A hydraulic press brake plays a vital role in industries involved in sheet metal fabrication. Within the sheet metal fabrication community, two popular types are commonly used: manual press brakes and hydraulic-powered press brakes.

When compared to mechanical brakes, hydraulic press brakes offer enhanced safety and greater control. They typically feature multiple speed settings and allow for precise bends, providing superior control during the process of inching down and preparing for a job.

An additional advantage of hydraulic brakes is the ability to reverse the stroke at any given time. But how do they actually work? Let’s delve into the detailed workings of hydraulic press brakes to gain a better understanding of this essential machinery.

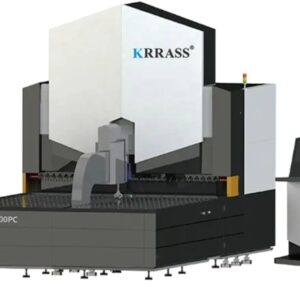

Due to the different types of Press Brake machines on the market, it can be difficult to decide which one is the best for your needs. But don’t worry, KRRASS are here to help!

How Does a Hydraulic Press Brake Work?

A hydraulic press brake utilizes the power of a hydraulic motor to exert force on the metal, compressing it into the die and shaping it accordingly. The shape of the die determines the final shape achieved through the metal bending process.

Why Choose a Hydraulic Press?

Hydraulic press brakes enable automated bending processes, making them a preferred choice for many manufacturers seeking cost-effective bending operations. The precision of the bending is also exceptional. Furthermore, hydraulic press brakes are designed in user-friendly formats, allowing operators to carry out metal bending operations quickly and easily.

The Bending Device in a Hydraulic Press

The bending device of a hydraulic press brake employs a stamping process in which the sheet metal is pressed into the mold or dies to form the desired shape. The sheet metal is fed into the device and aligned with the die. As force is applied, the metal is shaped according to the contours of the die.

The Die in a Hydraulic Press

The die is a critical component of a hydraulic brake as it determines the shape and strength of the metal. With the latest devices equipped with standard and upgraded options, it is possible to shape the metal into nearly any desired form. Hydraulic press brakes are also designed to be vibration-free, ensuring accuracy during the shaping process.

Which press brake machine is right for you?

If you need any questions answered or to discuss your Press Brake requirements for your unique business, please contact us today on 0086 18952087956 or using our online contact form.

KRRASS manufactures an exceptional line of CNC hydraulic press brakes. For instance, the Hybrid Series is highly regarded in the industry, offering increased productivity and cost-effectiveness with its user-friendly CNC controller and low-maintenance hydraulic system. We hope this detailed explanation of how hydraulic press brakes work has provided you with valuable insights into the internal operations of this essential equipment.