In this article, we will be looking at the process involved in CNC fiber laser cutting and how it benefits over traditional cutting methods.Unlike in the olden days, customers are now on the lookout for state-of-the-art technology to fulfill their stringent design requirements with advanced machines capable of doing these jobs. CNC fiber laser cutting is the machining technology accepted worldwide by all machinists, even though CNC plasma cutting and CNC wire cutting are still in use. Understanding the CNC fiber laser cutting machine price is essential for making an informed purchase decision, as it influences the quality and efficiency of your machining processes.

What Is CNC Laser Cutting?

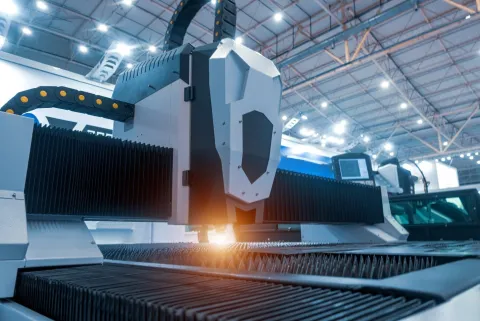

Computer Numeric Controlled (CNC) Laser cutting machines work on the principle that a focused high-power laser beam is used to cut, inscribe, or engrave a metal surface to get the desired shapes.They are specially used to cut intricate shapes and minute holes with a high level of accuracy. This is possible because of their unique design and process of Laser cutting machines.

What Is A CNC Cutter?

A CNC cutter works on computer numerical controls and special computer instructions called G-code to execute the required operations accurately. When it comes to CNC laser cutting, the machine design and its working are slightly different from conventional CNC machines. It works on the principle of a non-contact thermal process. CNC laser cutting machines include a laser head consisting of a laser-focusing lens and a nozzle.

The focusing head and lens focus a beam of the laser through the nozzle. A laser beam is a group of extremely high-intensity light pointed at the workpiece, which gets melted and gets cut into the desired shape. Compressed gas is made use of in CNC lasers to cool the lens and eject the vaporized metal from the workpiece.

How Does A CNC Laser Cutting Machine Work?

When a point on the metallic surface is focused with a high-powered laser beam, rapid heating happens at that point due to the high heat concentration. Not only will it result in rapid heating at that point but also vaporization. The movements of the laser head and laser beam are controlled by the CNC technology which will help to create desired cuts.

Different Types Of CNC Laser Cutting Machines

· CNC CO2 laser cutter

· CNC crystal laser cutter

· CNC fibre laser cutter

Let’s discuss in detail the various models of CNC Laser cutting machines.

CNC CO2 Laser Cutter

In simple words, CNC CO2 laser cutting machines are the ones where carbon dioxide is used as the operating laser medium. The capacity and capability of these machines to produce superpower output make them the most widely used laser cutters in the market.

The output power of 15KW and generally up to 30% efficiency can be expected in these machines. Suitable for cutting small elements and acute angles, these machines are commonly used to work on sheet metals or any other metals which are lower than 10mm thick.

The greater the power of the machines, the better the quality of the cut on thick metal surfaces.

What Is CNC Fiber Laser Cutting Machines?

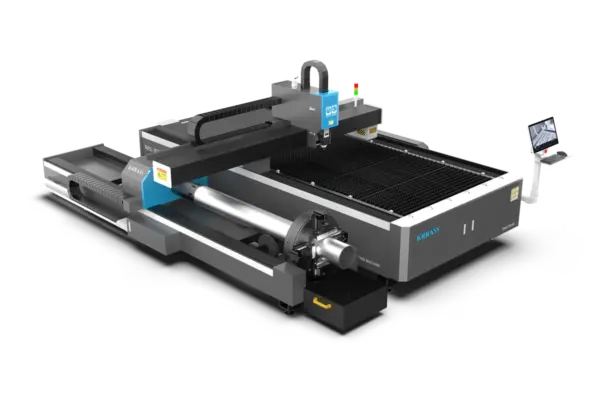

One of the most recent advanced technologies in laser cutting is CNC fibre laser cutting. In this technology, the laser beam is created with the help of a group of diodes and is passed across a fibre optic cable. Fibre laser cutting is comparatively faster as well as a cleaner cutting method when it comes to cutting on materials less than 5mm thick. This cutting process is highly compatible with almost all materials, though extra care must be given when using silver metal.

Silver metal has the capability to hold the heat of the laser beam which can in turn damage the whole metal during the cutting process. This is a great challenge faced while using this technology to cut silver metals. To overcome this challenge, machinists usually make use of a bracket to transfer the heat from the metal surface.

What Is CNC Crystal Laser Cutting Machines?

In CNC crystal laser cutting machines, as the name suggests, the laser beam is created with the help of crystals like neodymium-doped yttrium aluminium garnet and neodymium-doped yttrium ortho-vanadate. CNC crystal laser cutting machines are commonly used to cut thick materials because of the high power of the laser beam. These laser-cutting machines are highly compatible with a wide range of materials be it wood, metals or plastics or glass.

