Are you planning to buy a fiber laser cutter for sale? Selecting laser equipment is never simple. Researching laser types, machine features, technical parameters, and how different materials are affected by lasers can be overwhelming, especially with the myriad options available on the market. Equally important is estimating the equipment's benefits and the return on your investment to get the best value for your money. In this post, we will discuss ten essential factors to consider when purchasing a fiber laser cutter for sale, helping you focus on your needs and make an informed decision.https://www.youtube.com/watch?v=T5PJww12hWY

What Is A Fiber Laser Cutter and How It Works

Every laser system is built with a “gain medium,” which is a material that can amplify light. Also known as a “laser medium” or “active medium,” gain mediums can be solid, gas, or liquid, and these different materials affect the system’s beam qualities. Depending on what kind of material a laser system uses as a gain medium, the system will fall under one of these three categories:

- Solid-state laser

- Gas laser

- Liquid laser

To create a beam, laser systems use “pump sources” (i.e., external power supplies) to energize the gain medium through a process called “pumping.” Laser systems can use various pump sources, including flashlamps, electrical currents, and radio frequencies. By pumping the gain medium, laser systems excite the material into releasing photons.

On a basic level, laser systems take these released photons and use mirrors to increase energy and form a beam. Once the beam is strong enough, the system releases it toward the substrate to complete the intended application.

Fiber Laser Systems: Principles and Material Compatibility

With these details in mind, let’s explore how fiber laser systems function and their capabilities.

Fiber lasers are solid-state devices using fiber optic cables doped with rare earth ions to amplify light. Here’s how they operate:

- Energy Injection: A laser diode or similar source injects energy into the optic fiber, exciting the rare earth ions to emit photons.

- Photon Amplification: The emitted photons bounce within the fiber, increasing energy.

- Beam Formation: Photons are funneled to a mirrored optical cavity, forming a concentrated beam.

- Material Interaction: The focused beam is directed at the material for marking, engraving, or cutting.

These principles allow fiber lasers to efficiently handle a variety of materials with high speed and precision. Fiber, CO2, and UV lasers each operate at different wavelengths, affecting their compatibility with various materials. Here's a general overview:

| Laser Type | Compatible Materials |

|---|---|

| Fiber | Metals (steel, aluminum, copper, brass) |

| CO2 | Non-metals (wood, acrylic, glass) |

| UV | Plastics, some ceramics, and metals |

This variety in laser systems ensures suitability for diverse industrial applications, each excelling in specific material interactions.

| Material Category | Material | Fiber Laser | CO2 Laser | UV Laser |

| Wood, Paper, and Board | Wood | ✔ | ✔ | ✖ |

| Thermal Label | ✔ | ✔ | ✖ | |

| Paper | ✔ | ✔ | ✖ | |

| Board | ✔ | ✔ | ✖ | |

| Metallized Board | ✔ | ✔ | ✖ | |

| Glass | Glass | ✖ | ✔ | ✔ |

| Glass Fiber | ✔ | ✔ | ✔ | |

| Ceramic | Ceramic | ✔ | ✔ | ✔ |

| Plastics | Polypropylene (PP) | ✔ | ✔ | ✔ |

| Low-density polyethylene (LDPE) | ✔ | ✔ | ✔ | |

| High-density polyethylene (HDPE) | ✔ | ✔ | ✔ | |

| ABS | ✔ | ✖ | ✔ | |

| Polyacetal (POM: polyoxymethylene) | ✔ | ✔ | ✔ | |

| Polyamide (PA) | ✔ | ✔ | ✔ | |

| Polycarbonate (PC) | ✔ | ✖ | ✔ | |

| Polyethylene terephthalate (PET) | ✖ | ✔ | ✔ | |

| Metals | Steel | ✔ | ✔ | ✔ |

| Galvanized Steel | ✔ | ✔ | ✔ | |

| Aluminum | ✔ | ✔ | ✔ | |

| Titanium | ✔ | ✔ | ✔ | |

| Copper | ✔ | ✖ | ✔ | |

| Brass | ✔ | ✖ | ✔ |

Cutting, Marking, and Engraving: 3 Basic Uses of Fiber Laser Cutter

The chart above highlights that fiber laser systems exhibit exceptional compatibility with a variety of materials, particularly metals and plastics. These systems are predominantly used by companies working with:

- Metal sheets

- Metal pipes

- Aluminum cans, foil, and bottles

- Plastic bags

- Plastic bottles

- Rigid plastic materials

- Plastic PVC pipes

- Tetra Pak® and aseptic packaging

- Flexible packaging

- Shrinkwrap and flexible film

Fiber laser systems can be employed to cut, mark, or engrave these materials depending on the company's specific operational needs. However, not all fiber laser systems are capable of handling every type of application effectively.

