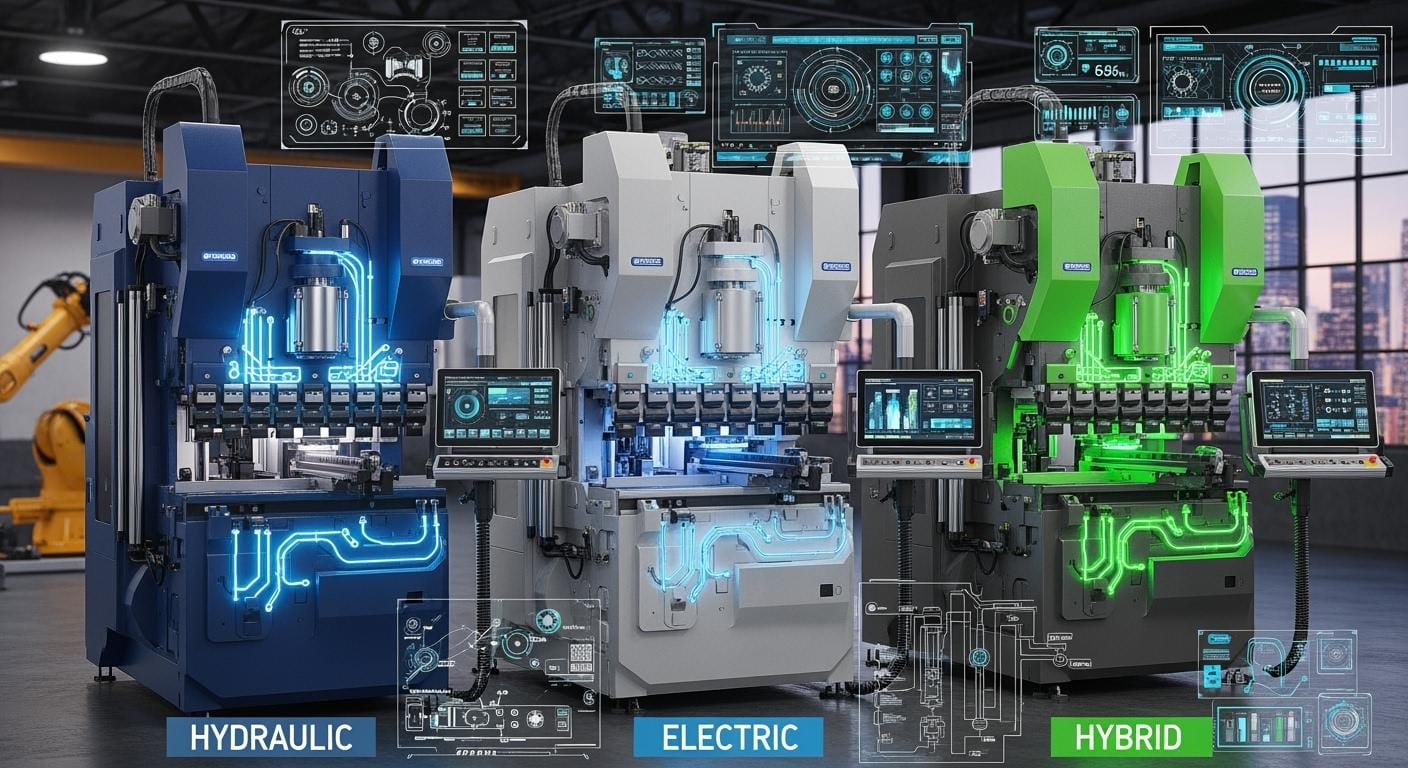

You want the best press brake machine for 2026. Your choice depends on your goals and needs. You should also think about new trends in the industry. KRRASS is a top company in press brake technology. Many manufacturers around the world trust KRRASS. When you choose, think about what matters most to you. You should look at performance, cost, maintenance, and sustainability. The market is changing fast:

- Hydraulic press brakes have 49% of the market. But fewer people want them now.

