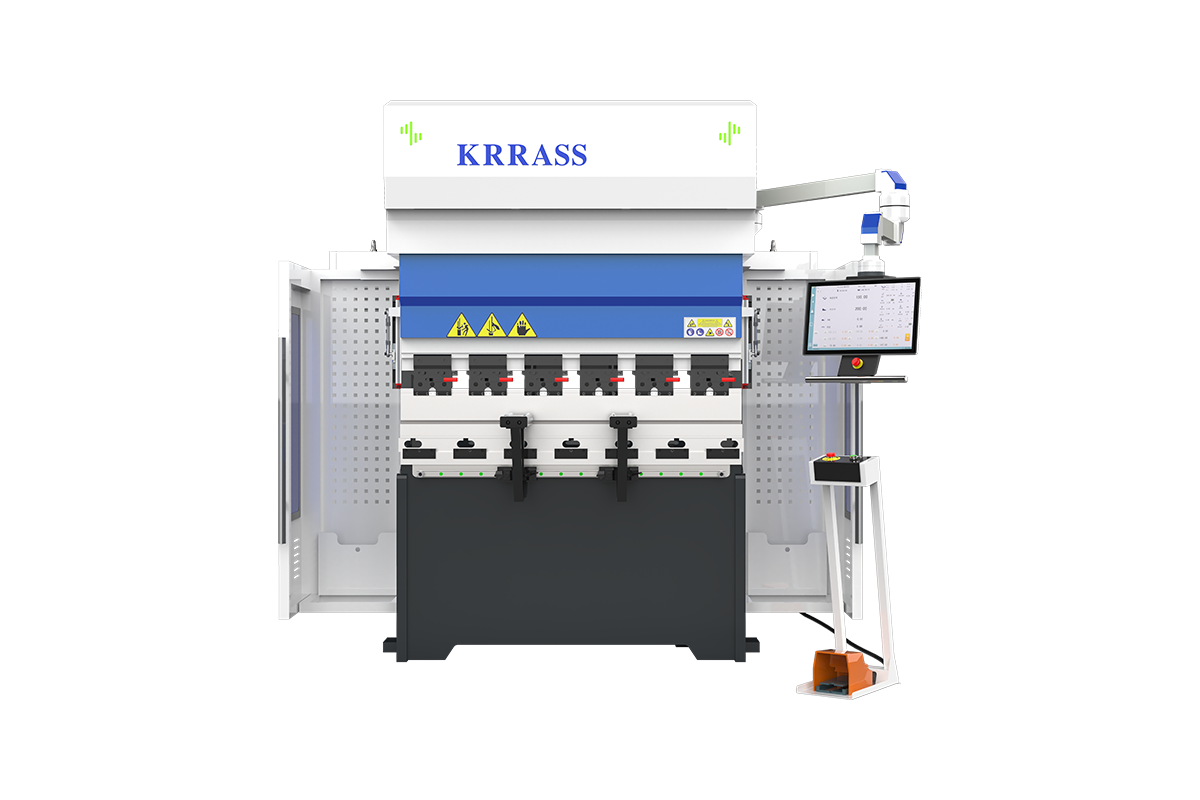

Here are the top 5 best-rated 25 ton press brakes for small businesses in 2025: Krrass Electric Press Brake, Amada HG Series, Bystronic Xpert 25, Trumpf TruBend 7050, and Accurpress Advantage Series. These press brake models get high scores for being precise, fast, and well-made. Each 25 ton press brake brings new ideas to the market. Small businesses like the help and trust that come with each press brake. Owners believe these machines give them good results every time. The Krrass Electric Press Brake is a CNC press brake that gives great quality and precision for every job. These 25 ton press brake choices help businesses work on quality and new ideas every day.

Table of Contents

Key Takeaways

- The Krrass Electric Press Brake is very accurate and saves energy. This makes it great for small shops.

- A 25 ton press brake is good for small businesses. It has the right amount of power and works well in small spaces.

- Automation in press brakes helps save time and lowers mistakes. This makes work faster and better.

