In modern manufacturing, press brake bending is a vital process, which directly affects the quality and precision of the product. Precision bending not only requires high performance of the machine itself, but also requires the operator to have an in-depth understanding of the bending process. This blog will provide you with a series of practical tips on improving the accuracy of press brakes. Whether you are an experienced technician or a newbie, this information will help you accurately control the bending process and ensure that every bend can be Achieve the highest standards of accuracy.

1.Introduction to Press Brake Basics

Press brakes are indispensable in the metal fabrication industry, serving as the cornerstone for transforming flat sheets into parts with complex geometries. The mastery of press brake operations is a blend of art and science, requiring a thorough understanding of the machine’s mechanics, the material’s behavior, and the intricacies of the design to be executed.

The Role of Press Brakes in Metal Bending

- Functionality: The essence of a press brake lies in its ability to transform metal sheets into desired shapes with meticulous control over the bending angle and radius. The force exerted by the press brake is both powerful and precise, allowing for a wide range of bending operations from acute angles to complex, multi-angle folds.

- Types: The diversity of press brakes, from traditional mechanical models to advanced hydraulic and electric versions, offers manufacturers the flexibility to choose a machine that aligns with their specific production needs. Each type brings distinct advantages, such as the speed of mechanical presses, the power of hydraulic systems, and the energy efficiency of electric models.

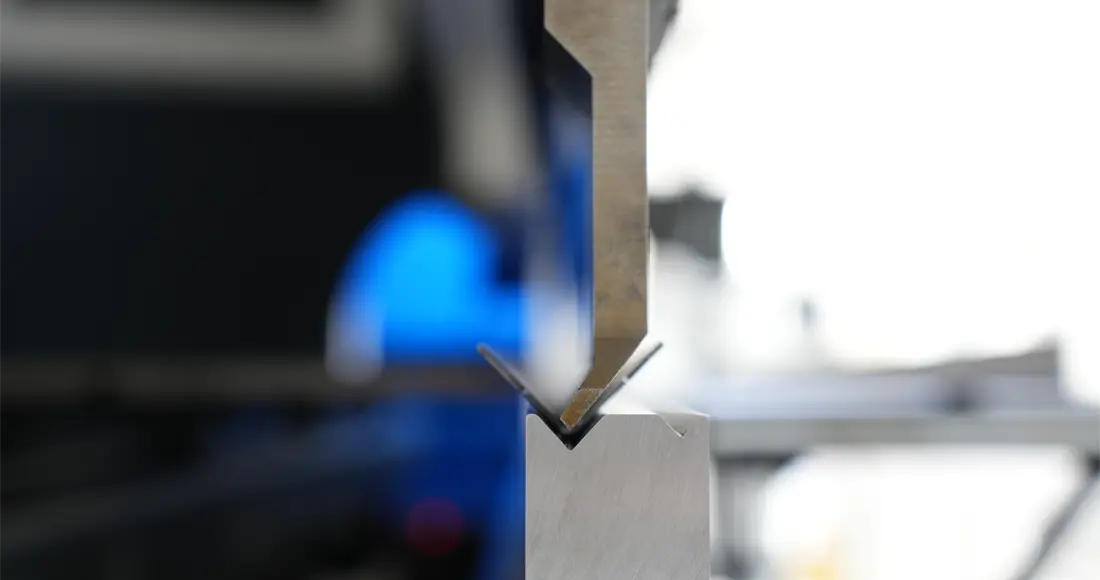

- Tooling: Selecting the right dies and punches is critical for not only achieving the desired bend but also for minimizing wear and tear on the machine. Tooling must be chosen based on the material thickness, bend angle, and required bend radius to ensure optimal results.

Controlled Processes for Precision

- Programming: The integration of CNC controls has revolutionized press brake operations, enabling operators to program complex bend sequences and store them for future use. This digital precision ensures that each bend is executed with consistent force and angle, contributing to the overall accuracy of the finished product.

