Welcome to the definitive guide on laser cutting machine costs! In the intricate realm of manufacturing, precision is paramount, and laser cutting machines are the unsung heroes. Join us as we navigate through the nuances of CO2, Fiber, and Nd:YAG machines, unraveling the factors that influence costs. From power considerations to industry-specific insights, this guide is your compass in the realm of laser precision.

- What is Laser Cutting Machines

- Importance of Understanding Laser Cutting Machines Costs

- What is the Average Price of a Laser Cutting Machine?

- Types of Laser Cutting Machines

- Factors Influencing Costs

- Additional Costs to Consider

- Industry-Specific Considerations

- Used vs. New Machines

- Summary of Key Considerations

1. What is Laser Cutting Machines

Laser cutting machines have revolutionized the manufacturing landscape, offering precision and efficiency that traditional methods often struggle to match. These machines, powered by the incredible technology of lasers, have become indispensable in various industries. Let's take a closer look at what laser cutting machines are and how they function.

1.1 The Basics of Laser Cutting Technology

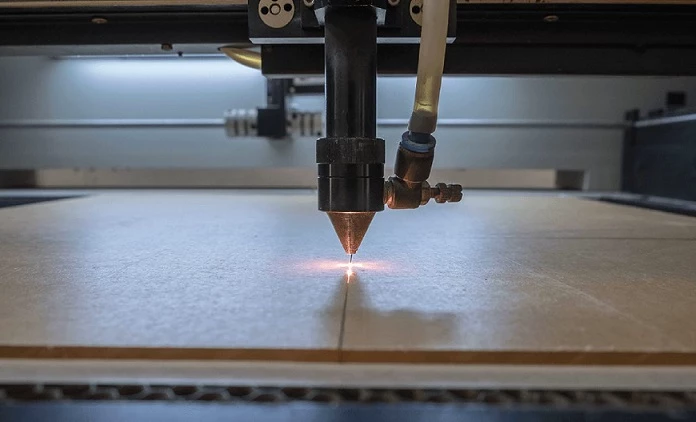

Laser cutting machines operate on the principles of utilizing a concentrated beam of light to cut through materials with remarkable precision. This beam, typically generated by CO2 or fiber lasers, is directed through a series of mirrors and lenses onto the material's surface. The intense heat of the laser beam vaporizes or melts the material, creating clean and precise cuts.

These machines are versatile and can cut through a wide range of materials, including metals, plastics, wood, and more. The ability to make intricate cuts and the minimal material waste make laser cutting machines an attractive choice for manufacturers seeking efficiency and accuracy.

1.2 Applications of Laser Cutting Machines

The applications of laser cutting machines are diverse and continue to expand across industries. From crafting intricate designs in the automotive sector to creating precise components in electronics manufacturing, these machines play a crucial role in shaping the modern production landscape.

Industries such as aerospace, fashion, and healthcare have embraced laser cutting technology for its ability to handle both prototyping and mass production with equal finesse. The precision offered by laser cutting machines allows manufacturers to push the boundaries of design and functionality.

1.3 Key Components of a Laser Cutting Machine

Understanding the key components of a laser cutting machine is vital for manufacturers looking to invest wisely. These components include the laser source, focusing optics, CNC (Computer Numerical Control) system, and the bed where the material is placed. Each component plays a critical role in determining the machine's performance and the quality of the cuts it produces.

Investing in a high-quality laser cutting machine involves evaluating the specifications of these components to ensure they align with the specific needs of the manufacturing process.

2. Importance of Understanding Laser Cutting Machines Costs

As manufacturers navigate the landscape of modern production, understanding the costs associated with laser cutting machines becomes paramount. In this chapter, we'll explore why gaining a comprehensive understanding of these costs is crucial for businesses aiming to thrive in the competitive manufacturing industry.

2.1 Driving Informed Investment Decisions

Investing in a laser cutting machine is a strategic decision that directly impacts a company's production capabilities and bottom line. By comprehending the costs involved, manufacturers can make informed investment decisions, ensuring that the chosen machine aligns with both their budget and operational requirements.

Whether it's a small-scale operation or a large manufacturing facility, having a clear understanding of laser cutting machine costs allows businesses to allocate resources efficiently and avoid unnecessary financial strain.

