Welcome to our comprehensive guide on Press Brake Crowning. Here, we'll unravel the mysteries surrounding this essential element in metalworking and manufacturing. Whether you're grappling with Hydraulic Crowning Systems or wondering about Motorized Crowning Systems, this article is your one-stop resource.

- What is a Press Brake?

- The Role of Press Brakes in Metalworking and Manufacturing

- Why Bending Accuracy Matters in Metal Fabrication

- The Concept of Bending Accuracy

- Why Bending Accuracy Matters in Metal Fabrication

- What Is Crowning?

- Types of Press Brake Crowning Systems

- Why is Crowning Necessary?

- The difference between mechanical crown system and hydraulic bending machine crown system

- How to choose the correct bending crown system?

- How to choose the correct bend compensation?

- Crowning for Different Types of Material

- Tips for Optimal Crowning

Chapter 1: What is a Press Brake?

So, you're in the market for a Press Brake, or perhaps you've heard the term thrown around in industry conversations. But what exactly is a Press Brake? Hold that thought, we're about to delve deep into what makes a Press Brake not just a machine, but a cornerstone in metal fabrication processes.

In its simplest form, a Press Brake is a machine used for bending sheet and plate material, typically metal. Imagine a piece of paper; when you want to fold it, you apply force with your hands. Now scale that up by a hundred—or even a thousand times—with metal sheets. Your hands won't suffice. Enter the Press Brake.

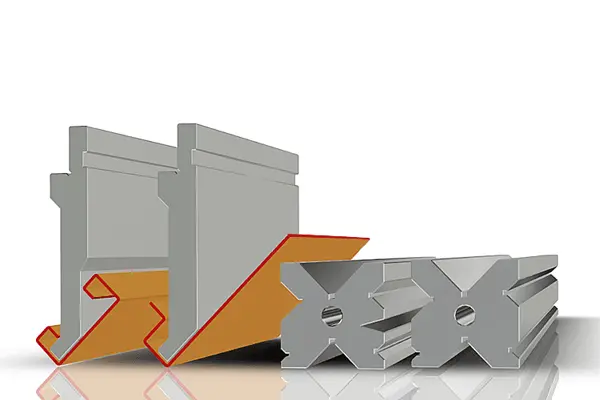

Comprising two C-frames, the bed and ram, a Press Brake exerts force via a set of punches and dies. These aren't your average paper punches; they're engineered to withstand enormous amounts of pressure, ensuring that the metal bends precisely where you want it to. It's the go-to machine for any serious metal fabricator. Why settle for less when you're crafting the backbone of buildings, vehicles, or even aircraft?

While there are several types of Press Brakes—Hydraulic Crowning Systems and Motorized Crowning Systems to name a few—they all serve the purpose of bending metal to exact specifications. The choice between hydraulic and motorized systems usually boils down to the complexity of your projects. But we'll dig deeper into that in the coming chapters.

Chapter 2: The Role of Press Brakes in Metalworking and Manufacturing

You've got a grasp on what a Press Brake is, but understanding its role in metalworking and manufacturing requires a more in-depth look. Ever wondered how a flat piece of metal transforms into a fully functional part of a car or a structural building element? That's right—the unassuming yet powerful Press Brake is behind the scenes, doing the heavy lifting.

So, what role does a Press Brake play in the grand scheme of things? Well, to start with, it's a game-changer in precision bending. Forget the days when manual labor struggled with hefty metals, attempting to get the angle just right. A Press Brake ensures each bend is a carbon copy of the last, upholding the highest standards of precision and quality. Consistency is king in manufacturing, isn't it?

Another huge benefit of Press Brakes is their adaptability. With the advent of Hydraulic Crowning Systems and Motorized Crowning Systems, these machines can adapt to various materials and thicknesses, making them incredibly versatile. Got a complex project? The Press Brake's got your back!

Let's not forget the efficiency factor. In a world where time is money, the speed at which a Press Brake can bend metal sheets is a marvel. Automated systems have only accelerated this process, integrating seamlessly with other stages of production. The end result? A streamlined, efficient workflow that any manufacturer would dream of.

Lastly, the Press Brake is an ally in reducing waste. Because it bends metal with surgical precision, the amount of material scrapped is minimal. This isn't just good for your budget; it's also a win for sustainability. In an era where every industry is scrutinized for its environmental impact, using a Press Brake is a step in the right direction.

Read More: How to Choose the Right Press Brake Tool for Your Press Brake

Chapter 3: Why Bending Accuracy Matters in Metal Fabrication

As someone involved in metal fabrication, you already know that close enough just won't cut it. But why is bending accuracy so crucial? Is it all about meeting specifications, or is there more to the story? Grab a seat, because we're about to unravel the compelling reasons that make bending accuracy non-negotiable in metal fabrication.

