In the world of metal fabrication, choosing the right press brake tooling is paramount for precision and efficiency. From understanding the intricacies of press brake punches and dies to exploring the multifaceted realm of sheet metal bending dies, this comprehensive guide shines a light on all you need to know to make the best decisions for your operations. Dive in and discover the nuances of tool selection, the workings of press brakes, and the importance of partnering with the right manufacturers.

- Importance of Choosing Right Press Brake Tool

- Working principle of Press Brake

- The Anatomy of Press Brake Tools

- Understand Your Bending Requirements

- V-dies: The Common Choice

- Rotating Dies: Flexibility at its Best

- Acute Angle Dies: For Precision Bends

- Gooseneck Dies: Mastering Complex Jobs

- The Role of Flattening Dies

- Factors Affecting Press Brake Tool Choice

- Considering Press Brake Tool Material

- The Impact of Tool Length

- Importance of Tool Radius

- Proper Maintenance and Storage

- The Cost Factor: Investing Wisely

- Common Mistakes to Avoid

1.Importance of Choosing Right Press Brake Tool

In the competitive landscape of manufacturing, the efficiency and accuracy of your production process can set you apart. Thus, understanding the types of press brake dies and selecting the ideal one for your needs can be the difference between average and excellence.

Firstly, the right tooling ensures optimal performance of the press brake. Using incorrect or substandard tooling can result in poor product quality, potentially leading to rejections and increased costs.

Moreover, tool longevity is directly linked to the tool choice. High-quality sheet metal bending dies and punches not only perform better but also last longer, leading to fewer disruptions in the production cycle and, consequently, more consistent output. Over time, this translates to cost savings and higher profitability.

Another significant factor is safety. The right tool minimizes the risk of equipment damage or worker injury. An improperly selected or fitted press brake punch or die could lead to machine malfunctions or, in extreme cases, accidents. As every manufacturer knows, a safe working environment is paramount not just for ethical reasons but also for maintaining uninterrupted operations.

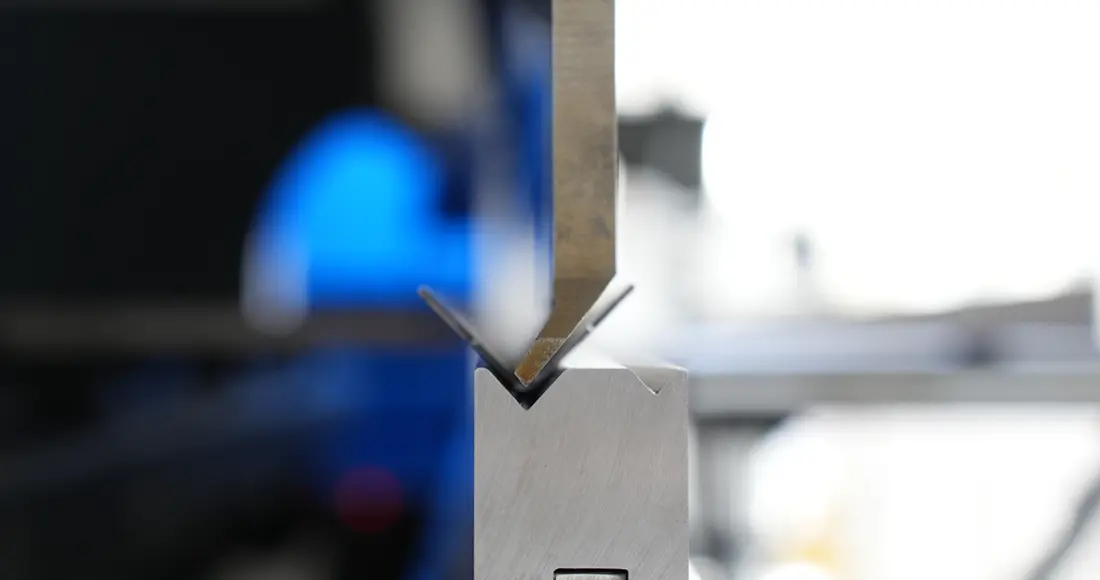

2.Working Principle of Press Brake

A press brake is a specialized machine tool used primarily for bending sheet and plate material, most commonly sheet metal. At its core, the working principle of a press brake is relatively straightforward, yet the intricacies of its components and their synergies make it an essential tool in metalworking. Let's dive deep into understanding its working mechanism.

1. Basic Structure: A standard press brake comprises two primary components: the top tool known as the press brake punch, and the bottom tool called the die. These tools are mounted on a stable frame, which ensures they maintain their relative positions and alignments during the bending process.

2. Force Application: The press brake operates by applying a significant force to a sheet metal that is placed between the punch and die. This force is generated through hydraulic, pneumatic, or mechanical means, with hydraulic press brakes being the most common in modern manufacturing due to their precision and power.

3. Bending Process: Once the sheet metal is positioned, the punch descends and presses the material into the die, creating a bend. The depth to which the punch descends and the shape of the die determine the angle and form of the bend. Different types of press brake dies can be used to achieve various bend profiles and angles.

4. Precision Control: Modern press brakes come equipped with computerized numerical control (CNC) systems, allowing operators to program the desired bend angles, depth, and sequences. This ensures high precision, repeatability, and efficiency in the bending process.

5. Backgauge System: One of the pivotal components of a press brake is the backgauge system. It determines the position of the bend on the sheet metal by controlling where the material is placed relative to the press brake tooling. The backgauge can be adjusted, either manually or through a CNC system, to ensure accurate bend locations.

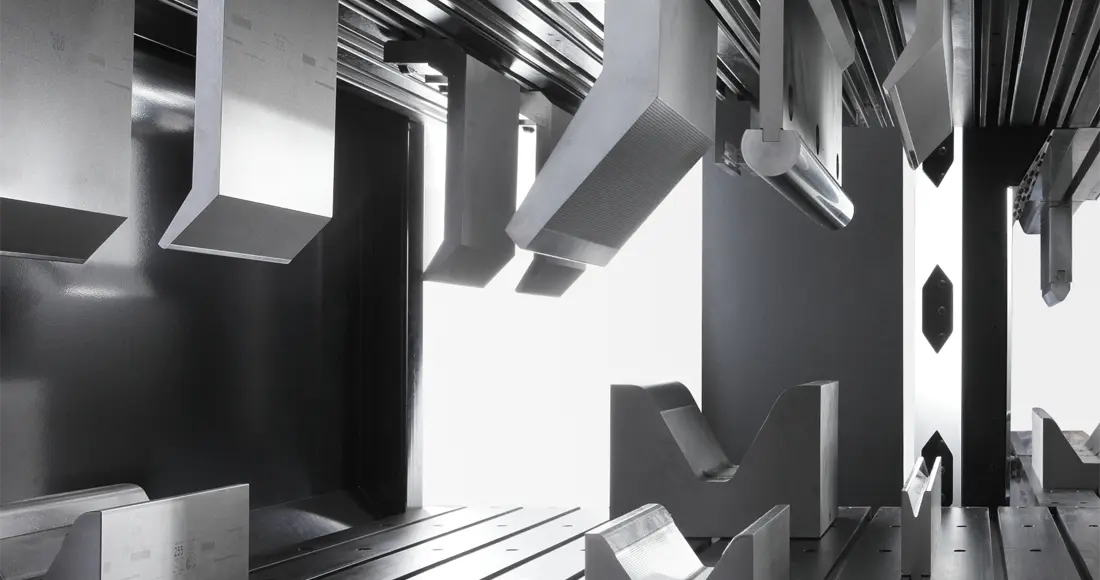

3.The Anatomy of Press Brake Tools

Understanding the anatomy of press brake tools is fundamental for manufacturers aiming for precision and efficiency. These tools, though appearing simple, have complex designs that play a crucial role in sheet metal bending operations. Let's dissect the core components: the press brake punch and the press brake die.

Press Brake Punch

The press brake punch is the upper component that comes into direct contact with the sheet metal to initiate the bending process. Here's a closer look:

1. Tip: The punch's tip is its most critical part, determining the inside radius of the bend. Sharper tips are used for smaller radii, while more rounded ones give larger radii.

2. Body: The body is the main portion of the punch that absorbs the pressure exerted during the bending process. It's robustly built to handle the stresses without deformation.