- Picking the right press brake means looking at tonnage, bed length, and controls. These things help match the press brake to your shop’s needs.

- Taking care of your press brake and setting it up right is important. This helps it last longer and work well.

- Good help and training from makers can make press brakes work better. This also helps people use them more easily.

- Reading reviews and asking for demos can help shop owners choose the best press brake.

- Custom options let shops change press brakes for their own jobs. This makes them more useful and better at different tasks.

25 Ton Press Brake Overview

Definition and Uses

A press brake is a tool that bends metal sheets. It works by putting metal between a punch and a die. The machine pushes down to make the shape you want. Many shops use a press brake for metal work. It gives very exact and repeatable bends. Operators can use CNC systems to control the machine. These systems help save material and make bends more accurate.

- Bending metal sheets into special shapes

- Getting exact bends with a punch and die

- Using automation for better control and less waste

The press brake is important in metalworking. It helps with jobs in cars, buildings, and planes. Shops trust this machine for good and steady results.

Why 25 Ton Is Ideal

A 25 ton press brake has the right power for small shops. It can do most metal jobs and does not need much space. Many shops pick this size for its balance of power and efficiency. The 25 ton model fits well in small work areas. It also uses less energy than bigger machines.

Small shops want their work to be exact and high quality. The 25 ton press brake gives both. Operators can use automation to set up jobs fast. This saves time and cuts down on mistakes. The machine’s power works for many metal tasks. It can handle easy and hard bending jobs.

Tip: A 25 ton press brake lets small shops do more jobs without spending too much on machines.

Applications for Small Businesses

Small shops use a 25 ton press brake for many jobs. They make brackets, panels, covers, and custom parts. The machine bends metal for HVAC, electrical, and furniture work. Shops can change jobs quickly because of automation and simple controls.

- Making custom parts from sheet metal

- Bending brackets and panels with technology

- Automation for faster work and fewer errors

The press brake helps small shops meet demand. It gives exact and high-quality results every time. Automation lets workers focus on quality, not manual changes. The machine’s accuracy and steady work make it a good pick for growing shops.

Top 25 Ton Press Brake Models

Picking the right press brake helps small shops grow. Here are three top models you should know about. The table below shows important details for each machine. You can see tonnage, bed length, technology, energy use, control system, price, and support.

| Model | Tonnage | Bed Length | Technology | Energy Efficiency | Control System | Price Range | Support |

|---|---|---|---|---|---|---|---|

| Krrass Electric Press Brake | 25 ton | 4-17 ft | Hybrid (Electric) | 55%-78% savings | CNC Touch | $$-$$$ | Global, Local |

| Amada HG Series | 25 ton | 4-10 ft | Hydraulic | Moderate | CNC | $$$ | Global |

| Bystronic Xpert 25 | 25 ton | 4-8 ft | Electric | High | CNC | $$$$ | Global |

Krrass Electric Press Brake

Features

The Krrass Electric Press Brake uses hybrid technology. It mixes hydraulic power and electric motors for bending. The direct-drive motor only works when needed. This saves energy for the shop. The machine comes in different sizes and strengths. Operators use a CNC touch control to set up jobs fast. Shops can change the work area and tools easily. The machine is quiet and does not need much fixing.

- Hybrid system gives high precision and saves energy

- Direct-drive motor uses less power

- CNC touch control makes setup quick

- Modular work area fits many jobs

- Quiet running and low maintenance

Pros & Cons

Pros:

- High precision for every bend

- Energy savings from 55% to 78%

- Easy for anyone to use

- Can be changed for different jobs

- Less noise in the shop

Cons:

- (No cons listed for this model)

Best For

The Krrass Electric Press Brake is good for small shops. It helps businesses that want precise bends and lower energy bills. Shops with many bending jobs will like this machine. It helps shops grow and keeps quality high.

Amada HG Series

Features

The Amada HG Series is a hydraulic press brake. It gives steady force and good precision. The CNC control helps set up jobs quickly. The frame is strong and lasts a long time. The bed length works for most small shops. Amada gives good support and training.