While fiber laser systems are versatile, the requirements for cutting, marking, and engraving differ significantly. Cutting is the most demanding application and relies on several crucial factors. The two key elements are:

System Power: The power of fiber laser systems is typically measured in watts (W), with models ranging from 10W to 10,000W. Higher power systems are more effective at cutting various materials. For instance, a 10W system is not suitable for cutting, while a 40W system can cut thin plastic sheets. A 200-500W system is capable of cutting thicker plastic, and a 500W system can handle thin metal sheets.

Material Thickness: The thickness of the material determines the power required for cutting. Thin plastic sheets can be cut with a more affordable 100W system, whereas thicker metals, such as those used in pipes and construction materials, require a minimum of 1,000W for reliable cutting performance.

Given the high power requirements for cutting, many fiber laser systems are primarily designed for marking and engraving applications. For these tasks, different power levels are needed based on the material:

Marking and Engraving: To mark or engrave metal products, a minimum of 10W is required, with 50W being ideal for efficient and high-speed results. For plastics and other non-metallic materials, a 10W-20W system will generally suffice.

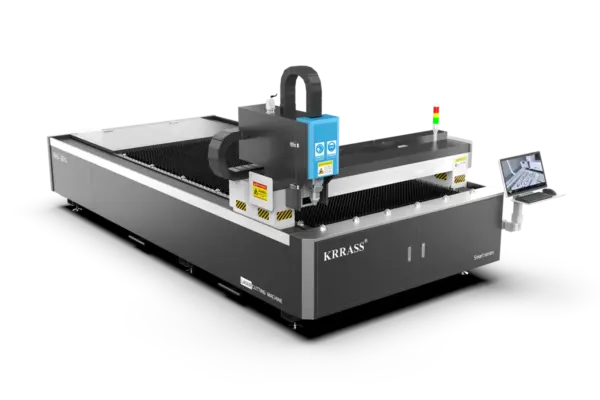

Regardless of whether you are working with metal or plastic, the more powerful and well-built your system is, the better your results. Consider the KRRASS Smart 3015 series fiber laser marking machine, for example. The Smart 3015 is a 50W system designed to produce long-lasting codes and highly-defined images (see the marking example to the right and the engraving example below). Thanks to the Smart 3015’s 50W power output, robust design, and advanced software, the system is capable of:

- Achieve marking speeds up to 2,000 characters/second (when using the high-speed scanner)

- Operate on lines moving at 200m/min.

- Create intricate graphics and complex codes

- Greatly reduce coding errors and misprints compared to other marking methods

- Offer high-contrast marking for machine-scannable codes

Fiber Laser Cutter for Sale: What to Think Before Buying

Fiber Laser Machines: Industrial vs. Hobby Use

Fiber laser machines are renowned for their versatility and are valuable tools across a wide range of industries. They cater to both large-scale businesses and individual hobbyists, craftsmen, and small-scale manufacturers. These machines are increasingly popular in small workshops and garage-based businesses for their ability to enhance productivity and enable creative projects.

