Plate fiber laser cutting machine uses high-speed laser beam to cut the plate, it has the advantages of high efficiency, high precision and high power.

1. The working principle of fiber laser cutting machine

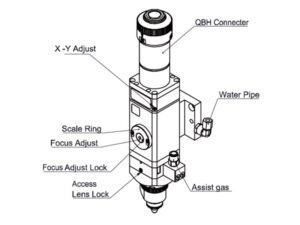

Fiber laser cutting machine uses the thermal effect of the laser to heat the material to be processed, so that it generates high temperature and high pressure gas inside to expand, so as to process the workpiece. It is detected by infrared or ultraviolet light, and controls the temperature and pressure by control system according to the actual situation to complete the entire processing process. Fiber laser cutting machines are generally divided into two types: low-speed and high-speed . When using, do not to let the laser penetrate the plate, to avoid damage to the equipment. If you need to weld or melt for a long time, you should consider choosing a high-speed continuous working method.

Due to the different types of plate fiber laser cutting machines on the market, it can be difficult to decide which one is the best for your needs. But don’t worry, KRRASS are here to help!

2. Analysis of usage and advantage

Fiber laser cutting machine is a kind of equipment specially used for cutting metal sheet. It uses advanced cutting technology to process plates efficiently and accurately. Analysis of usage and advantage: plate fiber laser cutting machine is mainly divided into three types: flat, horizontal and wall-mounted. Flat plate fiber laser cutting machine generally only needs a workbench to complete the work, which has high efficiency. Horizontal plate fiber laser cutting machine must be installed on the workbench to operate a special tool. The wall-mounted plate fiber laser cutting machine needs to be placed on the machine, and then the cable is connected to the control system, so that it can operate normally.

Note: If you want to buy a good plate fiber laser cutting machine, you must choose the right model according to your needs. At the same time, don’t forget to understand the various functions and related precautions !

3. Conclusion

Plate fiber laser cutting machine has the advantages of high precision, high efficiency, energy saving and environmental protection, which can effectively improve production efficiency and reduce energy consumption and costs, it is one of the indispensable equipment in the manufacturing industry. In order to further improve the efficiency of the plate fiber laser cutting machine, it is necessary to optimize the design. According to the analysis of the working principle of the plate fiber laser cutting machine, it can be seen that the plate fiber laser cutting machine adopts advanced three-dimensional CAD technology to realize the product design scheme, which can make the design scheme more in line with the production process requirements, and greatly improve the productivity. In addition, fiber laser cutting machine is also equipped with a perfect performance test system, which can accurately detect product defect and improve the product, thereby improving product quality and reducing production costs.

Which plate fiber laser cutting machine is right for you?

If you need any questions answered or to discuss your plate fiber laser cutting machine requirements for your unique business, please contact us today on 0086 18952087956 or using our online contact form.