- Hydraulic system gives steady force

- CNC control makes programming easy

- Strong frame lasts many years

- Good support and training from Amada

Pros & Cons

Pros:

- Reliable force for many jobs

- Good precision for most tasks

- Easy to learn and use

- Strong support from Amada

Cons:

- Uses more energy than hybrid or electric machines

- Costs more for small shops

Best For

The Amada HG Series is best for shops needing a reliable press brake. It fits businesses that want steady force and good quality. Skilled operators will get the most from this machine.

Bystronic Xpert 25

Features

The Bystronic Xpert 25 is an electric press brake. It gives high precision and bends metal fast. The CNC system helps set up jobs quickly. It uses less energy than hydraulic machines. The frame is small and fits tight spaces. Bystronic gives strong global support.

- Electric system gives high precision

- Fast bending and setup

- Small frame fits small shops

- CNC control is easy to use

Pros & Cons

Pros:

- High precision for detailed work

- Fast cycles for busy shops

- Uses less energy

- Good support from Bystronic

Cons:

- Costs more than some other machines

- May need skilled operators for best results

Best For

The Bystronic Xpert 25 is good for shops needing high performance. It works well for businesses that want fast, precise bends. Shops with lots of jobs and tight deadlines will like this press brake.

Tip: When picking a press brake, check tonnage, bed length, and control system. These things help you choose the best machine for your shop.

Trumpf TruBend 7050

Features

The Trumpf TruBend 7050 is easy for operators to use. It helps workers feel comfortable and work fast. The setup is ergonomic, so tables and aids can be moved. Operators change them to fit how they like to work. The machine has a 6-axis backgauge. This part helps put metal in the right spot for bending. The ACB Wireless system uses sensor disks to check angles. It fixes any mistakes to keep bends correct.

The BendGuard safety device watches under the upper tool. It keeps workers safe while they use the machine. The TruBend Touchpoint panel is simple to use. Operators see 3D pictures that help them do their jobs. The 2D code scanner reads barcodes to pick the right program. This saves time and stops errors. The press brake links with other Trumpf machines and software. This makes it easy to use in a modern shop.

| Feature | Description |

|---|---|

| Ergonomics | Tables and aids move for operator comfort |

| 6-axis backgauge | Helps put metal in the right spot |

| ACB Wireless system | Checks and fixes angles with sensors |

| BendGuard safety | Watches tool area to keep workers safe |

| TruBend Touchpoint | Simple panel with 3D pictures |

| 2D code scanner | Reads barcodes to pick programs fast |

| Integration | Links with other Trumpf machines and software |

Pros & Cons

Pros:

- Very precise for every press brake job

- Comfortable design helps operators work better

- Fast setup with barcode scanner

- BendGuard keeps workers safe

- Easy to link with shop systems

Cons:

- Costs more than some other press brakes

- Needs skilled workers for best results

Best For

The Trumpf TruBend 7050 is good for shops that want top precision and comfort. It works well for businesses that need fast and repeatable bends. Shops that care about safety and new technology will like this press brake. The machine helps keep quality high and work moving.

Accurpress Advantage Series

Features

The Accurpress Advantage Series is a reliable press brake for small shops. It uses new technology to give steady results. The CNC controls are easy for anyone to use. Operators can set up jobs quickly. The press brake works with many materials and lets shops change tools. This helps shops do different jobs.

The Advantage Series saves energy and lowers costs. It helps shops make more parts in less time. The machine is accurate and does the same job every time. Shops trust it to work well day after day.

Pros & Cons

Pros:

- Reliable for everyday use

- Saves money for small businesses

- New technology helps with precision

- CNC controls are simple

- Energy savings help lower bills

- High quality and repeatable results

- Flexible tools for many jobs

Cons:

- No big problems reported for this model

Best For

The Accurpress Advantage Series is great for shops that want a press brake they can trust. It is best for businesses that need accurate and high-quality bends. Shops that use many materials and change jobs often will like its flexible design. The machine helps save money and keep quality high, so it is smart for growing companies.

