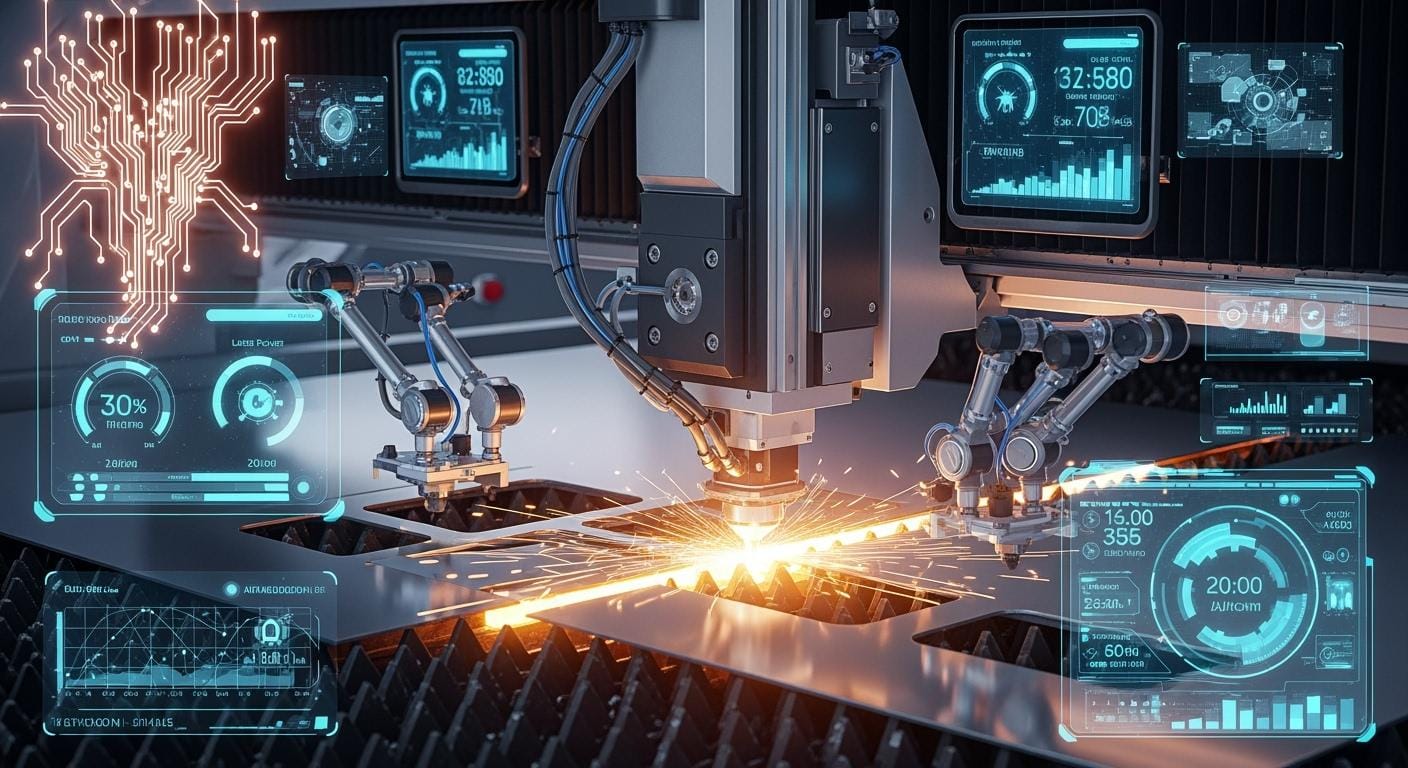

Cutting lasers are changing how things are made. Smarter automation, advanced AI, and eco-friendly ways are making laser cutting better. These new trends help you work faster and get better quality. They also help you use resources more wisely.

- Robotic arms use computer vision to check products. They make sure the quality stays the same.

- AI-powered systems help organize work and fix problems early. This means less waiting and fewer delays.

- Eco-friendly solutions use less energy and make less waste. This helps your business run better.

Using the newest cutting laser technology helps you stand out in the market.

Table of Contents

Key Takeaways

- Automation in laser cutting makes work faster and more accurate. This helps companies finish jobs quickly.

- AI integration watches the process as it happens. It finds mistakes and stops delays. This makes work more efficient.

- Eco-friendly laser systems use less power. This saves money for companies. It also helps them reach green goals.

- Smart nesting techniques help use materials better. They cut down on waste and lower costs.

- KRRASS has advanced machines that work with many materials. This makes them useful for lots of industries.

- Buying new laser technology can save a lot of money. It also helps people get more work done.

- Training and support from KRRASS help people learn new technology. This makes users feel more confident.

- Learning about new laser cutting trends helps companies grow. It also helps them stay competitive in the future.

Latest Trends In Laser Cutting Technology

Cutting Lasers: 2026 Overview

Key Industry Shifts

Big changes are happening in cutting lasers for 2026. Automation is now very important. Machines can do more work with less help from people. AI helps watch each step and fix problems early. Saving energy is a bigger deal now. Companies use less power and follow new clean rules. People want machines that are good for the planet. You see more ways to use laser cutting. Businesses cut many kinds of materials for different products.

Tip: To stay ahead, learn about these changes and how they affect your job.

Market Drivers

The market wants you to use the newest trends. Customers ask for better quality and faster service. You need smart machines that save energy. New rules about pollution make you look for green choices. More people want custom products. Laser cutting helps you meet these needs. You can cut metals, plastics, and ceramics with great accuracy.

| Trend | Description |

|---|---|

| Automation | More automation in laser cutting systems for better precision and productivity. |

| AI Integration | AI helps monitor in real time and fix problems before they cost money. |

| Energy Efficiency | Using less energy because of new rules about pollution. |

| Sustainability | Using eco-friendly laser systems to help the environment. |

| Expansion into New Applications | Laser cutting is used for more materials and jobs because of what the market wants. |

KRRASS Leadership In Innovation

Brand Mission And Achievements

KRRASS is a leader in new ideas for laser cutting. The brand helps you work faster and more accurately. KRRASS spends money on research and new ideas. You get better machines with new features. The company has won awards for metal work. Experts say KRRASS is a leader. You get the newest technology that sets new standards.

| Achievement | Description |

|---|---|

| Best 10 Laser Cutting Manufacturer | KRRASS is known as a top company for laser cutting and sheet metal, with new technology and great machines. |

| Production Facilities | KRRASS has over 100,000 square meters and makes 600 fiber laser cutters each year. |

| Commitment to R&D | KRRASS keeps spending on research to make products better and keep up with the industry. |

- KRRASS has won awards for great work in metal technology.

- Experts call KRRASS a leader in making new industry rules.

Global Impact

KRRASS sells to customers in more than 50 countries. You find their machines in many factories worldwide. The brand has many products to choose from. You can pick fiber laser cutters, CNC press brakes, and more. KRRASS helps you with sales and good service after you buy. Their global reach means you get help wherever you are. KRRASS shows the newest laser cutting trends and helps you stay ahead.

Advancements In Cutting Lasers

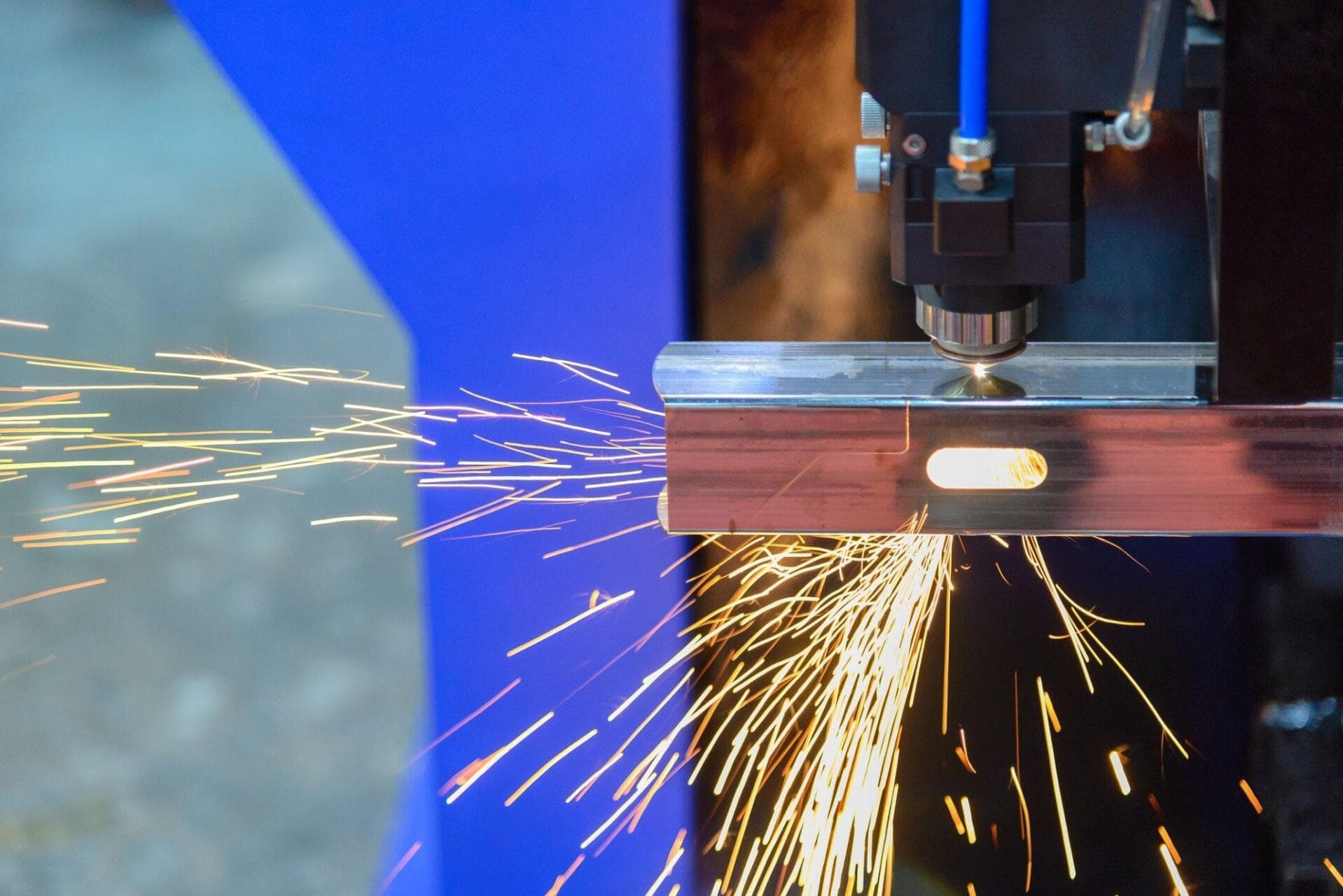

Fiber Laser Technology

Performance And Efficiency

Fiber laser cutting machines are changing fast. They use strong laser beams to cut metal quickly and accurately. Fiber lasers help you get better results and save time. You can cut many metals, like steel, aluminum, and copper. These machines use less energy than co₂ laser cutters. They also need less fixing and cleaning. You get smooth edges and clean surfaces. This means you do not need extra work.

Here is a table that shows how the RAS-3015-Smart 6000W fiber laser system works:

| Metric | Description |

|---|---|

| Laser Power | 6000W, gives high efficiency and a small size. |

| Cutting Speed | Fast servo motors help control movement and speed. |

| Advanced Features | Smart cutting heads watch in real time and keep things stable. |

You can use fiber laser cutting machines for 3d laser cutting. This helps you make cool shapes and designs. These new laser sources make machines faster and more exact.

RAS-3015-Smart 6000W Features

The RAS-3015-Smart 6000W is special in the market. It has a Max China MFSC 6000W laser source. This gives strong and steady power. The BLT421S smart cutting head lets you set pressure with one click. Fast focusing and quick movement come from high-speed servo motors. The FSCUT4000E control system moves data fast and keeps it safe. You can cut steel, aluminum, titanium, brass, and copper.

The working area is 3000mm x 1500mm. This fits big sheets. The water cooling system keeps the machine cool. You get clean cuts and save energy. The machine helps you do 3d laser cutting for custom jobs. You can trust the RAS-3015-Smart 6000W to work well every day.

Tip: If you want to make more products, pick fiber laser cutting machines with smart features and strong power.

Hybrid And Ultrafast Lasers

Versatility In Applications

Factories now use new hybrid laser cutting systems. These mix different laser types for better results. You can cut metals and non-metals with one machine. Ultrafast lasers help with tough materials. You get high precision and less heat damage. These systems work for 3d laser cutting in aerospace, electronics, and medical devices.

- Ultrafast lasers give high precision and less heat damage.

- Green lasers help cut shiny metals like copper and brass.

- Hybrid laser cutting systems mix laser types for better work.

You get more choices for your business. One machine can do many jobs.

Precision Cutting

Ultrafast lasers give better surface finishes. You can lower heat damage by 62% when cutting aluminum with 300 fs pulse control. You get 0.8 µm surface finishes on hard metals. This is 400% better than grinding. You can drill 12,000 holes per minute in semiconductor wafers. Heat damage stays below 1 µm.

Ultrafast lasers are changing science and industry. You see them in atomic microscopy and advanced nanolithography. These lasers help you find new ways to make things.

OPMT’s 2025-certified laser technology, with multi-wavelength switching and femtosecond laser systems, sets new standards for efficiency and precision in factories.

You get more accurate cuts and less waste. You can use 3d laser cutting to make detailed parts for many industries.

Automation And AI In Laser Cutting

Smart Systems And Robotics

Real-Time Monitoring

Smart systems are changing how cutting lasers work. These systems use sensors and cameras to watch each step. They check for problems as they happen. You get alerts if something goes wrong. This helps your work go smoothly. Smart robots move fast and handle materials carefully. You finish jobs quicker and waste less. Better cut quality means you fix fewer mistakes. Lower costs help your business grow.

- Jobs finish faster

- Less waste

- Better cut quality

- Lower costs

Smart systems plan the best way to cut. Kerf compensation helps make edges perfect. Smart processing lets you change settings for each job. You have more control and get better results.

Automated Material Handling

Automated systems pick up and move metal sheets by themselves. Robots load and unload materials quickly. You save time and make fewer mistakes. Smart robots know where to put each piece. This keeps your work steady. You see fewer delays and finish more products each day. Fast automation helps you meet tight deadlines.

AI Optimization

Adaptive Control

AI optimization gives you control over laser cutting. The machine changes settings as it works. You get the best results for every material. If metal is thick or thin, the system adjusts right away. This makes work faster and more exact. You do not need to stop and reset the machine. Industry 4.0 lets machines connect and share data. You see how each job does and make changes fast.

Predictive Maintenance

AI helps your machines last longer. The system checks sensors and records to guess when parts need fixing. You get alerts before something breaks. This means less downtime and saves money. Predictive maintenance helps you spend less on repairs. You keep working without long stops. AI can tell you which parts will wear out soon. You plan ahead and avoid surprises.

KRRASS Automation Solutions

Integration With RAS-3015-Smart 6000W

KRRASS leads in automation and ai for laser cutting. The RAS-3015-Smart 6000W uses smart systems and robots to help you work better. You get real-time monitoring and automated material handling. AI optimization gives you control and helps with repairs. Industry 4.0 connects your machines for smoother work.

| Improvement Type | Evidence |

|---|---|

| Production Speed | 50% Faster Production Speeds |

| Edge Quality | Higher Edge Quality |

| Energy and Material Costs | Lower Energy and Material Costs |

| Operational Costs | Perfected Operational Costs |

| Downtime Reduction | Remarkable Reduction in Downtime |

| Cut Quality | Enhanced Cut Quality |

Smart manufacturing grows with KRRASS solutions. Automated systems help you work faster and smarter. You get better quality, lower costs, and less downtime. KRRASS helps you stay ahead in the market.

Tip: Pick smart laser cutting technology with automation and ai to help your business and meet new standards.

Eco-Friendly Laser Cutting Practices

Energy Efficiency

Reduced Consumption

You can use less energy with the right cutting lasers. Fiber laser machines need less power than older ones. This saves you money and helps the planet. The table below shows how much energy each technology uses:

| Technology Type | Energy Efficiency | Energy Reduction Potential |

|---|---|---|

| Fiber Laser | Up to 70% | Up to 50% |

| CO₂ Laser | ~20% | N/A |

| Plasma Cutting | N/A | 2-3 times more than fiber |

| Mechanical Cutting | N/A | Longer cycle times increase energy use |

Fiber laser machines use 25-30% less energy than CO₂ lasers. Plasma cutting uses much more energy than fiber lasers. You see big savings when you switch to fiber lasers.

Green Manufacturing

Green manufacturing means using less energy and making less pollution. You help the earth and make your business better. Many companies pick lasers for energy-saving jobs. Lasers work well for things like making solar panels. You get good results and use less power.

Lasers are seen as a low-energy choice for making things. They save a lot of energy when used for jobs like heating thin-film solar panels.

Green lasers can cut shiny metals like copper and brass. This helps you follow new clean rules.

Waste Minimization

Smart Nesting

Smart nesting helps you use all your material. You put parts close together to stop waste. Automated software finds the best way to fit shapes. You test layouts before cutting to avoid mistakes. You save money and protect resources.

- Smart nesting puts parts close to save material.

- Good part placement helps cut down empty spaces.

- Automated nesting software uses math to save material and make better cuts.

Material Utilization

You get more from each metal sheet with precision cutting. Lean manufacturing helps you make less pollution. The table below shows how these methods help you save:

| Method | Benefit |

|---|---|

| Precision cutting techniques | Reduces material waste |

| Energy efficiency | Lowers production costs |

| Lean manufacturing integration | Decreases carbon emissions |

Life Cycle Assessment lets you check your work’s impact. You find ways to use less energy and fewer materials. This helps you keep laser cutting eco-friendly.

KRRASS Sustainable Solutions

RAS-3015-Smart 6000W Eco Features

KRRASS is a leader in eco-friendly laser cutting. The RAS-3015-Smart 6000W uses compressed air cutting. You spend less on nitrogen and make less CO₂. The machine’s small size needs fewer resources. You get a system that works well and helps the planet.

- KRRASS uses compressed air cutting to lower costs and CO₂.

- Smaller machine designs use fewer resources and help the environment.

- By 2030, air cutting will be common in fiber laser machines. This helps the planet and saves money.

You can pick eco-friendly laser cutting for your shop. You save money, use less energy, and help the earth. KRRASS gives you tools to reach your energy and sustainability goals.

Expanding Applications And Materials

Advanced Metals And Alloys

Automotive And Aerospace

Laser cutting machines are changing how cars and planes are made. Car companies use lasers to cut and weld parts with great accuracy. You can shape metal sheets for car bodies and batteries very fast. Lasers help you waste less metal and make things quicker. Plane makers use lasers to build light and strong parts for aircraft. You get smooth cuts and strong welds. This makes planes safer and work better. Electric cars need special laser cutting for batteries and light materials.

- Lasers are used for welding, cutting, and marking parts.

- Lasers help make fuel injectors and engine blocks with exact shapes.

- Laser welding joins parts together for strong connections.

- Metal sheets are shaped faster and with less waste.

Electronics And Medical Devices

Laser cutting helps make tiny and complex parts for electronics. You can cut circuit boards with great detail. This helps make smaller and smarter devices. Medical device makers use lasers to make fine and exact parts. You can cut special metals for implants and tools. Smart systems help you cut more accurately. You follow strict safety and quality rules in both fields.

- Lasers cut special metals for electronics and medical devices.

- Lasers help make small, detailed parts with high accuracy.

- You follow safety rules and make better products.

Non-Metal Cutting

Plastics And Ceramics

Laser cutting is not only for metals. You use lasers to cut plastics and ceramics for many jobs. Strong CO₂ lasers make very fine cuts, as small as 0.01mm. You can shape 3D objects with more flexibility. Green lasers give clean cuts with little damage nearby. Micro laser cutting helps make tiny parts for medical tools.

| Innovation Type | Benefits |

|---|---|

| Enhanced Flexibility | Cut 3D shapes and structures |

| Green Laser Technology | High-quality cuts, minimal damage |

| Micro Laser Cutting | Fine, precise cuts for medical devices |

| High-Power CO₂ Lasers | Efficient cuts, outputs from 150W to 500W |

You waste less material and work more efficiently with these new ideas. Laser cutters use computers and do not touch the material. They turn material into vapor, which helps you make detailed designs and save material.

Artistic And Custom Uses

Laser cutting helps artists and small businesses do new things. You can make custom signs for events and shops. Artists use lasers to make detailed jewelry and home decorations. You meet the need for special and unique products. Car makers, builders, and stores want custom laser cutting. You get very accurate cuts for crafts, so your designs look great.

- You make custom signs and decorations for customers.

- You create special jewelry and art pieces.

- You help industries that want custom laser cutting.

- You meet the need for more personalized products.

KRRASS Versatility

RAS-3015-Smart 6000W Material Range

KRRASS lets you cut many materials with one machine. The RAS-3015-Smart 6000W can cut steel, aluminum, titanium, brass, copper, and iron. You use it for cars, planes, electronics, and medical devices. The machine’s smart features let you switch between metals and non-metals easily. You get exact cuts for circuit boards, light plane parts, and custom designs. KRRASS helps you grow your business and try new jobs.

Tip: Pick the RAS-3015-Smart 6000W if you want a machine that works with many materials and industries. You get more choices and stay ahead in a changing market.

Software And User Experience

Intuitive Interfaces

Touchscreen Controls

You use KRRASS laser cutting machines with a modern touchscreen. The screen is easy to understand and simple to use. You tap and swipe to pick settings. All the important info is on one screen. You can change cutting settings quickly. You do not have to remember hard commands. The touchscreen helps you work faster and make fewer mistakes.

Tip: Touchscreens help everyone learn and use the machine more easily.

Training Benefits

You learn to use KRRASS machines in less time. The design shows you what to do step by step. You follow instructions on the screen for setup and use. You can practice with built-in lessons and try out simulations. You get better as you learn each part. Training is easier, and you start making good work sooner.

CAD/CAM Integration

Workflow Optimization

You link design and making with CAD/CAM. When you change something in CAD, it shows up in CAM right away. You do not need to update things by hand, so you save time. Design and cutting data stay matched, so there are fewer mistakes. You can fit many parts on one sheet to use less material. This helps you work better and make more money.

- Speed: CAD changes show up in CAM fast.

- Accuracy: Matched data means fewer mistakes.

- Cost Savings: Shorter wait times and less waste help profits.

Real-Time Simulation

You can see your cutting job before you start. You watch a preview of the process on the screen. You find problems and fix settings before cutting. You make sure the design is right. You avoid wasting material and making mistakes. You can test hard cuts and tricky designs with the simulation.

- You move from design to making things faster.

- You make fewer mistakes in cutting.

- You can do hard cuts and designs with more confidence.

Remote Monitoring

Data Analytics

You can check your KRRASS machine from anywhere. IoT sensors watch things like heat and speed. You get updates right away and can change things fast. Data analytics tells you when to fix the machine. You plan repairs and save money. You see how the machine is working and spot problems early. You stop surprise breakdowns and keep things safe.

- Predictive maintenance helps stop machine failures.

- Good schedules save money.

- Checking performance makes machines work better.

Support And Troubleshooting

You get help and fix problems from far away. You get alerts and reminders to do repairs. You can watch and control machines from any place. You solve problems fast with real-time info. You keep making products even if something goes wrong. KRRASS systems help you keep working and make good products.

Note: Remote monitoring and support help you feel safe and keep your work running well.

KRRASS systems use smart software, easy screens, and strong connections. You get easier training, faster work, and good support. These changes help you work smarter and get better results every day.

Business Impact And Future Outlook

ROI And Cost Efficiency

Investment Considerations

It is smart to think before buying new laser cutting machines. Modern cutting lasers help you save money and earn more. These machines work fast and use less energy. You spend less on materials because they cut with care. Advanced systems do not break down often, so you pay less for repairs. Good equipment gives you better results and fewer errors. You finish more jobs and keep your customers happy.

| Benefit | Description |

|---|---|

| Lower Energy Costs | Machines use less power |

| Less Material Waste | Precision cutting saves resources |

| Reduced Downtime | Smart systems prevent breakdowns |

| Higher Productivity | Faster jobs mean more output |

KRRASS Value Proposition

KRRASS gives you machines that work well for a long time. The RAS-3015-Smart 6000W is easy to use and works fast. You get help and training to use your machine the right way. KRRASS helps you reach your goals with new features and worldwide service. You can trust KRRASS to give you good solutions that help your business.

Tip: Pick KRRASS if you want a partner that helps you grow and stay ahead.

Transition Strategies

Training And Support

You need good training and help when you get new machines. KRRASS teaches you with hands-on lessons so you learn fast. You get step-by-step help to use your machine safely. Training helps you feel sure about your skills. Support teams answer your questions and fix problems quickly.

Technology Partnerships

Transition plans help you switch to new technology without trouble. Working with trusted suppliers like KRRASS makes things easier. Technology partnerships give you help and updates when you need them. You can change slowly so your business does not stop. You keep working while you learn new skills.

- Training programs help your team learn.

- Technology partnerships give expert help.

- Changing slowly lowers risks.

- Ongoing support keeps things running smoothly.

Future Of Laser Cutting

Emerging Opportunities

Laser cutting grows as technology gets better. More people want fast and exact work. Automation and ai bring new ways to work smarter. Industry 4.0 connects machines and gives better data. New markets in Asia-Pacific and Latin America are growing fast. Companies that try new ideas and care about customers do well.

Staying Competitive

You stay ahead by using the newest cutting lasers and smart systems. You watch what is popular and change your business when needed. You train your team and build strong partnerships. You find new ways to use your machines and get more customers. KRRASS helps you get ready for changes with good products and expert help.

Note: Being flexible and open to new ideas helps your business stay strong in a changing market.

Big changes are coming to laser cutting in 2026. Smarter automation helps machines work better. Eco-friendly designs make cutting safer for the planet. New materials let you do more jobs.

- Cutting systems use sensors to change settings fast.

- More companies want custom solutions and local suppliers.

- Laser technology is used in electric cars and medical tools.

| Aspect | Benefit |

|---|---|

| Energy Efficiency | Saves resources and lowers spending |

| Automation | Makes cuts more exact and improves quality |

| Sustainability | Helps meet green goals and follow new rules |

Check out KRRASS solutions to stay ahead. If you buy new technology, your business gets ready for the future. New ideas in laser cutting will bring more chances.

FAQ

What materials can you cut with a KRRASS fiber laser cutting machine?

You can cut steel, aluminum, titanium, brass, copper, and iron. The machine works with many metals. You get smooth edges and good accuracy every time.

How does automation help your laser cutting process?

Automation helps you finish jobs faster. Robots move materials and check the quality. You save time and make fewer mistakes. You get more products with less work.

Why should you choose fiber laser technology over CO₂ lasers?

Fiber lasers use less energy and need less fixing. You get faster cutting and smoother edges. You save money and help the environment.

What is smart nesting, and how does it save material?

Smart nesting puts parts close together on each sheet. You use more material and waste less. Automated software finds the best layout for every job.

How do you keep your KRRASS machine running smoothly?

You use real-time monitoring and predictive maintenance. Sensors check the machine and warn you before problems happen. You plan repairs and avoid long stops.

Can you cut non-metal materials with KRRASS machines?

You can cut plastics and ceramics with special laser settings. The machine gives you fine cuts and detailed shapes. You get flexibility for many jobs.

What support does KRRASS offer after you buy a machine?

KRRASS gives you training, remote help, and quick answers to questions. You learn how to use your machine and fix problems fast. You get support worldwide.

How does using eco-friendly laser cutting help your business?

Eco-friendly cutting uses less energy and makes less waste. You save money and meet green standards. You help the planet and make your company look better.