Welcome to the comprehensive world of metal forming, where precision meets durability. This article delves into the essence of metal forming, unraveling its techniques, processes, and varied applications across industries. From the basic mechanics of metal deformation to the advanced equipment used, we cover the intricate details that define this manufacturing cornerstone. Whether you're a seasoned professional in the industry or new to the concept of metal forming, this guide offers valuable insights into choosing the right method and equipment for your manufacturing needs.

- What is Metal Forming

- Mechanics of Metal Forming: Stress, Strain, and Deformation

- Thermal Dynamics in Metal Forming: Heat and Its Impact

- Metal Forming Techniques

- What is the Difference between Hot Working and Cold Working Metal Forming?

- What are Metal Forming Tools and Equipment?

- Industry Applications

- How to Choose the Right Metal Forming Technique

1.What is Metal Forming?

Metal forming stands as a cornerstone in the realm of manufacturing, a process as ancient as it is pivotal in modern industry. At its core, metal forming involves the manipulation of metal into desired shapes and sizes through various techniques without removing any material. This transformative process can range from simple bending to complex shaping, all aimed at meeting specific functional and aesthetic requirements in a multitude of industries.

Why is metal forming so crucial, you might wonder? Its significance lies in its versatility and efficiency. Manufacturers prefer metal forming due to its ability to produce strong, durable, and uniform components. These characteristics are indispensable in sectors like automotive, aerospace, construction, and consumer goods. Moreover, the sustainability aspect of metal forming is noteworthy, as it often involves recycling materials, thereby contributing to a more eco-friendly production cycle.

In the context of a manufacturer's perspective, particularly in the B2B sector, understanding the nuances of metal forming is vital. This process isn't just about altering the shape of metal; it's about precision, efficiency, and creating value for various applications. Whether it's through stamping, forging, extrusion, or bending, each method of metal forming brings its unique advantages to the table, catering to different industrial needs while ensuring quality and consistency.

2.Mechanics of Metal Forming: Stress, Strain, and Deformation

The mechanics of metal forming is a fascinating interplay of stress, strain, and deformation – concepts that are the very backbone of this process. To truly grasp the efficacy and challenges of metal forming, it's essential to understand these fundamental principles.

Stress, in the context of metal forming, refers to the internal forces that particles of a metal exert on each other. This is typically caused by external forces applied during the forming process. Stress is a critical factor in determining the strength and ductility of the metal, influencing how much force can be applied before the metal reaches its yield point or ultimately fails.

Strain, on the other hand, is the measure of deformation a metal undergoes under stress. It's the change in dimensions of the metal — be it stretching, compression, or twisting. Understanding strain is crucial for manufacturers as it dictates the limits to which a metal can be shaped without compromising its structural integrity.

Deformation in metal forming is the actual change in shape or size of the metal under stress. It can be elastic (temporary) or plastic (permanent). Elastic deformation occurs when the metal returns to its original shape after the stress is removed. Plastic deformation is what metal forming aims for, where the shape change is permanent, allowing the creation of new forms and shapes.

3.Thermal Dynamics in Metal Forming: Heat and Its Impact

Thermal dynamics play a pivotal role in the metal forming process, particularly through the influence of heat. Understanding how heat affects metal is crucial for mastering metal forming techniques and ensuring the desired outcome in terms of metal's strength, flexibility, and durability.

Heat significantly alters the properties of metals. During metal forming, applying heat (known as hot working) can increase the metal's ductility, making it more malleable and easier to shape. This process reduces the yield strength of the metal, allowing it to be formed with less force and energy. Hot working is particularly beneficial when dealing with large or complex shapes, or metals that are typically hard and brittle at room temperature.

Conversely, cold working, or shaping the metal at or near room temperature, often results in increased strength and hardness due to strain hardening. However, it requires more force and may not be suitable for all metal types or shapes. Cold working can enhance the metal's structural integrity, making it ideal for applications where durability is key.

The choice between hot and cold working depends on various factors, including the type of metal, the desired properties of the final product, and the specific application. In B2B manufacturing, making the right choice in terms of thermal dynamics can greatly influence the efficiency of production and the quality of the final products.

4.Metal Forming Techniques

4.1 Compressive Stress Forming

Rolling: Rolling involves passing metal through rollers to reduce its thickness. This process is fundamental in creating sheets, plates, and strips of uniform thickness and is essential in numerous manufacturing sectors.

Extrusion: Extrusion is the process of pushing metal through a die to create long objects with a fixed cross-sectional profile. This technique is widely used for producing pipes, tubes, and various structural shapes.

4.2 Die Forming

Forging: Forging involves shaping metal using localized compressive forces. It's known for producing parts of superior strength and is widely used in automotive and aerospace industries.

Indenting: Indenting is a less common but equally important method, where a tool is pressed into the metal to create a shape or a design, often used for decorative or functional embossing.

4.3 Tensile Stress Forming

Stretching: This technique involves elongating the metal to a desired shape and size. It's crucial in applications where large, flat surfaces are needed, such as in the aviation industry.

Expanding: Expanding metal involves stretching it to create a mesh or a lattice-like structure, used in applications like filters or grates.

Recessing: Recessing is a specialized form of metal forming where portions of the metal are pressed inward, often used in creating specific geometries for functional or aesthetic purposes.

4.4 Combined Stress Forming

Techniques in Combined Stress Forming: This category includes methods that utilize a combination of compressive and tensile stresses, like deep drawing. Such techniques are vital in creating complex shapes in a single operation.

4.5 Other Metal Forming Processes

Shearing: Shearing is used to cut large sheets of metal. This process is foundational in metal fabrication and is often the first step in the manufacturing process.

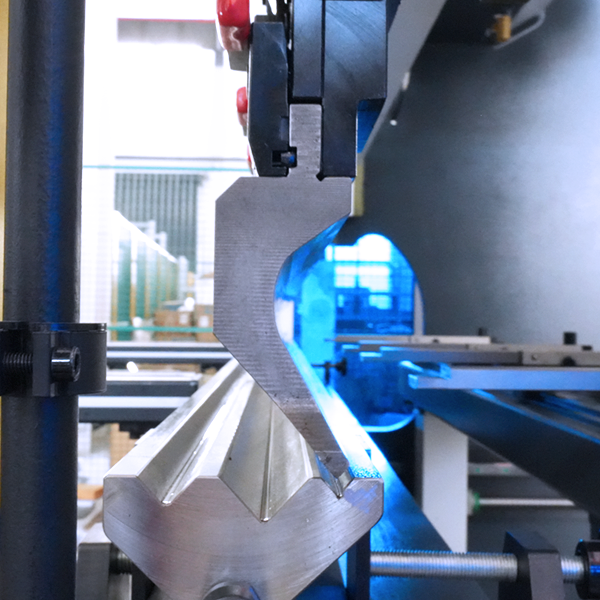

Bending: Bending involves deforming metal around a straight axis, creating a fold, bend, or coil. It's essential in creating angles and channels in metal sheets.

Punching: Punching is a process where a punch and die are used to create holes in metal. This method is frequently used in creating parts for construction and automotive industries.

Laser Cutting: A modern technique that uses lasers to cut metal, offering high precision and control. It's ideal for intricate designs and is increasingly popular in custom manufacturing.

Casting: Casting involves pouring molten metal into a mold where it solidifies. This method is used for making complex shapes that would be difficult or impossible to achieve with other metal forming techniques.

Welding: Welding is the process of joining two pieces of metal together. It's a fundamental technique in metalworking, used across various sectors for constructing and repairing metal structures.

Ironing: Ironing is a finishing process used to smooth and flatten surfaces of metal products. It's particularly useful for achieving fine finishes and precise dimensions.

5.What is the Difference between Hot Working and Cold Working Metal Forming?

What is Hot Working Metal Forming?

Hot working metal forming involves shaping metals at temperatures above their recrystallization point. This process makes the metal more pliable, allowing it to be formed into complex shapes with less force compared to cold working.

Advantages:

- Increased ductility: Metals are more malleable at higher temperatures, facilitating easier shaping and forming.

- Reduced strength and hardness: This makes the metal easier to work with, requiring less energy and force.

- Improved workability for complex shapes: Ideal for creating intricate or large components.

- Reduced residual stresses: Leading to less warping and distortion after cooling.

Disadvantages:

- Higher energy consumption: Due to the need for heating the metal.

- Potential for oxidation: High temperatures can lead to surface oxidation, affecting the metal's properties.

- Stringent environment control: Requires careful temperature management to prevent adverse effects.

What is Cold Working Metal Forming?

Cold working metal forming is the process of shaping metals at or near room temperature. This approach strengthens the metal through strain hardening, making it harder and stronger.

Advantages:

- Increase in strength and hardness: Due to strain hardening, making the metal more durable.

- No heating required: Saves energy and reduces production costs.

- Better surface finish: Cold working often results in a smoother finish, enhancing aesthetic appeal.

- Precise control: Allows for tighter tolerances and better dimensional accuracy.