- Electric press brakes are becoming more popular. They are used a lot in car and airplane factories.

- Experts think electric press brakes will be 60% of new machines by 2030.

This article looks at hydraulic, electric, and hybrid press brake machines. It uses real examples from KRRASS.

Table of Contents

Key Takeaways

Pick the best press brake for your needs. Think about how it works, how much it costs, and how you will take care of it. Hydraulic press brakes are strong and good for big jobs. They use more energy and need regular care. Electric press brakes are very accurate and save energy. They work well with thin materials and small pieces. Hybrid press brakes mix hydraulic and electric features. They give you both power and efficiency for many jobs. KRRASS has many press brake choices. You can get simple NC models or advanced CNC machines. These fit different production needs. Taking care of your machine often helps it last longer. You should clean it, check safety parts, and write down what you do. Buying machines that save energy can cut costs. It also helps your workshop be more eco-friendly. Learn about new trends like automation and digital tools. This can help you work faster and make better products.

Press Brake Machines Overview

Hydraulic Press Brakes

Hydraulic press brakes are important in metal work. You see them in big industries like shipbuilding and car making. These machines use hydraulic cylinders for strong bending force. They are good for hard sheet metal jobs. Hydraulic press brakes bend thick materials and big parts easily. They are great for lots of bending and big projects.

Hydraulic press brakes have standard precision, about ±10 microns. They use more energy because the hydraulic system is always on. You need to do regular maintenance like changing oil. This keeps them working well. Many factories pick hydraulic press brakes for their power and dependability in tough metal work.

| Feature | Hydraulic Press Brake | Electric Press Brake |

|---|---|---|

| Bending Force | High; heavy-duty applications | Lower; lighter materials |

| Precision | ±10 microns | ±1 micron |

| Speed | Slower; longer cycle times | Faster; 30%-50% quicker |

| Energy Efficiency | High consumption | Low consumption |

| Maintenance Needs | Frequent; oil changes needed | Low; less frequent |

| Industries | Shipbuilding, automotive | Aerospace, electronics |

Electric Press Brakes

Electric press brakes have changed metal work a lot. These machines use electric motors, not hydraulic systems. They are faster and more precise, up to ±1 micron. Electric press brakes only run when you need them. This saves energy and money. They are quieter and make the workspace cleaner.

You use electric press brakes in jobs that need accuracy, like aerospace and electronics. They are best for lighter materials and smaller parts. Many companies like electric press brakes for their speed and efficiency. You spend less time fixing them, so you can focus on making things.

Electric press brakes have advanced features like CNC controls. You can program hard bending jobs and get the same results every time. These machines are good for smart factories where automation and precision are important.

Hybrid Press Brakes

Hybrid press brakes mix hydraulic and electric systems. You get the power of hydraulic press brakes and the efficiency of electric press brakes. Hybrid press brakes use both systems to bend sheet metal well and save energy. You can use them for many metal jobs.

Hybrid press brakes are good for shops that need strength and accuracy. You can bend different materials and thicknesses without losing performance. Many businesses pick hybrid press brakes to balance work speed, cost, and saving energy in metal work.

KRRASS Product Range

When you want a press brake machine, you need choices. KRRASS gives you many options. You can pick machines for easy jobs or hard tasks. KRRASS started in China. Now, they help customers in more than 50 countries. Their machines work in factories, workshops, and smart plants.

KRRASS has different press brakes:

- NC Press Brakes: These are for simple bending jobs. They have easy controls and strong frames. Small shops like NC press brakes because they work well.

- CNC Press Brakes: These give you high precision and automation. Computer controls help make tough bends. You can program them for repeat jobs. Big factories use CNC press brakes for fast and accurate work.

- Hydraulic Press Brakes: These are for heavy-duty jobs. They bend thick sheets and big parts. Shipyards and car makers trust hydraulic press brakes for their power.

