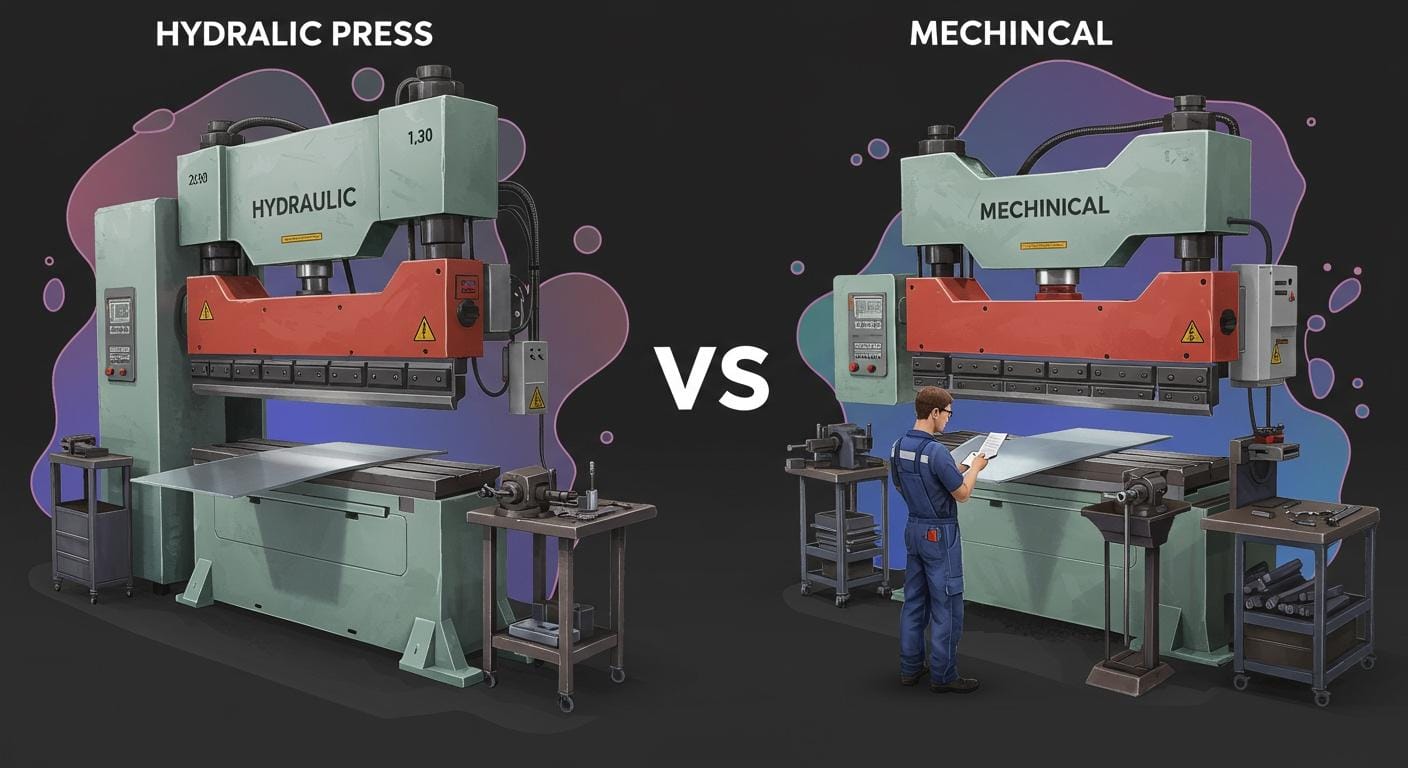

Hydraulic presses are flexible and very accurate. They work well for shops that do tricky bending jobs or need to change settings often. Mechanical presses are very fast. This helps shops that make lots of parts quickly. Every shop should pick a metal bending press that fits its needs. KRRASS has many choices. They offer CNC press brakes and other advanced bending machines. Shops can find the right machine for their work.