- Accuracy: Achieving precision in bending is a symphony of controlled speed, pressure, and back gauge positioning. The ability to fine-tune these parameters allows for minute adjustments that can significantly impact the quality of the bend.

- Repeatability: The true measure of a press brake’s capability is its consistency. The ability to replicate bends with unwavering accuracy is what sets apart high-quality fabrication from the rest. This repeatability is crucial for maintaining uniformity across production runs, especially for large-scale manufacturing.

Achieving Precision in Bending

Precision bending is a holistic process that extends beyond the press brake itself. It encompasses the operator’s expertise, the material selection, and the machine maintenance. Each element plays a pivotal role in the final outcome, and a lapse in any one area can compromise the integrity of the bend.

Material Selection and Preparation

- Material Properties: The selection of material is not a decision to be taken lightly. Factors such as tensile strength, ductility, and thickness dictate the bending process and the force required. Materials with higher tensile strength require more force to bend, while those with greater ductility allow for tighter bend radii without cracking.

- Preparation: The condition of the metal surface can greatly influence the bending process. Surface treatment such as priming or coating, along with thorough cleaning, ensures that impurities do not affect the metal’s behavior during bending. This preparation is essential for achieving a clean, sharp bend.

Advanced Techniques and Considerations

- Air Bending: The air bending technique stands out for its minimal contact between the tooling and the workpiece, which translates to less wear on the tools and greater flexibility in handling different material thicknesses.

- Angle Measurement: The use of laser angle measurement systems provides real-time feedback, allowing for on-the-fly adjustments to ensure the bend angle is precise. This technology is invaluable for maintaining high standards of accuracy.

- Tool Maintenance: Regular inspection and maintenance of the tooling are non-negotiable for preserving the quality of bends. Dull or damaged tools can lead to defects in the workpiece and reduce the lifespan of the press brake.

2. Understanding Press Brake Bending Accuracy

Defining Bending Accuracy

Press brake bending accuracy is the cornerstone of precision metalworking. It is the degree to which the machine can match the intended bend specifications, which includes the angle, radius, and position of the bend on the sheet metal. This accuracy is paramount as it determines the fit and function of the final assembled product. Even a minor deviation can lead to assembly issues, functional defects, or aesthetic discrepancies.

Key Factors Influencing Accuracy

- Material Thickness: The thickness of the material being bent plays a pivotal role in the bending process. Thicker materials require more force and may spring back more than thinner ones, necessitating careful calibration of the press brake to compensate for these factors.

- Machine Setup: A well-calibrated machine setup is essential for achieving precise bends. This involves selecting the correct tooling, such as the punch and die, and ensuring that the press brake is programmed accurately for the job at hand. The setup must account for the material type, thickness, and desired bend angle.

Ensuring Consistent Accuracy

Importance of Consistency

- Uniformity: Consistency in bending ensures that every piece produced by the press brake adheres to the design specifications. This uniformity is crucial in industries where metal components must fit together seamlessly, such as in aerospace or automotive manufacturing.

- Quality Control: A consistent bending process is a key aspect of quality control. It minimizes the risk of producing non-conforming parts, which can lead to waste, increased production costs, and potential safety issues.

Maintaining High Precision

Machine Maintenance

- Regular Inspections: Routine inspections are necessary to identify any signs of wear or potential issues that could affect the press brake’s performance. Components such as hydraulic systems, electrical parts, and tooling should be checked regularly to ensure they are in good working condition.

- Adjustments: Over time, press brake components may require adjustments to maintain optimal performance. This could include realigning the back gauge, calibrating the ram, or adjusting the pressure settings to match the material’s properties.

Operator Expertise

- Training: Operators must receive comprehensive training on the press brake’s setup, operation, and maintenance. This training should cover the nuances of working with different materials and the importance of precision in the bending process.

- Measurement and Inspection: Operators should use precision measurement tools, such as protractors, angle finders, or laser-based systems, to verify the accuracy of each bend. Regular inspection of the parts during production helps catch any deviations early and allows for immediate correction.

By focusing on these detailed aspects of press brake bending accuracy, manufacturers can ensure that their products meet the highest standards of precision and quality. The combination of a well-maintained machine, skilled operation, and rigorous quality control processes is the key to achieving and maintaining bending accuracy in metal fabrication.

3. Factors Affecting Bending Accuracy

Expanding on the factors affecting bending accuracy, we can delve deeper into the nuances that contribute to the precision of the press brake bending process.

Material Types and Thickness

- Variability in Material Properties: Different materials, such as aluminum, steel, or copper, have unique responses to bending forces due to their molecular structure and composition. For instance, aluminum is generally more malleable than steel, allowing for tighter bend radii without cracking. Understanding these properties is essential for predicting how the material will behave under stress and for adjusting the press brake settings accordingly.

- Thickness Consistency: The consistency of material thickness across the sheet is vital for even bending. Variations can cause the material to bend more on one side than the other, leading to an uneven final product. It’s important to source materials from reputable suppliers who adhere to strict manufacturing tolerances to ensure thickness uniformity.

Stress and Straightness

- Pre-Bending Stress: Materials often have residual stresses from previous manufacturing processes, such as rolling or welding, which can affect bending accuracy. Techniques like stress-relieving or annealing can be employed to reduce these stresses and promote more consistent bending results.

- Reference Plane Straightness: The reference plane, typically the surface of the die, must be perfectly straight to achieve precise bends. Any imperfections in the die surface can be transferred to the bent material, compromising the accuracy of the bend.

Bend Angle Settings

- Precision in Angle Measurement: Achieving consistent angles requires precise settings on the press brake. This often involves using digital protractors or laser-based angle measurement systems that provide real-time feedback and allow for micro-adjustments to the bend angle during the operation.

- Real-Time Adjustments: Modern press brakes equipped with CNC technology can make real-time adjustments to the bending process. This adaptability is crucial when working with materials that may have slight variations in properties or thickness, ensuring that each bend meets the exact specifications.

Tooling Integrity

- Tool Wear and Maintenance: The condition of the tooling is directly linked to the quality of the bend. Regular inspection of tools for signs of wear, such as nicks or rounding, is crucial. Implementing a maintenance schedule for tooling can extend its life and maintain the quality of bends.

- Die Compensation and Clamping: Die compensation devices can adjust for tool wear and material springback, ensuring that the bend angle remains accurate. Clamping precision is also critical; inconsistent clamping can lead to material slippage and inaccurate bends.

Machinery and Operator Influence

- Machinery Accuracy: The manufacturing precision of the press brake’s mechanical parts must be within high tolerances to ensure bending accuracy. This includes the alignment of the ram and die, the condition of the hydraulic system, and the accuracy of the back gauge.

- Human Factor: The skill of the operator plays a significant role in bending accuracy. Operators must be well-trained in both the theory and practice of metal bending, including understanding material properties, machine setup, and the nuances of the bending process. Automation, such as robotic press brakes, can complement human operators by providing consistent force and precision, reducing the potential for human error.

4. Selecting the Right Bending Tools and Dies

Selecting the right bending tools and dies is a nuanced process that requires a deep understanding of both the equipment and the materials being worked with. Here’s an expanded look at the critical factors and recommendations for achieving optimal precision in press brake bending.

The Critical Role of Tool and Die Selection

The selection of tools and dies is not merely a matter of preference but a strategic decision that can make or break the success of a bending operation. The right tools can reduce production time, enhance accuracy, and extend the life of the press brake itself.

Factors to Consider

- Material Compatibility: The compatibility of tools with the material type and thickness is essential. For example, bending high-strength steel requires tools made from equally strong materials to withstand the forces without deforming.

- Bend Specifications: Tools must be chosen to match the required bend angle and radius precisely. This is particularly important for complex designs where multiple bends of varying angles are required.

Recommendations for Achieving Optimal Precision

- Tool Quality and Precision: High-quality materials for tools are non-negotiable. Tools made from premium-grade steel or carbide can resist the high stresses of bending operations and maintain their shape over time.

- Precision Manufacturing: Tools should be manufactured with tight tolerances to ensure they produce consistent bends. Precision-ground tooling, for instance, can provide the accuracy needed for high-tolerance parts.

Die Selection and Maintenance

- Appropriate Die Features: The features of the die, such as the V-opening, should be selected based on the material thickness and type. A die with a V-opening that is too small can result in over-bending, while one that is too large can lead to under-bending.

- Regular Die Maintenance: Dies should be inspected regularly for signs of wear, such as rounding of the edges or scratches. Maintenance practices might include resurfacing or grinding to restore the die to its original condition.

By focusing on these aspects of tool and die selection and maintenance, fabricators can ensure that their bending operations are as precise and efficient as possible. The right tools not only improve the quality of the final product but also contribute to the longevity of the press brake and the safety of its operation. Remember, in metal fabrication, precision is not just about the capabilities of the machine but also about the quality and condition of the tools it uses.

5. Machine Maintenance and Calibration

Ensuring precision in press brake operations is a multifaceted endeavor that hinges on diligent machine maintenance and meticulous calibration. Here’s an expanded exploration of these critical components.

Regular Maintenance: Ensuring Long-Term Reliability

Routine Checks: The Foundation of Machine Health

- Daily Inspections: These quick yet essential checks are the first step in a proactive maintenance strategy. Operators should look for any signs of wear and tear, such as cracks in the machine frame or misalignment of the ram. They should also check for proper fluid levels, ensuring that hydraulic and lubricating oils are at the correct levels to facilitate smooth operation.

- Scheduled Servicing: To maintain the high standards required for precision bending, press brakes must undergo scheduled servicing. This includes the replacement of hydraulic filters, checking the integrity of electrical systems, and ensuring that all safety features are functioning correctly. Scheduled servicing is also an opportunity to update the machine’s software, ensuring that the press brake is running on the most current and efficient operating system.

Troubleshooting Common Issues: Keeping Operations Smooth

- Identifying Symptoms: Operators must be attuned to the subtleties of the machine’s performance. For instance, a decrease in bending speed or an increase in noise could indicate hydraulic issues, while inconsistent bending angles might suggest a need for recalibration of the CNC controls.

- Swift Resolution: Addressing issues quickly is crucial to minimize downtime. Operators should be trained to perform basic troubleshooting and repairs, such as realigning the back gauge or replacing worn tooling. For more complex issues, a specialized technician should be consulted to ensure that repairs are carried out effectively and safely.

Calibration for Accurate Bending: Aligning Precision with Performance

Calibration Steps: Ensuring Machine Accuracy

- Benchmarking: Establishing a benchmark involves setting the press brake to a known standard, which could be a specific angle or material thickness. This benchmark serves as a reference point for all subsequent operations, ensuring that each bend is consistent with the last.

- Adjustments: Precise adjustments are critical for maintaining bending accuracy. This includes calibrating the pressure settings for different material types and thicknesses, as well as ensuring that the ram and die are perfectly aligned. Operators should also verify that the CNC control system is accurately translating the programmed instructions into physical movements.

Avoiding Bending Errors: Maximizing Quality and Efficiency

Common Errors and Solutions: Enhancing Operational Excellence

- Springback: To counteract springback, operators can use empirical data and software simulations to predict the material’s behavior and adjust the bend angle accordingly. This preemptive approach allows for more accurate final products and reduces the need for rework.

- Angle Inconsistency: To prevent angle inconsistency, operators should regularly check the calibration of angle measurement tools and ensure that the back gauges are set correctly for each job. Using sensors and real-time feedback systems can also help in making dynamic adjustments during the bending process.

6.Advanced Techniques for Precise Control in Press Brake Bending

Precision in press brake bending is not just a goal; it’s a necessity for ensuring the quality and functionality of the final product. In the realm of metal fabrication, the difference between success and failure can hinge on the accuracy of a single bend. Advanced techniques are therefore not just beneficial; they are essential for handling complex tasks and achieving consistent results. Below is a detailed exploration of these techniques, structured to enhance the readability and aesthetics of the content.

Handling Complex Bending Tasks

Complex bending tasks challenge even the most skilled operators and robust machines. They require a nuanced approach to ensure that the final product meets the exact specifications. Here are some advanced techniques:

Specialized Tooling

- Custom-Made Tools: Utilize custom-made tools designed for specific bending operations. This might include tools with unique profiles or materials that can withstand high-stress applications.

- Tooling Innovation: Developments in tooling materials, such as the use of carbide or advanced polymers, can extend tool life and enhance performance under high-load conditions.

- Precision Engineering: The design of these tools often involves computer-aided engineering to ensure that they meet the exact requirements of the bending task.

Step Bending

- Incremental Approach: Implement step bending for large bend radii or when bending thick materials. This technique involves making incremental bends along the length of the material, which can reduce the amount of force required and improve control over the bend angle.

- Controlled Deformation: By breaking down the bending process into smaller steps, the material is less likely to be overstressed, which can prevent cracking and other forms of deformation.

Coining

- High Tonnage Stamping: Employ coining for precise bends with minimal springback. This method uses a higher tonnage to essentially “stamp” the bend into the material, resulting in a very accurate bend angle.

- Reduced Springback: The coining process effectively “sets” the material in the desired shape, which can be particularly beneficial when working with materials that are prone to springback.

Achieving Consistent Results

Consistency is the hallmark of quality in press brake operations. The following techniques can help maintain uniformity across all bends:

Programmable Back Gauges

- CNC-Controlled Precision: Use CNC-controlled back gauges that can be programmed for complex bending sequences. This ensures that each bend is positioned accurately, contributing to the overall consistency of the piece.

- Complex Sequencing: The ability to program a sequence of bends into the CNC system allows for the production of complex parts with multiple bends in a single setup, reducing the potential for error.

Pressure Adjustments

- Material-Specific Settings: Adjust the pressure exerted by the press brake for different materials and thicknesses. Consistent pressure is crucial for achieving uniform bends, especially when working with materials that have varying properties.

- Dynamic Pressure Control: Advanced press brakes can automatically adjust pressure in real-time, compensating for variations in material properties and ensuring consistent bending across the entire length of the material.

Real-Time Monitoring

- Feedback Systems: Incorporate sensors and monitoring systems that provide feedback during the bending process. This allows for immediate adjustments to be made, ensuring that each bend is as accurate as possible.

- Quality Assurance: The use of these systems can also play a role in quality assurance, providing data that can be analyzed to improve processes and reduce waste.

7.Conclusion

In conclusion, achieving precision in press brake bending is a multifaceted process that hinges on a deep understanding of material properties, meticulous selection and maintenance of tooling, precise machine setup and calibration, and the skillful operation by trained professionals. By implementing advanced techniques and maintaining a commitment to quality, manufacturers can ensure that each bend meets the exact specifications required for high-quality metal fabrication.

For those seeking to enhance their bending operations, KRRASS stands as a high-end sheet metal equipment brand with a long history of excellence. Our commitment to innovation and quality ensures that our equipment meets the rigorous demands of precision bending. We invite you to contact us to learn more about how our solutions can benefit your manufacturing processes and help you achieve the highest standards of accuracy and efficiency. KRRASS is more than just a brand; it’s a promise of reliability and precision in metal fabrication.