When choosing a fiber laser machine for business purposes, prioritizing productivity is crucial. Here are key factors to consider:

Power

Industrial fiber lasers typically offer higher power outputs compared to their hobbyist counterparts. Higher power allows for greater flexibility, enabling the processing of thicker materials and faster job completion. In contrast, hobbyist models usually have lower power and are suited for lighter tasks.Capabilities

Industrial fiber lasers are built to handle demanding tasks such as cutting thick metal sheets, welding large structures, and marking on extensive surfaces. Hobbyist lasers, on the other hand, are generally designed for more manageable tasks like small part cutting or engraving.Features

Industrial models often come with advanced features including high precision, speed, beam quality, and stability. These machines are equipped to meet rigorous production standards. Hobbyist machines may have more basic features and are aimed at simpler, less demanding applications.Size

Fiber laser machines vary significantly in size, from compact desktop engravers to large gantry-style systems. It's important to consider not only the machine’s dimensions but also its power consumption, ventilation requirements, and safety features.Cost

Due to their higher power and advanced features, industrial fiber lasers tend to be more expensive than hobbyist models. Hobbyist machines are more affordable, reflecting their more basic functionality and lower power output.

Understanding Fiber Laser Machine Functions

Fiber laser machines operate using a fiber laser source to generate a laser beam through specialized optical fibers. This beam is then directed via mirrors and lenses to focus intense energy onto the material's surface. The concentrated heat from the laser beam either melts, vaporizes, or burns away the material, enabling precise cuts, engravings, or markings.

When considering a fiber laser, ask yourself: What are my specific needs? Are you involved in creating custom gifts, signs, jewelry, or do you work in auto repair or metal fabrication? Various laser machines are tailored for specific tasks, including metal cutting, marking, engraving, surface cleaning, and welding. Additionally, different types of laser sources determine which materials the laser can effectively work with. Identifying your intended application will guide you in selecting the right fiber laser machine.

Cutting:

Fiber laser cutting machines are designed to deliver powerful, high-precision beams that cut through materials such as metal, plastic, and wood quickly and efficiently. These machines typically feature high power output, exceptional accuracy, and rapid cutting speeds.Engraving:

Fiber laser engraving systems are built for high-speed, high-precision marking and engraving. They can create detailed text, images, photos, barcodes, and designs on various surfaces, including metal, plastic, and glass. Known for their accuracy and speed, these machines are ideal for intricate engraving tasks.Welding:

Fiber laser welding equipment uses high-power, high-quality beams to weld both similar and dissimilar metals. These machines are designed for high power output, precision, and stability, making them suitable for robust welding applications.Cleaning:

Fiber laser cleaning machines are equipped with high-power lasers capable of effectively cleaning surfaces of materials such as metal, wood, and concrete. These machines are renowned for their efficiency and effectiveness in surface cleaning.

Materials Compatible with Laser Technology

Laser machines are versatile tools that can permanently mark and cut a wide range of materials. They provide significant business opportunities by transforming everyday materials into customized products, making them a valuable investment for many industries.

Here are some common materials that can be effectively laser engraved:

- Granite: Ideal for personalizing granite memorials, countertops, outdoor signage, and flooring.

- Brick and Stone: Useful for creating fundraising bricks, stepping stones, retaining walls, and landscaping features.

- Glass and Crystal: Perfect for awards, personalized gifts, interior and furniture design, and packaging for food, drinks, cosmetics, and pharmaceuticals.

- Wood: Versatile applications include custom flooring, cabinetry, furniture, gun stocks, personalized gifts, business cards, signage, and awards, as well as educational projects.

- Plastics and Acrylic: Commonly used for indoor and outdoor signage, plastic part marking and cutting, and architectural models.

- Metals: Suitable for marking metal parts (such as tools and machine components), automotive applications, firearm personalization, jewelry, metal urns, and awards. Note that while coated metals can be easily engraved, uncoated bare metals may require a marking compound.

- Rubber: Frequently used for marking tires, creating rubber stamps, and manufacturing part handles.

- Leather and Fabric: Used in fashion design, interior design, and textile creation or modification.

The ability of a fiber laser to work with these materials depends on the type of laser source and its power. The wavelength of the laser is a critical factor in determining its effectiveness on various materials. Therefore, it's important to consider the properties of the material and the intended application when selecting a fiber laser machine. If you want to test your material, please email us directly.

Choosing the Right Size

Selecting the appropriate size for a fiber laser machine is crucial and depends largely on your specific needs and the dimensions of the materials you plan to work with. The size of the machine affects both the scope of your projects and the efficiency of the engraving or cutting process. While a larger machine offers the ability to work with bigger materials, it’s important to balance this with other factors, as a larger working area can also mean a larger laser focal length, potentially reducing the machine’s power and precision.