2.2 Impact on Overall Production Costs

The cost of laser cutting machines goes beyond the initial investment. It encompasses operational expenses, maintenance, and potential downtime. Recognizing the holistic impact on production costs enables businesses to develop accurate pricing models, stay competitive in the market, and maximize profitability.

Efficiency gains and material savings achieved through laser cutting can positively influence the overall cost structure of a manufacturing process. This chapter will delve into the factors that contribute to the total cost of ownership for laser cutting machines.

2.3 Adapting to Evolving Technological Trends

The manufacturing industry is dynamic, with technological advancements shaping the way products are designed and produced. Understanding the costs associated with laser cutting machines positions businesses to adapt to evolving trends seamlessly.

Whether it's upgrading to a more advanced laser cutting system or incorporating automation features, a clear grasp of costs facilitates strategic planning for technological integration. This adaptability is crucial for staying ahead in a rapidly changing manufacturing landscape.

3. What is the Average Price of a Laser Cutting Machine?

When it comes to investing in a laser cutting machine, one of the pivotal considerations is the cost. In this chapter, we'll unravel the complexities surrounding the average price of laser cutting machines, providing prospective buyers with a clear understanding of the financial landscape they are entering.

3.1 Understanding the Price Spectrum

The cost of a laser cutting machine can vary significantly, ranging from as low as $3,000 to well over $1 million. This broad spectrum might seem daunting at first, but breaking it down into key factors helps potential buyers navigate the options effectively.

Factors influencing the price include the machine's power, cutting capabilities, brand reputation, and additional features such as automation and software integrations. As we explore further, we'll delve into each element, empowering buyers to make informed decisions aligned with their specific requirements.

3.2 Power and Cutting Capabilities

The power of a laser cutting machine significantly affects its price. Higher-powered machines capable of cutting through thicker and denser materials generally come with a higher price tag. Understanding the specific cutting capabilities needed for a particular application is crucial in determining the appropriate power level and associated cost.

3.3 Brand Reputation and Quality

Brand reputation and the overall quality of a laser cutting machine play a pivotal role in its pricing. Established manufacturers with a history of delivering reliable and high-performance machines may command a higher price. Evaluating the reputation and reviews of a brand ensures that the investment is in a machine that meets industry standards and expectations.

4. Types of Laser Cutting Machines

Not all laser cutting machines are created equal. In this chapter, we'll explore the diverse landscape of laser cutting technologies, highlighting the unique characteristics and applications of three main types: CO2 laser cutting machines, Fiber laser cutting machines, and Nd:YAG laser cutting machines.

4.1 CO2 Laser Cutting Machines

CO2 laser cutting machines utilize a gas mixture to generate the laser beam. These machines are versatile and suitable for cutting a wide range of materials, including wood, acrylic, and certain metals. They are known for their precision and are often preferred for applications where intricate detailing is essential, such as in the creation of signage, textiles, and packaging materials.

While CO2 laser cutting machines are effective for various materials, their wavelength is less absorbed by metals compared to other types, making them less efficient for cutting thick metal sheets.

4.2 Fiber Laser Cutting Machines

Fiber laser cutting machines use optical fibers to amplify and transmit the laser beam. These machines excel in cutting metals, particularly stainless steel and aluminum. Their high energy efficiency and low maintenance requirements make them a cost-effective choice for industrial applications, where precision and speed are paramount.

Manufacturers often turn to fiber laser cutting machines for tasks like sheet metal fabrication, automotive component production, and aerospace applications. The concentrated energy of fiber lasers enables them to achieve exceptional results on metal surfaces.

4.3 Nd:YAG Laser Cutting Machines

Nd:YAG laser cutting machines use a crystal as the laser medium, emitting a powerful and focused beam. These machines are well-suited for cutting thicker materials, such as ceramics and certain metals. Their ability to cut reflective materials, like brass and copper, sets them apart in specific applications.

While Nd:YAG lasers are not as commonly used as CO2 or fiber lasers, they find their niche in industries requiring precision cutting of challenging materials.

5. Factors Influencing Costs

When it comes to determining the cost of a laser cutting machine, multiple factors come into play. In this chapter, we'll dissect the key influencers that significantly impact the overall cost, empowering buyers to make informed decisions based on their specific needs and budget constraints.