3. Flats: These are flat sections at the bottom of the punch, ensuring it mounts securely to the press brake's upper beam.

4. Tang: A tang is an extension, often grooved or keyed, that allows the punch to connect to the machine securely, ensuring it remains stable during operation.

Press Brake Die

The press brake die, typically found on the lower side, is where the sheet metal gets pressed into, forming the desired angle. Here's what constitutes a die:

1. V-opening: This is the V-shaped gap where the metal is pressed into. The size and angle of this opening play a pivotal role in determining the bend's angle and radius.

2. Shoulders: Positioned on either side of the V-opening, shoulders provide the support structure for the die. They endure the opposing force when the metal is pressed into the V-opening.

3. Die Space: This is the space beneath the V-opening, ensuring the metal has room to move and form without obstruction.

4. Mounting Slot: This slot, usually found at the base, allows the die to be securely fastened to the press brake's lower beam or table.

4.Understand Your Bending Requirements

Before diving into the world of press brakes and the vast array of press brake tooling types, it's essential to have a clear understanding of your bending requirements. A precise grasp of these specifics ensures that you not only achieve desired results but also optimize efficiency and reduce wastage. Let's delve into the crucial aspects of comprehending your bending needs.

The Material You Will Be Bending

The material you choose to bend significantly affects the tool selection and the bending process. Here's why:

1. Material Thickness: Different materials have varying thicknesses. The press brake punch and die selection are directly influenced by how thick or thin your material is. For instance, thicker materials may require larger V-openings in the die.

2. Material Type: Whether you're bending stainless steel, aluminum, brass, or any other metal, each has its unique properties. Some materials might be more malleable, while others could be more resistant. Understanding this helps in selecting the right pressure and tooling for the job.

3. Grain Direction: Metals often have a grain direction, much like wood. Bending parallel or perpendicular to this grain can affect the final result, so it's crucial to account for this in the planning stage.

Desired Bend Radius and Angles

Determining the desired bend radius and angles is essential to ensure the finished product meets specifications and functionality:

1. Bend Radius: The bend radius, influenced by the press brake punch tip and the die's V-opening, determines how sharp or broad a bend is. A smaller radius results in a sharper bend, while a larger one produces a more gradual curve.

2. Bend Angle: The angle of the bend defines how much the material is turned from its original flat position. Whether you need a slight 10° angle or a complete 90° fold, understanding and specifying this angle is paramount to achieving the desired result.

In essence, bending sheet metal is as much an art as it is a science. The synergy between understanding material properties and desired outcomes lays the foundation for optimal press brake tooling selection and successful bending operations.