Top Press Brake Manufacturers

Industry Leaders 2025

Many shops want the best press brake manufacturers to help them do better work. These companies are the leaders in 2025. They are known for making machines that are precise and reliable. Amada, Bystronic, Trumpf, Accurpress, and Krrass are the top names. Each company has something special to offer.

- Amada has been making press brakes for a long time. Their machines are strong and very precise. Many shops pick Amada because they have many models to choose from.

- Bystronic is famous for using smart technology. Their machines have features that help shops work faster and more accurately. Bystronic helps shops get jobs done quickly.

- Trumpf makes machines that are easy and safe to use. Their press brakes help workers do their jobs faster. Trumpf also lets shops connect machines with software for better control.

- Accurpress builds press brakes that last a long time. Their machines work every day without problems. Accurpress also helps shops save money by using less energy.

- Krrass is a leader in hybrid technology. Their electric press brakes use less power and are very precise. Krrass gives help to shops both near and far.

These top press brake manufacturers help shops reach their goals. They make machines for many jobs, from easy bends to hard shapes.

What Sets Them Apart

Top manufacturers do more than just sell machines. They bring new ideas and give strong support. Shops want press brake manufacturers that help them work better and fix problems fast. The table below shows what makes these companies special.

| Key Factor | Description |

|---|---|

| Advanced Technology | Companies use new CNC systems and smart features for better efficiency. |

| Customer Service | Fast help and technical skill make a big difference for shops. |

| Quality of Support | Training, spare parts, and warranty keep machines running without delays. |

Shops pick top press brake manufacturers for more than just the machine. They want every job to be precise. They need help when something goes wrong. They want training to learn new features. These companies spend money on research and new ideas. They bring out new technology every year.

Many shops buy a press brake from these leaders because they want to grow. They trust the machines to work the same way every time. They know help is always close by. These companies stay at the top because they focus on precision, new ideas, and service.

Note: When picking a press brake, check the company’s support and training. Good support means less waiting and better work.

Key Press Brake Features

Bending Capacity

Bending capacity tells workers what the press brake can do. It shows how much force the machine uses to bend metal. A 25 ton press brake is good for most small shops. Shops use it for thin and medium sheet metal. The right bending capacity helps workers shape metal without problems.

Precision is important for every bend. If the press brake does not have enough power, the metal will not bend right. Operators check the metal’s thickness and type before starting. Stronger metals need more force to bend. This changes how the press brake works. Shops pick a press brake with enough power for their jobs.

A press brake with the right bending capacity gives steady bends. It helps workers finish jobs on time. Shops can do more work because they trust the machine’s accuracy.

Tip: Always use a press brake with the right bending capacity for the job. This keeps the machine working well and helps make bends precise.

Build Quality

Build quality is important for how long a press brake lasts. Strong materials and good design help the machine stay steady. Shops want a press brake that does not shake or move when bending. This keeps every bend correct.

Here is a table that shows common materials and what they do in a press brake:

| Material Type | Purpose |

|---|---|

| High-quality steel plates | Makes the frame strong and steady |

| Pipes and angle steels | Adds strength to the structure |

| Hydraulic components | Helps the machine use its full power |

| Chromium Molybdenum Steel | Makes tools strong and last longer |

| High-Speed Steel | Helps the machine work well and last longer |

| Low Alloy Tool Steel | Adds more strength and makes tools last |

The kind of material in a press brake changes its quality and accuracy. Stronger metals need more force to bend. This means the press brake needs a strong frame and tough tools. Shops look for machines with good steel and strong parts. This helps every bend stay accurate.

- The type of material and build changes how precise the press brake is.

- Shops trust machines with strong frames for the same bends every time.

Control Systems

Control systems help workers use a press brake easily. There are three main types: manual, NC, and CNC. Each type changes how workers set up and use the machine.

| Control System Type | Description | Impact on Ease of Use |

|---|---|---|

| Manual | Workers set everything by hand. | Harder to use because it takes more time. |

| NC (Numerical Control) | Some parts are automatic. | Easier to use and good for simple jobs. |

| CNC (Computer Numerical Control) | Software controls the machine. | Easiest to use and best for hard jobs. |

Manual systems need workers to set up every part by hand. This takes longer and can cause mistakes. NC systems add some automatic steps. They help with easy jobs and save time. CNC systems use software to control everything. They give the best accuracy and make hard jobs easier.

