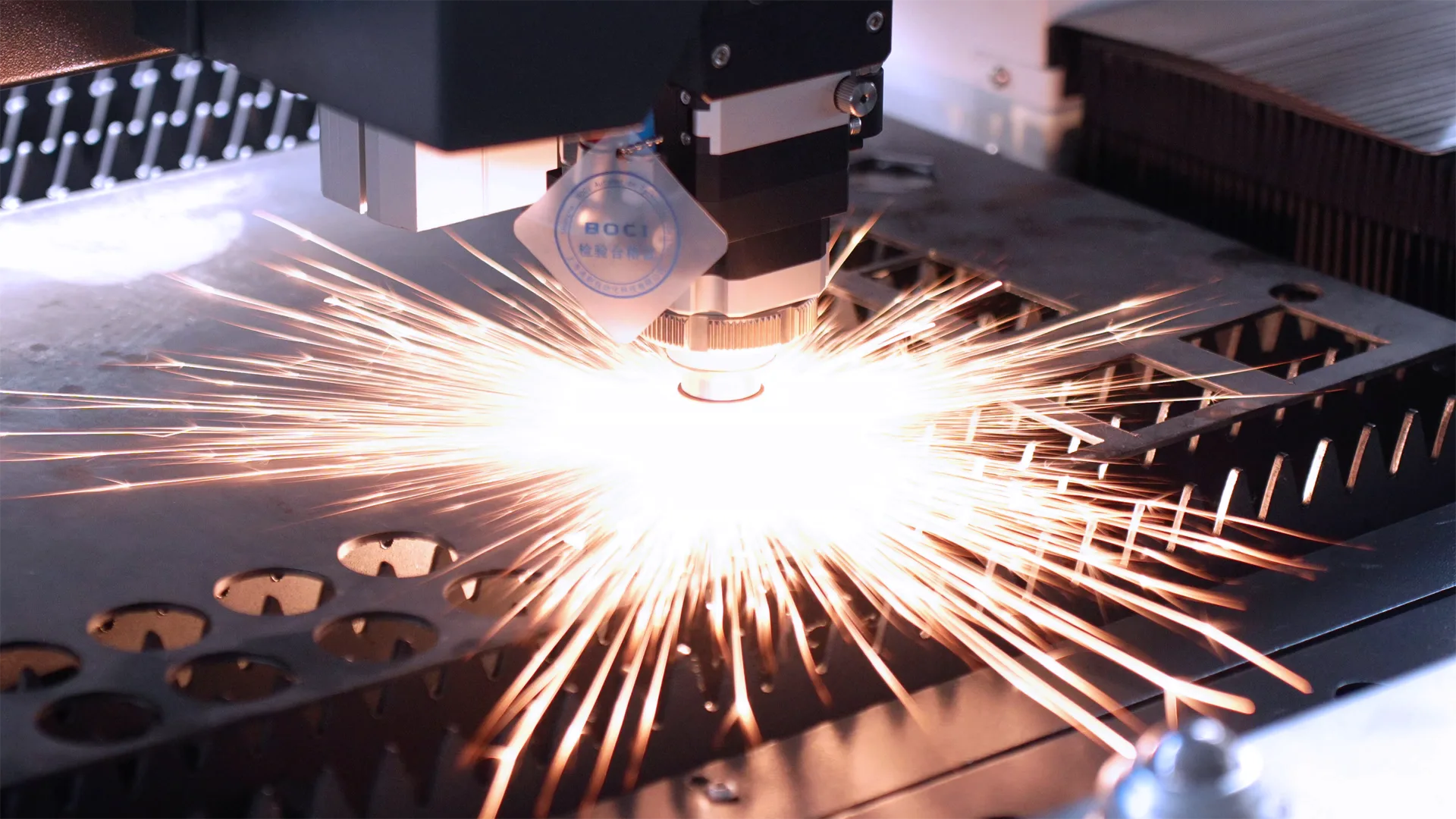

You want the best deal when picking a laser cutting machine supplier in 2026. The market is getting bigger, and you see more choices each year. It is important to compare every laser cutting machine supplier. Your business needs safety, good work, and smart spending. You should look at safety features, warranty details, and how each supplier keeps things safe. The right supplier helps you save money and keep your business working well. They also help you work faster. You may wonder why businesses use laser cutting machines. These machines, like the Fiber Laser Cutting Machine or the 3000W Laser Cutting Machine from KRRASS, work well and are safe for any business. When you compare suppliers, you keep your team and your money safe by checking safety rules and being careful.