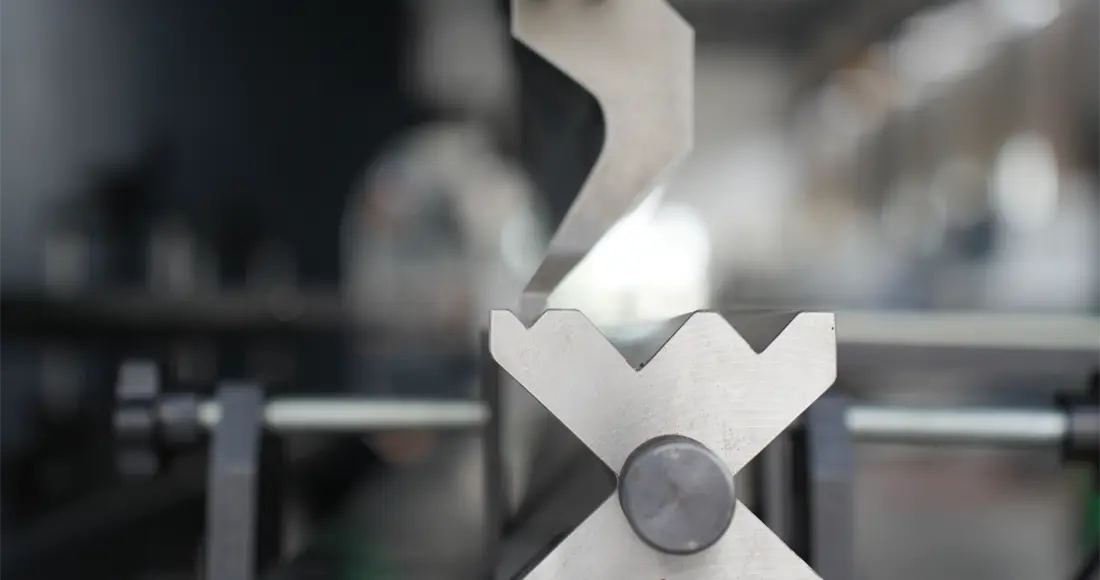

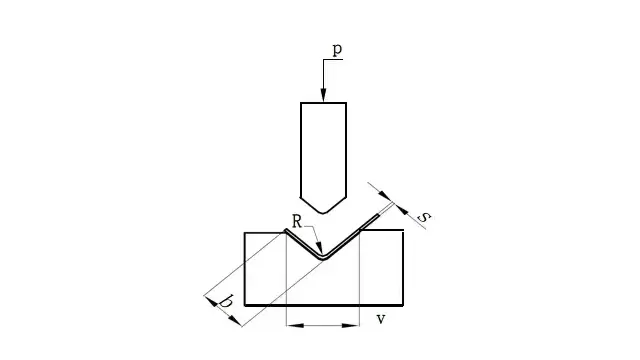

5.V-dies: The Common Choice

Among the myriad of press brake tooling types available, V-dies have emerged as a common choice in the manufacturing realm. But what makes them stand out? Let's dive deep into the world of V-dies to understand their structure, benefits, drawbacks, and the often-mentioned "Rules of 8."

What are V-dies?

V-dies, as the name suggests, are characterized by their V-shaped opening. They form the lower component of the press brake tooling setup, where the sheet metal gets pressed into during the bending process. Their distinct shape enables them to produce a wide range of bend angles, making them versatile tools in the realm of sheet metal bending.

Pros and Cons of Using V-dies

Pros:

1. Versatility: V-dies can handle a wide array of bending angles and metal thicknesses, making them suitable for various applications.

2. Efficiency: Their design allows for rapid tool changes, facilitating quicker job turnovers and enhanced productivity.

3. Consistency: V-dies ensure consistent bends, especially when used in tandem with modern press brake machinery.

Cons:

1. Limited Deep Bending: For very deep bends, V-dies might not be the ideal choice due to their design limitations.

2. Potential for Marking: V-dies can sometimes mark the sheet metal, especially softer materials, if not correctly aligned or maintained.

Rules of 8

In the realm of press brake operations, the rule of 8 stands as a foundational principle. Tailored for 60,000 PSI tensile cold-rolled steel, this rule posits that the V-opening die's width should be a multiple of eight times the material's thickness being bent.

Regarded as a benchmark for numerous bending tasks, the rule of 8 can help generate an internal radius roughly equivalent to the material's thickness, as long as the tonnage stays within the recommended range. Yet, it's worth noting that this rule isn't ironclad. Depending on the variance in material thickness, this factor might increase or decrease. Hence, it isn't rare to come across V-die openings measuring 6 times, 10 times, or even a whopping 12 times the material's thickness.

When it comes to bending thicker plates, the challenges intensify. Such plates often demand a V-opening that's about 10 times their thickness. This adjustment ensures an even force distribution across a broader surface, minimizing the risk of cracks – a common occurrence given the material's diminished ductility.

So, before you finalize your press brake die selection, start by identifying both the thickest and thinnest metal sheets you'll be bending. Harness the rule of 8 to ascertain the right V-die size. Begin with the smallest V-die, double its size, and continue this pattern until you reach the maximum mold. In instances where an exact match proves elusive, it's prudent to round off to the closest available mold size.

6.Rotating Dies: Flexibility at its Best

In the dynamic world of sheet metal bending, rotating dies have emerged as a beacon of flexibility. These versatile tools, often employed in the most advanced press brake operations, offer distinct advantages that can significantly improve efficiency and precision. Let's journey through the universe of rotating dies to comprehend their mechanism and ascertain when and why they might be your best choice.