Main Benefits of Fiber Laser Cutting Machine

1. Fiber lasers have a higher energy conversion rate that can reach up to 30%, saving money on operation and maintenance.

2. The fiber laser metal cutter machine is designed with semiconductor modularity and redundancy, and the resonant cavity lacks an optical lens. As a result, there is no need to spend a significant amount of time starting and adjusting the machine prior to cutting work, which is incomparable among traditional laser machines.

3. In order to protect the focus lens and reduce part consumption, a protective lens is configured in the fiber laser head.

4. The laser head will not come into direct contact with the materials in order to avoid scratching them and to ensure a quality cutting effect.

5. Fiber lasers have the smallest kerf and thermal area, which maintains cutting stability and prevents material deformation.

6. Cutting accuracy of 0.2mm/min and fast cutting speed significantly improves the work efficiency of metal parts manufacturing.

7. The fiber laser cutting machine is both safe and environmentally friendly. There will be little pollution and noise, and the workshop environment will be well protected.

This machine is also recommendable to others due to its incredible features and versatility. You will have to pay the price at once, providing more value than you spent on it. Its maintenance cost is nothing much and will benefit you in the long term.

Advantages Of CNC Laser Cutting Machines

Since we have learnt about CNC Laser cutting, the various types of it and how each variant is different, let’s now investigate the advantage of these machines over conventional cutting machines. Unlike conventional cutting machines, CNC Laser cutting machines help you to work on jobs where you need to cut complicated shapes and designs and even holes as small as 2mm with greater precision and accuracy.

Since the CNC laser cutting machines used high power laser beams to cut, the cuts are super clean, and the outcome is highly finished cuts thereby eliminating the need for additional finishing processes.

In conventional cutting technology, various other machines like milling and deburring machines are made use of to complete a cutting job. With the arrival of CNC machines, the need for all these additional machines or tools is eliminated.

Since this laser cutting is a non-contact process, making use of this cutting technology reduces the challenges of metal damage or contamination. For a faster cutting process, you can always opt for CNC laser cutting machines, whereas when it comes to cutting materials of greater thickness and jobs where super finishing is required you can choose CNC wire cutting.

How to Find the Best Deals on CNC Fiber Laser Cutting Machinesre

1. Understand Your Requirements

To find the best CNC fiber laser cutting machine deals, start by understanding your specific needs. Identify the materials you will be cutting, including their thickness and the precision required for your projects. Additionally, consider how often you will be using the machine, as this will help you choose one with the appropriate durability and features to handle your usage frequency. By clearly defining these specifications, you can narrow down your options and ensure that the machine you select meets your operational demands efficiently.

2. Research Different Brands and Models

Explore the market to understand the offerings of various reputable brands known for their quality and reliability, such as Trumpf, Amada, and KRRASS. Compare different models within your budget, focusing on features and capabilities that align with your needs. This thorough research will help you identify the best value options.

3. Check Prices Online

Visit manufacturer websites to get an idea of the base prices and then compare these with listings on online marketplaces like Alibaba, eBay, and Amazon. These platforms often provide competitive pricing and customer reviews that can offer valuable insights into the machine’s performance and reliability.

4. Consider Used or Refurbished Machines

To save costs, look into used or refurbished CNC fiber laser cutting machines. Ensure the machine is in good working condition by checking for warranties or service agreements. This option can provide significant savings while still meeting your operational needs.

5. Look for Promotions and Discounts

Take advantage of seasonal sales during holidays or end-of-year clearances. Attending industry trade shows can also be beneficial, as manufacturers often offer special deals and discounts at these events. Staying alert for these promotions can lead to substantial savings.

6. Negotiate with Suppliers

Engage with suppliers to negotiate the best possible deal. If you are purchasing multiple machines, inquire about bulk discounts. Additionally, ask for value-added services like installation, training, and maintenance to be included in the price, which can enhance the overall value of your purchase.

7. Read Reviews and Testimonials

Investigate customer feedback to gauge satisfaction and reliability. Look for reviews from other buyers and check for case studies or testimonials from businesses similar to yours. This research can provide insights into the machine’s real-world performance and reliability.

8. Evaluate Total Cost of Ownership

Consider not just the initial cost but the long-term value of the machine. Evaluate factors such as maintenance, spare parts, and energy consumption. Ensure the machine comes with a comprehensive warranty and reliable customer support to minimize future expenses.

9. Explore Financing Options

Investigate various financing options to make the purchase more manageable. Leasing can allow you to use the machine with lower upfront costs, while installment plans can help spread out the expense over time, making it easier to fit into your budget.

10. Consult with Experts

Seek advice from industry professionals or consultants who can provide insights into the best machines and deals. Join online forums or communities where you can get recommendations and tips from other users, enhancing your decision-making process.