When picking a press brake, shop owners should think about these things:

| Priority | Description |

|---|---|

| Precision | Needed for parts with exact sizes or hard shapes. It helps make sure angles and fits are correct. |

| Cost | It is important to balance price and quality. Cheaper options may not last or work as well. |

| Speed | Speed matters for finishing jobs on time. It is extra important when business gets busier. |

Thinking about precision, cost, speed, maintenance, and use helps shops get the best results and stay flexible.

Table of Contents

Key Takeaways

- Hydraulic presses are flexible and very accurate. They are good for hard bending jobs and different settings.

- Mechanical presses are fast and work well. They are best for making many parts and easy bends.

- Think about accuracy, price, and speed when picking a press brake. This helps you get the right one for your shop.

- You must take care of both hydraulic and mechanical presses often. This stops them from breaking and keeps everyone safe.

- CNC press brakes use smart machines for very exact work. They help shops make the same parts fast.

- Look at what materials you use. Hydraulic presses work best with hard metals like steel. Mechanical presses are better for lighter metals like aluminum.

- KRRASS has many press brake models. Shops can pick the best one for how much they make and how hard the jobs are.

- Buying energy-saving models can lower your shop’s bills. It also helps your shop be more eco-friendly.

Metal Bending Press Overview

Hydraulic Presses

Hydraulic bending machines use fluid power to shape metal sheets. First, the electromagnets are off, and oil moves through valves. When the operator starts the machine, the electromagnets turn on. Oil goes into the master cylinder, making it move down fast. As the cylinder gets close to the metal, the oil return circuit slows it down. This helps control the bending. The slider stops when it touches the stroke switch. After bending, the lower cylinder piston lifts up to push out the workpiece. Then it goes back down. Operators can change the pressure in the lower cylinder. This keeps the blank holder steady while bending.

Hydraulic bending machines let operators control speed and pressure. They can change settings for each job. This helps shops work with many metals and shapes.

KRRASS makes hydraulic press brake models for shops that need accuracy and flexibility. The MB8 Series has controls that are easy to use and strong frames. These machines use European clamping systems to help bend better. KRRASS hydraulic press brake models help shops get exact angles and repeat results.

Steps in Hydraulic Bending Machines:

- The machine starts with no power to electromagnets, and oil moves through valves.

- Electromagnets turn on, and oil goes into the master cylinder for fast movement down.

- The cylinder slows near the metal, so bending is careful.

- The slider stops at the stroke switch.

- The lower cylinder piston lifts to push out the finished part and then goes back down.

- Operators change blank holder pressure for each bending job.

Mechanical Presses

Mechanical press brake machines use a motor and flywheel to move the ram. The operator sets up the machine, and the motor spins the flywheel. When the clutch connects, the flywheel sends energy to the ram. The ram moves down and bends the metal. Mechanical presses are good for making lots of parts fast. They give quick cycles and steady force.

Shops that want speed and repeatable results often pick mechanical press brake models. These machines do simple bends and big batches of parts. Mechanical presses are not as flexible as hydraulic bending machines. But they are great for jobs that need to be done quickly.

KRRASS has mechanical press brake solutions for shops that care about speed and efficiency. Their machines work well and help shops finish jobs on time.

KRRASS is a top manufacturer in the metal bending press industry. They make hydraulic, mechanical, NC, CNC, hybrid, and electric press brakes. Each model fits different shop needs, from precise work to making lots of parts.

Pros and Cons

Press Brake Advantages

Hydraulic Presses

- Operators can change the pressure for each job. This helps them control the bending well. Hydraulic presses do many jobs. They can mold, crush, and shape metal. They do more than just bend. Shops use hydraulic presses for small groups of parts. It is easy to set up and switch jobs. These machines work with hard shapes and forms. KRRASS hydraulic press brake models save energy and work fast. The hybrid press brake uses less energy than old models. It can cut energy use by 30%. Hybrid models are quiet and need less fixing. They keep the oil cool. This helps the machine last longer. KRRASS machines help shops use less energy. They also help shops save money.