Disadvantages:

- Increased force requirement: Harder metals require more force to shape and form.

- Limited ductility: Reduced pliability can restrict the extent of deformation without cracking.

- Residual stresses: Can lead to distortion or warping during subsequent processes or uses.

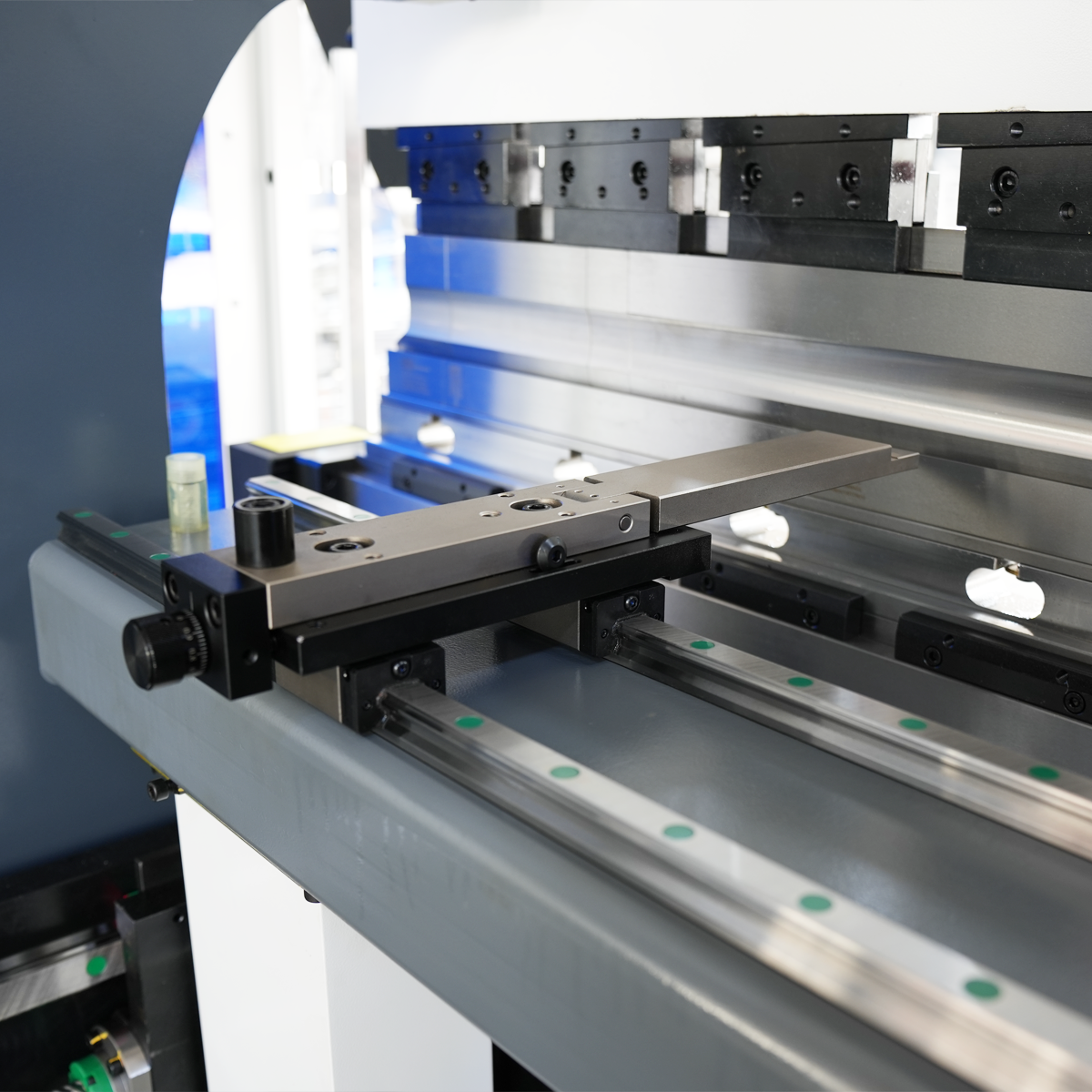

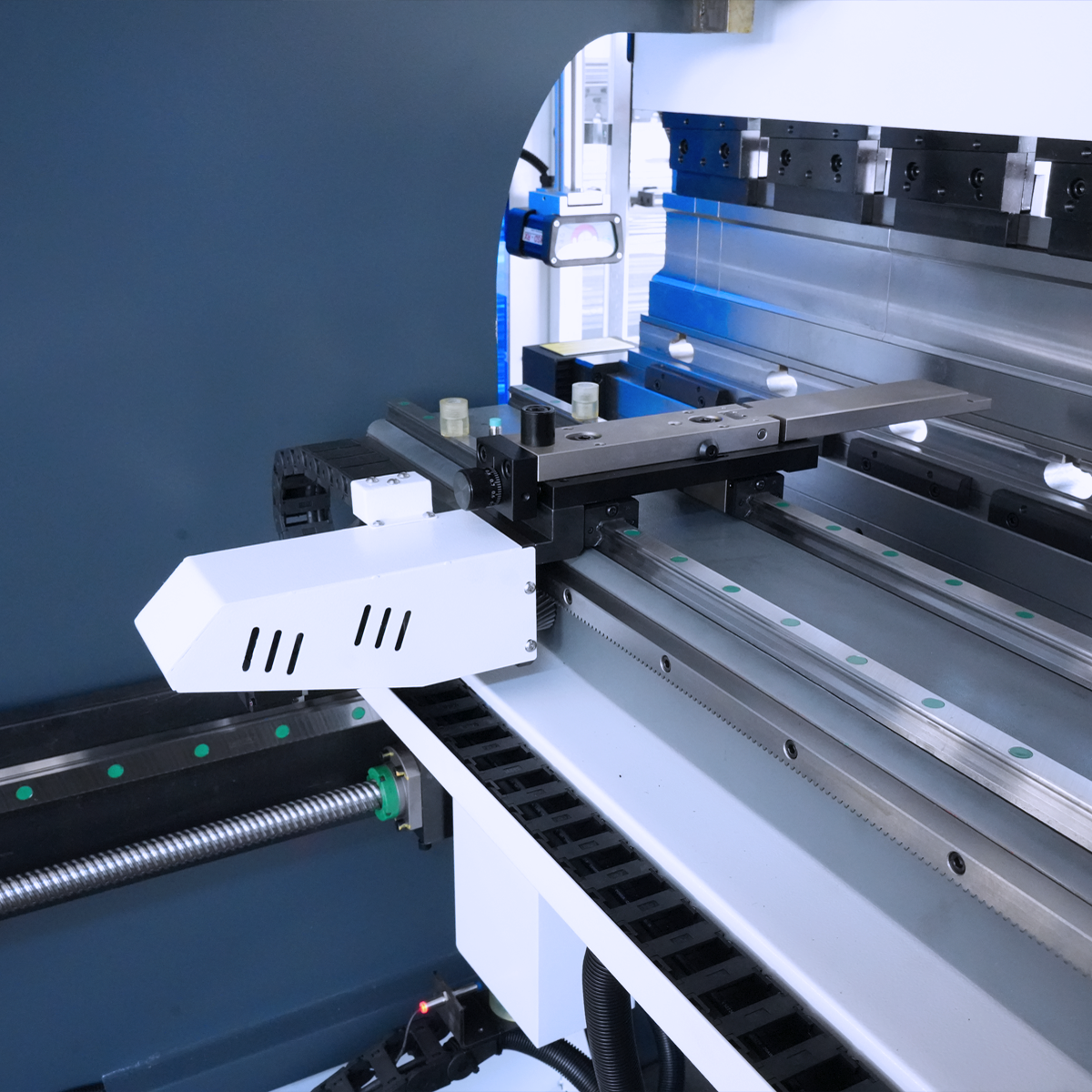

6.What are Metal Forming Tools and Equipment?

In the world of metal forming, tools and equipment play a crucial role in shaping and molding metals into desired forms. These tools and machines vary widely depending on the metal forming process and the specific requirements of the product being manufactured.

Presses: Presses are fundamental in metal forming, used in processes like stamping, forging, and extrusion. They come in various types, including hydraulic, mechanical, and pneumatic, each suited for different applications and force requirements.

Rollers: Rollers are essential for processes like rolling and bending, where metal sheets are passed through rollers to alter their shape or thickness. They can be used for both hot and cold metal forming processes.

Dies and Molds: Dies and molds are custom-made tools that provide the shape and dimensions for the metal during forming processes like die casting, forging, and stamping. Their design is critical for achieving the desired final product.

Shearing Machines: Used primarily in cutting operations, these machines are designed to cut large sheets of metal into smaller, more manageable pieces or specific shapes.

Laser Cutters: For precision cutting, laser cutters are increasingly popular. They offer high accuracy and can create intricate designs, especially beneficial in custom manufacturing.

Welding Equipment: Welding machines are used to join metal parts together, a key process in many metal forming applications, especially in fabrication and construction.

Furnaces: In hot working processes, furnaces are used to heat the metal to the required temperatures. They vary in size and type, depending on the metal and the specific process requirements.