Table of Contents

Key Takeaways

Look at prices and features of laser cutting machines. This helps you find the best deal for your business. Think about long-term costs like fixing and running the machine. Do not just look at the first price you see. Pick suppliers who give good warranties and help after you buy. This keeps your money safe. Make sure the machines are built well and use good technology. They should work for what you need to make. Ask if you can change parts of the machine to fit your needs. Read what other customers say and check if the supplier is trusted. Get price quotes from different suppliers. This lets you compare and ask for better deals. Make sure you know what the warranty and service rules are before you buy.

Supplier Comparison Criteria

Price and Value

Upfront Costs

When you look at laser cutting machine suppliers, you first see the price. The cost can be very different. Some entry-level machines cost about $5,000. High-end machines can cost up to $500,000. You want to know what you get for your money. Some suppliers have cheaper machines, especially from China. Premium brands cost more because they have extra features and better support. KRRASS sells the RAS-3015-Smart 3000W laser cutting machine at a good price. This makes it a smart pick for many businesses. Always check what features come with the price. Does the machine have advanced technology, a strong laser source, and a sturdy frame? These things can help you do your work better.

Long-Term Expenses

You should not only look at the first price. Think about what you will pay later. Laser cutting machines need regular maintenance. This can cost $1,000 to $5,000 each year. You also pay for electricity and gas. Some machines use less energy, so you save money over time. When you compare suppliers, ask about service fees, spare parts, and warranty. KRRASS gives a two-year warranty and good after-sales help. This can stop surprise costs. Look for suppliers who are clear about their prices. Ask if they give discounts if you buy more machines.

Tip: Always ask for a list of laser cutting machine prices and costs before you buy. This helps you plan your money and avoid surprises.

Machine Quality

Build and Technology

You want a laser cutting machine that works well for a long time. The build quality is important. Check the frame and gantry material. A strong bed helps you cut straight and true. Advanced technology, like fiber lasers and smart CNC control, makes the machine work better. The RAS-3015-Smart 3000W from KRRASS uses a Max China MFSC 3000W laser source and FSCUT2000E control system. These help you get sharp angles and smooth curves. Always ask about the main parts and how they help the machine work.

Performance and Precision

Performance is very important when you compare laser cutting machines. You want a machine that can cut sharp angles and long lines. It should also cut complex shapes without mistakes. Good machines keep the cut-face smooth, even when working fast. Precision means the machine always returns to the same spot. Features like smart sensors and fast servo motors help a lot. KRRASS machines have these features, so you get good results every time. Ask suppliers for sample cuts and data to see what each machine can do.

| Criteria | Description |

|---|---|

| Technology & Precision | Advanced laser types and accuracy levels. High precision reduces waste. |

| Capacity & Scalability | Handles volume changes and big projects. |

| Cost Structure | Transparent pricing and discounts. |

| Quality Assurance | ISO standards and safety protocols. |

| Customer Support | Responsive service and customization. |

After-Sales Support

Service Availability

After you buy a laser cutting machine, you want help when you need it. Service is important. Some suppliers give 24/7 support and fast spare parts. KRRASS is known for its global service and strong after-sales help. You can get help quickly, so your business keeps running. Always check if the supplier has a local team or remote support.

Training and Maintenance

You need training to use your laser cutting machine safely and well. Good suppliers give training and clear manuals. Maintenance help lets you fix problems fast. KRRASS gives both, so you get the most from your machine. Ask about training and maintenance before you pick a supplier. These things can save you time and money. They also help you avoid problems like downtime or expensive repairs.

Note: Good after-sales support and training help you get the best results from your laser cutting machines.