- Electric Press Brakes: These are fast and save energy. Electric press brakes work quietly and use less power. Electronics and aerospace companies like these machines for their accuracy.

- Hybrid Press Brakes: These give you strength and efficiency. Hybrid press brakes mix hydraulic force with electric control. You can bend many types of metal with one machine.

Tip: KRRASS machines have easy controls. You can learn to use them fast, even if you are new.

KRRASS machines have advanced features. Many models have CNC controllers, quick clamps, and safety tools. You get steady performance and good results. KRRASS checks every machine before shipping. You get a product that works well from the start.

The CNC Press Brake MB8-250T3200 4+1 Axis is special in the KRRASS lineup. It has a DELEM DA-53T controller with a big color screen. You control up to four axes for exact bends. The machine uses a Siemens motor for quiet work. You get an electric crowning system for accurate bends. The MB8-250T3200 bends heavy sheets and tricky shapes easily.

| Model | Key Feature | Best For |

|---|---|---|

| NC Press Brake | Simple controls | Small shops |

| CNC Press Brake | Programmable automation | Large factories |

| Hydraulic Press Brake | High bending force | Shipbuilding, automotive |

| Electric Press Brake | Energy efficiency | Electronics, aerospace |

| Hybrid Press Brake | Power + precision | Mixed production needs |

KRRASS helps you with direct sales and good service. You get support when you need it. You can ask for custom machines for special jobs. KRRASS makes sure you have the right tools to do well.

Working Principles

Hydraulic Press Brakes Operation

You use hydraulic press brakes to bend metal sheets with strong force. The machine works by pushing a ram down onto the metal. The ram moves because hydraulic fluid powers it. You control the ram with a special controller. The punch touches the metal and shapes it. The die sits below and helps form the bend. The frame holds everything steady. The bed supports the metal sheet. You set the backgauge to position the metal before bending. The bending process pushes the metal into the die’s groove. Harder metals spring back more after bending, so you adjust the force for each job.

Here is a table showing the main parts and what they do:

| Component | Function |

|---|---|

| Ram | Moves up and down to drive the punch. |

| Punch | Shapes the metal by pressing it into the die. |

| Die | Works with the punch to create the bend. |

| Frame | Holds the machine steady during bending. |

| Bed | Supports the metal sheet, often with a groove for bending. |

| Backgauge | Positions the metal sheet for accurate bends. |

| Controller | Lets you set the force and control the bending process. |

| Bending Process | Pushes the metal into the die’s shape. |

| Material Grade | Changes how much force you need and how much the metal springs back. |

Tip: You should check the oil and keep the machine clean for best results.

Electric Press Brakes Operation

Electric press brakes use motors to bend metal sheets. You get precise control over the bending process. The electric motor drives gears and transmission rods. These parts move the upper and lower dies. You set the machine to bend the metal exactly how you want. The controller helps you choose the right settings. You can bend thin sheets quickly and with high accuracy. The machine only uses energy when you need it.

Here is a table showing how the main parts work together:

| Component | Function |

|---|---|

| Electric Motor | Powers the movement for precise bending. |

| Gears | Move the dies up and down. |

| Transmission Rods | Connect the motor to the dies for accurate movement. |

| Upper and Lower Dies | Bend the metal sheet with high precision. |

Electric press brakes work quietly and help you save energy.

Hybrid Press Brakes Operation

Hybrid press brakes combine hydraulic and electric systems. You get the power of hydraulics and the precision of electric motors. The machine uses hydraulic force for tough bends. Electric controls help you set the exact position and speed. You can bend thick and thin sheets with one machine. The controller lets you switch between modes for different jobs. You use less energy and get better accuracy.

- You set the job on the controller.

- The hydraulic system provides strong force.

- The electric system controls speed and position.

- The machine bends the metal with high precision.

Hybrid press brakes help you balance power, speed, and energy savings in your workshop.

Performance Comparison

Speed and Productivity

You want your press brake to work quickly. Making more parts in less time is important. This matters if you have a busy shop or factory. Hydraulic press brakes bend thick sheets with strong force. They help you make lots of parts fast. Electric press brakes move faster in each cycle. They are good for bending many small or thin pieces. Hybrid press brakes use both systems together. You get good speed and strong force for different jobs.

Here is a table that shows how speed and productivity compare:

| Feature | Hydraulic Press Brake | Electric Press Brake |

|---|---|---|

| Bending Force | High bending force, suitable for thick sheets | Lower force, ideal for thin materials |

| Bending Speed | Fast bending speed, high production volume | Slower, but can automate multiple bends |

| Stability | Stable and reliable bending effect | High transmission accuracy, less mechanical error |

| Energy Efficiency | Consumes more energy due to hydraulic system | More energy-efficient, uses electricity only when moving |

| Maintenance | More complex, requires professional maintenance | Easier maintenance due to fewer moving parts |

| Noise Level | Noisy due to hydraulic operation | Quieter operation, no hydraulic oil pumping |

| Cost | Generally lower cost for the machine | Higher initial cost, but lower operational costs |

Tip: Pick a press brake that fits your workload and material type. This helps you work faster and better.

Bending Accuracy

You need your metal parts to be bent very precisely. Accuracy makes sure parts fit together well. CNC press brakes give you very high accuracy. You can get bending accuracy between 0.0254 mm and 0.1016 mm. Hydraulic, electric, and hybrid press brakes usually reach 0.1 mm to 0.2 mm. Manual press brakes do not always give the same results.

Here is a table that shows typical bending accuracy:

| Type of Press Brake | Typical Bending Accuracy (mm) |

|---|---|

| CNC | 0.0254 – 0.1016 |

| Hydraulic | 0.1 – 0.2 |

| Electric | 0.1 – 0.2 |

| Manual | Varies, generally less precise |

| Hybrid | 0.1 – 0.2 |

CNC press brakes give you very precise bends. Hybrid and electric models also give steady results. If you need parts with tight tolerances, look for advanced controls and sensors.

Energy Efficiency

Saving energy helps you spend less and protect the environment. Hydraulic press brakes use more energy because they run all the time. Electric press brakes only use power when moving. Hybrid press brakes use smart systems to save energy during each cycle.

You can see the difference in energy savings in the table below:

| Machine Type | Energy Savings (%) |

|---|---|

| EVO III Hybrid | 73 |

| Green Press FX Servo | 69 |

| Conventional Hydraulic | 0 |

Electric and hybrid press brakes use less electricity. This lowers your costs and makes your shop quieter and cleaner. If you want better energy efficiency, think about getting newer press brake machines.

Note: Picking a press brake that saves energy helps you meet your sustainability goals and pay less for electricity.

Press brake machines have different strengths. Hydraulic models are powerful and fast for heavy jobs. Electric models are very precise and save energy. Hybrid models give you a mix of both. Compare these features before you choose your next press brake.

Cost and Maintenance

Initial Investment

Press brake machines have different prices. Hydraulic press brakes usually cost less at first. Small hydraulic models can be a few thousand dollars. Big hydraulic machines with more power cost much more. The price changes with size, tonnage, and extra features.

Electric press brakes cost more than hydraulic ones. You pay extra for better motors and controls. Hybrid press brakes cost the most if you need lots of power.

| Type | Average Initial Cost Range |

|---|---|

| Hydraulic | A few thousand dollars to six figures |

| Electric | Higher upfront price than hydraulic |

| Hybrid/Servo | Significantly higher than hydraulic at high tonnage |

Think about what you need before you buy. Big factories may save money with electric or hybrid models. Small shops might pick a basic hydraulic press brake to save money.

Tip: Check the machine’s size, tonnage, and features before buying. These things change the price a lot.

Operating Costs

After you buy a press brake, you must think about running costs. Hydraulic press brakes use more energy because they run all the time. You also spend more on oil and regular checks. Electric press brakes use energy only when moving. This means you pay less for electricity. Hybrid press brakes save energy too, but not as much as electric models.

Here is a table that shows how operating costs compare over five years:

| Machine Type | Energy Costs | Maintenance Costs | ROI Timeline |

|---|---|---|---|

| Electric | Lower due to on-demand usage | Minimal, fewer components | Justified by lower ongoing costs and improved productivity |

| Hydraulic | Higher due to continuous operation | Ongoing expenses for fluid management | Lower initial cost but higher running costs |

| Hybrid | Moderate, energy savings | Moderate maintenance | Compromise between electric and hydraulic benefits |

Electric press brakes are smart if you want lower maintenance costs. You spend less on repairs and parts. Over time, these savings add up.

Maintenance Needs

You need to keep your press brake working well. Regular maintenance helps your machine last longer. Some tasks should be done every day, some every week, and some every month or year. Always write down what you do. This helps you find problems early.

Here are some common maintenance tasks:

- Test emergency stop buttons

- Check foot pedals

- Verify light curtains

- Ensure proper machine alignment

| Maintenance Task | Frequency |

|---|---|

| Regular cleaning | Daily |

| Safety system verification | Weekly |

| Machine alignment | Monthly |

| Documentation of tasks | Ongoing |

Make sure the ram moves smoothly and safety systems work. Doing these steps keeps your press brake safe and reliable.

Note: Good maintenance helps you avoid expensive repairs and keeps your machine running for many years.

Longevity

If you buy a press brake machine, you want it to last. Longevity is important because it affects your costs. You do not want to replace your equipment often. Look at build quality, technology, and maintenance routines. These things help you know how long a machine will work.

Hydraulic press brakes have strong frames and tough parts. If you take care of them, they can last ten to twenty years. Electric press brakes have fewer moving parts. This means less damage over time. With good care, electric models may last even longer. Hybrid press brakes use both hydraulic and electric systems. They have a balanced lifespan for mixed jobs.

You can make your press brake last longer by doing these things:

- Routine Maintenance: Clean the machine often. Check for loose parts. Lubricate moving sections.

- Quality Components: Pick machines with certified motors, valves, and controllers.

- Proper Usage: Do not overload the machine. Follow bending limits.

- Environment: Keep your workshop clean. Control humidity. Dust and moisture can hurt your machine.

Tip: Keep a maintenance log. Write down repairs and checks. This helps you find problems early.

Here is a table that shows how long each type lasts:

| Machine Type | Expected Lifespan (Years) | Key Factors for Longevity |

|---|---|---|

| Hydraulic Press Brake | 10–20 | Regular oil changes, sturdy frame |

| Electric Press Brake | 15–25 | Fewer moving parts, clean power |

| Hybrid Press Brake | 12–22 | Balanced design, smart controls |

KRRASS press brake machines are known for being durable. They use high-quality steel frames and European parts. The CNC Press Brake MB8-250T3200 4+1 Axis has a Siemens motor and Rexroth hydraulic valve. These parts help the machine work well for many years. KRRASS tests every machine before shipping. You get a product that is built to last.

You can trust KRRASS for good support after you buy. If you need spare parts or help, you get fast service. This support helps your machine last longer and keeps your work going.

When you pick a press brake, think about how long it will last. A strong machine saves you money and stops downtime. KRRASS gives you reliable machines that help your business for years.

Environmental Impact

Energy Consumption

You want a press brake that does not waste energy. Electric press brakes only use power when you work with them. This means they use 40% to 60% less energy than old machines. Hydraulic press brakes use energy even when you are not bending metal. The hydraulic system stays on and uses more power, so it is less efficient. Hybrid press brakes use both systems together. You get strong bending and save more energy. Many factories pick electric or hybrid models because they save energy. You pay less for electricity and help the earth.

Tip: Picking a press brake that saves energy is good for your business and the planet.

Noise and Emissions

Noise and emissions are important in your shop. Electric press brakes are quiet when they run. You hear less noise, so your shop is safer and more comfortable. Hydraulic press brakes are louder because the pump runs all the time. You also have to watch for oil leaks with hydraulic machines. Oil leaks can hurt the environment and cause safety problems. Electric press brakes do not make emissions. Hybrid press brakes are quieter and have fewer emissions because of smart controls.

Here is a table that shows how noise and emissions are different:

| Type of Press Brake | Noise Levels | Emissions |

|---|---|---|

| Electric | Low | None |

| Hydraulic | High | Oil leaks |

| Hybrid | Medium | Minimal |

Note: A quieter press brake helps you follow safety rules and keeps your team healthy.

Sustainability

You want your business to be good for the environment. Electric and hybrid press brakes help you do this. They use less energy and make less pollution. You spend less money on oil and repairs. You also make less waste in your shop. Many companies want machines that help them go green. KRRASS has press brakes with smart controls and strong parts. These machines last longer and need less fixing. You help the planet and save money in the long run.

- Electric press brakes use less energy and are quieter.

- Hydraulic press brakes need more oil and make more waste.

- Hybrid press brakes give you both power and better sustainability.

Picking the right press brake helps you make your business cleaner and more responsible.

Future Trends in Press Brake Machines

Automation and Smart Features

By 2026, press brake machines will use more automation. Automated press brakes help you set up faster. They also make more parts in less time. These machines can work for hours without losing quality. Robotic Bending Cells move metal and keep bends accurate. They work well even if the metal changes. You can count on these systems for steady results.

AI-powered press brakes look at data while you work. They change bending force, speed, and angle for each metal. These smart systems make bends more exact and help you work faster. They also find problems before mistakes happen. Electric press brakes use servo-driven motors. These motors use less energy and need less fixing. These machines follow world rules for the environment. Many have systems that save and reuse energy.

Tip: Automation lets you plan and check quality. The machines do the same jobs over and over.

Digital Integration

Digital integration changes how you use and watch your press brake. Sensors and cameras give you quick feedback. If something is wrong, the system fixes it fast. This means better parts and fewer errors.

New press brake machines use tools like AutoSense and BendVision. AutoSense lets you watch your machine as it works. BendVision helps you control bend angles and see tools. AutoSense Plus shows alerts if there is a problem. You can fix issues quickly and keep working.

You get more exact bends and waste less metal. Digital systems help you answer key questions about your shop. You get info for fixing problems before they stop your machine. This keeps your press brake working well and helps you stay ahead.

Material and Design Advances

Press brake machines now have better safety features. Sensors stop accidents and keep workers safe. This focus on safety means less downtime and lower costs. You get more work done.

Modern machines give you new benefits:

| Feature | Modern Machine Benefits |

|---|---|

| Maintenance & Downtime | Predictive maintenance stops surprise breakdowns and keeps machines running. |

| Cost of Quality | Real-time angle checks lower scrap rates from 3-5% to under 1%. This saves metal and labor. |

| Accuracy & Repeatability | Laser angle checks keep bends within ±0.25 degrees and repeat position within ±0.002mm. |

| Productivity & Throughput | Automated Tool Changing sets up in less than 3 minutes. You make more parts each shift. |

| Material & Labor Efficiency | Easy controls help workers learn fast and need less training. |

You will see smart systems that watch and change things as you work. Automation lowers mistakes and helps you make more parts. Safety sensors protect your team and stop costly breaks.

Note: Picking a press brake with these features helps you get better quality, safety, and efficiency in your shop.

KRRASS Innovations

You want to do well in metalworking. KRRASS helps you get better. The company makes smart press brake machines with new technology. Every product has something special. KRRASS listens to customers and brings new ideas.

KRRASS spends money on research and development. Their team works with experts from many countries. They use feedback from users to make machines better. You get tools that fix real problems in your shop.

Key KRRASS Innovations:

- Advanced CNC Controls:

Many KRRASS machines have the newest CNC controllers. You use touchscreens and smart programs. The DELEM DA-53T controller on the MB8-250T3200 4+1 Axis helps you set up fast and bend metal exactly. - Electric Crowning System:

You want every bend to look good. KRRASS uses electric crowning to fix bending mistakes. This system keeps your angles the same on the whole sheet. - Energy-Efficient Design:

KRRASS makes machines that save power. You use less electricity and pay less money. The Siemens main motor and Rexroth hydraulic valve in the MB8-250T3200 help you work quietly and use energy well. - Smart Safety Features:

Safety is important in your shop. KRRASS adds light curtains, emergency stops, and quick clamps. You work faster and stay safe every day. - Custom Solutions:

Your business is different from others. KRRASS gives OEM and ODM services. You can ask for special features or sizes. The team helps you get the best machine for your work.

Tip: KRRASS checks every machine before sending it. You get a press brake that works right away.

Here is a quick look at the CNC Press Brake MB8-250T3200 4+1 Axis:

| Feature | Benefit for You |

|---|---|

| DELEM DA-53T Controller | Easy setup, high precision |

| Electric Crowning | Consistent bending accuracy |

| Siemens Motor | Quiet, reliable performance |

| Rexroth Valve | Stable hydraulic control |

| Quick Clamping | Fast tool changes |

KRRASS keeps making its machines better. You see new things every year. The company wants you to work smarter. When you pick KRRASS, you get a partner who cares about your success.

Recommendations by User Scenario

High-Volume Production

You have a busy shop or factory. You need press brake machines that work fast. Advanced CNC controls help you do jobs quickly and with care. Automation and robots move metal sheets and set up bends. These tools do not slow down your work. Smart technology and AI watch your process. They make changes to help you get better results. You make fewer mistakes and finish more parts each day.

- Advanced CNC controls help you work faster and better.

- Automation and robots make your shop more flexible.

- Smart technology and AI help you bend metal the best way.

KRRASS has good machines for busy shops. The CNC Press Brake MB8-250T3200 4+1 Axis sets up fast and works well. You can trust this press brake for big orders. It helps your shop run without problems.

Tip: Pick a press brake with smart controls and automation. You will save time and make fewer mistakes.

Precision Fabrication

You want every part to fit just right. Precision is very important in metal work. You need features that help you bend metal exactly. Modern CNC hydraulic press brakes can bend metal within ±0.1mm. These machines use strong frames and smart controls. You get the same bend every time, even with different materials.

| Feature | Importance |

|---|---|

| Advanced CNC control systems | Lets you change settings while bending to keep bends exact. |

| High-quality tooling | Makes sure bends are strong and accurate, so you do not redo work. |

| Regular calibration | Keeps the machine working well and gives you steady results. |

| Robust machine design | Stops the machine from bending too much and helps you get precise bends. |

Look for machines with very good positioning and repeatability. Servo-controlled or ball screw systems help you get the same bend every time. Crowning systems, angle sensors, and automatic tool setup make your work easier.

Note: Calibrate your machine often and use good tools. This keeps your work accurate and steady.

Sustainability-Focused Businesses

You want your shop to help the environment. Electric and hybrid press brake machines use less energy. They also make less noise. You pay less for electricity and make less pollution. These machines help you reach your green goals and follow new rules.

KRRASS makes press brake machines with motors that save energy. Smart controls help you bend metal well and use fewer resources. Hybrid models give you both power and efficiency. They are good for shops that want to help the planet.

- Electric press brakes use much less energy.

- Hybrid press brakes give you power and help the environment.

- Quieter machines make your shop a better place to work.

Tip: Choose a press brake that helps your shop go green and saves you money.

SMEs and Budget Buyers

If you run a small or medium-sized business (SME), you want machines that give you the best value for your money. You need equipment that works well, lasts long, and does not cost too much. Budget buyers also look for machines that are easy to use and maintain. You want to grow your business without spending too much at the start.

KRRASS understands your needs. The company offers a wide range of press brakes that fit smaller budgets. You can choose from NC press brakes for simple jobs or CNC models for more advanced work. These machines have strong frames and easy controls. You do not need a lot of training to start using them.

Why KRRASS Press Brakes Work for SMEs and Budget Buyers:

- Affordable Pricing: KRRASS offers factory direct sales. You pay less because there are no middlemen.

- Reliable Performance: Each machine uses high-quality parts. You get steady results every time.

- Easy Maintenance: The design makes it simple to clean and check the machine. You spend less time and money on repairs.

- Flexible Options: You can pick the size and features that match your shop. KRRASS helps you find the right fit.

Tip: Start with a basic model. You can upgrade later as your business grows.

Here is a table to help you compare options:

| Feature | NC Press Brake | CNC Press Brake |

|---|---|---|

| Price | Lower | Higher |

| Ease of Use | Very easy | Easy with training |

| Automation | Manual controls | Programmable |

| Best For | Simple bends, small runs | Complex jobs, repeat work |

You can also ask KRRASS for custom solutions. If you have special needs, the team can help you choose the right machine. You get support before and after your purchase. This helps you avoid costly mistakes.

Many SMEs pick the KRRASS CNC Press Brake MB8-250T3200 4+1 Axis. It gives you advanced features at a fair price. The machine has a strong frame, smart controls, and a good warranty. You can trust it to help your business grow.

Note: Always check the warranty and after-sales service. Good support saves you money and keeps your machine running.

If you want to save money and get reliable results, KRRASS press brakes are a smart choice. You get quality, support, and value in one package.

You can pick from many press brake machines. The best one for you depends on your shop’s needs. Think about how much you want to spend and how you want to work. Some machines use more energy, and some use less. Some cost less at first, but others cost more. Some need oil checks often, but others do not. Some make more noise and heat, and some are quieter and cooler.

| Feature | Hydraulic Press Brake | Electric Press Brake |

|---|---|---|

| Energy Efficiency | Uses more energy | Uses less energy |

| Initial Investment | Costs less at first | Costs more at first |

| Maintenance | Needs oil checks often | Needs little maintenance |

| Environmental Impact | Makes more pollution | Makes less pollution |

| Noise Levels | Makes more noise | Makes less noise |

| Heat Generation | Gets hotter | Stays cooler |

Here are some tips for picking a press brake:

- Choose a machine that fits your metal size and bends.

- Pick one that matches how much you make and your workers’ skills.

- Think about price, but also how long it will last and how much care it needs.

KRRASS can help you pick the right press brake. You can talk to their team for help and learn about new features. Look for machines that use smart technology and save energy. This helps you keep up with new trends and work better.

FAQ

What is a press brake machine?

A press brake machine bends sheet metal into different shapes. You use it in factories and workshops. You can choose hydraulic, electric, or hybrid models for your work.

How do I choose the right press brake for my shop?

You should look at your production needs, budget, and material type. Electric models work best for precision. Hydraulic models handle heavy-duty jobs. Hybrid models balance power and efficiency.

What maintenance does a press brake need?

You clean the machine often. You check safety systems every week. You test alignment every month. You keep a log of all maintenance tasks.

How long does a press brake last?

You can expect a press brake to last 10 to 25 years. Regular maintenance and quality parts help your machine work longer.

Are electric press brakes more energy efficient?

Yes. Electric press brakes use less energy because they run only when needed. You save money and help the environment.

Can I get custom features for my press brake?

You can ask KRRASS for custom solutions. You choose special sizes, controls, or safety features. The team helps you find the best fit.

What warranty does KRRASS offer?

KRRASS gives you a 2-year limited machine warranty. You also get a 30-day money-back guarantee. You receive support after your purchase.

Where can I get help or support for my press brake?

You contact KRRASS by phone or email. You get fast help with questions, spare parts, or service. Visit KRRASS Official Website for more details.