What Is the CNC Fiber Laser Cutting Machine Price

The cost of laser cutting machines varies depending on the type and wattage of the machine. CO2 laser cutting machines start at around $2000, while fiber laser cutting machines can cost up to $100,000. YAG laser cutting machines are the most expensive, with prices starting at $200,000.

Laser cutting machine prices can vary from manufacturer to manufacturer. In general, laser cutting machines made in China are cheaper than laser cutting machines made in the United States or Europe. Some of the popular laser cutting machines are:

- The Epilog Zing laser cutter: starts at $8,000.

- The Trotec Speedy laser cutter: starts at $10,000.

- The Trumpf Trulaser laser cutter: starts at $100,00

These laser cutting machines are popular because they are made by well-known and trusted manufacturers. They are also popular because they offer a good balance of price and performance.

Different Types of Fiber Laser Cutters Prices

On the market can vary widely. On average, you can expect prices to range from $20,000 to $200,000 USD. The variation in prices is due to several factors, including the manufacturer’s brand reputation, the machine’s power output, configuration, cutting table size, and the type of materials it can cut. Different manufacturers offer machines with various specifications and features, which can significantly affect the price.

Entry-level Fiber Laser Cutting Machines: Basic fiber laser cutting machines (typically entry-level models) with power ratings of 1000w, 1500w, 2000w, and 3000w cost approximately $20,000 to $30,000 USD.

Mid-range Fiber Laser Cutting Machines: Machines with power ratings of 4kw, 6kw, and 8kw are priced in the range of $40,000 to $50,000 USD.

High-end Fiber Laser Cutting Machines: High-end models with power ratings of 12kw, 15kw, 20kw, 30kw, and even 60kw can cost between $70,000 to $200,000 USD.

Additional Costs for Laser Cutting Machines

Apart from the initial purchase cost, there are ongoing expenses associated with operating laser cutting machines. These include electricity costs, expenses for auxiliary gases such as oxygen and nitrogen, and the consumption of consumables like focusing lenses, nozzles, and ceramics. All of these factors should be considered when budgeting for a laser cutting machine.

Financing for Laser Cutting Machine Purchasesere

Many manufacturers and distributors offer financing plans for their machines, and KRRASS is no exception. However, it’s worth noting that financing options can vary. As of now, KRRASS offers comprehensive financing plans primarily for purchasers within China, with export options being more limited. Financing can be a cost-effective way to acquire equipment, allowing businesses to lease or purchase in installments. This helps manage budgets effectively while gaining access to high-quality KRRASS CNC fiber laser cutting machines. By exploring KRRASS financing options, you can optimize your investment and ensure smooth operational scaling.

Factors Impact CNC Fiber Laser Cutting Machine Price

Power:

Different powers correspond to different maximum limits for plate cutting. Choosing the appropriate power will help to better utilize the performance of the laser cutting machine;

Laser cutting machine table size:

The laser cutting machine table sizes on the market are 30001500mm, 40001500mm, 40002000mm, 60001500mm, 14000*2500mm.Different manufacturers can also customize according to customer needs. Currently, the sizes of steel plates on the plate market are:

| Type of Steel Plate | Thickness (mm) | Width (mm) | Length (m) |

| Thick Steel Plate | >4, 5, 6, 8, 10 | <2000 | 4, 5, 6, 8, 10, 12, 14, 16, 20, 25, 30, 40, 50, 10-12 |

| Thick Steel Plate | >4, 5, 6, 8, 10 | 2000, 2500 | 4, 5, 6, 8, 10, 12, 14, 16, 20, 25, 30, 40, 50, 10-12 |

| Thin Steel Plate | <4 | 500-1500 | 1.5-4 |

Laser brand:

Different brands have different service lifes of lasers. Large brands are relatively better and guaranteed;

Cutting material performance:

Different materials absorb laser energy to different degrees, such as aluminum plates and copper, which are highly reflective materials and require special lasers;

Other features and accessories:

Some customers need to add some large enclosures or vacuum and smoke-proof treatments, which is also possible. The appearance, color, etc. are all customizable.

Where to Buy the Best CNC Fiber Laser Cutting Machines?

KRRASS is one of the leading companies in manufacturing high-quality fiber laser cutting machines. With exceptional quality and service, they provide localized services and technical support for global customers. KRRASS is the ideal place to order your machine. They don't compromise on quality and will provide you with a reliable, efficient fiber laser cutting machine with outstanding performance.

Final Thoughts

The average cost of a fiber laser cutting machine depends on various factors such as size, specifications, and features. If you're considering buying a new fiber laser machine, the KRRASS CNC fiber laser cutting machine is an excellent choice. Known for their exceptional quality and reliability, KRRASS machines offer great value for money. When evaluating the CNC fiber laser cutting machine price, it's important to consider the long-term benefits of investing in a high-performance machine from KRRASS. With their commitment to customer satisfaction and technical support, you can be confident that a KRRASS CNC fiber laser cutting machine will meet your needs efficiently and effectively.

Reviewed by 1 user

Thank you for such a professional team to help me choose the right laser machine