Mechanical Presses

- Mechanical presses work very fast. They finish jobs quickly and handle big orders. These machines give the same force every time. This helps make parts that match. Mechanical presses are good for easy bends and big groups of parts. The mechanical press brake has a flywheel. This part helps the machine work better for long jobs. Operators trust mechanical presses for quick, hands-on work.

Press Brake Disadvantages

Hydraulic Presses

- Hydraulic presses need regular checks and fluid changes. Skilled workers must do this job. The machine can get too hot if used for a long time. Operators need to watch the system. Hydraulic presses cost more at first than manual machines. Shops must plan for regular care and fluid changes.

Mechanical Presses

- Mechanical presses cannot control pressure like hydraulic presses. This makes it hard to do tricky bends. These machines are not as flexible. They are best for easy jobs and big batches. Operators cannot change the force easily. This can make some jobs less exact.

Tip: KRRASS hybrid press brakes fix many common problems. They save energy, run quietly, and need less fixing. These things help shops work better and spend less money.

| Feature | Hydraulic Press | Mechanical Press |

|---|---|---|

| Precise Force Control | Yes, good for changing pressure | Not very exact |

| Energy Efficiency | Hybrid models save energy, good for small jobs | Good for long, hands-on jobs |

| Speed | Works slower | Works very fast |

Manual bending machines are still good for shops with simple needs or few jobs. But hydraulic and mechanical presses have clear benefits for today’s metalworking. Knowing the good and bad points of each type helps shop owners pick the best metal bending press for their shop.

Application Suitability

Precision Needs

Many shops want to make parts that are very exact. They often pick CNC press brakes for this. These machines use computers to help with hard bending jobs. Operators can set up many bends in a row. They can make sure each part is almost the same. KRRASS CNC models help shops control every step. This is good for parts that must be perfect. Hydraulic press brake models are also very exact. They are great for jobs that need changes or special bends. The MB8 Series from KRRASS is known for being very accurate. It gives the same results every time, even for tough jobs.

CNC press brakes help shops make tricky shapes. They make sure each part is just like the plan. This helps shops work faster and waste less.

| Feature | Description |

|---|---|

| Precision | Bends hard shapes with high accuracy |

| Tolerance Variations | Keeps size changes very small |

| Accuracy | Made to be very exact |

| Bending Force | Can bend thick or big metal sheets |

| Durability and Performance | Built strong for hard jobs and long use |

- CNC press brakes make bends that are always the same.

- Operators can do many bends and hard shapes.

- Computer controls help shops work faster and better.

Production Volume

Some shops need to make lots of parts fast. They often use mechanical press brake machines. These machines work quickly and push with the same force each time. This helps shops finish big orders on time. KRRASS mechanical models help shops work fast when they are busy. If a shop needs both speed and control, hybrid press brakes are a good choice. Hybrid models mix the speed of mechanical presses with the control of hydraulic ones.

Shops should pick a machine that matches how much they make. Shops that make many parts fast like mechanical presses. Shops that do different jobs like hybrid or CNC models.

- Mechanical press brake machines are best for making lots of parts.

- Hybrid press brakes are good for jobs that need both speed and accuracy.

- KRRASS NC and CNC models can change to fit new jobs.

Material Types

Different metals need different presses. Hydraulic presses are best for steel and stainless steel. These metals are hard and need a lot of force to bend. Mechanical presses work well with aluminum. Aluminum is light and easy to bend. KRRASS hydraulic press brake models can bend thick or tough metals. Electric and hybrid models from KRRASS can bend many kinds of metal and work fast.

| Material | Recommended Press Type | Reason for Recommendation |

|---|---|---|

| Steel | Hydraulic Press | Needs a lot of force to bend well |

| Aluminum | Mechanical Press | Light metal, easy to bend |

| Stainless Steel | Hydraulic Press | Very hard, needs strong force |

Picking the right press helps shops bend metal the right way. It also helps them work fast. KRRASS has a press for every kind of metal and job size.