First and foremost, let's talk safety. Whether you're creating parts for automobiles, constructing bridges, or manufacturing aircraft, a minor inaccuracy in bending can lead to catastrophic failures. Lives could literally be at stake. With a reliable Press Brake and Hydraulic Crowning Systems, you can trust that each bend meets the highest safety standards.

Speaking of standards, precision bending ensures that your fabricated metal components are compliant with industry-specific regulations. Non-compliance isn't just a headache; it can result in financial penalties, legal actions, and a tarnished reputation. Why take the risk when a high-quality Press Brake can take care of accuracy for you?

Let's get down to the nitty-gritty—cost. Inaccurate bending often results in wasted material and extra labor for corrections. Add in the expense of halting production lines, and the costs quickly stack up. In contrast, accurate bending minimizes waste and streamlines the manufacturing process. That's what I call a win-win!

A less obvious but equally important aspect of bending accuracy is customer satisfaction. Imagine delivering a project that just doesn't fit right. Not only will you have a disappointed customer, but you'll also face delays, additional costs, and, potentially, loss of future business. Accurate bending ensures that your parts fit perfectly the first time, enhancing customer satisfaction and fostering long-term relationships.

So, how do you achieve this coveted bending accuracy? The answer lies in modern technology like Motorized Crowning Systems that can adapt to different materials and bending angles, offering unparalleled precision.

Read More: What is Press Brake Tonnage

Chapter 4: The Concept of Bending Accuracy

We've talked about why bending accuracy is important, but what does "accuracy" mean in this context? How is it measured, and what variables come into play? Stick with me, and by the end of this chapter, you'll be a mini-expert in the concept of bending accuracy in metal fabrication.

Let's start with the basics. Bending accuracy refers to how closely the bend in a metal sheet or plate matches the intended angle, radius, and length. In other words, it's all about hitting that sweet spot where your fabricated metal part conforms to the engineering drawings down to the smallest detail.

So, how do we measure this? Typically, bending accuracy is quantified using tolerances specified in the design. These tolerances indicate the acceptable range of variation from the target measurements. And, of course, the tighter the tolerances, the higher the level of accuracy required.

You might wonder, what affects bending accuracy? Here's where things get a bit technical. Factors such as material properties, the type of Press Brake used, and even the condition of the tooling can influence accuracy. For instance, if you're working with a Hydraulic Crowning System, the hydraulic fluid's temperature could affect the system's performance, thereby influencing the bend's accuracy.

Another pivotal factor is the type of crowning system used—be it Hydraulic Crowning Systems or Motorized Crowning Systems. These systems correct for inconsistencies in the material and the machine itself, making it possible to achieve high levels of bending accuracy.

So what happens when you nail the concept of bending accuracy? You get parts that are easier to assemble, better functionality, and less wasted material. It's not just about meeting specifications; it's about exceeding them and delivering a product that stands out for its quality.

Chapter 5: Common Challenges in Achieving Accurate Bends

By now, we've established that bending accuracy is a cornerstone in metal fabrication. But let's face it—achieving that perfect bend isn't a walk in the park. Even with a top-notch Press Brake and advanced Hydraulic Crowning Systems, challenges can arise. So what are these obstacles, and how can they be overcome? Let's delve in.

First off, material inconsistency is a big one. The properties of metal can vary from sheet to sheet, affecting how it reacts under the force of a Press Brake. Even slight variations in thickness or hardness can throw off your bend accuracy. How do you counter this? Regular material inspections and calibrations are key, as is choosing a Press Brake with a robust crowning system.

Tool wear and tear is another common culprit. Like any piece of machinery, the components of a Press Brake are subject to wear over time. Worn-out tooling can produce bends that are off the mark, reducing the overall quality of your output. Regular maintenance and timely replacements are crucial for avoiding this pitfall.

Operator error can't be overlooked either. Even the most advanced Motorized Crowning Systems can't compensate for human mistakes. Improper setup, incorrect input data, or even just a momentary lapse in attention can lead to inaccurate bends. Adequate training and perhaps even automated systems can help mitigate this risk.

Temperature changes also throw in a curveball. Remember, metal is a material that expands and contracts with temperature. A workshop that's too cold or too hot can subtly affect the metal's properties and, consequently, the accuracy of your bends. Environmental control can go a long way in maintaining consistent accuracy.