Overview of Rotating Dies

Rotating dies are specially designed tools that feature rotating components. These rotating elements allow the die to adjust dynamically during the bending process. Unlike static dies that maintain a fixed profile, rotating dies can adapt and reposition, ensuring that the sheet metal is bent precisely according to the specified requirements. This unique attribute grants them a higher level of precision and adaptability compared to traditional dies.

When and Why to Consider Them

When:

1. Complex Bending Operations: If you're dealing with intricate bending tasks that demand precision and adaptability, rotating dies are likely your best bet. They shine when you're navigating bends that would be challenging or impossible with static dies.

2. Varied Material Profiles: When working with materials of diverse profiles or those that have intricate geometries, the adaptability of rotating dies can be a game-changer.

Why:

1. Adaptability: Rotating dies adjust in real-time during the bending process, ensuring optimal contact and bending angles. This dynamic adjustment can significantly reduce tool changes, saving both time and resources.

2. Precision: Their ability to adapt on-the-fly ensures that even the most intricate bends are executed with precision. This leads to higher-quality finished products that meet or even exceed specifications.

3. Reduced Wear and Tear: Given that rotating dies can adjust to the material, they experience more uniform wear. This can extend the life of the tool and reduce maintenance costs over time.

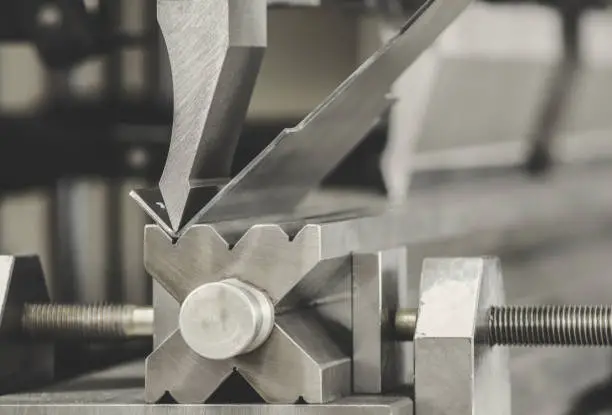

7.Acute Angle Dies: For Precision Bends

Acute angle dies stand as a testament to the intricate detailing that press brake operations can achieve. These specialized tools have been tailored for tasks where precision is paramount. In this section, we'll explore the nuanced world of acute angle dies, understanding their specific attributes and the myriad of situations where they shine the brightest.

The Specifics of Acute Angle Dies

As the name suggests, acute angle dies are designed to produce bends that are less than 90 degrees. These dies feature a sharper angle in their V-opening, allowing for more controlled and precise bending operations. The meticulous design ensures that the material is bent to an acute angle with minimal deformation, maintaining the integrity of the sheet metal throughout the process.

Advantages and Situations for Usage

Advantages:

1. Precision: Acute angle dies allow for exacting bends, ensuring that the finished product adheres to stringent specifications.

2. Reduced Deformation: The specialized design ensures that the material undergoes minimal deformation during the bending process, retaining its quality and aesthetics.

3. Optimized for Thin Materials: These dies excel when working with thinner materials, ensuring crisp and precise bends without overstraining the sheet.

Situations for Usage:

1. Detail-Oriented Projects: Any project demanding bends with high levels of precision—like aerospace components or intricate architectural elements—benefits from acute angle dies.

2. Specialized Manufacturing: Industries that focus on high-quality products, where even the minutest deviation from the desired specification is unacceptable, often opt for these dies.

3. Thin Sheet Metal Applications: Acute angle dies are the go-to choice when dealing with thinner materials that require precision without compromising the material's structural integrity.

8.Gooseneck Dies: Mastering Complex Jobs

Among the various tools in the press brake toolkit, gooseneck dies have garnered significant attention for their specialized design and capability. Their unique profile allows them to tackle complex jobs with finesse and precision. In this section, let's dive deep into the world of gooseneck dies, uncovering their design essence and the scenarios where they truly excel.

Introduction to Gooseneck Dies

Gooseneck dies are characterized by their distinct shape that resembles the neck of a goose. This specialized design features an elongated, curved upper section that grants it unparalleled accessibility. Unlike conventional dies, goosenecks can reach areas that are typically challenging to bend, such as flanges, offsets, or other intricate configurations. Their design ethos centers around flexibility, making them indispensable for specific bending tasks that other dies might struggle with.