Cost and Maintenance

Initial Investment

Shops need to think about how much money they spend at first. The price changes based on the model and what it can do. Cheaper machines cost less, but fancy ones need more money. The table below shows how much different models cost:

| Model Type | Price Range (USD) |

|---|---|

| Entry-Level Models | $20,000 – $50,000 |

| Mid-Range Models | $50,000 – $150,000 |

| High-End Models | $150,000 – $500,000+ |

A shop that wants good quality and safety will buy better machines. These machines work faster and help make more parts. KRRASS has machines for every budget. This helps shops pick the right one for their needs.

Operating Costs

How much it costs to run a metal bending press matters over time. Hydraulic press brake models use power to keep working, so bills can go up. Mechanical press brake machines use less power for easy jobs. Shops also need to pay for oil, hydraulic fluid, and fixing the machine. The table below shows the main things that cost money:

| Cost Category | Details |

|---|---|

| Energy Usage | Energy-saving servo-controlled hydraulic presses can cut costs by up to 40%. |

| Oil and Hydraulic Fluid | Oil and fluid cost about 5–10% of yearly running costs. |

| Maintenance and Spare Parts | Regular checks are important; fixing and new parts can cost a lot. |

| Labor and Training | Skilled workers help stop problems and save money. |

| Depreciation | Machines lose value each year, usually 8–15%. |

KRRASS hybrid and electric press brakes help save energy. Electric models only use power when bending metal. Hybrid machines turn on the hydraulic system only when needed. This helps shops use less energy and spend less money. Shops that pick these models save money and work safer every day.

Maintenance Needs

Regular care keeps machines safe and working well. Hydraulic presses need oil checks often. Dirty oil can cause trouble and make things unsafe. Mechanical parts like piston bolts and guides should be checked two times a year. Moving parts need oil every week. Electrical parts should be checked once a year to stay safe. Tooling must be clean and checked often. Broken tooling should go back to the maker for checking.

Maintenance Checklist:

- Check hydraulic oil levels and keep oil clean.

- Look at piston bolts and guides two times a year.

- Oil moving parts every week.

- Check electrical parts once a year.

- Clean and check tooling often.

Safety is always the most important thing when doing maintenance. Shops that follow these steps keep workers and machines safe. KRRASS makes machines that are easy to care for. This helps shops work safely and quickly.

KRRASS hybrid and electric press brakes make maintenance easier. These machines use new technology to last longer and work better. Shops have less downtime and safer places to work.

Decision Guide

Shop Assessment

Every fabrication shop is different. Before picking a metal bending press, shop owners should look at how they work now and what they want later. They need to think about the kinds of materials they bend. They should check how thick the materials are. They also need to know the size of their usual projects. Tonnage is very important. It shows the most force the press brake can use. This tells what thickness and type of metal it can bend. Bending length matters too. It tells how long a metal piece the machine can bend at one time.

A shop should also look at how many parts they make. Shops that make lots of parts fast may want a mechanical press. Shops that do many different jobs may like a hydraulic or hybrid press. These presses are more flexible. The backgauge system helps put metal in the right spot for good bends. Some machines have CNC controls, tool changers, and safety systems. These features help shops work faster and safer. Reliable and strong machines help shops work without stopping. Shops should also think about adding new parts or making the shop bigger later.

Tip: Looking at these things helps shops pick the best press brake for their work.

Key factors to assess:

- Tonnage needed

- Bending length

- Backgauge system quality

- Advanced features (CNC, automation, safety)

- Reliability and strength

- Room to upgrade

Feature Checklist

A checklist helps shop owners compare press brake models. The right features help shops work better, safer, and more accurately. Here is a simple checklist for looking at any press brake, even ones from KRRASS:

| Feature Category | Key Considerations |

|---|---|

| Hydraulic System | Check hoses, look at fluid, test pressure and flow |

| Electrical System | Make sure grounding is good, check wires, test parts, look for errors |

| Mechanical Components | Oil moving parts, check if parts line up, look at die holders and punches |

| Safety Features | Make sure guards are there, test emergency stops, check lights |

| Calibration & Inspection | Set for accuracy, look over machine, write down checks |

Checklist for selecting a press brake:

- High precision bending with advanced hydraulic or CNC controls

- Strong frame for steady work

- Easy controls for simple use

- Tooling that fits many dies and punches

- Safety features like emergency stops and light curtains

Shops that use this checklist can work faster and keep making parts. KRRASS has many press brakes with these features. Their team can help shops pick the best machine and plan for the future.

Note: Talking to KRRASS helps shops get a press brake that fits their goals and helps them grow.

KRRASS Press Brakes

Product Range

KRRASS has many press brakes for different shops. They make nc, cnc, hydraulic, hybrid, and electric models. Shops can pick a simple nc press brake for easy jobs. If they need more, they can use a cnc press brake for hard bends and automation. Cnc models help workers do tricky jobs with great accuracy. Hydraulic press brakes are strong and bend thick metal. Hybrid and electric models save energy and are quiet. Every KRRASS machine is made to help shops work well and bend metal right.

| Model Type | Main Use | Key Feature |

|---|---|---|

| NC Press Brake | Basic bending jobs | Simple controls |

| CNC Press Brake | Complex, high-precision production | Automated programming |

| Hydraulic | Heavy-duty, thick materials | High force, flexibility |

| Hybrid | Versatile, energy-saving | Reduced energy use |

| Electric | Fast, efficient production | Low noise, high efficiency |

Technology and Innovation

KRRASS is special because it uses new technology. Their cnc press brake models have smart automation. This helps workers make fewer mistakes and bend metal better. The PBE-Hybrid series uses up to half the energy, so shops save money and help the planet. KRRASS lets shops pick custom machines for their own needs. The company has won awards for making new and smart machines.

| Feature Type | Details |

|---|---|

| Smart Automation | KRRASS uses advanced automation for better accuracy. |

| Energy Saving | The PBE-Hybrid series saves up to 50% energy. |

| Custom Options | They provide machines that can be tailored to your needs. |

| Industry Awards | KRRASS has earned awards for its innovative designs. |

Cnc technology lets workers set up many bends and repeat them. This helps shops keep up when jobs change. Cnc press brake models are quick to set up and easy to adjust. This makes shops work faster every day.

Support and Service

KRRASS gives strong support and service to all customers. They have service stations in more than half the countries in the world. Skilled engineers travel to places like Georgia, Singapore, and Saudi Arabia to help. KRRASS answers calls fast, sometimes in just 12 hours. Most spare parts are ready to ship the same day, so shops do not have to wait. The service team can make parts for any press brake or guillotine shear, so repairs are quick.

- Service stations in over 50% of countries worldwide

- Chinese engineers travel to Georgia for customer service

- Argentine dealer installation service

- Peru agent service customers

- Singapore customer factory

- Saudi Arabia customers factory

- Canadian agent installation services

KRRASS usually fixes machines in only 2.5 hours. Their prices match what other companies charge, and they always act professional. Shops can trust KRRASS for fast help. This keeps shops working well and stops long delays.

Real-World Scenarios

Small Shops

Small metal shops need machines that are easy to use. These shops also have little space. Hydraulic metal benders are a good choice for them. Workers can move these machines around the shop. They can bend sheet metal up to 6 mm thick. They can also bend pipes up to 1 inch wide. Many shop owners pick hydraulic presses because they are simple to learn. This helps new workers start fast. Some shops, like G.E. Mathis Co., use two hydraulic press brakes together. This helps them do more jobs and take on new work.

- Hydraulic benders are easy to move and use.

- They can bend different metal thicknesses and pipe sizes.

- Shop owners can teach workers quickly and keep up with orders.

High-Volume Production

Big factories care about speed and making many parts. Mechanical press brakes help these shops work fast. These machines use robots to load and unload metal. Robotic arms and sensors keep the work moving. Operators check angles during bending to make sure they are right. Fast hydraulic drives and strong tools help the machines run a long time.

| Specification | Description |

|---|---|

| Automation Integration | Robots load and unload parts to save time. |

| In-Process Angle Correction | Angle checks fix bends as they happen. |

| Drive System Robustness | Fast hydraulic drives help make many parts. |

| Tooling Durability | Strong tools keep working and last longer. |

Robots and automatic systems also make work safer. These features help shops finish big orders and keep workers safe.

Custom Fabrication

Custom shops need machines for many kinds of jobs. KRRASS press brakes help with flexible controls and strong frames. Precision Metalworks in the Midwest uses KRRASS machines to save money and work better. They make good parts for many businesses. Technical Training Institute in Southeast Asia uses KRRASS press brakes to teach students. The machines last a long time and help make new friends in the industry.

| Company/Institution | Location | Industry | Outcome |

|---|---|---|---|

| Precision Metalworks | Midwest, USA | Custom Metal Fabrication | More flexibility, cost savings, better part quality |

| Technical Training Institute | Southeast Asia | Vocational Training | Skilled graduates, long machine life, new partnerships |

Custom shops like machines that can change for different jobs. KRRASS models help these shops do good work and try new projects.

Common Mistakes

Maintenance Oversights

Many shops have problems when they forget simple care. Sometimes, workers do not clean or check machines every day. Small problems can get worse if ignored. Moving parts need oil, but this step is often missed. Without oil, parts rub together and break faster. Shops also forget to check the hydraulic system. If fluid is low, machines can get too hot or not work right. Calibration is skipped sometimes. If a machine is not set right, it will not bend metal correctly. Electrical parts need to be checked often. If not, the machine might stop working or become unsafe. Tooling needs care and must be lined up right. Bad tooling can make mistakes and hurt the machine.

| Maintenance Oversight | Description |

|---|---|

| Daily Cleaning and Inspection | Not cleaning or checking can make small problems turn big. |

| Lubricate Moving Parts | Skipping oil makes parts rub and break, so the machine works worse. |

| Monitor the Hydraulic System | Not checking fluid can make the machine hot or weak. |

| Regular Calibration | Not setting the machine right can make bends wrong. |

| Inspect Electrical Components | Not checking wires can stop the machine or make it unsafe. |

| Tooling Maintenance and Alignment | Bad tooling care can cause mistakes and hurt the machine. |

Doing regular care keeps machines safe and working well. Shops that follow a plan do not lose time or money.

Misjudging Production Needs

Some shops buy a press brake that does not fit their work. They might pick a machine that is too big or too small. When work changes, the machine cannot keep up. Shops that do not plan for more work may have slowdowns. They might need to spend more money on new machines. It is smart to pick a press brake that fits now and later. Shops should think about what jobs they do, how big the parts are, and how many they make each day. Picking the right machine helps the shop finish work on time.

- Think about what jobs you do now and later.

- Look at part sizes and how many you make each day.

- Pick a press brake that can grow with your shop.

Training Gaps

Workers need good training to use press brakes safely. Some shops do not train workers enough. This can cause mistakes when bending metal. Workers who are not trained may skip safety steps or use the wrong settings. They might forget to check the machine or set it up wrong. Training teaches workers how to use the machine and stay safe. Shops that train workers have fewer accidents and better work.

- Give hands-on training to all workers.

- Go over safety rules often.

- Update training when new machines or features come.

Trained workers help the shop run well and keep everyone safe.

Optimization Tips

Maintenance Best Practices

Shops should follow a clear plan to keep press brakes working well. Workers need to check machines every day for leaks or loose bolts. They should look for worn parts too. Cleaning the machine after each shift is important. Oil levels must be checked before work starts. Filters should be changed when needed. Operators should keep the area clean and free of dust. A simple checklist helps workers remember what to do.

Daily Maintenance Checklist:

- Look for oil leaks or spills

- Check hydraulic oil level

- Clean the machine surface

- Remove metal shavings from the area

- Tighten any loose bolts or screws

Taking care of the machine stops breakdowns and keeps everyone safe.

Operator Training

Shops that train workers have fewer mistakes and safer jobs. New operators should learn how to set up the machine. They need to know how to use safety features. They should practice loading and unloading metal sheets. Training should teach how to read job instructions. Workers must learn to adjust settings for each job. They should know how to stop the machine fast if needed. Refresher classes help experienced workers stay good at their jobs.

Key Training Topics:

- Safe machine start-up and shutdown

- Using safety guards and emergency stops

- Reading and following bending instructions

- Changing machine settings for different jobs

- Telling supervisors about problems

Good training helps shops avoid accidents and keeps work moving.

Upgrades

Shops can work better by adding new features or technology. Upgrading to a CNC control system helps make bends more exact. Automatic tool changers save time between jobs. Shops can add better safety systems like light curtains or two-hand controls. Some shops pick energy-saving drives to use less power. Upgrades help shops do harder bending jobs and meet new customer needs.

Popular Press Brake Upgrades:

- CNC control units for better precision

- Automatic tool changers for faster setup

- Advanced safety systems for worker protection

- Energy-efficient drives to cut costs

Upgrades help shops get ready for new jobs and meet higher standards.

Picking a hydraulic or mechanical metal bending press depends on what your shop needs. Hydraulic presses use full force the whole time they bend. This helps with hard bending jobs. Mechanical presses are faster and good for making lots of parts. The table below shows important things to think about:

| Decision Point | Hydraulic Press | Mechanical Press |

|---|---|---|

| Speed | Slower, precise | Faster, high-rate |

| Maintenance | Complex | Simple |

| Versatility | Wide range | High-volume jobs |

| Precision | Full tonnage | Max force at bottom |

| Safety | More controls | Full stroke once started |

| Cost | Higher, adaptable | Lower, simple upkeep |

Shop owners should pick a press that fits how they work. They can look at the decision guide or ask KRRASS for help. Next, they should check what their shop needs now or ask for a demo.

FAQ

What is the main difference between hydraulic and mechanical press brakes?

Hydraulic press brakes bend metal using fluid power. Mechanical press brakes use a motor and a flywheel. Hydraulic models let workers control the bending better. Mechanical models finish jobs faster.

Which press brake suits high-volume production?

Mechanical press brakes are best for making many parts. They work fast and give the same force each time. Shops that need to make lots of parts pick mechanical models.

Can KRRASS press brakes handle thick steel?

KRRASS hydraulic press brakes can bend thick steel sheets. These machines have strong force for tough jobs. Shops use them when they need to bend heavy metal.

How often should operators maintain a press brake?

Operators should look at the machine every day. They need to clean it and check the oil. Doing this keeps the machine safe and working right.

Do KRRASS press brakes support automation?

KRRASS CNC press brakes can use automatic controls. Shops use these controls for hard bends. Automation helps shops work better and faster.

What safety features do KRRASS press brakes include?

KRRASS press brakes have emergency stop buttons and safety guards. Light curtains help keep workers safe. These features stop accidents from happening.

How does a shop choose the right press brake?

A shop looks at what metal they bend and how thick it is. They also think about how many parts they make and how exact they need to be. KRRASS experts help shops pick the best machine.

Are energy-saving models available from KRRASS?

KRRASS has hybrid and electric press brakes that save energy. These machines use less power. Shops can spend less money on bills with these models.