5.1 Power and Wattage

The power and wattage of a laser cutting machine directly correlate with its cutting capabilities. Higher-powered machines are capable of handling thicker and denser materials, but they often come with a higher price tag. Understanding the power requirements for your intended applications is essential in balancing performance with cost-effectiveness.

5.2 Cutting Speed

Cutting speed is a crucial factor influencing the efficiency of a laser cutting machine. Faster cutting speeds often translate to higher productivity but may also impact the machine's cost. Striking the right balance between cutting speed and precision is key to optimizing the cost-performance ratio for a specific manufacturing process.

5.3 Bed Size and Working Area

The physical dimensions of the bed and working area determine the maximum size of materials a laser cutting machine can accommodate. Machines with larger beds generally command a higher price. Manufacturers need to assess their typical material sizes and production requirements to select a machine with an appropriately sized working area, optimizing both cost and operational efficiency.

5.4 Automation Features

Automation features, such as robotic loading and unloading systems or advanced software integrations, can streamline production processes but also contribute to the overall cost. Assessing the level of automation required for specific tasks is essential in evaluating the cost-effectiveness of these features for your operation.

5.5 Brand and Manufacturer

The reputation of the brand and the track record of the manufacturer play a significant role in determining the cost of a laser cutting machine. Established brands with a history of delivering reliable and high-performance machines often come with a premium price. Evaluating the brand's standing in the industry ensures that the investment aligns with the expectations of quality and longevity.

6. Additional Costs to Consider

Investing in a laser cutting machine involves more than just the initial purchase. In this chapter, we'll explore the additional costs that manufacturers should factor into their budget, ensuring a comprehensive understanding of the financial commitment associated with laser cutting technology.

6.1 Installation and Setup

Installation and setup costs are often overlooked but are crucial in the overall investment. Ensuring that the machine is installed correctly and calibrated to meet specific production requirements is essential for optimal performance. Professional installation services may come at an additional cost but contribute to the long-term reliability and efficiency of the laser cutting machine.

6.2 Maintenance and Repairs

Maintenance is a key aspect of ensuring the longevity and performance of a laser cutting machine. Regular maintenance checks and timely repairs are essential to prevent costly breakdowns and production downtime. Manufacturers should budget for routine maintenance and be prepared for unforeseen repair costs to keep the machine operating at peak efficiency throughout its lifespan.

6.3 Training and Certification

Operating a laser cutting machine requires skilled personnel. Training programs and certifications ensure that operators have the necessary knowledge and expertise to handle the machine safely and efficiently. Investing in training not only enhances operational capabilities but also contributes to a safer working environment. Manufacturers should consider the cost of training programs as part of the overall investment in laser cutting technology.

7. Industry-Specific Considerations

As we navigate the intricacies of laser cutting machine costs, it's essential to recognize that different industries have unique requirements and considerations. In this chapter, we'll explore how the cost of laser cutting machines can vary across industries and the importance of customization for specific applications.

7.1 Cost Variances in Different Industries

The cost of laser cutting machines is not one-size-fits-all, and it can vary significantly based on the specific needs of different industries. For example, the aerospace industry may prioritize high precision and cutting speed, leading to investments in more advanced and higher-priced machines. Understanding these industry-specific nuances is crucial for manufacturers to align their investment with the unique demands of their production sector.

Throughout this section, we'll explore case studies and examples to illustrate how different industries navigate the landscape of laser cutting machine costs, providing valuable insights for manufacturers in various sectors.

7.2 Customization for Specific Applications

Customization is a key consideration when evaluating laser cutting machine costs, especially when tailoring the technology for specific applications within an industry. Whether it's precision cutting in the medical field or large-scale fabrication in the automotive sector, adapting the machine to meet the unique requirements of the application often involves additional costs.

We'll delve into the importance of customization, examining how it not only enhances the machine's performance but also contributes to overall efficiency and cost-effectiveness in the long run. Manufacturers will gain insights into the benefits of investing in laser cutting machines that are finely tuned for their specific applications.

8. Used vs. New Machines

When considering an investment in a laser cutting machine, one must weigh the pros and cons of buying used versus new equipment. In this chapter, we'll specifically focus on the potential drawbacks and challenges associated with purchasing a used laser cutting machine.