A press brake with a CNC system lets shops do more work faster. Workers can program jobs and get the same results each time. This helps shops be more accurate and grow.

Note: Shops that want the best accuracy and easy use often pick a press brake with a CNC system.

Safety & Efficiency

Safety and efficiency matter a lot in any shop. Workers want to feel safe when they use a press brake. Owners want machines that save time and money. Modern 25 ton press brakes help with both.

Shops see many safety features on today’s machines. These features protect workers and help them focus on the job. The table below shows some common safety features and what they do:

| Safety Feature/Technology | Description |

|---|---|

| ANSI B11.3-2022 | Sets safety rules for press brakes. Covers hazards, control systems, and emergency stops. |

| Hand/Foot Safety Sequence | Uses two-hand controls and a three-position footswitch. Keeps hands and feet safe during use. |

| Optional Safety Features | Light curtains, laser systems, and physical barriers. Add extra protection for workers. |

Shops often use two-hand controls. Workers must press two buttons at once to start the machine. This keeps hands away from moving parts. A three-position footswitch adds another layer of safety. If a worker moves their foot, the machine stops right away.

Some shops add light curtains or laser systems. These tools watch the work area. If something crosses the light or laser, the machine stops. This helps prevent accidents. Physical barriers can block access to dangerous spots.

Tip: Shops should check that their press brake meets the latest safety standards. This keeps everyone safe and helps avoid problems.

Efficiency also plays a big role in small shops. Modern press brakes use less energy than older models. Hybrid and electric systems only use power when needed. This cuts down on waste and lowers bills. Shops can run more jobs without using extra power.

CNC controls help with efficiency, too. Workers set up jobs fast and make fewer mistakes. The machine remembers settings for each job. This means less downtime and more finished parts.

Some machines run quietly. This makes the shop a better place to work. Less noise helps workers stay focused and comfortable.

Here are a few ways shops boost safety and efficiency:

- Use two-hand and foot controls for every job.

- Add light curtains or laser systems for extra safety.

- Pick machines with energy-saving technology.

- Train workers on safe and efficient use.

A safe and efficient press brake helps shops do more work. Workers stay safe. Owners save money. The shop runs better every day.

Press Brake Buying Guide

Performance & Reliability

Small businesses need a press brake that works every day. Good performance means it bends metal the same way each time. Reliability means it does not break down a lot. Shops can plan jobs and finish on time when they trust their machine.

Here is a table with important points about performance and reliability:

| Metric | Description |

|---|---|

| Remarkable Reliability | Regular care keeps the press brake working and jobs on track. |

| Maximized Asset Value | Checking parts often helps them last longer and saves money. |

| Equipment Lifecycle Strategy | Keeping notes helps find problems early and see how the press brake works. |

| Identify Replacement Triggers | Knowing when to get a new press brake saves money and keeps work going. |

| Understand Average Lifespans | Knowing how long a press brake lasts helps with planning and spending. |

A shop that checks these things can keep the press brake working well. Operators should look at the press brake often and write down repairs. This helps the press brake last longer and work better.

Cost & Value

The price of a 25 ton press brake can be very different. Some hydraulic models cost $10,000 to $30,000. Electric press brakes start at $50,000 and can cost much more. Used machines can be less than $5,000, but their shape matters. Press brakes with more features can cost over $500,000.

Things that change value for money are:

- Type of press brake (hydraulic, mechanical, CNC)

- How much automation and energy savings it has

- How much it costs to fix and run

A shop should think about more than just the price. A press brake that uses less energy or needs fewer repairs can save money later. Shops should think about how much bending they do and what features help them work faster. Picking the right press brake helps a business grow and keeps costs low.

Tip: Always look at the total cost, not just the price. Think about energy, repairs, and how much work the press brake can do.

Support & Warranty

Support and warranty are important when buying a press brake. Good support helps shops fix problems quickly. A strong warranty helps owners feel safe. Top brands give many ways to get help.

Here is a table with common support and warranty features:

| Feature | Details |

|---|---|

| Onsite Training | Workers get training at the shop after the press brake arrives. |

| Warranty | 5 years for parts, 5 years for onsite labor, 2 years for CNC controls. |

| Extended Warranty | You can add 7 more years of coverage. |

| Telephone Support | Free phone help for as long as you own the press brake. |

| Service Availability | Service teams work all over the United States. |

A shop should ask about training and how fast help comes. Good support keeps the press brake running and helps workers learn new things. A long warranty shows the company trusts their press brake. This helps small businesses feel good about their choice.

Customization Options

Every shop works in a different way. Some need special tools or features to get the job done right. Press brake makers know this. They let buyers pick options that fit their work. Customization helps a shop do more jobs and handle new projects.

Here are some common ways shops can customize a press brake:

- Tooling Choices: Shops can pick punches and dies for different shapes. Some need sharp bends. Others need wide curves.

- Backgauge Systems: A backgauge helps line up metal. Shops can choose simple or advanced systems.

- Control Upgrades: Some shops want a basic control panel. Others want a touchscreen or software that saves jobs.

- Work Area Adjustments: Shops can ask for a longer bed or a wider gap. This helps with bigger pieces of metal.

- Safety Features: Shops can add light curtains or guards for extra safety.

Tip: Shops should talk to the supplier about what they need. A good supplier will help pick the right options.

A table can help compare some popular customization choices:

| Custom Option | What It Does |

|---|---|

| Special Tooling | Makes new shapes possible |

| Extra Backgauge | Helps with tricky bends |

| Touchscreen Panel | Makes setup faster |

| Safety Add-ons | Keeps workers safe |

| Bed Extensions | Fits larger metal sheets |

Shops that plan for growth often pick more options. This helps them take on new jobs later. Customization can cost more at first, but it saves time and trouble down the road.

Space & Power Needs

A press brake takes up space. Shops need to check if the machine will fit before buying. They should measure the floor and leave room to move around the machine. Some shops work in tight spaces. They may need a smaller model or a machine with a compact frame.

Here are some steps to check space needs:

- Measure the shop floor.

- Mark where the press brake will go.

- Leave space for loading and unloading metal.

- Make sure doors and aisles stay clear.

Power needs matter too. Press brakes use electricity. Some use more power than others. Electric and hybrid models often use less power than hydraulic ones. Shops should check the voltage and power supply in the building.

A simple table can help compare power needs:

| Machine Type | Power Use | Shop Needs |

|---|---|---|

| Hydraulic | High | Strong power supply |

| Electric | Low to Medium | Standard outlets |

| Hybrid | Low | Energy savings |

Note: Shops should ask an electrician to check the wiring before installing a new press brake.

A shop that checks space and power first will have fewer problems. This helps the machine run well and keeps workers safe.

Common Mistakes to Avoid

Over/Underestimating Needs

Many small businesses do not check what they really need. Some buy a press brake that is too strong. Others pick one that cannot do their jobs. Both choices make work harder for the shop. If a shop buys too much power, it wastes money and space. If it buys too little, work is slow and bends are not good.

Shops sometimes forget to check how much bending force they need. If they do not know this, they might break the press brake or tools. Dirty machines also cause trouble. Dust and dirt wear out parts and make the machine work worse. If parts are not oiled, they break faster. If the machine is not level, metal bends wrong and pressure goes up. Too much space in the gib makes bends uneven. Old or wrong tooling makes bad flanges and parts. If tooling is not lined up, bends are not straight and flanges change size.

Tip: Shops should always measure what they need to bend and check the press brake’s capacity before buying. Keeping the machine clean and set up right helps it work well.

- Not cleaning the press brake often

- Ignoring limits and making the ram upset

- Forgetting to oil moving parts

- Setting up the machine on a floor that is not flat

- Using old or wrong tooling

- Not lining up the tooling

- Not checking how much bending force is needed

Ignoring Support

Support is important when using a press brake. Some shops do not ask about support before they buy. They find out later that help is slow or not there. Without good support, shops have trouble fixing problems and keeping work going. Fast support helps shops fix things and get back to work.

Shops need training, spare parts, and quick help. If a press brake stops working, good support means less waiting. Shops that forget about support can lose money and miss deadlines. Good support helps shops keep bends good and the machine working.

Note: Shops should ask about support before buying a press brake. Good support means less waiting and better results.

Skipping Training

Training teaches workers how to use the press brake safely. Some shops skip training to save time or money. This makes accidents and mistakes more likely. Workers who do not know the machine make errors that hurt work.

Workers who are not trained set up the press brake wrong. They may not follow safety rules or know what to do in emergencies. Accidents happen when workers reach around safety devices or do not follow safety steps. Shops that skip training have more accidents and bad bends.

Risks of skipping training:

- More mistakes when using the press brake

- Wrong settings that can cause accidents

- Bad safety habits and more risk of getting hurt

- Mistakes that make work worse and bends less accurate

Workers need to know how the press brake works. They should learn about controls, safety parts, and what to do in emergencies. Shops that train workers see better work and safer jobs.

Tip: Shops should always train workers before they use the press brake. Training keeps everyone safe and helps make better bends.

Focusing Only on Price

Many small business owners look at the price tag first when shopping for a press brake. Saving money feels important, especially when budgets are tight. But picking the cheapest option can cause problems later. Price matters, but it should not be the only thing that guides a decision.

When someone chooses a press brake based only on cost, they might miss out on important features. Some machines cost less because they use lower-quality parts. These parts can wear out faster. Repairs and replacements add up over time. A press brake that breaks down often can stop work in the shop. Downtime means lost jobs and unhappy customers.

Here are some common issues that come from focusing only on price:

- Overlooking quality can lead to higher operational costs.

- Ignoring service can result in increased downtime.

- Focusing only on price may negatively impact profitability and customer satisfaction.

A low-cost press brake might not come with good support. If something goes wrong, help may not arrive quickly. Shops can lose hours or even days waiting for repairs. This delay can hurt a business’s reputation. Customers want their orders on time. If a shop cannot deliver, customers may go somewhere else.

Some press brakes use less energy or need less maintenance. These features can save money in the long run. A machine with better controls can help workers finish jobs faster. Shops that look past the price tag often find better value. They get machines that last longer and work better.

Tip: Think about the total cost of owning a press brake. This includes repairs, energy use, and lost time from breakdowns. A higher upfront price can mean lower costs over the life of the machine.

Small businesses grow when they make smart choices. Picking a press brake is a big step. Owners should ask about support, training, and parts. They should look at how easy the machine is to use. A good press brake helps a shop do more work and keep customers happy.

Choosing the right press brake means looking at more than just the price. Quality, support, and features all play a part. A smart choice today can help a business succeed tomorrow.

Choosing the Right Press Brake

Assessing Your Needs

Choosing the right press brake starts with knowing what your shop needs. Every small business has different jobs and goals. A good fit helps you get the best performance and avoid wasted money.

Here are some steps to help you figure out what you need:

- Check the types and thicknesses of materials you plan to bend.

- Measure the longest piece you will need for bending.

- Think about the shapes and complexity of the bends you want.

- Decide how accurate your bends must be for your parts.

- Estimate how many parts you will make each day or week.

- Look at the skill level of your team.

You should also:

- Figure out the tonnage needed for your material’s hardness and thickness.

- Decide what control and gaging system fits your bending jobs.

- Pick the tooling style that works with your current tools.

A shop that follows these steps will find a press brake that matches its work. This helps keep performance high and jobs on track.

Tip: Write down your needs before you start shopping. This makes it easier to compare models and features.

Requesting Demos

A demo gives you a real look at how a press brake works. You can see the machine in action and test its performance. Many suppliers offer demos at their showrooms or online. Watching a demo helps you check if the press brake can handle your materials and bending jobs.

During a demo, pay attention to:

- How fast the press brake sets up and runs.

