Welcome to our comprehensive guide on troubleshooting common hydraulic issues in Press Brake systems. From symptoms to mechanical checkpoints and advanced checks, we cover all the vital aspects you need to know to keep your system running smoothly. Whether it's an issue with the ram, hydraulic control valves, or even the oil pump, understanding these checkpoints can significantly help in efficient and effective troubleshooting.

- What is a Hydraulic Press Brake

- Importance of Troubleshooting

- Understanding Hydraulic Press Brake Mechanics

- Pre-Troubleshooting Precautions

- No Pressure in the Hydraulic System or Pressure Button Not Working

- Long Pause Time at Speed Change Points

- Ram Doesn't Descend in Manual Mode

- Ram Returns Slowly or With High Pressure

- Ram Not Vertical and Makes Abnormal Noises

- Ram Only Moves Down

- Impact Sound During Quick Ram Movement

- Ram Doesn't Move Down Quickly

- Ram Doesn't Move Down Slowly

- Backgauge Axis Issues

- Cylinder and Ram Connection Issues

- Oil Pump Issues

- Slow Pressure Generation (REXROTH Hydraulic System)

1.What is a Hydraulic Press Brake?

At the heart of a hydraulic press brake is the hydraulic system, which uses fluid to generate force. The hydraulic fluid transfers pressure from one point in the system to another, enabling the movement of the machine's ram, which in turn bends the metal. This system is a hallmark of reliability, ensuring that press brake operations are both accurate and repeatable.

Hydraulic press brakes stand out from other types of press brakes—like mechanical or pneumatic—for a variety of reasons. They offer greater control and accuracy, are easier to operate, and are far more energy-efficient. All these factors make hydraulic press brakes an industry standard for jobs that demand precision.

If you're in the business of metal fabrication, understanding the ins and outs of your hydraulic press brake is essential for optimizing your operations. And when it comes to troubleshooting, that understanding becomes even more critical.

2.Importance of Troubleshooting

Troubleshooting isn't just a buzzword; it's a critical aspect of maintaining the long-term functionality and efficiency of your hydraulic press brake. As a leading press brake manufacturer, we cannot stress enough the role that effective troubleshooting plays in your production process. So, why is troubleshooting so important?

First and foremost, troubleshooting helps you identify problems before they escalate into major issues that can bring your operations to a grinding halt. Time is money in the manufacturing world, and even minor disruptions can lead to significant losses in productivity and revenue.

Secondly, regular troubleshooting ensures the longevity of your hydraulic press brake. Preventive measures can significantly extend the machine's lifespan, helping you get the maximum return on your investment.

Third, troubleshooting can improve the quality of your finished products. Inconsistent bends or errors in metal fabrication can occur if your press brake is not operating at its optimum level. Troubleshooting helps you pinpoint these issues, ensuring that you deliver high-quality products that meet or exceed customer expectations.

Lastly, troubleshooting is instrumental in ensuring the safety of your workforce. Hydraulic press brakes are powerful machines, and even minor malfunctions can result in dangerous situations. Effective troubleshooting can identify safety hazards early, allowing you to take corrective action promptly.