Warranty and Guarantees

Coverage Details

When you buy a laser cutting machine, you need to know what the warranty covers. Most suppliers give a warranty for important parts like the laser source, control system, and power supply. Some parts, like optics and wear items, are not always covered. Always check the warranty before you buy. Here is a quick look at what you might get:

| Warranty Component | Coverage Scope | Cost Estimation for Repair (Without Warranty) |

|---|---|---|

| Laser Source | Full replacement or repair | $10,000 – $20,000 |

| Control System | Limited coverage | $5,000 – $15,000 |

| Optics | Often excluded | $500 – $2,000 |

| Power Supply | Full replacement | $2,500 – $7,000 |

| Wear and Tear Items | Often excluded | Varies depending on usage |

You want a supplier who gives a two-year limited warranty for all machines. Lifetime customer support helps you feel safe. Some companies, like KRRASS, give a 30-day money-back guarantee. This kind of warranty and return policy makes you feel better about your purchase.

Claim Process

You should know how to use your warranty if something breaks. Ask the supplier about how to make a claim. Some companies make it simple. You contact their support team, tell them your problem, and they help you step by step. Fast help is important. You want your machine fixed quickly so your business does not stop. KRRASS gives clear instructions and quick help for warranty claims. Always keep your purchase papers and warranty documents safe.

Tip: Before you buy, ask for a copy of the warranty and return policy. Read it carefully so you know what is covered and how to make a claim.

Delivery and Logistics

Lead Times

Delivery speed can change your plans. Some suppliers ship machines in a few weeks. Others take months. Ask about lead times before you order. Fast delivery helps you start work sooner. KRRASS ships quickly and keeps you updated about your order.

Shipping Options

You need to think about how your machine will get to you. Some suppliers offer door-to-door shipping. Others use local dealers or third-party services. Make sure the supplier can deliver to your location. Ask if they help with installation and setup. The right shipping option saves you time and trouble. KRRASS offers global delivery and helps you get ready for installation.

- Ask about service availability to keep downtime low.

- Make sure parts can be delivered quickly to avoid delays.

- Prepare your facility for installation and pick a good spot for your machine.

Customization Options

Tailored Solutions

Every business is different. You may need a machine with special features or sizes. Many suppliers let you customize your machine. You can choose the laser power, table size, and control system. KRRASS lets you pick models that fit your needs, like the RAS-3015-Smart 3000W, which works with many materials and thicknesses.

Upgrade Potential

You want your machine to grow with your business. Some suppliers offer upgrades for software, laser power, or automation. This helps you keep up with new technology. KRRASS gives upgrade paths so you can add new features when you need them. Always ask about future upgrades before you buy.

Note: Customization and upgrade options help you get the most value from your laser cutting machine. Pick a supplier who helps your business grow.

Supplier Reputation

When you pick a laser cutting machine supplier, their reputation is important. You want to trust that they will do what they say. A good reputation means you can count on their products and service. There are ways to check a supplier’s reputation before you choose.

Industry Reviews

Industry reviews show how suppliers do in real life. Experts and workers write these reviews. They test machines and share what they think. You can find reviews in magazines, online forums, and industry sites. These places compare features, how well machines work, and support. Sometimes, you see tables that list brands with safety standards like CE or ISO9001. Certifications mean a supplier follows strict rules for safety and quality.

| Supplier Name | Years in Business | Certifications | Industry Awards |

|---|---|---|---|

| KRRASS | 30+ | CE, SGS | Multiple |

| Competitor A | 15 | CE | Few |

| Competitor B | 10 | ISO9001 | None |

You should look for suppliers with lots of experience. If a company has been around a long time, they know how to fix problems. They also know how to keep customers happy. KRRASS has over 30 years in the business and has CE and SGS certifications. These things show that KRRASS cares about quality and safety.

Tip: Always look for certifications and awards. These prove the supplier meets high standards.

Customer Feedback

Customer feedback helps you know what to expect. Real people talk about buying, setting up, and using machines. You can read reviews on supplier websites, social media, and review sites. Look for comments about how fast the machine arrives, how it works, and if the support is good. Good feedback means the supplier cares about customers.

You should notice how suppliers fix problems. Fast help and good support are very important. KRRASS gets praise for quick service and strong after-sales help. Customers often say warranty claims are easy and training is helpful. These things show that KRRASS puts customers first.

- Look for reviews about how well machines work.

- Check for feedback on shipping and setup.

- See if people talk about technical support and training.

If you see lots of good reviews and high ratings, you can feel sure about your choice. Suppliers with good customer reviews and reputation usually give better value and support.

