In the manufacture of sheet metal, the first step is to cut the sheet metal to size, and a shearing machine performs this function. These machines can be used in cutting alloy or other sheet metal for various purposes.

What is a hydraulic shearing machine?

A shearing machine is a machine that uses a reciprocating linear motion of one blade relative to the other to cut the plate. Through the movable upper blade and the fixed lower blade, the reasonable blade gap is used to apply shearing force to the metal plates of various thicknesses so that the leaves are broken and separated according to the required size. Usually, the shearing operation is carried out with the help of two blades, one of which is fixed on the shearing bed, and the other blade moves in the vertical direction with little or no gap. Shearing is done gradually from one side of the material to the other.

What are the types of shears?

The shearing machine is a cutting equipment widely used in mechanical processing, which can cut steel plate materials of various thicknesses. Under normal circumstances, according to the working principle and the driving mode, the shearing machine is usually divided into several types: pedal shearing machine, mechanical shearing machine, electric shearing machine, pendulum shearing machine, and gate shearing machine. The following is a detailed introduction to the working principles and characteristics of each type:

Pedal shears

Principle: Pedal shears are a kind of shears that reduce two-thirds of the operating force by sliding a fixed fulcrum. The practice has proved that the machine tool partially equipped with pressure feeding is high in quality, light in weight, flexible in action, and widely suitable for manual shearing in the metal sheet industry.

Principle: Pedal shears are a kind of shears that reduce two-thirds of the operating force by sliding a fixed fulcrum. The practice has proved that the machine tool partially equipped with pressure feeding is high in quality, light in weight, flexible in action, and widely suitable for manual shearing in the metal sheet industry.

Features: No need for electricity or too much workforce, reasonable structure, automatic reset, portable pedal, cutting baffle and folding pedal installation, clean cutting, no burrs, guaranteed cutting accuracy. Power saving, easy operation, economical and practical.

Mechanical shears

Principle: When the mechanical shearing machine works, the motor drives the connecting rod on the frame to rotate, and the eccentric wheel connected to the rotating shaft goes the knife holder to tilt backward to cut the plate.

Principle: When the mechanical shearing machine works, the motor drives the connecting rod on the frame to rotate, and the eccentric wheel connected to the rotating shaft goes the knife holder to tilt backward to cut the plate.

Features: The structure is simple; only the foot switch is needed for control and operation, the body is of a single casting structure, and the rear baffle must be manually adjusted.

Electric Shearing Machine

Principle: The motor chain rotates the connecting rod when the electric shearing machine works. The eccentric wheel connected to the rotating shaft drives the blade adapter to perform a backward tilting movement to cut the plate.

Principle: The motor chain rotates the connecting rod when the electric shearing machine works. The eccentric wheel connected to the rotating shaft drives the blade adapter to perform a backward tilting movement to cut the plate.

Features: single-knife, jog control, only foot switch for control operation, better cutting speed, overall single-piece casting structure of the fuselage, and the tailgate needs to be adjusted manually.

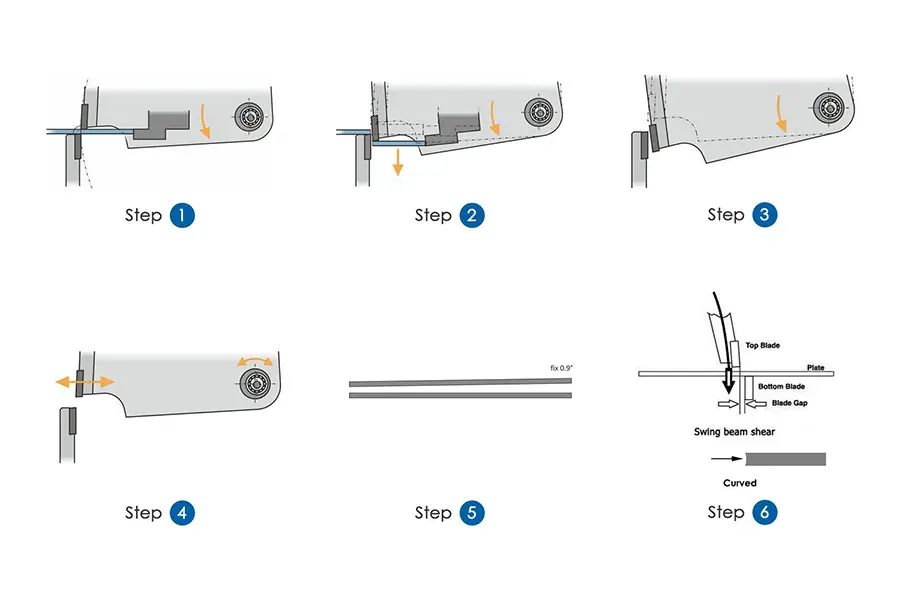

Swing Beam Shearing Machine

Principle: The upper blade of the pendulum shearing machine is fixed on the knife holder, and the lower edge is set on the workbench. The tool holder makes a curved movement back and forth on the fixed torsion axis to repeatedly vertically cut the metal sheet.

Principle: The upper blade of the pendulum shearing machine is fixed on the knife holder, and the lower edge is set on the workbench. The tool holder makes a curved movement back and forth on the fixed torsion axis to repeatedly vertically cut the metal sheet.

Features: The upper knife has two blades, the lower knife has four edges, the knife gap [2] is adjustable, the cutting angle [1] is not flexible, the performance is poor when cutting thick materials, the structure is simple, and the maintenance frequency is low.

Model: QC12K Series Hydraulic Shearing Machine

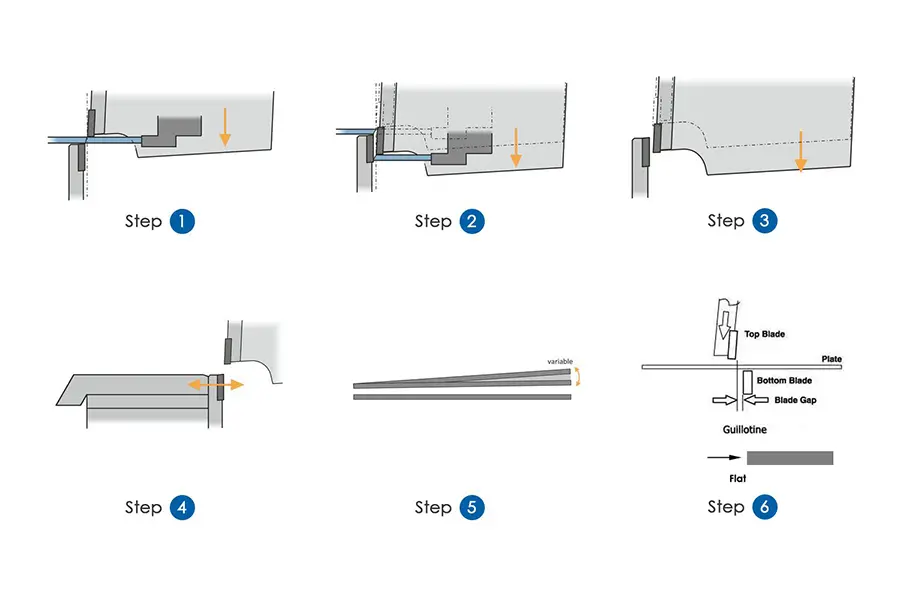

Guillotine Shears

Principle: The gate shearing machine relies on the hydraulic system to work. Its oil cylinder is installed on both sides of the engine, which drives the knife holder to move back and forth vertically to achieve straight cutting.

Principle: The gate shearing machine relies on the hydraulic system to work. Its oil cylinder is installed on both sides of the engine, which drives the knife holder to move back and forth vertically to achieve straight cutting.

Features: The upper and lower blades have four cutting edges, the knife gap [2] can be adjusted, the cutting angle [1] can be adjusted electrically, the knife holder is returned by the nitrogen cylinder (or hydraulic return), when cutting thick metal plates, can achieve better performance.

Model: QC11K Series Hydraulic Guillotine Shears

Remark:

[1]Shearing angle: the angle formed by the upper and lower blades moving downward.

[2] Knife gap: the distance between two blades.

Parameter System of Hydraulic Shearing Machine

CNC system: E21S (swing type/gate type)

Features: Single/cycle, concession function, store 40 programs, each with 25 steps, workpiece counting, average or frequency conversion control motor.

What are the standard operating procedures of the shearing machine?

The shearing machine is a cutting equipment widely used in mechanical processing, which can cut steel plate materials of various thicknesses. Therefore, when operating the shearing machine, the following points should be paid attention to:

- Before work, carefully check whether all parts of the shearing machine are standard, whether the electrical equipment is in good condition, and whether the lubrication system is in good condition; remove tools, measuring tools, and other sundries and corner garbage placed on and around the table.

- Do not operate the shearing machine alone. Feeding, controlling dimensional accuracy, retrieving, etc., should be coordinated by 2-3 people to ensure one person is in command.

- Adjust the shear gap of the shear angle according to the specified shear thickness. It is not allowed to cut two kinds of plates with different specifications and materials simultaneously; the cut plates need to have smooth edges, and it is not permitted to cut narrower leaves that cannot be compacted.

- The moving parts, such as the shearing machine’s belt, flywheel, gear, and shaft, must be equipped with a protective cover.

- The hands of the operator of the shearing machine should keep a distance of at least 200mm from the scissors and the pressing device. A guard placed over the shear trigger must not obscure the operator’s eyes or the part being cut. The waste generated after the operation has edges and corners, and the operator should remove them in time to prevent stab wounds and cuts.

- Flywheels, gears, chains, shafts, belts, and other moving parts of the shearing machine should be equipped with protective covers.

- Place a fence to prevent the operator’s hands from entering the area where the scissors fall. It is strictly forbidden to pick up garbage on the ground during work so as not to be injured by falling workpieces.

- It is impossible to cut the quenched material, and it is forbidden to cut the fabric that exceeds the working capacity of the shearing machine.

How to maintain the shearing machine?

- Operate the shearing machine in strict accordance with the operating procedures;

- Before starting the machine, add lubricating oil regularly, at fixed points, and in a quantitative manner according to the requirements of the lubrication instruction diagram. Lubricating oil should be clean and free of any sediment;

- The shearing machine must always be kept clean, and the unpainted parts should be protected with grease to prevent rust;

- The lubricating oil in the motor bearing should be replaced and filled regularly, and the electrical parts should be regularly checked to see if they are operating normally, safely, and reliably;

- Regularly check whether the triangle belt, handle, knob, and button are damaged. If the wear is severe, it should be replaced in time, and spare parts should be reserved;

- Regularly check and maintain switches, buttons, and handles to ensure their reliable operation;

- Lubricate and clean the shears 10 minutes before the end of work every day;

- Non-designated personnel are strictly prohibited from operating the equipment. Usually, the machine should be powered off as soon as the operator is not around the shear.

KRRASS: the best choice for

all sheet metal processing manufacturers

Learn more about our products, please visit and subscribe to our Youtube channel