3.Understanding Hydraulic Press Brake Mechanics

Basic Components

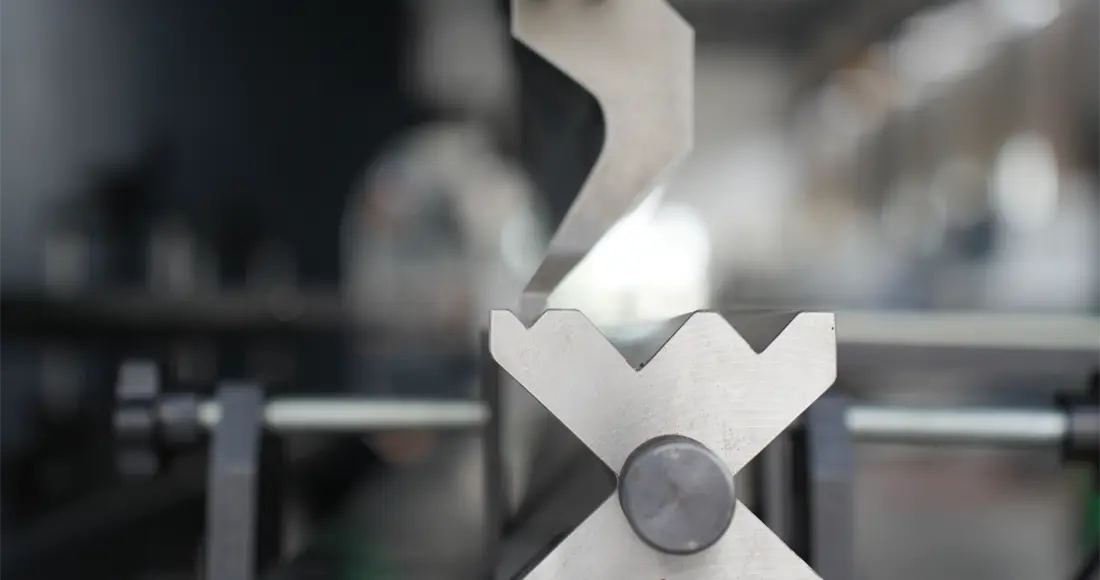

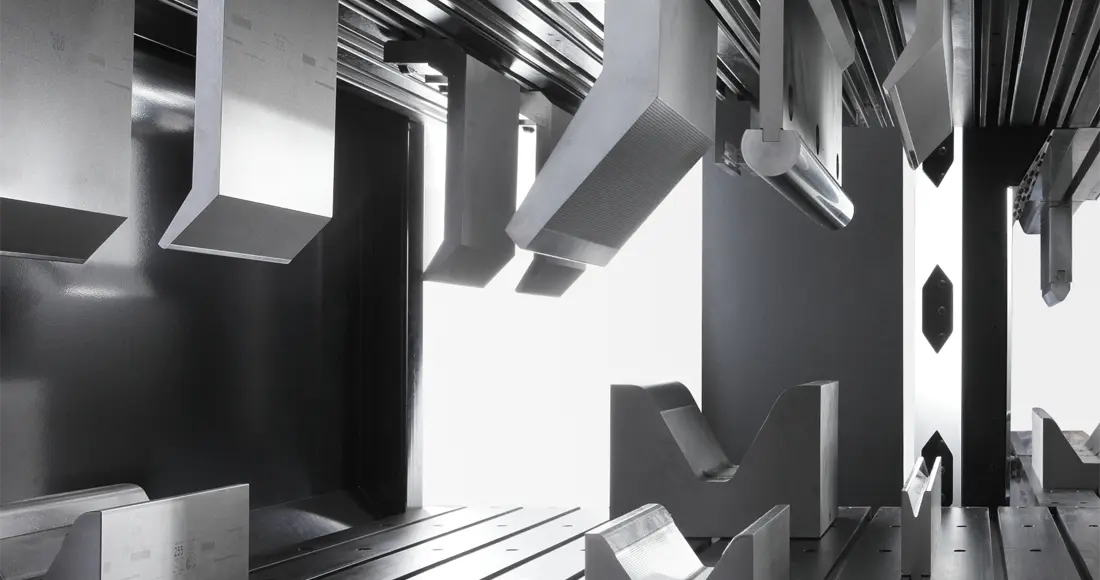

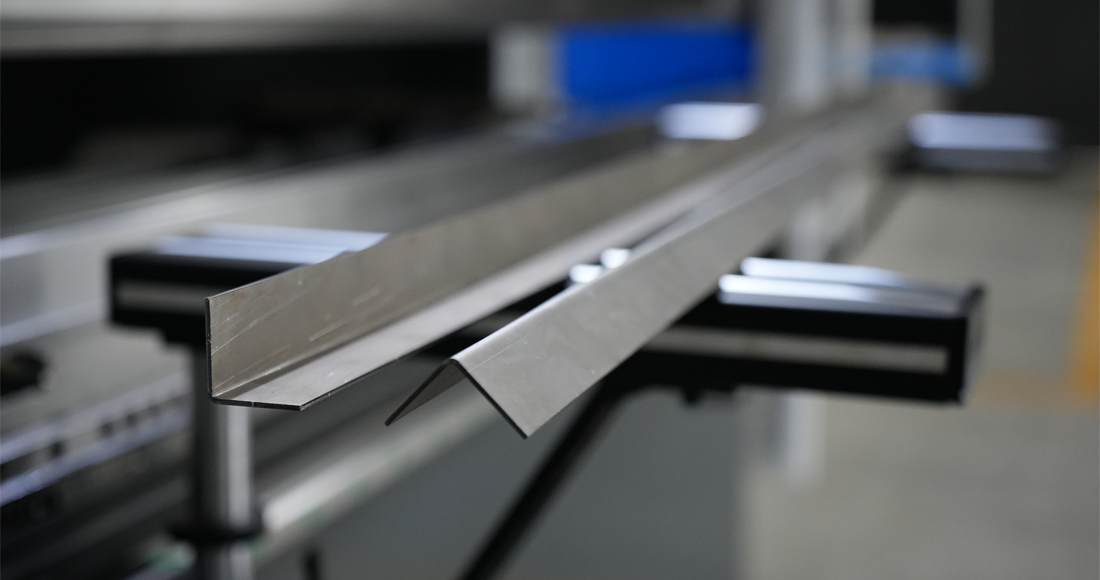

To truly understand the mechanics of a hydraulic press brake, it's crucial to familiarize yourself with its basic components. The main parts include the frame, hydraulic system, ram, die, and back gauge. Each of these components has a specific function that contributes to the overall operation of the machine.

How It Works

The hydraulic press brake operates using a straightforward principle: hydraulic pressure moves the ram, which then bends the metal sheet placed over the die. The hydraulic system consists of a pump, hydraulic fluid, and a series of valves and cylinders to generate and transfer the force. When you activate the machine, the hydraulic fluid flows, creating pressure that moves the ram downwards to bend the metal precisely as programmed.

Common Uses

Hydraulic press brakes are commonly used in various industries for different applications. From the automotive sector to construction and aerospace, the versatility of these machines is remarkable. Whether it's forming car parts, creating HVAC components, or manufacturing aerospace elements, hydraulic press brakes offer a level of precision and reliability that makes them indispensable in modern manufacturing processes.

4.Pre-Troubleshooting Precautions

Safety Guidelines

Safety should be your utmost priority when troubleshooting your hydraulic press brake. Always turn off and disconnect the machine from its power source before starting any inspection or repair. Wear appropriate safety gear like gloves and eye protection. Additionally, make sure you're familiar with the operator's manual as it often contains specific safety protocols for troubleshooting.

When to Consult a Professional

While some issues with your hydraulic press brake may be straightforward to diagnose and fix, others might require a more specialized skill set. If you encounter complex electrical problems or hydraulic system failures that you're not confident in tackling, it's wise to consult a professional. Skilled technicians, especially those certified by your press brake manufacturer, can diagnose and resolve issues more effectively and safely.

Tools Needed for Troubleshooting

Having the right tools on hand can make the troubleshooting process much easier. Basic tools such as wrenches, screwdrivers, and multimeters are generally required. For more specific issues, specialized tools like hydraulic pressure gauges and electrical testing equipment may also be necessary. Consult your operator's manual for a comprehensive list of tools you might need for troubleshooting.

5: No Pressure in the Hydraulic System or Pressure Button Not Working

Symptoms and Importance

Importance of Hydraulic System Pressure

The hydraulic system pressure is crucial for the optimal functioning of the hydraulic press brake. Insufficient pressure can lead to ineffective operation, affecting the quality of the workpiece.

Symptoms Indicating Pressure Issues

Symptoms may include sluggish machine operation, inability to complete bends, or warning messages on the machine interface.

Electrical Checkpoints

Verifying Voltage in Solenoid Coil

Check if the voltage of the solenoid coil meets the requirements and if it is energized.

Electrical Faults in Pressure Control Valve

Inspect the electrical signal of the pressure control valve. Look for any irregularities that could affect its functioning.

Mechanical Checkpoints

Checking for Stuck Valves and Blockages

Examine cartridge valves and main spools for sticking or blockage, especially in the damping holes.

Checking Oil Pump Rotation and Damages

Ensure the oil pump is rotating in the correct direction and is free from damage.

Inspecting the Pressure Gauge

Check if the pressure gauge is functioning correctly or is damaged.

Advanced Checks

Using 24V Electricity for Testing

You can directly supply 24V electricity to determine issues with the valve oil pump.

Adjusting the Compensation Amplifier

If the pressure can only reach a certain value, consider adjusting the compensation amplifier.

6.Long Pause Time at Speed Change Points

Symptoms and Importance

Identifying the Issue

It's important to determine the cause of the delay in speed change as it can significantly affect the efficiency of operations.

Ram Behavior During Pause

Note any unusual activity or vibrations in the ram during the pause to help identify the issue.

Mechanical Checkpoints

Filling Valve Issues

Check if the filling valve is functioning correctly, as it could be a source of the delay.

Checking for Air Suction in the Oil Cylinder

Ensure there is no air being suctioned into the oil cylinder, which could cause delays.

System Parameters

Adjusting CNC Parameters

You may need to adjust the CNC parameters to optimize speed changes.

Work Advance Pressure Parameters

Check and adjust the work advance pressure parameters to reduce pause time.

Additional Checks

Oil Level in the Tank

Verify that the oil level in the tank is sufficient and meets operational requirements.

Checking the Filling Valve for Contamination

Ensure the filling valve is free from contamination, which could affect its performance and result in pauses.

7. Ram Doesn't Descend in Manual Mode

Symptoms and Importance

Identifying the Issue

Determining the root cause is crucial for troubleshooting and ensures that the ram can be operated safely in manual mode.

Ram Behavior During Manual Mode

Observations about how the ram behaves during manual mode can provide important clues for diagnosis.

Checkpoints

Verifying Functionality of "Three-Position Four-Way" Valve

Check whether the "three-position four-way" valve is functioning correctly to rule out this potential issue.

Checking for Stuck Filling Valves

Inspect the filling valves to ensure they are not stuck, as this can prevent the ram from descending in manual mode.

8. Ram Returns Slowly or With High Pressure

Symptoms and Importance

Identifying Slow Return Speed and High Pressure

Understanding the symptoms like slow return speed and high pressure is vital for effective troubleshooting.

Contrast with Issue 3

Unlike Issue 3, where the ram doesn't descend, this issue deals with the ram's upward movement. Recognizing the differences can help in diagnosing the problem accurately.

Troubleshooting

Solution Related to Issue 3

If you've already addressed Issue 3, some of those solutions may apply here as well. Review those steps as part of your troubleshooting process.

9. Ram Not Vertical and Makes Abnormal Noises

Symptoms and Importance

Identifying the signs of an abnormal noise or non-vertical movement in the ram is crucial for maintaining operational efficiency and safety.

Mechanical Checkpoints

Guide Rail Issues

Checking the condition and alignment of the guide rail can help pinpoint the source of the noise and vertical misalignment.

Rail Pressure Plate Condition

Inspect the condition of the rail pressure plate as it could be a major contributing factor to the issue.

Solution

Replacement or Adjustment of Pressure Plate and Guide Rail

Depending on the condition and severity of the issues, replacement or adjustment of the pressure plate and guide rail may be necessary to resolve the problem.

10. Ram Only Moves Down

Symptoms and Importance

Identifying the symptoms of a ram that only moves downward is crucial for understanding the severity of the issue and taking corrective measures.

Mechanical Checkpoints

Circuit Issues

Inspect the electrical circuit that controls the ram's movements for any malfunctions or disconnections.

Pressure Regulating Valve Condition

Check the condition of the pressure regulating valve. A faulty valve could cause the ram to move only in the downward direction.

Hydraulic Checkpoints

Hydraulic Control Valve State

Inspect the state of the hydraulic control valve for any leaks or malfunctions.

Solenoid Valve Spool Condition

Check the condition of the solenoid valve spool. A damaged spool can disrupt the hydraulic flow and cause the ram to move only downward.

Additional Checks

Lifting Cylinder Screw Issues

Inspect the screws in the lifting cylinder for any wear or damage that could affect the ram's vertical movement.

Machine Tool-Specific Issues

Be aware of any machine tool-specific issues that might contribute to this problem and require specialized solutions.

11. Impact Sound During Quick Ram Movement

Symptoms and Importance

Detecting impact sounds during quick ram movement is crucial for identifying potential mechanical issues that could lead to system failure.

Mechanical Checkpoints

Loose Rail Plate

Inspect the rail plate for looseness. A loose rail plate could cause instability and create impact sounds during quick ram movements.

Incorrect Grating Ruler or Travel Switch Position

Check the position of the grating ruler or travel switch. Incorrect positioning can result in abrupt stops, causing impact sounds.

12. Ram Doesn't Move Down Quickly

Symptoms and Importance

It is essential to address issues where the ram doesn't move down quickly, as it can significantly affect machine performance and safety.

Electrical and Mechanical Checkpoints

Quick Lower Valve Condition

Inspect the quick lower valve to ensure it is functioning correctly. Faults in this component can slow down the ram.

Electromagnetic Proportional Directional Valve

Check the condition of the electromagnetic proportional directional valve, as malfunctions can affect the speed of the ram's downward movement.

Mechanical Tightness Like Guide Rail Plate

Inspect for mechanical tightness in components like the guide rail plate, which can contribute to slow ram movements.

Additional Checks

Grating Ruler and Foot Switch Condition

Ensure the grating ruler and foot switch are in good condition, as faults in these can also slow down the ram.

13. Ram Doesn't Move Down Slowly

Symptoms and Importance

Understanding and diagnosing why the ram doesn't move down slowly is crucial for both operational efficiency and safety.

Checkpoints

Electromagnetic Proportional Directional Valve

Check the electromagnetic proportional directional valve for any issues, as malfunctions here can affect the ram's movement speed.

Filling Valve Condition

Inspect the filling valve for wear and tear or blockages that might be causing the ram to not move down slowly.

14. Backgauge Axis Issues

Symptoms and Importance

Identifying and addressing backgauge axis issues are essential for the precise and safe operation of the machine.

Mechanical Checkpoints

Transmission Structure Condition

Inspect the condition of the transmission structure to ensure that it is not causing the backgauge axis issues.

Timing Belt and Servo Motor Issues

Check the timing belt and servo motor for wear or malfunctions that might affect the backgauge axis performance.

15. Cylinder and Ram Connection Issues

Symptoms and Importance

Identifying issues in the connection between the cylinder and ram is crucial for the proper functioning and safety of the system.

Solution

Tightening or Replacing the Connection

The connection between the cylinder and ram can be either tightened or replaced to resolve any issues and ensure optimal performance.

16. Oil Pump Issues

Symptoms and Importance

Understanding the symptoms and significance of oil pump issues is crucial for maintaining a safe and efficient hydraulic system.

Mechanical and Environmental Checkpoints

Oil Pump Suction and Oil Level

Ensure that the oil pump's suction level is adequate and that the oil reservoir is properly filled.

Oil Temperature and Viscosity

Check the oil temperature and viscosity to ensure they are within acceptable ranges for optimal pump performance.

Additional Checks

Outlet High-Pressure Oil Filter Condition

Inspect the condition of the outlet high-pressure oil filter to avoid any flow restrictions.

Pump Installation Issues

Examine the installation of the oil pump to identify any potential problems that could affect its efficiency or safety.

17. Slow Pressure Generation (REXROTH Hydraulic System)

Symptoms and Importance

Understanding the symptoms and significance of slow pressure generation in a REXROTH hydraulic system is crucial for proper maintenance and efficient operation.

Checkpoints

Orifice and Cartridge Valve Condition at Pressure Valve

Inspect the condition of the orifice and cartridge valve located at the pressure valve to ensure that they are functioning properly.

High-Pressure Oil Filter State

Check the state of the high-pressure oil filter to avoid any issues that might hinder efficient pressure generation.

Conclusion

Thank you for reading our in-depth guide on diagnosing and resolving hydraulic issues with Press Brake systems. Whether you're dealing with slow pressure generation, oil pump issues, or ram behavior, this guide has got you covered. If you're in need of high-quality Press Brake or other sheet metal machinery, look no further than Krrass. As a leading manufacturer, Krrass offers a range of highly durable and efficient machines tailored to your needs. Visit Krrass to explore our extensive range of products.

Read More: