacturers invest heavily in research and development, leading to the incorporation of cutting-edge technology into their fiber laser cutting machines. This commitment to innovation ensures that their machines offer high precision and efficiency. Additionally, the competitive market drives continuous improvement, allowing customers to benefit from the latest advancements in laser technology.

Quality and Reliability

Chinese manufacturers adhere to strict quality control standards, ensuring that their fiber laser cutting machines are both reliable and durable. Many companies have earned international certifications such as ISO and CE, reflecting their commitment to quality. Reputable brands like KRRASS and Han’s Laser are well-regarded globally for their high-quality products.

Versatility and Customization

Chinese fiber laser cutting machines come in a wide range of models, catering to diverse needs across various industries. From entry-level options to advanced industrial machines, there is a broad selection available. Many manufacturers also offer customization options, allowing businesses to tailor machines to their specific requirements.

Comprehensive After-Sales Support

Chinese manufacturers typically provide robust after-sales support, including technical assistance and troubleshooting services. They offer easy access to spare parts and maintenance services, which helps minimize downtime and extends the lifespan of the machines. This support ensures that businesses can maintain and operate their equipment effectively.

Strategic Geographic Advantage

China's strategic location facilitates efficient distribution to major markets around the world, including Asia, Europe, and North America. This results in faster shipping times and reduced logistics costs for international buyers. Additionally, established supply chains in China ensure timely delivery of components and raw materials, contributing to the reliability of the production process.

Positive Market Feedback

Global customers frequently provide positive feedback on the performance and quality of Chinese fiber laser cutting machines. Successful implementations across various industries demonstrate the effectiveness and satisfaction that these machines deliver, reinforcing their reputation as a reliable investment.

Factors Affecting China Fiber Laser Cutting Machine Price

Power Output plays a significant role in determining the fiber laser cutting machine price. Machines with higher power outputs are capable of cutting through thicker materials and operating at faster speeds, which often translates to a higher price due to the increased capabilities and energy requirements. These high-power machines deliver enhanced performance and efficiency, making them suitable for more demanding applications.

Machine Size and Work Area also influence the overall cost. Larger machines with more extensive work areas can handle bigger materials and accommodate larger projects. While these machines offer greater versatility and productivity, they come with a higher price tag due to their size and the additional costs associated with their installation and operation.

Brand and Manufacturer Reputation impact pricing as well. Established brands with a strong reputation for reliability and performance often command higher prices. The premium associated with well-known manufacturers reflects the quality, durability, and advanced features of their machines, which are valued by businesses seeking dependable and high-performing equipment.

Software and Control Systems add to the cost of fiber laser cutting machines as well. Advanced control systems and sophisticated software for precise cutting and automation enhance operational efficiency and accuracy, making these machines more expensive. The integration of these technologies improves the overall functionality and ease of use of the equipment.

Additional Features and Capabilities can significantly affect the price of fiber laser cutting machines. Features such as auto-focus, advanced cooling systems, and dust extractors, along with the ability to cut through thicker materials or perform detailed engravings, contribute to higher costs. These enhancements provide added value by improving performance and functionality.

Material Handling Capabilities influence pricing too. Machines designed to handle a wide range of materials, including various thicknesses and types, are typically more expensive. This versatility allows users to work with different materials, adding to the machine’s overall value and cost.

After-Sales Service and Support also play a role in the pricing of fiber laser cutting machines. The availability of comprehensive support, including technical assistance, warranties, and service contracts, can increase the cost. Quality after-sales service ensures smooth operation and longevity of the equipment, justifying the higher investment.

Certifications and Safety Features contribute to the cost as well. Machines that comply with safety standards and have necessary certifications often come with a higher price tag. These features ensure safe operation and adherence to regulatory requirements, adding to the overall cost of the equipment.

Shipping and Importation Costs can significantly affect the final price of fiber laser cutting machines. Shipping fees, taxes, and import duties vary depending on the location and can impact the overall budget, making it an important consideration in the total investment.

Customization and Special Requests also contribute to higher costs. Customizations tailored to specific needs or preferences can add to the price. Modifications or special features required for particular applications increase the total investment, reflecting the added value of tailored solutions.

2024 Best Fiber Laser Cutting Machines in China

1. Han’s Laser

Shenzhen-based Han’s Laser is a pioneer in china laser cutter equipment manufacturing industry. Known for its advanced technology and diversified products, it provides various metal solutions for different industries.

2. HG Laser

Huagong Laser is headquartered in Wuhan, the birthplace of best laser cutting machines equipment in China. It is a professional best cnc laser cutter equipment manufacturer. Its products are widely used in automobile manufacturing, aerospace, ship manufacturing, military industry, agricultural machinery manufacturing, electronics industry, etc. Committed to creating an excellent best chinese laser cutting machine.

3. Bodor Laser

Headquartered in Jinan, Bodor Laser is famous for its innovative and intelligent laser metal cutting machine solutions. The product enjoys a good reputation in the world, and has agents in many countries. The machine pays attention to the appearance design and user-friendliness. It has reached strategic partnerships with many companies and pays attention to brand promotion, making it one of the companies seeking reliable metal laser cutter machine solutions. one.

4. HSG Laser

Hongshan Laser is a high-tech enterprise in Guangdong Province. It recently established its own lazer cutter department in the north, focusing on breaking through the northern Chinese market. It is famous for its professional manufacturing technology. Its products are used in sheet metal production, automobile manufacturing, ship manufacturing, advertising signs, fitness equipment, kitchen appliances and other industries. It is one of the most potential laser cutting machine suppliers in China.

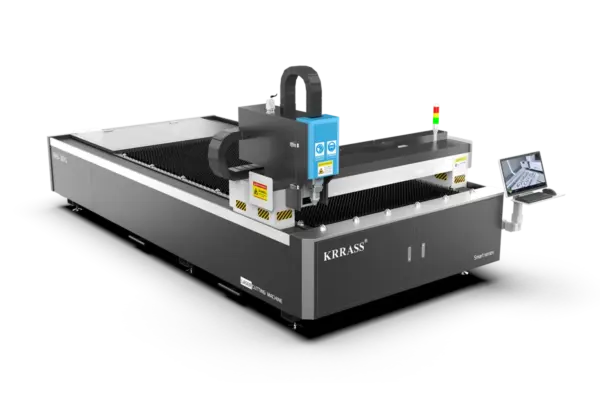

5. Krrass

KRRASS is a leading laser cutter brand based in Nanjing, renowned for offering competitively priced industrial laser cutting machines in China. If you are considering purchasing a laser cutter, KRRASS focuses on delivering affordable fiber laser cutting machines with a commitment to stable quality and high-speed cutting, all while maintaining exceptional precision. Partner with KRRASS for a reliable solution in your manufacturing process.

What Are China Fiber Laser Cutting Machine Prices

The prices of fiber laser cutting machines in China can vary widely based on several factors, including machine specifications, brand, features, and the level of customization. Here’s a general overview of the price ranges for different types of fiber laser cutting machines:

Entry-Level Fiber Laser Cutting Machines

- Price Range: $10,000 - $30,000

- Features: Suitable for small to medium-sized businesses, these machines typically offer basic cutting capabilities and are ideal for less demanding applications.

Mid-Range Fiber Laser Cutting Machines

- Price Range: $30,000 - $70,000

- Features: These machines offer enhanced features such as higher power output, larger work areas, and better precision. They are suitable for more complex and demanding cutting tasks.

High-End Fiber Laser Cutting Machines

- Price Range: $70,000 - $150,000+

- Features: High-end machines come with advanced technology, larger work areas, higher power outputs, and additional features like auto-focus systems and advanced cooling systems. These are designed for high-volume and precision-intensive applications.

FAQ Guide

How to choose china fiber laser cutting machine?

Types of Lasers: There are many types of lasers, each with its own advantages and disadvantages.

Laser Power: Determine the type of material you want to cut and choose the appropriate laser power.

Work area: The width of the bed must correspond to the size of the board being cut.

Functions: Customize various functions according to your needs.

Manufacturer: Choose a car from a manufacturer with a long history and high brand recognition.

What types of china cnc laser cutting machines are there?

Classified by laser type. Including CO2 laser cutting machine, fiber laser cutting machine and YAG laser cutting machine.

- CO2 laser cutting machine is suitable for a variety of materials, including metals, non-metals, ceramics, glass and composite materials;

- Fiber laser cutting machines are known for their fast speed and high precision;

- YAG laser cutters are known for their flexibility and portability.

What kind of platform does laser cutter china have?

The most commonly used models produced by metal laser cutting machines manufacturers are 3015 single platform plate fiber laser cutting machine and laser cutting machine with full cover. These two are the most commonly used models among laser cutting machine brands.

How powerful is the china fiber laser cutting machine?

The fiber laser cutting equipment produced by Chinese laser cutting manufacturers is 1000w 1500w 2000w 3000w 4000w 6kw 10kw 12kw 15kw, with the maximum power of 20kw 30kw 60kw. With the upgrade of chinese laser cutter technology, higher power machines will appear.

Conclusion

Laser cutting machines made in China are a powerful force in the global market, offering an ideal mix of economy, versatility, and technological advancement. The competitive fiber laser cutting machine prices in China make these advanced tools accessible to a wide range of businesses. By selecting a fiber laser cutting machine that aligns with your specific needs and ensuring reliable after-sales support, you can significantly enhance your production capabilities.

As technology progresses, the potential applications of these machines are expected to expand, further strengthening their role in modern manufacturing and other sectors. Whether you are a small workshop or a large industrial enterprise, exploring the fiber laser cutting machine price options from China provides abundant opportunities for innovation and development.