Press brakes are machines that greatly enhance the speed and quality of metal fabrication and processing. That is why they are commonly found in metalworking workshops. However, professionals who are new to this technology often question the advantages of using a press brake. In this article, we will explore these advantages in detail and examine how press brakes can benefit various industries.

Overview of Press Brakes

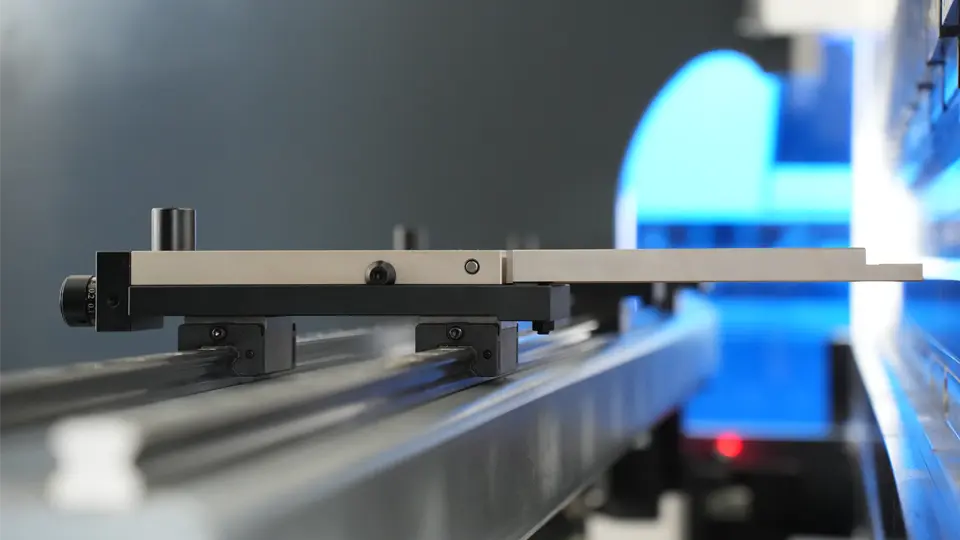

A press brake is a machine designed for bending metal, whether it be sheet metal or metal plates. The bending process is achieved by applying force to the clamped workpiece using a V-shaped die. Press brakes can have different movement mechanisms, including hydraulic, manual, and electrical.

Advantages of Press Brakes

Press brakes offer numerous benefits compared to alternative processes like folding and panel bending for sheet metal. Some of the advantages of using press brakes include:

- Waste Reduction: Press brakes provide accurate metal bending, helping to minimize waste and eliminate rejections.

- Smart Technology: CNC press brakes offer advanced automated solutions for metal bending, making them highly efficient and intelligent machines.

- Increased Production Speed: Press brakes streamline the production process by combining automated processing with reduced defects, resulting in faster production.

- Easy Operation: Press brakes are user-friendly and do not require highly skilled operators like some other machines, making them easy to operate.

- Reduced Labor Costs: Automated press brake machines reduce labor costs, thereby lowering the overall cost per part.

- Improved Safety: Modern press brake machines come equipped with safety measures like laser sensors, which halt the metal fabrication operation when the operator is at risk of harm.

- In-house Manufacturing: Traditional metal fabrication workshops often outsource the bending process to third parties. However, modern press brakes are affordable, enabling workshops to perform the entire manufacturing process in-house.

- Versatility: Modern press brakes can handle various shapes of bends and can bend sheet metal of different thicknesses without requiring frequent setup changes, thanks to automated thickness detection software.

- Programmability: Press brakes can be easily programmed to make changes to the setup parameters, eliminating the need for manual adjustments by the operator.

- Complex Bends: With the use of different types of dies and modified programming, modern press brakes can create complex bends such as cones.

- Affordability: Simple press brakes are cost-effective machines, allowing even small-scale metal fabrication shops to install them in their facilities.

- Wide Range of Options: There are many types of press brake machines available to suit different requirements, ensuring that you can find a machine that meets your specific demands.

- Seamless Workflow: CNC press brakes can seamlessly integrate into the assembly line of your metal fabrication workshop.

Are There Any Disadvantages to Press Brakes?

While press brakes are excellent for bending sheet metals, they do have certain disadvantages for certain users. These potential disadvantages include:

- Cost: Press brakes with automation come with a significant price tag, which can deter small workshops from investing in high-end models.

- Training: Although press brakes do not require the same level of skill as some other metalworking machines, operators still require some training on the technology, leading to additional training costs.

- Space Requirements: Press brakes can be large machines, requiring a considerable amount of workshop floor space.

- Maintenance: Like all industrial equipment, press brakes need regular maintenance to prevent breakdowns. Failure to maintain them properly can lead to machine malfunctions.

- Noise: Press brakes generate a significant amount of noise during operation, necessitating the use of ear protection equipment for the workforce. They can also cause vibrations in the workplace.

Different Types of Press Brakes and Their Advantages

There are various types of press brakes, each offering specific benefits based on the applications. These types include:

- Mechanical Press Brake: These press brakes use a flywheel mechanism operated by electrical motors to move the bending ram. They have a simple mechanism, are beginner-friendly, and are cost-effective to maintain and repair. They also have a high bending capacity.

- Hydraulic Press Brake: Hydraulic press brakes generate force using water pressure instead of a mechanical system like a flywheel. They offer a higher degree of customization and superior precision in bending.

- Servo-electric Press Brake: Servo-electric press brakes utilize servo motors and a belt and pulley mechanism for moving the bending die. They have a simple setup, easily fixable parts like servo motors, and cost-effective bending operations. The absence of a hydraulic mechanism eliminates the risk and cost associated with oil leakage.

- CNC Press Brake: CNC press brakes employ Computer Numerical Control for automated bending processes. These modern machines can have either a hydraulic or electrical movement system, and the movement is controlled through CNC programming. The benefits of CNC press brakes include automation in the bending process, remote adjustment of setup parameters, and integration into the assembly line. Changes to bending values can be made by adjusting the values in the programs.

- Tandem Press Brake: A tandem press brake consists of multiple smaller press brake machines working together. These smaller individual press brakes are coupled to bend large workpieces or create consistent bends in smaller workpieces. The advantages of a tandem press brake include the ability to bend sheet metal with lengths up to 60 feet, faster bending for large volume parts requiring the same bending angle, and lower cost compared to building a single large press brake.

- Pneumatic Press Brake: Pneumatic press brakes utilize air pressure to move the bending die, similar to hydraulic press brakes but replacing liquid pressure with air pressure. They provide high-speed operation for bending small-scale parts, have no risk of oil leakage, and have low maintenance requirements.

How to Get the Most Out of a Press Brake?

To maximize the benefits of a press brake, consider the following tips:

- Choose the Right Press Brake: Select a press brake that is ideal for your specific requirements. For complex bends, a multi-axis CNC press brake is recommended. Tandem press brakes are suitable for bending large sheet metal, while a 3-4 axis CNC press brake with automation is ideal for simple bends. Custom press brakes are available for niche applications.

- Focus on Build Quality: Opt for a press brake with a good build quality, as it needs to withstand the heavy punching of sheet metals. Compromising on build quality to save costs can result in machine breakdowns and potential injuries to workers.

- Consider Bending Capability: Ensure that the press brake you choose can handle the bending requirements of your sheet metal. Hydraulic and pneumatic machines have lower punching force and may not perform well for heavy-duty applications.

- Be Patient: Achieving precise results with a press brake may require some time and practice. Invest time in learning the machine before using it for projects directly.

Who Benefits from a Press Brake?

Manufacturers and metal fabrication workshops seeking modern machines to produce complex parts in-house benefit the most from press brakes. Press brakes provide a cost-effective solution for the metal bending process in metal forming. Machines like KRRASS's CNC press brake machines take it a step further by reducing overall labor costs while ensuring correct angle bends.

In conclusion, press brakes offer more advantages and applications than any other alternative in metal fabrication. They are widely used across various industries, from small workshops to large manufacturing facilities. With the added automation of modern technology, CNC press brakes can achieve precise angle bends without human intervention, making them a valuable investment for the metal fabrication industry.

KRRASS: the best choice for

all sheet metal processing manufacturers

When considering the overall costs of purchasing, maintaining, and operating a sheet metal equipment setup, a sheet metal fabrication service: KRRASS brand is your best choice. KRRASS has a tremendous reputation in the market due to its focus on consistency and quality at the most competitive price. Whether it's press brake or any other application equipment, our team of experts has the right combination of industry knowledge and the latest tool to provide you with the best products and services on the market. Moreover, we set ourselves apart with our advanced system that is completely online. Just let us know what your product needs, request a quote, and start the process.

Make a request and Get Started Today

Get Instant Quote

Learn more about our products, please visit and subscribe to our Youtube channel