Types of Laser Cutting Machine Suppliers

When you want to buy a laser cutting machine, you have many choices. Each way to buy has good and bad points. Let’s see the main types of laser cutting machine suppliers you can find.

Direct Manufacturers (KRRASS)

Factory Direct Benefits

If you buy straight from a manufacturer like KRRASS, you get some big perks. You do not pay extra to a dealer, so you save money. The machine comes right from the factory, so you know it is made well. You also get strong help after you buy. Here are some reasons people like this choice: You save money because there are no dealer fees. You know the machine is good because it comes from the maker. You get a two-year warranty and a simple return policy. You can talk to the people who built your machine.

Innovation and Quality

Direct manufacturers like KRRASS make new and better machines. They design and build their own laser cutting machines, so you get the newest features. KRRASS gives you machines with smart control systems and strong laser sources. You can trust your machine to work well for a long time. When you buy from a direct manufacturer, you can get upgrades and custom options. This helps your business keep up in a fast-changing market.

Authorized Distributors

Added Services

Authorized distributors work with manufacturers to help you more. They do more than just sell you a laser cutting machine. Distributors give you technical support, help with setup, and fix problems. They make sure you get the right machine for your needs. If you have trouble, they can talk to the manufacturer and help you faster.

Product Range

Distributors have many kinds of laser cutting machines. You can look at different brands and models in one place. Here is what they offer:

| Service Provided | Description |

|---|---|

| Relationship with Manufacturer | Distributors talk to the maker for better help. |

| After-Sale Services | They answer questions and give technical support. |

| Issue Resolution | Distributors help fix problems and talk to the maker for you. |

| Logistics and Storage | They take care of shipping and storage, so it is easier for you. |

| Additional Services | Distributors may install, service, and repair your laser cutting machine. |

Online Marketplaces

Selection and Pricing

Online marketplaces give you lots of choices. You can find many laser cutting machines from sellers around the world. Prices are often lower because sellers compete. You can compare features, prices, and reviews before you buy.

Quality Risks

Buying from an online marketplace can be risky. Not every machine will be right for you. Some sellers may not tell the truth or use cheap parts. It can be hard to get help after you buy, especially if the seller is far away. Always check seller ratings, read about the warranty, and look for sellers with good reviews. Think about shipping costs and how easy it is to get help if you need it.

Tip: When you shop for a laser cutting machine online, pick sellers with good reviews and check what other buyers say.

You have many ways to buy a laser cutting machine. Each way has its own good points. Think about what is most important for your business before you choose.

Local Dealers

Personalized Support

When you walk into a local dealer’s shop, you get a different experience. You talk face-to-face with someone who knows the machines inside and out. Local dealers often remember your name and your business needs. They listen to your questions and help you find the right laser cutting machine for your shop. You do not have to wait for an email reply or a call from another country. You get answers right away.

Local dealers build strong relationships with their customers. They want you to trust them, so they go the extra mile. You might get a demo of the machine right in their showroom. If you have a problem, you can call or visit, and they will help you fix it fast. Many local dealers offer:

- Personalized service and direct relationships that make you feel valued.

- Expert advice based on years of experience with laser cutting machines.

- Quick after-sales support and help with warranty claims.

- Training sessions to help you and your team use the machine safely and efficiently.

- Local presence, so you get faster delivery and setup.

You can count on local dealers to guide you through every step. They help you choose, buy, and use your laser cutting machine. This kind of support builds trust and keeps you coming back.

Limited Selection

While local dealers give you great support, they may not have every machine you want. Their showrooms usually carry a smaller range of brands and models. You might see only a few options on the floor. Sometimes, you want a special feature or a high-powered machine, but the dealer does not have it in stock.

Here’s what you might notice with local dealers:

- Fewer brands and models compared to big online stores or direct manufacturers.

- Limited stock, so you may need to wait if you want a specific machine.

- Some dealers focus on certain brands, which means less variety for you.

- Custom orders can take longer because the dealer must work with the manufacturer.

You should think about what matters most for your business. If you want hands-on help and fast support, a local dealer is a great choice. If you need a wide selection or the latest technology, you might look at direct manufacturers like KRRASS or large distributors.

Tip: Visit your local dealer to see machines in person and ask questions. You get a feel for the machine and the support you will receive.

Local dealers make buying a laser cutting machine easier and more personal. You get expert advice, quick help, and a friendly face every time you visit. Just remember, you may have fewer choices, so weigh your options before you decide.

Advantages and Disadvantages of Buying a Laser Cutting Machine

When you think about buying a laser cutting machine, you want to know what is good and bad. Each supplier type has its own pros and cons. Let’s look at what you get from direct manufacturers, distributors, and online marketplaces.

Direct Manufacturer Pros and Cons

Cost Savings

Buying from a direct manufacturer like KRRASS can help you save money. You do not pay extra fees to dealers. Manufacturers often give good prices and sometimes special deals if you buy more than one machine. For example, KRRASS sells the RAS-3015-Smart 3000W at a price that lets you get high performance without spending too much.

Here’s a simple table about direct manufacturers:

| Benefit | What You Get |

|---|---|

| Lower Prices | No dealer fees, so you pay less. |

| Factory Direct | Machines come straight from the maker, so they are new and reliable. |

| Negotiation Power | You can ask for quotes and compare offers for the best deal. |

You also save on hidden costs. You do not need to pay for extra storage or work with many suppliers. This makes buying easy and saves money.

Support and Warranty

Direct manufacturers usually give strong support and clear warranties. KRRASS gives 24/7 technical help and fast spare parts delivery. If something breaks, you get help quickly. This support can lower downtime by up to 15%, so your business keeps working.

You also get a good warranty. KRRASS gives a two-year limited warranty and a 30-day money-back guarantee. You feel safe because you have backup if you need it. Training and setup help come from the people who built your machine, so you learn fast and make fewer mistakes.

Tip: Always check the warranty and ask about after-sales support before you buy. Good support can save you time and money later.

Distributor Pros and Cons

Service Levels

Distributors help connect you and the manufacturer. They give flexible service and make it easy to get help. If you want different machines or want to see many brands, a distributor can help. They keep machines in stock and can move inventory between warehouses, so you get what you need faster.

Here’s a table to show how distributors and direct manufacturers compare:

| Aspect | Distributors | Direct Manufacturers |

|---|---|---|

| Service Levels | Flexible, easy access, handle complex orders | Direct, but may have longer lead times |

| Inventory | Keep safety stock, shift between warehouses | Need accurate forecasting |

| Cost Structure | Add markup for storage and support | Lower cost per unit, but possible hidden costs |

| Risk Management | Adjust to demand, offer payment terms | Less flexible with demand changes |

| Best For | Small, frequent orders, variety of products | Large, consistent orders |

Distributors also help with installation, training, and repairs. You get everything you need in one place.

Pricing Differences

Distributors make things easier, but you usually pay more. They add extra costs for their services, storage, and support. Sometimes, this is worth it because you get more help and faster delivery. But if you want the lowest price, direct manufacturers are usually better.

If you need many machines or want to avoid working with lots of suppliers, a distributor can be a smart choice. Just remember to compare prices and ask about all the fees.

Marketplace Pros and Cons

Variety

Online marketplaces give you lots of choices. You can look at machines from all over the world and compare prices, features, and reviews. This helps you find something that fits your needs and budget. You might even find a great deal on a machine you did not know about.

- You get many brands and models.

- You can read reviews from other buyers.

- You can compare prices quickly.

Quality Control

The downside is that quality can be different. Some sellers may not tell you everything about the machine. You might get a machine that looks good online but does not work well. Support and warranty can also be hard to get. If you have a problem, it might take longer to get help or a replacement.

Always check seller ratings and read customer reviews before you buy. Look for sellers who give clear warranties and easy returns.

Quick Recap: What You Gain and What You Risk

When you look at the advantages and disadvantages of buying a laser cutting machine, you see each supplier type has good and bad points:

- Direct Manufacturers: Save money, get strong support, and clear warranties. You work with the maker, like KRRASS, and get the newest technology.

- Distributors: Get flexible service, easy access to many brands, and help with installation and repairs. You pay a bit more for these extras.

- Marketplaces: Find lots of choices and compare prices fast. Watch out for problems with quality and support.