Finally, let's not forget machine limitations. Even the best Press Brakes have their limits when it comes to tolerances. If you're working on a project that demands super-precise bends, ensure that your machine is up to the task. Upgrading to a more precise system or using specialized tooling can often solve this problem.

Chapter 6: What Is Crowning?

Definition and Basic Concept

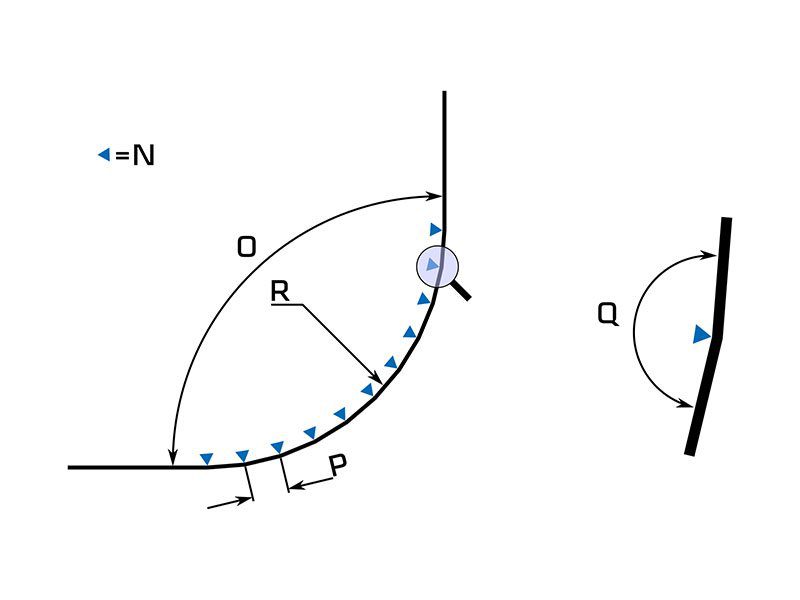

Crowning is a term that frequently pops up in conversations about Press Brakes, but what exactly does it mean? Simply put, crowning is the system that compensates for a machine's deflection during the bending process. In the world of metal fabrication, even the most rugged and well-built Press Brake can experience some level of deflection. When that happens, you need a crowning system to step in and keep things accurate.

Crowning systems can be categorized into various types, the most common of which are Hydraulic Crowning Systems and Motorized Crowning Systems. These systems counteract the natural tendency of the machine to bow or deflect under pressure, ensuring that the bend is uniform across the length of the material.

How It Differs From Other Bending Techniques

You might be wondering, "Well, aren't all bending techniques designed to achieve the same goal?" True, but crowning offers a unique set of benefits that sets it apart. Unlike manual shimming, which is time-consuming and prone to errors, or segmented tooling, which can be limiting, crowning systems provide a more flexible and precise way to correct for machine deflection.

With a robust crowning system in place, you don't have to fret about slight inconsistencies in your machinery or the materials you're using. The crowning system takes those into account and automatically adjusts, making your life easier and your bends more accurate. It's like having a personal trainer who corrects your form in real-time during a workout.

Crowning systems, especially advanced ones like Motorized Crowning Systems, also integrate well with modern software solutions, allowing for real-time monitoring and adjustments. This is something traditional bending techniques often can't offer.

So, while other bending techniques may get the job done, when it comes to achieving the highest level of accuracy and efficiency, crowning systems truly shine. They're the unsung heroes that make high-precision bends achievable, and for anyone serious about quality, they're nothing short of essential.

Chapter 7: Types of Press Brake Crowning Systems

Manual Crowning Systems

Let's start with the most basic, yet reliable form: Manual Crowning Systems. These systems are pretty much what they sound like—manually operated devices that adjust the die or the lower beam to compensate for machine deflection. While they may not offer the high-tech features of their hydraulic or motorized counterparts, they have been around for ages and have a proven track record of reliability.

Manual Crowning Systems are ideal for smaller operations or for those who do not require extremely precise bends. They are generally more cost-effective but do require a skilled operator to make the necessary adjustments manually. Think of it like steering a car without power steering; it's totally doable, but it takes more effort.

Hydraulic Crowning Systems

Ah, the Hydraulic Crowning Systems. These are the middle ground, balancing both sophistication and ease-of-use. In this system, hydraulic cylinders are strategically placed to make real-time adjustments to the die holder or the lower beam. These adjustments counteract machine deflection and offer a considerably more accurate bend.

Given their automated nature, hydraulic systems reduce the chances of operator error, thereby enhancing the overall quality of the bend. If you're running a mid-sized operation with a mix of complex and straightforward projects, Hydraulic Crowning Systems can be a good fit. Imagine this system as the cruise control of your car; it's not self-driving, but it sure makes the ride smoother.