- The quality of each bend.

- How easy the controls are for your team.

- The noise level and safety features.

Ask the operator to show different bending tasks. Try to use your own material if possible. This gives you a clear idea of the machine’s performance in your shop.

Note: Bring your team to the demo. They can ask questions and see if the press brake fits their skills.

Reading Reviews

Customer reviews help you see how a press brake works in real shops. Reviews show what other users like and dislike. They also give you clues about long-term performance and support.

Look for reviews that talk about performance, bending quality, and support. Shops often mention if the press brake meets their needs or if they had problems. High ratings and many reviews can show a reliable machine.

Tip: Read both good and bad reviews. This helps you spot patterns and make a smart choice.

A shop that checks reviews, tries demos, and knows its needs will find a press brake that delivers strong performance and steady bending results.

Consulting Experts

Talking to an expert can help a small business owner make a smart choice when buying a press brake. Experts know the machines, the market, and the needs of different shops. They can answer questions, explain features, and help compare models. Many owners feel unsure when they see so many options. An expert can make things clear.

Most press brake suppliers have technical teams. These teams help buyers understand what each machine can do. They also know about new technology and changes in the industry. Some experts work for the manufacturer. Others work for local dealers or as independent consultants. Each one brings a different view.

Here are some ways experts help:

- They listen to the shop’s needs and goals.

- They suggest machines that fit the budget and space.

- They explain how each feature works.

- They help plan for future growth.

- They give tips on training and support.

Tip: Bring a list of questions to the meeting. This helps the expert give better advice.

A shop owner can meet experts in person, by phone, or online. Many companies offer free consultations. Some even give virtual tours of their machines. Owners can ask for a demo or a video call to see the press brake in action.

A table can help show what to ask an expert:

| Question | Why It Matters |

|---|---|

| What machine fits my jobs best? | Helps match needs to features |

| How much will it cost to run? | Shows long-term expenses |

| What support do you offer? | Tells about help after buying |

| How easy is it to train workers? | Prepares for smooth operation |

| Can I see the machine working? | Shows real performance |

Experts also help with planning. They can look at the shop’s workflow and suggest changes. Sometimes, a small change in setup can save time and money. Experts know about safety rules and can point out risks. They also know about new tools and upgrades.

Note: An expert’s advice can help avoid costly mistakes.

Some owners worry about asking for help. They may think it costs too much or takes too long. In most cases, expert advice saves money and time. It helps owners feel sure about their choice.

Consulting an expert is a smart step. It gives owners confidence. It helps them pick a press brake that works for their shop, their team, and their future.

These five press brake models stand out for their strong performance and support. Each press brake offers unique features that help small businesses work better. Readers can use the comparison table and buying guide to find the right press brake for their shop. Next steps include contacting suppliers, setting up a demo, or talking with an expert. A good press brake choice helps a business grow and keeps work on track.

FAQ

What is a 25 ton press brake?

A 25 ton press brake bends sheet metal using 25 tons of force. Many small shops use this machine for making parts like brackets and panels.

How much space does a 25 ton press brake need?

Most 25 ton press brakes fit in small shops. The machine usually needs a clear area around it for loading and unloading metal. Always check the machine’s size before buying.

Can one person operate a 25 ton press brake?

Yes, one person can run a 25 ton press brake. Many models have easy controls and safety features. Training helps operators work safely and get good results.

What materials can a 25 ton press brake bend?

A 25 ton press brake bends steel, aluminum, copper, and other sheet metals. The thickness it can handle depends on the material’s strength.

How does a CNC control help?

CNC controls let operators program bends and save jobs. This makes setup faster and helps get the same results every time.

How often should a press brake get maintenance?

Shops should check and clean the press brake every day. Regular oiling and inspections help the machine last longer and work better.

What safety features do modern press brakes have?

Modern press brakes use two-hand controls, foot switches, and sometimes light curtains. These features help keep workers safe during bending.

How can a shop choose the right press brake?

A shop should look at the types of jobs, material thickness, and space. Asking for demos and reading reviews helps make a smart choice.