7.Industry Applications

Automotive Industry: Metal Forming Techniques in Car Manufacturing

In the automotive industry, metal forming is integral to manufacturing almost every part of a vehicle. Techniques like stamping, forging, and extrusion are used to create components ranging from engine parts to the car body. Precision and strength are key, as these components must meet strict safety and performance standards. Metal forming in car manufacturing not only contributes to the durability of the vehicle but also to its aesthetic appeal and overall design.

Aerospace Applications: How Metal Forming Shapes Flight

In aerospace, metal forming is essential for creating components that can withstand extreme conditions while maintaining a lightweight profile. Techniques like superplastic forming and hot forming are commonly used to produce parts for aircraft and spacecraft. These processes allow for the creation of complex shapes and designs, which are crucial for aerodynamics and the overall efficiency of the aircraft. The precision and quality achieved through metal forming are critical in an industry where safety and performance are paramount.

Construction and Infrastructure: The Role of Metal Forming

Metal forming finds significant application in the construction and infrastructure sector. It is used to create structural components like beams, frames, and reinforcements. Techniques such as bending, rolling, and welding are essential in shaping metal for construction purposes. These processes ensure that the metal components can bear the weight and stress of buildings and infrastructures, contributing to their stability and longevity. Metal forming in construction not only supports structural integrity but also enables architectural innovation.

8.How to Choose the Right Metal Forming Technique

Choosing the right metal forming technique is a critical decision in the manufacturing process, as it directly impacts the quality, efficiency, and cost of production. Several factors need to be considered to make an informed choice.

Type of Metal: Different metals have different properties, such as ductility, strength, and heat resistance. The choice of metal forming technique largely depends on these properties, as some methods are better suited for certain types of metals than others.

Desired Shape and Complexity: The complexity of the desired shape also dictates the metal forming technique. Some methods, like extrusion and deep drawing, are ideal for complex shapes, while others, like bending and shearing, are better for simpler forms.

Tolerance and Precision Requirements: The required precision and tolerances of the final product are critical. Techniques that offer higher precision, such as laser cutting or forging, might be preferable when tight tolerances are necessary.

Production Volume: The scale of production is another significant factor. High-volume production might benefit from methods that are fast and consistent, like stamping or rolling, while low-volume or custom production might utilize more specialized techniques.

Cost Considerations: Budget constraints play a crucial role in the choice of metal forming technique. Some methods require more specialized equipment and therefore might be more expensive than others.

Environmental and Safety Factors: Environmental impact and safety are increasingly important considerations. Techniques that are more energy-efficient and safer for operators may be preferred choices, especially in a more eco-conscious market.

Choosing the Right Metal Forming Machine

As we conclude our exploration of metal forming, the significance of selecting the right machinery cannot be overstated. For those seeking exceptional quality and reliability in metal forming machines, look no further than Krrass – China’s leading manufacturer in this field. Krrass specializes in providing top-notch metal forming solutions tailored to meet diverse industrial needs. Discover more about their innovative products and how they can enhance your manufacturing process at www.krrass.com. Embrace the excellence of Krrass and transform your metal forming experience.

Read More:

Hydraulic Press Brake Cost: Buying Guide

Press Brake Buying Guide: How to Choose

Tube Laser Cutting vs Fiber Laser Cutting: Which One?

Frequently Asked Questions

What are the most common metals used in metal forming?

The most commonly used metals in metal forming include steel, aluminum, copper, and brass. Each of these metals has unique properties making them suitable for various applications – steel for its strength and durability, aluminum for its lightweight and corrosion resistance, copper for its conductivity, and brass for its malleability and aesthetic appeal.

How do different metal forming techniques compare in terms of efficiency and cost?

Efficiency and cost in metal forming vary greatly depending on the technique used. High-volume techniques like stamping and rolling are generally more efficient and cost-effective for large-scale production. In contrast, techniques like forging and laser cutting, while potentially more costly and time-consuming, offer higher precision and are ideal for specialized or custom work.

What are the major challenges faced in the metal forming industry today?

Key challenges in the metal forming industry include adapting to evolving technologies, meeting increasing quality standards, and managing environmental impacts. The industry also faces the ongoing need to balance cost with efficiency and to address the skilled labor shortage in many regions.

How is technology transforming traditional metal forming processes?

Technology is revolutionizing metal forming through the adoption of automation, advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, and cutting-edge processes like 3D printing. These advancements enhance precision, reduce waste, and improve overall efficiency, enabling more complex and intricate designs with reduced time and cost.