Fiber laser cutting machines have revolutionized the manufacturing and fabrication industries with their ability to achieve high precision and speed. Unlike traditional cutting methods, these machines use a concentrated laser beam to cut through various materials efficiently. This guide explores essential strategies to minimize material waste when using fiber laser cutting machines, ensuring cost-effectiveness and environmental sustainability.

Table of contents

I.Understanding Material Waste in Laser Cutting

II.Optimize Cutting Parameters to Reduce Waste

III.Nesting and Layout Optimization to Reduce Waste

IV.Material Selection and Utilization

V.Maintenance and Calibration to Reduce Waste

VI.Tracking and Analyzing Waste

I.Understanding Material Waste in Laser Cutting

Material waste in laser cutting can result from several factors, including inefficient nesting of parts on sheets, suboptimal cutting parameters, and the characteristics of the material itself. Waste not only increases production costs but also impacts environmental sustainability. Recognizing these factors is crucial for implementing effective waste reduction strategies.

II.Optimize Cutting Parameters to Reduce Waste

Achieving optimal cutting parameters is key to minimizing material waste. Adjusting parameters such as cutting speed, laser power, and focal length can significantly improve cutting efficiency and reduce scrap. Fine-tuning these settings according to the material type and thickness ensures precise cuts while minimizing unnecessary material removal.

III.Nesting and Layout Optimization to Reduce Waste

Efficient nesting and layout optimization are fundamental in reducing material waste. Advanced nesting software can intelligently arrange parts on sheets to maximize material usage and minimize scrap. By strategically positioning parts and considering cutting paths, manufacturers can achieve higher material yield and reduce overall production costs.

IV.Material Selection and Utilization

Careful selection and management of materials contribute to waste reduction in laser cutting. Choosing high-quality materials appropriate for the application ensures better cutting performance and less scrap. Additionally, utilizing sheet remnants and managing offcuts effectively through recycling or reuse practices further optimizes material usage and minimizes waste.

V.Maintenance and Calibration to Reduce Waste

Regular maintenance and calibration of fiber laser cutting machines are essential for optimizing performance and minimizing material waste. Ensuring the machine is properly calibrated and aligned prevents cutting errors that can lead to increased scrap. Routine maintenance checks also extend the lifespan of equipment, maintaining cutting precision and efficiency over time.

VI.Tracking and Analyzing Waste

Monitoring and analyzing material waste provide valuable insights into production inefficiencies. By tracking waste levels and analyzing data, manufacturers can identify patterns, root causes of waste, and opportunities for improvement. Implementing data-driven decisions allows for continuous optimization of cutting processes and reduction of material waste.

VII. Conclusion

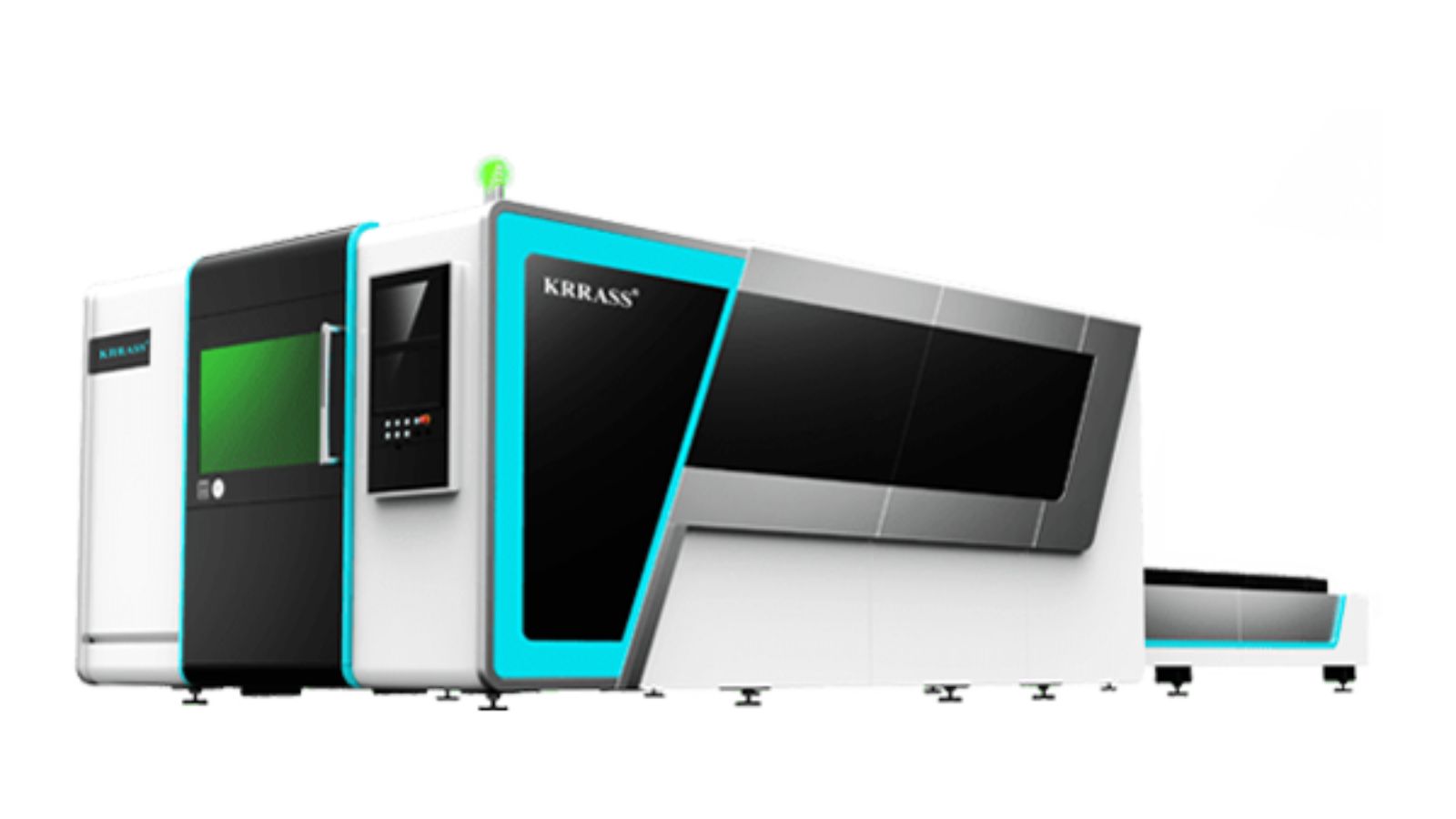

In conclusion, adopting these top tips for preventing material waste with fiber laser cutting machines not only improves operational efficiency but also promotes environmental sustainability. As technology advances, future trends in laser cutting will focus on further enhancing cutting precision, reducing energy consumption, and implementing smarter waste management practices. To learn more about Fiber Laser Cutting, please click here. KRRASS will be at your service.