Ideal Scenarios for Their Application

1. Deep Box Bending: With their extended neck, gooseneck dies are perfect for tasks that require deep box bending. They can navigate the depth and create precise bends without any hindrance.

2. Intricate Profiles: When dealing with profiles that have multiple flanges, recesses, or offsets, the design of the gooseneck die provides the necessary accessibility to bend such profiles accurately.

3. Tight Corners: Their distinct shape ensures that even tight corners, which are typically challenging for standard dies, can be bent with precision using gooseneck dies.

4. Reduced Tool Changeover: Given their versatility, gooseneck dies can be used across a variety of tasks, reducing the frequency of tool changes and enhancing operational efficiency.

9.The Role of Flattening Dies

In the realm of sheet metal bending, ensuring the perfect finish to a bend often requires specialized tools. Flattening dies come into play in these scenarios, offering a refined touch to the bent material. This section will elucidate the mechanics and virtues of flattening dies and their invaluable contribution to the press brake world.

The Mechanics Behind Flattening Dies

Flattening dies, as their name suggests, are designed primarily to flatten or iron out any inconsistencies that may arise post-bending. Unlike other dies which focus on creating angles and bends, flattening dies are about ensuring that the finished bend is smooth and free from deformities. Comprising of a flat surface, these dies exert uniform pressure across the bent area. When the press brake exerts force, the die effectively irons out any irregularities, rendering a smooth, flat surface to the metal sheet.

The Unique Benefits They Bring

1. Smooth Finishes: One of the most evident benefits of flattening dies is the impeccable finish they offer. By evening out any imperfections, they ensure the end product looks professional and is free from any defects.

2. Reduced Post-Processing: Since the bends are flattened to perfection, the need for additional post-processing steps, like grinding or buffing, is minimized. This leads to faster production cycles and cost savings.

3. Enhanced Structural Integrity: By ensuring a consistent and smooth surface, flattening dies contribute to the overall structural integrity of the bent component, ensuring it can withstand stresses better.

4. Increased Aesthetics: For industries where the visual appeal of a component is crucial, like automotive or home appliances, the role of flattening dies becomes even more significant. They guarantee that the parts not only function well but also look premium.

10.Factors Affecting Press Brake Tool Choice

Choosing the right press brake tool is more of an art combined with a science. This selection is pivotal as it can drastically affect the quality, efficiency, and productivity of the bending process. Let's delve into the primary factors that play a crucial role in making an informed decision about press brake tool selection.

Material Thickness and Type

The thickness and type of material you're working with are paramount in determining the appropriate tool. Here's why:

1. Material Thickness: Thicker materials require dies with broader openings, whereas thinner sheets might need tighter, more precise dies. Selecting a die with an inappropriate opening for the material's thickness can result in defects like cracking or incomplete bends.

2. Material Type: Different materials have varied bending properties. For instance, stainless steel behaves differently under stress compared to aluminum. Thus, understanding the material's properties ensures the selected tool will achieve the desired bend without damaging the material.

Bending Force and Tonnage Requirements

The force required to achieve a perfect bend directly ties to the tool's selection. Consider these points:

1. Bending Force: Different materials and thicknesses require different amounts of force. The tool you choose should be robust enough to handle the force exerted during the bending process, ensuring its longevity and the material's integrity.

2. Tonnage: Tonnage refers to the maximum force that a press brake can exert. If a job requires higher tonnage than the machine's capacity, there's a risk of damaging both the machine and the tool. Therefore, understanding the tonnage requirement and ensuring that the tool can handle that force is crucial.

11.Considering Press Brake Tool Material

Beyond the design and type of a press brake tool, the material from which it's crafted plays an instrumental role in its performance, durability, and the quality of the bend it produces. Understanding the nuances of tool material ensures optimal tool performance and longevity.

Tool Steel Types

Different tasks and bending requirements might call for specific tool steel types. Here's a breakdown:

1. Carbon Steel: A commonly used material due to its cost-effectiveness. However, while it's malleable and can handle a good deal of stress, it may not be suitable for high-tensile operations.