No matter which way you choose, always think about the pros and cons of buying a used or new laser cutting machine. Think about what matters most for your business—price, support, variety, or speed. This helps you make the best choice for your needs.

Local Dealer Pros and Cons

Immediate Support

If your laser cutting machine stops, you want help fast. Local dealers can help you right away. You can go to their shop and talk to someone who knows your machine. They help with setup, training, and fixing problems quickly. Local dealers often remember your name and what your business needs. They work hard to build strong relationships with you.

You get these benefits from local dealers:

- Personalized service and a real connection to your community

- Ongoing support and quick solutions for problems

- Local market expertise that helps you choose the right machine

- Flexible negotiation on pricing and service packages

- Quality-focused inventory with machines that fit your needs

You feel safe knowing help is close. If you need a part or have a question, you get answers fast. You do not have to wait for an email or a call from far away.

Tip: Go to your local dealer for a hands-on demo. You can see the machine working and get advice that fits your shop.

Higher Costs

You pay more for the help and service local dealers give. Their inventory is smaller than big stores or online shops. Sometimes, you see fewer brands or models. Local dealers set their own prices, so costs can change. You might pay extra for quick help and personal service.

Here’s a quick look at what you might notice:

| Pros | Cons |

|---|---|

| Fast, local support | Smaller inventory |

| Personalized relationships | Higher prices |

| Community expertise | Varying quality standards |

| Flexible negotiation | Less standardization in experience |

You get expert help and peace of mind, but you may spend more at first. Some dealers focus on good service and quality, but others may not be as good. Always ask about warranty, training, and support before you buy.

If you want quick help and a friendly touch, local dealers make buying easier. Just remember to check prices and choices so you get the best deal for your business.

Evaluating Your Needs Before Buying

Budget Planning

Cost vs. Features

When you want a laser cutting machine, you must think about money. Prices change a lot depending on type, power, and features. Some machines cost less but do not have many features. Others have more options, but they cost more.

- Compare the first price with how much you save later.

- Add shipping, setup, and training to your budget.

- Try to find deals or used machines to save money.

Remember, there are hidden costs too. You might pay more for extra parts or special features after you buy. Always check everything before you decide.

ROI Considerations

Your laser cutting machine should help your business grow. Think about how quickly you can earn back what you spend. If your machine works faster or cuts more things, you finish more jobs and make more money.

- Plan for regular care and future costs.

- Add staff training and supplies to your budget.

- Save money for learning new things about the machine.

A good machine with the right features can pay for itself fast. KRRASS machines help you get good value for your money.

Technical Requirements

Material Compatibility

You need to know what things you will cut. This is very important when you buy a laser cutting machine. Some machines work best with metals like steel or aluminum. Others can cut plastic or wood.

Safety is very important when you buy a laser cutting machine. Laser radiation can be dangerous and can hurt you badly or even cause death if you do not use safety rules. Make sure your machine has safety features like a laser interlock system and emergency stop buttons.

Here are some laser types and what they do:

- CO2 lasers cut thick metals and non-metals.

- Fiber lasers work well for thin and medium metals.

- Diode lasers are good for marking and engraving.

To pick the right laser, make a list of the materials and thicknesses you want to cut most.

Production Volume

Think about how much work your machine will do. If you get lots of orders, you need a machine that works fast. Look at the cutting speed, bed size, and power. More power means faster cutting and thicker materials.

- Pick a machine with a bed size that fits your materials.

- Make sure the software is easy and works with your designs.

- Check the speed, accuracy, and if it can do the same job again and again.

To choose the right laser, match your work needs with what the machine can do. KRRASS has machines for small and big jobs, so your business can grow.

Service Expectations

Support Response

You want help quickly if your laser cutting machine breaks. Good after-sales service is very important for buyers. Fast support keeps your business working and stops long delays.

| Service Feature | Why It Matters |

|---|---|

| Local Service Centers | Get help when you need it |

| Service Level Agreements | Know how fast you get support |

| Field Service Footprint | Quick fixes protect your machine |

Clear deals with your supplier help you feel safe. KRRASS has a strong support team and local helpers in many places.

Training Needs

You and your team must know how to use your laser cutting machine safely. Good training helps you avoid mistakes and keeps everyone safe.

- Ask if your supplier gives training classes.

- Look for easy manuals and guides.

- Make sure you know how to use all safety features.

To help the environment, buy a laser cutting machine that uses less energy and follows air rules. For example, pick a machine with a dust collector to lower dust and fumes in the air.

When you plan for training, your team works better and safer. KRRASS gives training and support, so you get the most from your machine.

Long-Term Costs

Maintenance

After you buy a laser cutting machine, you must think ahead. Maintenance helps your machine work well and stops big problems. You will need to change parts like filters, lenses, and belts. These parts get old and stop working right. If you skip maintenance, your machine can break and cost more money. Regular checkups help you find problems early. This saves time and keeps your business running.

Safety is very important for maintenance. Always follow safety rules from your supplier. Clean your machine and look for loose wires or broken parts. If you find something wrong, fix it fast. A clean and safe machine works better and keeps people safe. Train your team to use the machine carefully. Good training means fewer accidents and better work.

Here are some long-term costs you should know:

- Depreciation: Your machine loses value every year. This changes how much you can sell it for later.

- Expected Machine Lifespan: If you care for your machine, it lasts longer. You can plan when to buy a new one.

- Consumables and Spare Parts: You need to buy new parts often. This keeps your machine working well.

- Material Waste and Efficiency: If your machine uses materials well, you spend less. Efficient machines help you save money.

Upgrades

Technology gets better quickly. You want your laser cutting machine to have new features and work faster. Upgrades help your machine do more jobs. You can add new software, stronger lasers, or better control systems. These upgrades make your machine faster and able to cut more things.

Safety is important when you upgrade your machine. Always check if new parts or software are safe. Ask your supplier about safety in upgrades. Some upgrades add new safety systems, like better emergency stops or shields. Never skip safety checks when you add upgrades.

Upgrades help your machine stay useful. If your machine gets old, it may not work with new jobs. Upgrading keeps your business ready for new work. You also protect your money and keep your machine valuable.

Tip: Think about upgrades when you buy your machine. Ask your supplier, like KRRASS, about future upgrades and safety. This helps you get the most from your machine.

Practical Tips for Choosing a Laser Cutting Machine Supplier

Requesting Quotes

RFQ Essentials

Start by asking for a quote in a clear way. Make a list of what you need in a laser cutting machine. Write down the type, power, bed size, and what materials you want to cut. Fiber lasers are best for cutting metals. CO2 lasers work well for wood and plastic. Try not to pick old models that break down a lot. Ask each supplier about their warranty and service. Brands like KRRASS and Bodor usually give better help.

Comparing Offers

When you get quotes, look at them side by side. Here is how you can do it: First, set your budget and decide how much you want to spend. Next, look at different brands and models. Check their features and prices. Think about what you need to cut and match the machine to your jobs. Get quotes from a few suppliers to see who gives the best deal. Remember to check long-term costs like repairs, maintenance, and energy use.

You can make a table to keep track of your choices. Write down the price, warranty, service, and extra features for each machine. This makes it easier to pick the right one.

Service Agreements

Support Levels

Service agreements are important when you buy a laser cutting machine. You need to know what kind of help you will get. Some suppliers let you call for help or get support online. Others give regular checkups to keep your machine working well. Some plans cover repairs and parts for a set yearly fee. Condition monitoring helps find problems early. Software agreements keep your machine updated.

| Service Agreement Type | Key Features |

|---|---|

| Remote Service Agreement | Unlimited hotline and remote support; quick problem solving. |

| Maintenance Service Agreement | Regular checkups, technical hotline, and documentation. |

| Performance Service Agreement | Fixed annual rate for maintenance, repairs, and parts. |

| Condition Monitoring | Proactive checks to reduce downtime. |

| Software Service Agreement | Latest updates and expert support. |

Warranty Terms

Always read the warranty before you buy a laser cutting machine. Look for coverage on the laser source, control system, and main parts. Good suppliers make their warranty rules clear and easy to use. KRRASS gives a two-year warranty and a 30-day money-back promise. This helps you feel safe when you buy.

Tip: Ask for a copy of the warranty and service agreement. Read it so you know what is covered.

Checking Reviews

Reference Verification

You want to trust your supplier. Check their background and see how long they have sold laser cutting machines. Good companies have a strong reputation and many happy customers.

Learning from Others

Read reviews from other buyers. Look at ratings and comments online. Pay attention to both good and bad reviews. This helps you see how the supplier fixes problems and helps customers. Reviews help you spot problems before you buy. You learn from what others say and make a better choice.

Note: Visit the KRRASS website and product pages for more details and customer stories. This helps you see real results from their laser cutting machines.

Negotiating Terms

Price Strategies

You want a good deal for your laser cutting machine. You can save money by negotiating smartly. First, look up prices from different suppliers. If you know what other companies charge, you can use that to help you. Talk about similar machines when you speak to suppliers. This shows you know what is fair.

Try asking for more than just a lower price. You can ask for free upgrades or extra help. Suppliers might give you training, spare parts, or software updates for free. If you want to buy more than one machine, ask for a discount for buying in bulk. Suppliers like KRRASS often give better deals for bigger orders.

If you can pay quickly or with cash, offer that. Many suppliers give discounts for fast payments. You can start with a low offer and slowly raise it while asking for more extras. If you see any problems or missing features, use those to ask for a lower price.

Here are some tips for negotiating:

- Check what other suppliers charge before you start.

- Ask for upgrades or extra help together.

- Request a discount if you buy more than one machine.

- Offer to pay quickly for better terms.

- Point out problems to ask for a lower price.

- Be ready to leave if the deal is not good for you.

Tip: Always ask for papers like maintenance logs and service history. Ask for a live demo or a sample cut to see how the machine works. If you are spending a lot, think about hiring an expert to check the machine.

Payment Options

How you pay can change your buying experience. Suppliers have different ways to pay that fit your budget. Some let you pay everything before you get the machine. Others let you pay in parts over time. You might pay 30% first and the rest after delivery. Payment plans help you manage your money and lower your risk.

Talk about shipping costs and make sure you understand them. Sometimes shipping is included in the price. Other times, you pay extra. Ask about payment plans that protect you from surprise fees. Negotiate warranty terms for important parts like the laser source and control system.

Use a table to compare payment choices:

| Payment Option | Description | Benefit |

|---|---|---|

| Full Upfront Payment | Pay everything before you get the machine | You might get a discount |

| Installment Plan | Pay in smaller parts over time | Easier for your budget |

| Down Payment + Balance | Pay some first, rest after delivery | Less risk for you |

| Letter of Credit | Bank promises payment after delivery | Safer for both sides |

Write a clear contract with your supplier. Include return rules, warranty details, and software licenses. Suppliers like KRRASS give clear agreements to protect everyone.

Note: Always read the payment rules and contract closely. If you do not understand something, ask your supplier before you sign.

You should look for the best deal when you buy a laser cutting machine. Comparing suppliers helps you find machines that last, good help, and fair prices. Use the advice in this guide to make smart choices. If you want new ideas and trust, KRRASS is a great choice. Read reviews, ask questions, and check features before you pick. Start now—do your research, compare options, and pick the supplier that works for your business.

FAQ

What materials can a KRRASS laser cutting machine handle?

You can cut steel, aluminum, brass, copper, and titanium. The machine works with thick and thin pieces. Always check your model’s specs for the best results.

How long does it take to get my machine after I order?

Most orders arrive in a few weeks. KRRASS tells you when your machine will ship. You can ask for tracking details anytime.

Do I need special training to use a laser cutting machine?

Yes, you need training to use the machine. KRRASS gives training and easy guides. This helps you stay safe and get good results.

What kind of warranty does KRRASS provide?

You get a two-year limited warranty for your machine. KRRASS also gives a 30-day money-back guarantee. You can contact support if you have warranty questions.

Can I upgrade my laser cutting machine later?

You can upgrade many parts, like software or laser power. KRRASS lets you add new features as your business grows.

How do I get help if my machine stops working?

You can call or email KRRASS support for help. They give 24/7 help and send spare parts fast. You get quick answers to keep your business running.

What should I look for when comparing suppliers?

Check price, machine quality, after-sales support, warranty, delivery time, and customer reviews. KRRASS does well in all these areas.

Where can I find more information about KRRASS machines?

Visit the KRRASS official website. You can see product details, customer stories, and contact information.