8.1 Cons of Buying Used

While buying a used laser cutting machine may seem like a cost-effective option, it comes with its set of challenges and potential drawbacks that buyers should carefully consider:

- Wear and Tear: Used machines may have undergone extensive use, resulting in wear and tear on critical components. This can lead to reduced precision and performance compared to a new machine.

- Outdated Technology: Older models may lack the latest technological advancements, limiting the machine's capabilities and compatibility with modern software and automation features.

- Limited Warranty and Support: Used machines often come with a shorter or no warranty, and finding adequate support for repairs and maintenance might be challenging. This can result in higher long-term costs due to potential breakdowns and downtime.

- Unknown History: Understanding the usage history of a used machine can be challenging. Factors such as the intensity of past work and adherence to maintenance schedules may remain unknown, posing potential risks for the buyer.

- Resale Value: Unlike new machines, the resale value of used equipment may not hold up well over time. This can impact the overall return on investment, especially if the buyer plans to upgrade or replace the machine in the future.

9. Summary of Key Considerations

As we wrap up our exploration of laser cutting machine costs, let's summarize the key considerations that manufacturers should keep in mind when navigating this crucial decision-making process.

9.1 Recap of Critical Factors Influencing Costs

Throughout this comprehensive guide, we've delved into various factors that significantly impact the costs associated with laser cutting machines. Here's a brief recap of the critical considerations:

- Power and Wattage: The cutting capabilities and efficiency of a laser cutting machine are closely tied to its power and wattage.

- Cutting Speed: Balancing cutting speed with precision is essential for optimizing the efficiency and overall performance of the machine.

- Bed Size and Working Area: Choosing a machine with an appropriately sized working area ensures optimal material handling and production efficiency.

- Automation Features: While automation can enhance productivity, it's essential to evaluate the cost-effectiveness of these features for specific applications.

- Brand and Manufacturer: The reputation of the brand and the track record of the manufacturer play a pivotal role in determining the overall quality and reliability of the machine.

- Additional Costs: Beyond the initial purchase, factors like installation, maintenance, and training contribute to the overall cost of owning and operating a laser cutting machine.

- Industry-Specific Considerations: Different industries have unique requirements that influence the cost dynamics of laser cutting machines.

- Used vs. New Machines: Buyers should carefully weigh the pros and cons of purchasing a used machine, considering factors like wear and tear, outdated technology, and limited warranty support.

9.2 Key Takeaways for Buyers

For manufacturers looking to invest in laser cutting technology, here are the key takeaways to guide your decision-making process:

- Define Your Needs: Clearly identify your production requirements and applications to choose a machine that aligns with your specific needs.

- Budget Wisely: Consider the total cost of ownership, including additional expenses like installation, maintenance, and training, to budget wisely for the entire lifespan of the machine.

- Stay Informed: Keep abreast of industry trends, technological advancements, and the unique considerations of your sector to make informed decisions that support your business goals.

- Explore Customization: Explore customization options to tailor the machine for specific applications, optimizing its performance for your unique production demands.

- Consider Long-Term Value: Look beyond the initial purchase price and consider the long-term value, including factors like efficiency, reliability, and the potential for future upgrades or expansion.

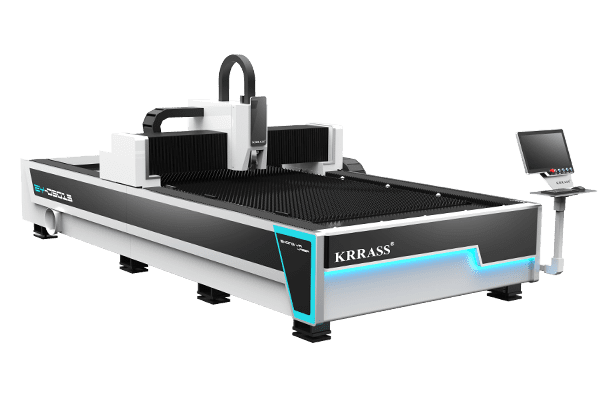

Choosing the Best Laser Cutting Machine

As you embark on the journey to elevate your manufacturing capabilities, consider the expertise of China's leading Laser Cutting Machine manufacturer, Krrass. Explore cutting-edge solutions at Krrass and witness innovation that shapes the future of precision engineering. Choose excellence, choose Krrass.