Here are key factors to consider when determining the size of your fiber laser machine:

Material Dimensions:

Consider the largest size of the materials you will be working with. Choose a fiber laser machine that accommodates your largest product, or plan for additional equipment like conveyor belts or XY-moving worktables to manage larger items. Ensuring your machine can handle the full size of your materials will streamline your production process.Object Shape:

The shape of your products will influence your choice of laser machine. For non-flat or irregularly shaped items, such as cylindrical objects, look into machines that offer rotary axis attachments or other accessories designed to handle these shapes effectively. This ensures that the laser can reach all areas of the object, regardless of its form.Materials Handling:

Efficiently handling large or oversized materials is essential. Specialized equipment like conveyors, material handling robots, or automated systems may be necessary to maneuver and position materials accurately for processing. Assess your needs for material handling to ensure smooth operation and minimize downtime.Operational Space:

Consider the physical space available in your workshop or production area. Larger machines require more space, so ensure that you have adequate room not only for the machine itself but also for any additional equipment and material handling processes.Precision vs. Size Trade-off:

While a larger machine provides the capability to work with bigger objects, it can also result in a larger laser focal length, which may impact precision. Balance the need for a larger working area with the machine’s ability to deliver high-precision results, especially if detailed engraving or cutting is a critical part of your operations.

Fiber Laser Machine Pre-Sale Options

Ensuring that the chosen laser equipment is right for you is a crucial first step. Find out if your supplier offers demonstrations and material tests. It’s a good idea to ask your dealer to perform a sample cut or engraving on your specific material to evaluate the machine’s performance and suitability for your needs.

The investment in a laser machine should be well-planned. Explore possible financing or leasing options before making a purchase. Financing allows you to start earning with the machine immediately without a large upfront investment. Additionally, leasing rates may be tax-deductible as business expenses and offer financial stability with a structured payment plan.

Gather comprehensive information before finalizing your purchase decision. Understand the machine's capabilities, maintenance requirements, and after-sales support to ensure it aligns with your business goals and operational needs.

Fiber Laser Machine Installation & Operation

When choosing your fiber laser machine, it’s crucial to consider not only its features but also the ease of its installation and operation. Modern laser machines are operated through software applications, so it’s important to assess the software’s features, compatibility with operating systems, and support for various graphical file formats. Ensure that you have access to comprehensive documentation, including installation procedures and software manuals. Factors such as quick setup and user-friendly software play a significant role in selecting the right fiber laser machine..

Understanding how to properly use and operate the machine is essential for maintaining optimal performance. Correct operation minimizes downtime and maximizes output, helping you keep up with production demands while reducing the risk of costly repairs and operational interruptions.

Fiber Laser Machine Lifespan & Maintenance

When selecting a fiber laser machine, considering its expected frequency of use is crucial. The durability and dependability of the machine are vital for those intended for regular use in a production environment. To handle such demands, invest in a machine with a long-lasting laser source and high-quality components designed to endure heavy use.

Additionally, factor in the maintenance routine and the cost of consumable products, as these will impact your overall production costs and efficiency. If you anticipate an increase in production volume, choose a machine that offers scalability, allowing for future upgrades to accommodate growing demands.

Fiber Laser Cutter Accessories

Exploring available accessories for your fiber laser machine is essential. Having access to a variety of accessories allows you to expand your product offerings without the need for significant additional investment in new machinery.

- Protective Eyewear: Essential for safeguarding your eyes from intense laser light.

- Field Lenses: Larger lenses can expand the working area of the laser, while smaller lenses enhance power output and precision.

- Lens Cleaning Supplies: Necessary for maintaining a clean lens, which is crucial for ensuring the quality of the laser beam.

- Cooling Systems: Some fiber laser machines require cooling systems to regulate temperature and prevent overheating.

- Nozzles: Used to direct the laser beam precisely onto the material being processed.

- Chiller: Helps maintain the laser’s temperature consistency and prevents overheating.

- Dust Collector: Removes dust generated during cutting or engraving processes.

- Fume Exhaust System: Ventilates fumes produced by the cutting or engraving process.

- Rotary Axis: A motor-driven attachment designed for working on cylindrical objects.

- Vise: A clamping table that holds the material securely during processing.

- Auto-Focus: A device that automatically adjusts the laser head to the correct focal length for accurate results.

Fiber Laser Machine Warranty and After-Sales Support

When purchasing a fiber laser machine, warranty and post-purchase support are crucial factors that ensure the longevity and performance of your investment.

Warranty: A warranty guarantees that the manufacturer will address any manufacturing defects or malfunctions within a designated period. Should any issues arise due to factory faults, the manufacturer will repair or replace the machine at no additional cost to the buyer.

Post-Purchase Support: This encompasses a range of services, including technical assistance, software updates, and troubleshooting help. Effective post-purchase support ensures that you can address any problems that come up and receive guidance to maintain optimal performance of your fiber laser machine.

Maintenance and Repair Service: It’s essential for the manufacturer or supplier to provide maintenance and repair services. This helps keep the machine in top working condition and reduces downtime from unforeseen repairs or maintenance needs.

Training: Proper operation and maintenance training are vital for safety and efficiency. Access to comprehensive training ensures that users can operate the machine correctly, maintain it properly, and maximize its lifespan.

Fiber Laser Machine Cost

Compared to other marking options, fiber laser systems are known for their relatively high upfront prices. Depending on your power requirements, you should be prepared to spend anywhere from $10,000 to well above $100,000 on a system.

However, higher price tags do not always equal better quality. For example, many coding and marking companies significantly inflate the prices of their laser models to discourage customers from choosing them over continuous inkjet or thermal inkjet printers. The logic is that ongoing fluid purchases are more profitable over time than laser system purchases. As a result, companies like Videojet charge customers close to $50,000 for a laser system, while companies like InkJet, Inc. that do not inflate prices will sell equivalent options for less than $20,000.

To ensure a good deal, you should take an exhaustive look at all of your viable options, compare specifications, speak to an expert, and make an educated decision on which systems are worth the asking price.

Where Can Buy A Qualified Fiber Laser Cutter

When looking to purchase a qualified fiber laser cutter, consider the following options:

1. Direct from Manufacturers

KRRASS: Known for high-quality fiber laser cutters with competitive pricing. They offer a range of models and robust pre- and post-sales support. Buying directly from KRRASS ensures you get their expertise and service.

TRUMPF: A leading manufacturer with a reputation for advanced technology and reliability. They provide comprehensive support and have a global presence.

AMADA: Offers a wide range of fiber laser cutters known for their precision and durability. They provide excellent customer service and technical support.

2. Authorized Dealers

Local Distributors: Many regions have authorized dealers for major brands like KRRASS, TRUMPF, and AMADA. These dealers offer local support, training, and service.

Specialized Equipment Suppliers: Companies that specialize in industrial machinery often have a selection of fiber laser cutters from various manufacturers and can provide personalized recommendations based on your needs.

3. Online Marketplaces

Alibaba: A platform where you can find various manufacturers and suppliers of fiber laser cutters, including KRRASS. It's important to check reviews and verify the credibility of the seller.

Made-in-China: Similar to Alibaba, this site lists multiple suppliers and manufacturers of fiber laser cutters. It’s a good place to compare prices and models.

4. Trade Shows and Exhibitions

Industry Events: Attending trade shows and exhibitions related to manufacturing and laser technology can provide hands-on experience with different models and direct interactions with manufacturers and dealers.

5. Industry Forums and Recommendations

- Professional Networks: Engaging in industry forums and seeking recommendations from peers can lead to valuable insights and referrals for purchasing high-quality fiber laser cutters.

Conclusion

Fiber laser machines are a valuable asset for businesses and organizations of all sizes due to their versatility and wide range of applications across various industries. When considering the purchase of a fiber laser cutter for sale, careful evaluation is crucial.

We have outlined 10 key factors to help you navigate the options and select the best fiber laser cutter for your needs. The most critical aspects include the intended application, the type and size of materials to be used, power output, and cost. Additionally, consider the equipment's lifespan, operational requirements, maintenance needs, and the quality of pre- and post-sales support.

By focusing on these factors, you can make an informed decision and find the perfect fiber laser cutter for sale that best suits your enterprise's requirements.