2. Alloyed Steels: Infused with other elements like chromium or tungsten, alloyed steels enhance specific properties, making the tools more wear-resistant and durable.

3. Tool Steels: These are specialized steels designed explicitly for tooling applications. They offer a balance of hardness, toughness, and resistance to abrasive wear.

Hardened Tools and Their Advantages

Hardening is a heat treatment process designed to increase the hardness and strength of steel. When it comes to press brake tools, the advantages of hardening are manifold:

1. Enhanced Durability: Hardened tools can withstand the rigors of repetitive bending tasks, reducing wear and increasing their operational life.

2. Resistance to Deformation: With a higher resistance to force, hardened tools maintain their shape and integrity even under immense pressure, ensuring precise bends every time.

3. Better Quality Bends: The resilience of hardened tools means they can offer cleaner, more consistent bends, particularly for thicker materials or complex bending operations.

12.The Impact of Tool Length

When it comes to the fine art of bending, not just any tool will do. The length of your press brake tool plays a pivotal role in determining the effectiveness, precision, and efficiency of the bending operation. Let's unravel the nuances of tool length and its critical impact.

Standard vs. Special Lengths

1. Standard Lengths: Most press brake tools come in standardized lengths. These are designed to meet the majority of bending operations in the industry. They are versatile, readily available, and often more cost-effective.

2. Special Lengths: For unique or highly specific jobs, manufacturers might require special lengths. These are custom-made, catering to particular bending needs, ensuring precision and accuracy for specialized tasks.

When to Opt for a Specific Length

Choosing between standard and specific lengths hinges on a few considerations:

1. Material Size: If the workpiece is longer or shorter than standard sizes, a specific length might be necessary to ensure uniform bending across the length.

2. Bending Complexity: For intricate or unconventional bend shapes, a custom length can provide the necessary flexibility and precision.

3. Production Volume: For large-scale operations or repeat jobs, investing in a custom-length tool tailored to the task might offer efficiency gains in the long run.

Minimum Length of the Flange or Leg

The flange or leg's minimum length is a crucial aspect to consider. This length directly relates to the bending tool's dimensions, specifically the width of the die opening and the size of the punch tip. Ensuring that the flange or leg length is compatible with the tool's dimensions is paramount for achieving clean, precise bends without causing material deformation or tool damage.

13.Importance of Tool Radius

The radius of press brake tools, often overlooked, is a linchpin in the bending process. It influences the final product's appearance, strength, and functionality. Recognizing its significance and making an informed choice can be the difference between an average bend and a precise one.

How Radius Affects Bending

1. Bend Angle Precision: The tool's radius directly correlates with the bend angle. A smaller radius might lead to a tighter bend, while a larger one can result in a more open bend. Thus, controlling the tool radius is essential for achieving desired bend angles.

2. Material Stress: The radius influences the distribution of stress across the bend. A smaller radius can concentrate stress, increasing the risk of material fracture or deformation, especially with thicker materials.

3. Material Springback: Springback, the tendency of a material to return to its original shape after bending, is influenced by the tool's radius. A tighter radius often leads to more springback, requiring compensation during the bending process.

Selecting the Right Radius for Your Task

Choosing the perfect radius is not a one-size-fits-all decision. It necessitates a blend of experience and knowledge. Consider these factors:

1. Material Type: Different materials react differently to bending forces. For instance, hard metals might require a larger radius to prevent cracks, while softer metals might allow for tighter radii.

2. Desired Finish: Aesthetic considerations play a role too. For some products, a tight, sharp bend might be visually appealing, while others might benefit from a gentler curve.

3. Functional Requirements: The end-use of the product might dictate the radius. For instance, a component that needs to fit snugly into another might necessitate a precise radius to ensure a perfect fit.

14.Proper Maintenance and Storage

The longevity and performance of press brake tools don't merely rest on their initial quality or design. A large part of their operational efficiency hinges on proper maintenance and storage. Ensuring the tools are in peak condition guarantees precise bends and extends the tool's lifespan, offering long-term cost savings and consistent results.

Maintenance Protocols

1. Regular Inspections: Always examine tools for signs of wear, damage, or deformity. Overlooking minor issues can escalate to significant problems, affecting performance and potentially damaging the workpiece.

2. Cleaning: After each use, clean the tools to remove any residues or particles. Not only does this keep them ready for the next job, but it also prevents contamination and rust.

3. Lubrication: Regularly lubricate the tools, especially moving parts. Proper lubrication reduces friction, wear, and potential seizing of components.

4. Sharpening: Ensure that punch tips and edges are sharp. Dull tools can compromise the quality of bends, demanding more force and leading to inaccurate results.

Storage Solutions

1. Environment: Store tools in a dry and clean environment. This minimizes the risk of rusting and environmental damage.

2. Organized Racks: Utilize tool racks or holders. This not only ensures easy access but also prevents potential damage from tools colliding or being piled on top of each other.

3. Protective Coatings: When storing tools for extended periods, consider using protective coatings or sprays. These provide an extra layer of defense against rust and corrosion.

15.The Cost Factor: Investing Wisely

Investing in press brake tools requires a strategic balance between cost and quality. While it's tempting to opt for the cheapest tools available, understanding the intricacies of pricing can help businesses make informed decisions and ensure they extract maximum value from their investments.

Factors Affecting the Price of Tools

1. Material: High-quality materials generally come with a steeper price tag. Tools made of premium-grade metals often offer longer life and better performance, but they're also more costly to produce.

2. Design Complexity: Advanced designs or those tailored for specific applications can drive up the price. Specialized tools or those with intricate features might be pricier than standard counterparts.

3. Brand Reputation: Established brands, recognized for their reliability and quality, might charge a premium compared to lesser-known manufacturers.

4. Post-Sale Services: Offerings like warranties, customer service, and post-purchase maintenance can also influence the tool's final price.

Ensuring Value for Money

1. Research: Start by understanding your specific needs and researching various tools that meet those requirements. Reading reviews and seeking industry recommendations can be insightful.

2. Long-Term Thinking: Don't be swayed solely by upfront costs. Consider the tool's longevity, maintenance expenses, and potential operational savings it might bring.

3. Negotiate: Suppliers often provide deals or discounts, especially for bulk purchases or loyal customers. Never hesitate to negotiate or explore bundled offers.

4. Test Before Buying: If possible, test the tool before making a purchase. This hands-on approach ensures it meets your expectations and operational demands.

16.Common Mistakes to Avoid

The precision and efficiency of press brake operations are often compromised by common oversights. By being cognizant of these pitfalls and adopting proactive measures, businesses can ensure optimal performance, reduce wastage, and maintain the integrity of their finished products.

Overlooking Tool Specifications

1. Not Matching the Material: Using tools not designed for a particular material can lead to poor bends, tool wear, and even damage. Always ensure the tool is suited for the material in use.

2. Ignoring Tool Limits: Every tool comes with specified tonnage limits. Exceeding these can result in tool deformation or breakage.

3. Focusing Solely on Price: While cost is important, purchasing tools based only on price without considering their specifications can lead to subpar results and frequent replacements.

Mismatched Tools and Machines

1. Incompatible Interfaces: Tools and machines must have matching interfaces. Using incompatible tools can not only result in poor bends but might also damage the machine or the tool itself.

2. Not Considering Machine Capacities: The machine's tonnage and tool's tonnage should align. Overloading the machine with a high-tonnage tool or vice-versa can be detrimental to both the tool and machine.

3. Lack of Calibration: Regularly calibrating the machine to ensure alignment with the tool is essential. Misalignment can lead to imprecise bends and unnecessary tool wear.

Choosing the Best Press Brake Manufacturer for Your Business

Finding the right tools is just half the journey; selecting the perfect manufacturer is the keystone to success in metal fabrication. Krrass, a renowned press brake and sheet metal machine manufacturer, stands out in the industry for its commitment to quality, innovation, and precision. When you choose Krrass, you're not just purchasing a tool; you're investing in decades of expertise, world-class craftsmanship, and unparalleled after-sales support. Explore the vast array of solutions tailored to your needs at www.krrass.com. Partner with the best, and let your business soar to new heights of excellence.

Read More: