To choose the right press brake, users need to align machine features with their specific requirements for metal forming. Every material type and thickness should be considered before selecting a CNC press brake. Many companies report improved performance after choosing the right machine:

- New press brake technology can enhance production speed by up to 30%.

| Factor | Impact |

|---|---|

| Material Thickness | Thicker materials require more force and specialized tools for optimal bends. |

| Bend Radius | The flexibility of the metal affects the smallest bend achievable without cracks. |

| Springback | The type of material influences how closely the bend angle matches the desired specification. |

| Tooling Selection | The appropriate tools facilitate precise bends and extend tool longevity. |

| Calibration | Regular machine checks ensure consistent bending accuracy. |

KRRASS provides solutions for every metal forming need.

Table of Contents

Key Takeaways

- Know what kind of material you have and how thick it is. This helps you figure out how much force and which tools you need for bending.

- Pick the right tonnage for your press brake. Make sure the machine’s power matches the job. This stops damage and makes sure bends look good.

- Think about the bend length. Choose a press brake that can handle the longest part you will bend.

- Choose the right tooling. Good dies and punches make better bends and help tools last longer.

- Focus on precision. Use CNC controls to make bends more accurate. This cuts down on waste and helps parts fit better.

- Check space and power needs. Make sure your shop has room for the machine and enough electricity.

- Look at the vendor’s reputation and support. A good vendor gives great service and fixes problems fast.

- Think about long-term costs. Remember energy use, maintenance, and tool costs when picking a press brake.

Press Brake Basics

What Is a Press Brake

A press brake is a machine that bends sheet metal. Factories and workshops use it to make parts for many industries. The machine uses a punch and a die to shape metal sheets. It can make angles or curves. Operators set the machine for each job to get different bends.

Press brakes are important in modern manufacturing. They help shape metal for cars, airplanes, buildings, and furniture. Many companies need press brakes to make strong and accurate parts. The machine works with many metals like steel, aluminum, and stainless steel.

Tip: Picking the right press brake saves time and cuts waste.

The main jobs of a press brake are:

| Function | Description |

|---|---|

| Bending | The press brake bends metal sheets into exact shapes and angles. This is important for making metal parts. |

| Precision | It uses punches and dies with high pressure to make exact bends. |

| Versatility | It can do many bending jobs at different angles for many industries. |

Press brakes help many industries:

- Car makers use press brakes to shape car panels.

- Airplane companies make parts like wings and fuselages.

- Builders use them for metal frames and supports.

- Furniture makers create frames and decorations.

- Food and chemical companies make metal containers for storage.

How It Works

A press brake works by pressing a punch into a metal sheet on a die. The punch goes down with force and bends the metal to match the die. Operators can change the punch and die to get different shapes and angles.

Modern press brakes often use computer controls. These controls help set the right force and position for each bend. CNC systems make bends precise and repeatable. This technology lowers mistakes and helps companies make the same part over and over.

The steps are:

- The operator puts the metal sheet on the machine.

- The punch moves down and presses the sheet into the die.

- The metal bends to match the die’s shape.

- The operator takes out the bent part and repeats if needed.

Press brakes can bend one piece of metal many times. This makes them good for making complex parts. Companies pick press brakes for their accuracy, speed, and flexibility in metal forming.

Types

Mechanical

Mechanical press brakes use a flywheel that runs on electricity. The flywheel saves energy and lets it out to move the ram down. Operators use levers or buttons to control the machine. This press brake is good for bending thick metal sheets. It gives the same force each time it bends.

Mechanical models are easy to understand. People must change settings by hand for each job. These machines are not great for tricky bends. Many shops use them for simple jobs that need strong force. You will often find mechanical press brakes in older factories.

Note: Mechanical press brakes are best for jobs that need a lot of force and do not need many changes.

Hydraulic

Hydraulic press brakes use fluid pressure to move the ram. Oil is pumped into cylinders, which pushes the ram down onto the metal. This way, the ram moves smoothly and is easy to control. Operators can change the pressure for different metals and thicknesses.

Hydraulic models can bend thick metal and do heavy jobs. They are good at making many kinds of bends. Shops use them for both easy and hard parts. Hydraulic press brakes need to be checked often to stop leaks.

| Type of Press Brake | Operation Description | Key Characteristics |

|---|---|---|

| Hydraulic Press Brakes | Work with fluid pressure to move the ram. | Bend thick metal, heavy jobs, precise, use more energy. |

| Mechanical Press Brakes | Use a flywheel with electricity to make force. | Simple to use, thick sheets, need hand changes. |

| Electric Press Brakes | Use servomotors for energy savings and automation. | Automated, tricky jobs, not for heavy work, cost less. |

Hydraulic press brakes use more power than other types. They use about 60 kWh each day. This makes them less good for shops that want to save energy.

Electric

Electric press brakes use servomotors to move the ram. These motors help control speed and where the ram stops. Operators can set up the machine for different bends. Electric models are good for jobs that need to be very exact.

Electric press brakes use less power than hydraulic ones. They use about 12 kWh each day. This helps shops save up to 80% on energy bills. Electric models are also quiet and do not need much fixing.

- Electric press brakes are good for jobs that need to be very exact.

- They work best with thin metal and small jobs.

- Shops can use electric models to do many steps by themselves.

KRRASS has electric press brakes with smart controls. These machines help shops work faster and spend less money. The MB8 Series has electric and hybrid choices for different needs.

Tip: Electric press brakes help shops save money on power and make better bends.

Hybrid

Hybrid press brakes use both hydraulic and electric systems. Electric motors move the machine parts. Hydraulic power gives the strong force needed to bend metal. This makes the machine fast and powerful. Operators pick hybrid models when they need both power and accuracy.

Hybrid press brakes help save energy. The electric system moves the ram to the right spot. The hydraulic part only works when force is needed. This setup uses less energy and makes less heat. Many factories buy hybrid models to save money.

KRRASS sells hybrid press brakes in the MB8 Series. These machines have smart controls. Operators can set the bend angle and force easily. The machine changes settings for each job. Shops use hybrid models for many metals and thicknesses.

Hybrid press brakes help companies use less energy and work faster.

Hybrid models are good for shops that want to save money and get exact bends. The machine can bend thick or thin metal. Operators can change jobs quickly. Hybrid press brakes are also quieter than old machines.

| Feature | Hybrid Press Brake |

|---|---|

| Power Source | Electric motors and hydraulic pumps |

| Energy Use | Low |

| Precision | High |

| Speed | Fast |

| Noise Level | Low |

| Best For | Mixed jobs, energy savings |

KRRASS hybrid press brakes work with NC and CNC controls. These controls help operators make perfect bends. The machines also have safety features. Shops use hybrid models to make car parts, building frames, and furniture.

Tandem

Tandem press brakes use two or more machines together. Operators connect the machines to bend long or wide metal sheets. Each machine works at the same time. This setup gives strong force and can bend big parts.

Factories use tandem press brakes for large jobs. The machines bend beams, panels, and frames. Operators control both machines with one system. This keeps all the bends straight and even.

KRRASS has tandem press brake solutions. The MB8 Series can work as a tandem system. Operators use smart controls to set up both machines. The system checks each bend to make sure it is right. Shops use tandem models for bridges, trucks, and big containers.

Tandem press brakes help companies finish big jobs faster. They keep parts straight and lower mistakes.

Tandem models are good for shops with space for big machines. Operators need training to use tandem systems. KRRASS gives help and safety features for these setups.

| Feature | Tandem Press Brake |

|---|---|

| Machine Count | Two or more linked |

| Bend Length | Very long |

| Force | High |

| Control | Centralized |

| Best For | Large parts, heavy jobs |

KRRASS tandem press brakes help shops do tough jobs and grow. The machines keep parts accurate and strong. Operators trust KRRASS for good machines and support.

Choose the Right Press Brake

Material and Thickness

Shops need to think about material type and thickness first. These things decide how much force and what tools are needed. Operators often use mild steel, stainless steel, or aluminum. Each metal bends in its own way. Thicker sheets need more force and special dies.

Key things to look at are:

- Tonnage: The press brake must give enough force for the metal and thickness.

- Length of the Material: The machine should fit the longest sheet for the job.

- Daylight or Open Height: Taller openings let you work with bigger parts and more tools.

- Deflection: Big machines can bend under heavy loads, which can hurt accuracy.

Shops that bend thick stainless steel need more force and strong tools. Shops that bend thin aluminum can use less force and lighter dies. KRRASS has machines with smart controls. These controls help set the right force for each job. This makes work safer and faster.

Tonnage

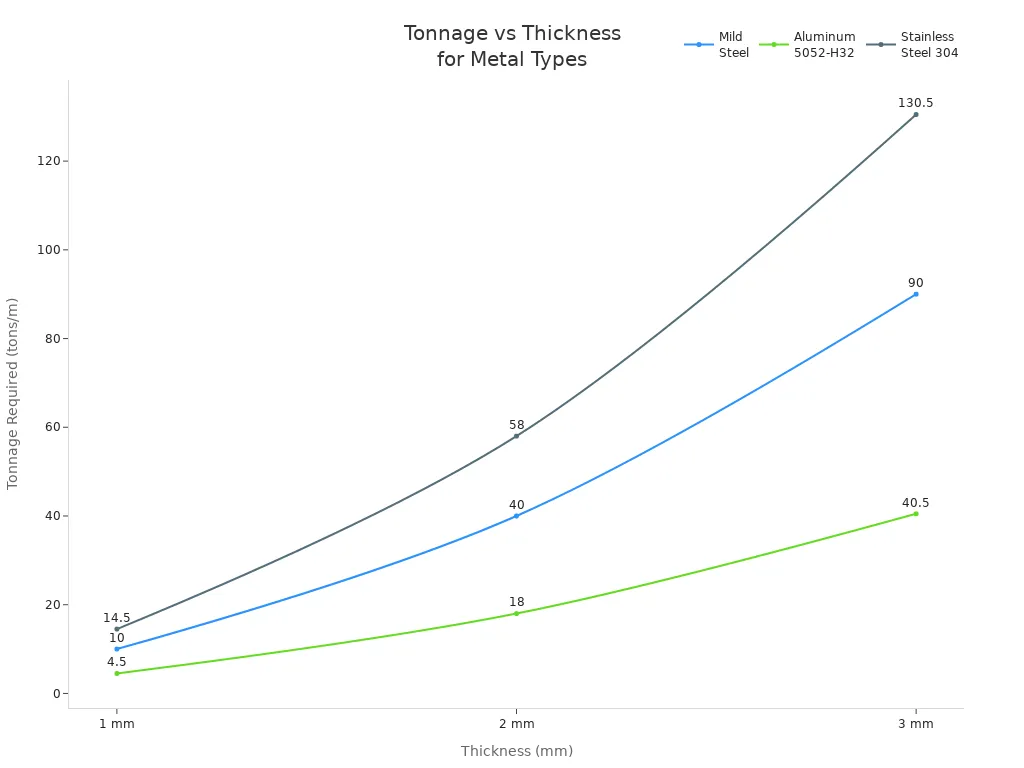

Tonnage needs change with each metal and thickness. Operators must match the press brake’s power to the job. The table below shows how much force is needed for common metals:

| Material | Thickness (mm) | Tonnage Required (tons/m) |

|---|---|---|

| Mild Steel | 1 | 10 |

| Mild Steel | 2 | 40 |

| Mild Steel | 3 | 90 |

| Aluminum (5052-H32) | 1 | 4.5 |

| Aluminum (5052-H32) | 2 | 18 |

| Aluminum (5052-H32) | 3 | 40.5 |

| Stainless Steel (304) | 1 | 14.5 |

| Stainless Steel (304) | 2 | 58 |

| Stainless Steel (304) | 3 | 130.5 |

Operators must check how much force is needed for each job. Not enough force can break the machine or make bad bends. Too much force can wear out tools faster. KRRASS press brakes have easy controls to set the right force. This keeps the machine safe and makes better parts.

Bend Length

Bend length helps decide which press brake to pick. Shops must choose a press brake that fits the longest part they will bend. Longer bends need bigger machines and more force. The way you bend changes as the length gets longer. Air bending works for short bends. Long bends may wrap around the punch nose.

Important things about bend length:

- When bend length goes up, the bending method may change from air bending to bottom bending or coining.

- Tools must fit the bending method and part length.

- The grain direction in metal changes the force needed. Bending across the grain needs more force and causes more springback than bending with the grain.

Operators should measure the longest part they want to bend. KRRASS has machines with different bed lengths for many jobs. Smart controls help users set up each bend length. This makes bends more exact and repeatable.

Tip: Always check the longest part and grain direction before picking a press brake.

Die and Tooling

Choosing the right die and tooling is important for bending jobs. Operators pick dies based on how thick the metal is and the bend angle. The die opening is usually six to eight times the metal’s thickness. This helps stop cracks and makes the bend smooth.

Tooling types include:

- Standard dies: Used for most bends.

- Gooseneck dies: Allow for deeper bends.

- Offset dies: Create Z-shaped bends.

- Radius dies: Form curved bends.

Operators must make sure the punch and die work with the press brake. Good tooling lasts longer and helps make better bends. Shops often use hardened steel tools because they last longer.

Tip: Always match the die opening to the metal’s thickness. This helps protect tools and makes better parts.

KRRASS press brakes use many European-style tools. The machines have quick-change clamps. Operators can switch tools fast and keep working. Advanced controls help set up the right die and punch for each job.

| Tool Type | Use Case | Benefit |

|---|---|---|

| Standard Die | Basic bends | Reliable results |

| Gooseneck Die | Deep bends | Prevents collision |

| Offset Die | Z-bends | Multiple bends |

| Radius Die | Curved bends | Smooth finish |

Precision

Precision is important for every metal forming job. Accurate bends help parts fit and cut down on waste. Operators set the press brake to the right angle and spot. CNC controls help make the same bend every time.

Things that affect precision:

- Backgauge accuracy: Puts the metal in the right place.

- Ram repeatability: Makes sure the ram goes to the same spot.

- Tool alignment: Keeps the punch and die lined up.

KRRASS press brakes use advanced CNC systems. These controls let operators make small changes. Operators type in bend angles and spots. The machine follows the steps and makes parts that match.

Note: High precision means less scrap and saves money.

Shops that need tight fits use CNC press brakes. KRRASS has models with high-resolution encoders and strong frames. These features help keep bends accurate for many jobs.

| Precision Feature | Description | KRRASS Advantage |

|---|---|---|

| CNC Control | Sets angles and force | Advanced programming |

| Backgauge | Positions material | Fast and accurate |

| Frame Stability | Reduces deflection | Strong construction |

Frequency

Frequency means how often a shop uses the press brake. Shops that bend metal a lot need tough machines and good controls. Operators who work every day need equipment they can trust.

Think about these points:

- Using the press brake every day wears out tools and parts.

- Frequent jobs are easier with quick setups and tool changes.

- Automated controls help finish repeat jobs faster.

KRRASS makes press brakes for shops that work a little or a lot. The MB8 Series has strong parts and easy controls. Operators finish jobs faster and have less downtime.

Tip: Pick a press brake that fits your work amount. Shops that bend metal a lot do better with CNC models and automated features.

Shops that bend metal sometimes may use manual or NC press brakes. KRRASS has choices for every shop. Support teams help operators keep machines working well.

Space and Power

Space and power are important when picking a press brake. Shops need to check how much room they have. Big machines take up more space. Small shops choose compact models to save room. Operators measure the area before putting in a press brake.

Press brakes need electricity to work. Hydraulic models use more power than electric ones. Shops must check the voltage and amperage in their building. Some machines need special wiring. KRRASS has press brakes that save energy. Hybrid and electric models use less power and help lower bills.

Operators think about these things:

- Size of the machine and how much space it needs

- Doorways and ways to get the machine inside

- Power needs for each type of press brake

- Cooling and air flow for the machine

The table below helps compare space and power for different press brakes:

| Model Type | Floor Space Needed | Power Use (kWh/day) | Special Wiring Needed |

|---|---|---|---|

| Mechanical | Medium | 20 | Sometimes |

| Hydraulic | Large | 60 | Often |

| Electric | Small | 12 | Rarely |

| Hybrid | Medium | 13 | Sometimes |

| Tandem | Very Large | 120 | Yes |

Tip: Always measure your shop and check your power before you buy a press brake.

KRRASS helps shops pick the right size and power. Their team gives advice on how to set up the machine.

Cost

Cost is important when buying a press brake. Shops look at the price and long-term costs. The first price covers the machine, tools, and delivery. Running costs include power, fixing, and repairs. Energy-saving models like KRRASS hybrid and electric press brakes help lower bills over time.

Operators think about these cost points:

- Price of the machine

- Cost of tools and extras

- Cost for setup and training

- Cost for fixing and spare parts

- Power bills each month

The table below shows common costs for press brakes:

| Expense Type | Description |

|---|---|

| Purchase Price | Cost of the machine itself |

| Tooling | Dies, punches, clamps |

| Installation | Delivery, setup, training |

| Maintenance | Regular checks, repairs |

| Energy Use | Monthly power bills |

KRRASS has machines with easy controls and strong parts. These features help cut down on repairs and save money. Their team helps with training and fixing. Shops save money by picking models that fit their work and power needs.

Note: Picking the right press brake helps control costs and makes your shop work better.

CNC or Manual

Picking between CNC and manual press brakes depends on the job. You need to think about how hard the job is. You also need to know how many parts you must make. Some jobs need very exact bends. Each type of press brake is good for different work. Operators should look at what their shop needs before they choose.

When to Select CNC

CNC press brakes are best for jobs that need to be very exact. These machines use computers to set the bend angle and force. Operators can program the machine for each job. This helps them make the same bend over and over. CNC press brakes help shops work faster and make fewer mistakes. They are great for tricky shapes and big orders.

| Advantage | Description |

|---|---|

| Speed | CNC press brakes bend metal fast and save time. |

| Precision | They make very exact bends, even for hard shapes. |

| Automation | The machine does most of the work for the operator. |

CNC press brakes help shops use less metal and save money. Operators can save programs for later jobs. This makes it easy to switch between parts.

Tip: CNC press brakes are good for shops that want to grow and do more work.

When Manual Is Enough

Manual press brakes are good for jobs that do not need to be fast. These machines are best for small orders and special parts. Operators move the machine by hand. This lets them make unique shapes.

Manual press brakes are helpful for:

- Custom metal work and making samples

- Small orders and jobs needed right away

- Fixing and keeping machines working in many shops

- Art and creative metal projects

Manual machines cost less and are simple to fix. Operators can set up the machine fast for one-time jobs. These machines are good for shops that do not make lots of parts at once.

Note: Manual press brakes are smart for shops that do custom jobs or repairs.

KRRASS CNC Solutions

KRRASS has CNC and NC press brakes with helpful features. Their machines use advanced CNC systems for exact bends. Operators use easy controls, often with touchscreens. This makes setup and use simple.

KRRASS CNC press brakes have these features:

| Feature | Description |

|---|---|

| Advanced CNC Systems | Give exact measurements and automatic bending. |

| User-Friendly Controls | Touchscreens make programming easy for everyone. |

| Industry 4.0 Integration | Machines connect with other systems for better tracking. |

| Advanced Backgauge | Moves in many ways for better accuracy and faster setup. |

| Low Operating Cost | Machines use less power and need less fixing. |

| Maximum Safety Standards | Built-in safety keeps operators safe while working. |

KRRASS also has NC press brakes for shops that want some automation. These machines balance cost and performance.

When you compare cnc and manual press brakes, think about your shop’s needs. You should also think about your budget and future plans. KRRASS has machines for every shop, from small jobs to big orders.

Safety

Key Features

Press brakes need good safety features to keep people safe. There are rules like ISO 13849-1 that say what safety is needed. Operators should look for these safety features before using a press brake:

| Safety Feature | Description |

|---|---|

| Mechanical Guards | Barriers that block people from moving parts. |

| Emergency Stop Buttons | Buttons that stop the machine right away if needed. |

| Two-Handed Controls | Both hands must press buttons to start, which helps stop accidents. |

| Hydraulic Overload Protection | Stops the machine from using too much force and getting damaged. |

| Light Curtains | Sensors that turn off the machine if someone gets too close. |

| Pressure Relief Valves | Keeps the hydraulic pressure at a safe level. |

| Precision Control Systems | Makes sure the machine bends metal safely and correctly. |

| Automatic Shutoff | Turns off the machine if something is wrong or unsafe. |

| Safety Interlocks | The machine only works when all safety steps are followed. |

Operators should always make sure all safety features work before starting.

Training and Support

Training is very important for safety at work. Workers must know how to use the press brake and follow safety rules. Good training teaches about the machine, safety steps, and gives practice. The table below shows why each part of training is important:

| Aspect | Importance |

|---|---|

| Knowledge of Machine | Operators learn about the ram, die, and back gauge to use the machine safely. |

| Safety Protocols | Knowing the rules helps stop injuries. |

| Hands-on Training | Practice helps workers use the machine safely. |

| Continuous Learning | Learning new things keeps everyone safer. |

KRRASS helps customers with training and easy-to-read guides. Their team teaches operators how to be safe and use all safety features. KRRASS also updates training when new technology comes out.

Maintenance

Doing regular maintenance keeps press brakes safe and working well. Operators should clean the machine every day and look for problems. Oiling moving parts helps them last longer. Checking the hydraulic fluid and looking for leaks keeps the system strong. Calibration checks help the machine bend metal the right way. Electrical parts need to be checked often to stop dangers. Tooling must be lined up for safe and good bends.

A simple checklist for maintenance includes:

- Clean and check the machine every day.

- Oil all moving parts.

- Check hydraulic fluid and look for leaks.

- Calibrate the machine often.

- Check electrical wires and connections.

- Make sure tooling is lined up.

KRRASS gives after-sales help and support for maintenance. Their team helps with checks and repairs. This support helps shops keep machines safe and working well.

Taking care of the machine and getting help stops accidents and keeps work going smoothly.

Vendors

How to Select the Right Press Brake Vendor

Picking the right press brake vendor helps shops get good machines and help when needed. Buyers look at a few things before they choose.

- The vendor’s reputation and support are very important. Shops check if the company is known for good service after the sale.

- Market share tells how many people trust the vendor.

- Technical skills mean what the machine can do, like how much it can bend and if it has automation. Shops want vendors with machines that fit their jobs.

- Quality certifications like ISO 9001 or AS9100 show the vendor follows world rules.

- Customer support and after-sales service help fix problems fast.

- Client stories and case studies show if the vendor is reliable.

Buyers also look at the warranty. A good warranty means the vendor trusts their machine. Service contracts for fixing and checking the machine give extra safety. Strong warranties help buyers feel sure about their choice.

| Manufacturer | Warranty Coverage | Extended Options |

|---|---|---|

| KRRASS Machine | One-year warranty | Yes |

Shops ask about the warranty before they buy. They want to know what is covered and how long help will last.

Tip: Always check the vendor’s reputation, warranty, and support before you pick a press brake.

KRRASS Advantages

KRRASS is a trusted press brake vendor. The company has offices in more than ten countries. Their support team answers fast, sometimes in just 12 hours. Most spare parts ship the same day, and repairs are done in a few hours.

| Feature | Description |

|---|---|

| Speed | Calls answered and help sent in as little as 12 hours. |

| Spare Parts | 90% of parts are ready to ship the same day. |

| Experience | Can make parts for any press brake or guillotine shear. |

| Efficiency | Repairs take about 2.5 hours on average. |

| Affordable | Fees follow the China machine tools group’s advice. |

| Passion | The team is professional and cares about helping. |

KRRASS press brakes meet world standards. The machines use good parts from top brands. Customers say the machines save money and are easy to use. Many users spend less on energy and training.

KRRASS gives strong customer satisfaction. Shops trust KRRASS for good machines and quick help. The team helps with setup, training, and repairs. KRRASS keeps parts in stock and fixes problems fast.

Note: KRRASS gives global support, quick service, and reliable machines to help shops do well.

Picking the right press brake takes a few clear steps. First, you need to know what material you will bend and how thick it is. Next, measure how long the bend will be. Then, figure out how much force, or tonnage, you need. Make sure the machine can bend the same way every time. Decide which press brake type fits your job best. Check if the tools you have will work with the machine. Look at options for automation and the back gauge. See if the controls are easy to use. Think about how much energy the machine uses and how often it needs care. Last, check if the maker gives good help and a strong warranty.

KRRASS gives advice to help you pick the right tools and understand what each machine can do. They also make sure your tools and machine work well together. You can ask KRRASS for help that fits your shop’s needs.

FAQ

What is the main job of a press brake?

A press brake bends sheet metal into shapes. It uses a punch and die for straight or angled bends. Many factories use press brakes for car, building, and machine parts.

How do you choose the right tonnage for a press brake?

Operators look at the metal type and thickness. They use a chart or calculator to find the right force. Picking the correct tonnage stops damage and makes good bends.

Can one press brake handle all types of metal?

Most press brakes work with steel, aluminum, and stainless steel. Operators change settings and tools for each metal and thickness.

What is the difference between CNC and manual press brakes?

CNC press brakes use computers for exact, repeatable bends. Manual press brakes need operators to set each bend by hand. CNC models are faster and make fewer mistakes.

How often should a press brake get maintenance?

Operators should check and clean the machine every day. They oil moving parts and look for leaks or damage. Regular care keeps the press brake safe and working well.

Why is safety important when using a press brake?

Press brakes use strong force. Safety features protect operators from harm. Training and checks help stop accidents and keep the shop safe.

Does KRRASS offer support after buying a press brake?

KRRASS gives training, setup help, and quick repairs. Their team answers questions and ships spare parts fast. Many customers trust KRRASS for good support.

How can a shop save energy with a press brake?

Shops can use electric or hybrid press brakes. These models use less power than hydraulic ones. KRRASS has energy-saving choices that help lower bills.