Motorized Crowning Systems

Last but definitely not least, we have the Motorized Crowning Systems, the crème de la crème of crowning technology. These systems use electric motors to make rapid, precise adjustments, often with the help of advanced software that can integrate with your Press Brake's control unit.

Motorized Crowning Systems are ideal for operations that demand the highest level of accuracy and efficiency. They can handle intricate bends and complex materials with ease, all while offering real-time monitoring and adjustments. Consider this the self-driving car of crowning systems; it's advanced, it's precise, and it's designed to make your life easier.

Chapter 8: Why is Crowning Necessary?

Addressing Machine and Material Inconsistencies

The first thing to understand is that no machine is perfect, and this includes Press Brakes. Over time, they wear down, and this is where inconsistencies can creep in. Now, couple this with material inconsistencies like varying thickness, and you've got yourself a real headache when it comes to achieving a perfect bend. This is where crowning swoops in like a superhero in a comic book. Crowning systems help address these issues by compensating for these inconsistencies, enabling you to maintain high-quality bends consistently.

Ensuring Product Quality and Precision

Think about it. What's the point of investing in a state-of-the-art Press Brake if you can't guarantee the quality of your products? Crowning ensures that your bends are accurate and consistent, which in turn ensures that your end products meet or exceed expectations. In industries where precision is non-negotiable—like aerospace, automotive, or medical devices—a high-quality crowning system is not a luxury; it's a necessity.

Components of a Crowning System

So, what makes up a crowning system? While it may vary from Hydraulic Crowning Systems to Motorized Crowning Systems, a typical crowning system comprises of the crown-adjusting mechanism (manual, hydraulic, or motorized), the crown rails, and the control unit that syncs with your Press Brake's software. These components work in tandem to make real-time adjustments, ensuring each bend is as accurate as can be.

Crowning Rails and Their Role

Let's give some attention to the unsung heroes of a crowning system: the crowning rails. These rails are the backbone of the system, ensuring that the force is distributed uniformly across the length of the bend. Depending on the system, these rails can be adjusted manually, hydraulically, or through motorized means, to achieve the perfect bend. Think of them as the rails on a railroad track. They may go unnoticed, but without them, the train simply couldn't move smoothly.

Chapter 9: The Difference Between Mechanical and Hydraulic Crowning Systems

The Basics of Mechanical Crowning Systems

Mechanical Crowning Systems operate through a mechanical linkage or screw mechanism that adjusts the height of the die holder. They are often found in older or simpler press brake setups and are generally manually adjusted. The operator turns screws or knobs to move the crown rails, making adjustments based on their experience and skill level.

The Fundamentals of Hydraulic Crowning Systems

On the other hand, Hydraulic Crowning Systems employ hydraulic cylinders that automatically adjust the die holder's height in real-time. This modern technology allows for precision and consistency that is tough to achieve with a Mechanical Crowning System. Hydraulic systems often feature advanced controls that can be integrated with the Press Brake's main control unit for seamless operation.

Comparing Accuracy

When it comes to accuracy, Hydraulic Crowning Systems generally have the upper hand. The hydraulic cylinders can make fine-tuned adjustments in real-time, reducing the margin for error and delivering a more consistent product. Mechanical systems, on the other hand, rely on the skill and judgment of the operator, which can lead to more variability in the end product.

Ease of Use

Hydraulic Crowning Systems often win in the 'ease-of-use' department too. Their automated nature requires less manual intervention, allowing the operator to focus on other aspects of the process. Mechanical systems, in contrast, can be labor-intensive and may require frequent adjustments during the course of a project.

Cost Considerations

Mechanical Crowning Systems are generally more affordable upfront but might cost you in labor and potential inaccuracies in the long run. Hydraulic systems, though pricier at the outset, can offer better efficiency and accuracy, making them a cost-effective choice for high-volume or precision-critical operations.

Chapter 10: How to Choose the Correct Bending Crowning System

Understanding Your Needs

First and foremost, know thyself—or in this case, your operation. Are you focusing on high-volume, repetitive tasks or more customized, small-batch productions? Do you require extreme precision, or can you afford some wiggle room? Your unique operational needs will significantly influence the type of crowning system that best suits you.

Manual vs Hydraulic vs Motorized

We touched on this in the last chapter, but it bears repeating. Mechanical systems, like Manual Crowning Systems, may suit smaller operations or lower budgets. Hydraulic Crowning Systems offer a middle-of-the-road solution, balancing cost and performance. Motorized Crowning Systems are your high-end option, delivering superior accuracy and automation, ideal for high-precision industries.

Budget Constraints

Don't we all wish we had an endless budget? But in the real world, cost matters. Keep in mind not only the initial investment but the long-term operating costs, which include maintenance and potential errors or inefficiencies that could arise from a less-than-ideal system.

Ease of Integration

It's like dating; your new crowning system should get along with your existing machinery. How easily can the new system be integrated into your current setup? Is it compatible with your existing software? These are questions worth asking before making your decision.

Consult the Experts

Finally, don't underestimate the value of expert opinions. Consult your in-house engineers, speak with vendors, and don't hesitate to reach out to other businesses who have been in your shoes before. A third-party perspective can often shed light on considerations you might have overlooked.

Chapter 11: How to Choose the Correct Bend Compensation

Why Bend Compensation Matters

Before we dive into the how, let's clarify the why. Bend compensation is crucial because it accounts for the material's elasticity and thickness, ensuring that your bends are accurate and consistent. Incorrect bend compensation can lead to waste of material, time, and yes, your patience too.

Factors to Consider

Several factors come into play when selecting the correct bend compensation: material type, thickness, and the radius of the bend. Different materials have varying degrees of elasticity, and this can drastically affect the bend angle. Do your research or better yet, conduct some test bends to get this right.

Calculating Bend Compensation

Math alert! Bend compensation can be calculated using specific formulas that take into account the above-mentioned factors. These calculations are often embedded in modern CNC press brake software, but it's good to know how it works manually for troubleshooting or fine-tuning purposes.

Sample Calculation:

Bend Compensation = (π/180) × (Bend Angle) × [(Inside Radius + (K-factor × Material Thickness))]

Consult the Machine's Manual

Your press brake's manual often contains guidelines on bend compensation for various materials and conditions. While these are not always 100% accurate for every situation, they offer a good starting point.

Trial and Error

Sometimes, there's no substitute for getting your hands dirty. Run a few tests, tweak the settings, and see how close you get to your desired result. This iterative process, while time-consuming, can be invaluable for nailing that perfect bend.

Chapter 12: Crowning for Different Types of Material

The Material Matters

Different materials have distinct characteristics like elasticity, tensile strength, and thickness—all of which play a role in the crowning process. Incorrect crowning can produce subpar products and result in costly mistakes. So, let's delve into specific materials.

Aluminum

Ah, Aluminum—the lightweight wonder. This material is easier to bend but also more susceptible to cracking if not handled correctly. Hydraulic Crowning Systems often work well with aluminum due to their adaptability and precision.

Stainless Steel

Tough and resilient, stainless steel is a hard nut to crack. It requires more force to bend, making Motorized Crowning Systems a good match for this material. They offer the kind of power and precision needed to deal with the stubborn nature of stainless steel.

Copper

Copper is often seen as a middle-of-the-road material when it comes to bending. It's not as easy as aluminum but not as challenging as stainless steel. For copper, both Hydraulic and Motorized Crowning Systems can be considered, depending on the complexity and precision of the job.

Chapter 13: Tips for Optimal Crowning

Adjusting Parameters for Different Materials

By now, you're aware that different materials require different crowning systems. But did you know that even with the right system, you'll still need to fine-tune the parameters? Parameters like bend angle, material thickness, and even humidity can have an impact. Keep these under constant review to ensure top-quality bends.

Maintenance Tips for Longevity

Regular maintenance is your best friend for extending the life of your crowning system. This includes periodic cleaning, lubrication, and alignment checks. Think of it like a car tune-up, but for your press brake crowning system.

Crowning vs. Other Bending Solutions

While crowning is a fantastic solution for many applications, it's not the only game in town. Let's compare it with some other bending solutions.

Air Bending

Air bending allows for a greater variety of bend angles, making it a flexible option. However, it may not offer the level of precision that hydraulic crowning systems do.

Bottoming

Bottoming provides highly accurate bends but usually requires more force. If your material is hard like stainless steel, crowning may be a better option for you.

Coining

Coining can also deliver highly accurate bends but at the cost of a more complex and time-consuming setup. If time is of the essence, crowning can be the quicker solution.

Conclusion: Taking Press Brake Crowning to the Next Level

There you have it—your ultimate guide to understanding Press Brake Crowning. As we've seen, the right crowning system can make all the difference in your metalworking projects. Whether it's Hydraulic Crowning Systems or Motorized Crowning Systems, each has its own set of pros and cons that cater to different material types and bending requirements. For world-class Press Brake machines and other sheet metal machinery, consider Krrass. Visit www.krrass.com to explore our top-of-the-line products and make your next project a soaring success.

Read More: