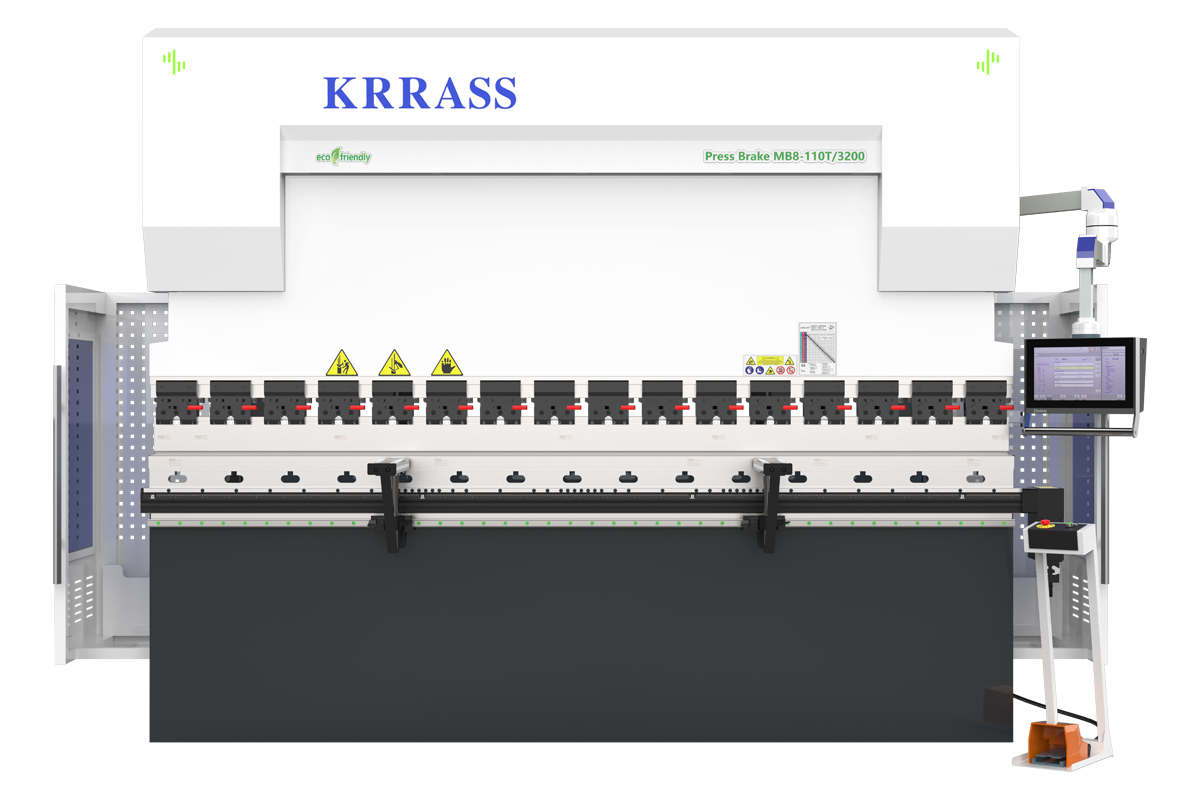

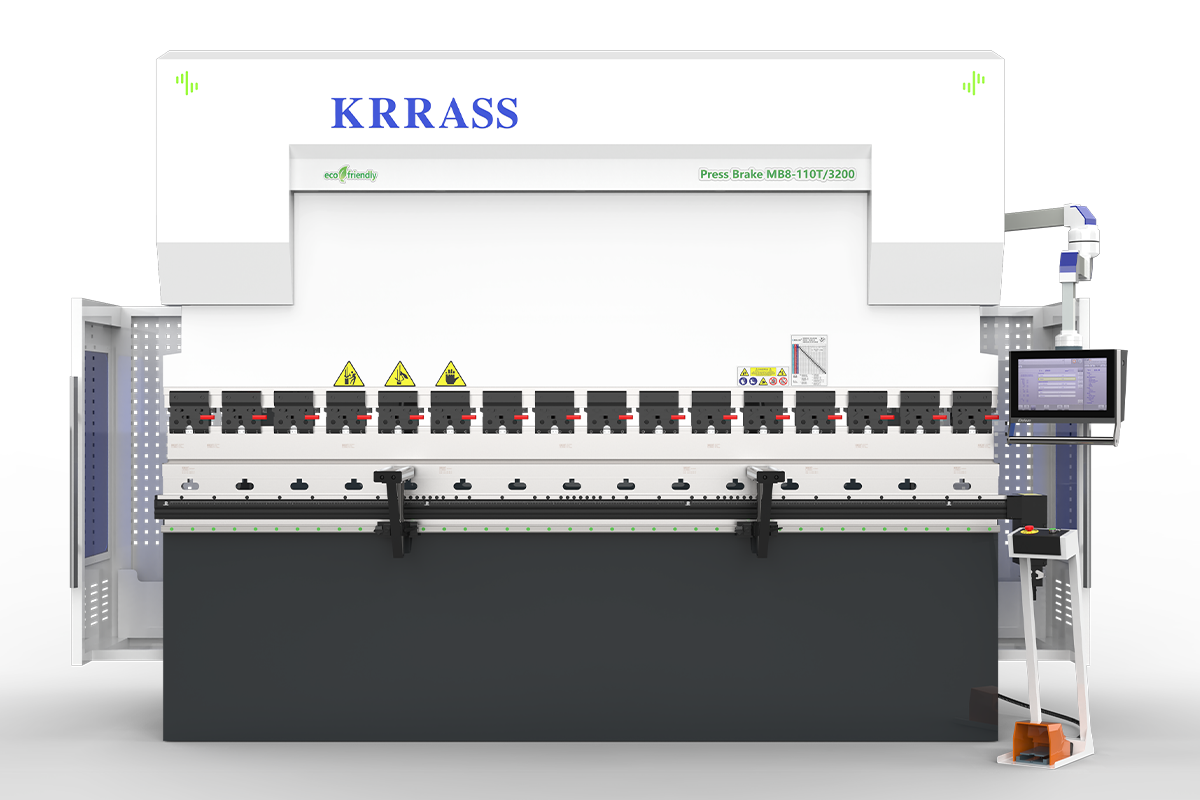

Sheet Metal Press Brake With DA-53Tx Controller (3-6 Axis)

Sheet Metal Press Brake 3-6 Axis

MB8 Series Sheet Metal Press Brake, it’s an affordable Sheet Metal Press Brake with an impressive number of features and options. Competitive pricing with advanced DELEM DA-53Tx or DA-58Tx 2D capable graphical controls. Advanced Series is your first choice in Y1/Y2 machine technology.

Simple and solid press brake

Work area can be customized and all types of tool clamping can be installed

Tailored-made sheet metal press brake

- Controller: DELEM DA-53Tx

- Electrics: Schneider Electric - France

- Main Motor: Siemens Motor - Germany

- Servo Motor: ESTUN

- Foot Switch: KACON - South Korea

- Hydraulic System: Bosch Rexroth - Germany

- Oil Pump: First - USA

- Sealing Ring: PARKER - America

- High Efficiency Motor - Class IE3

- Tube Connector: EMB - Germany

- Backgauge: Hiwin - Taiwan

- Grating Ruler: Fagor

Standard Equipment

Introduction to Configuration

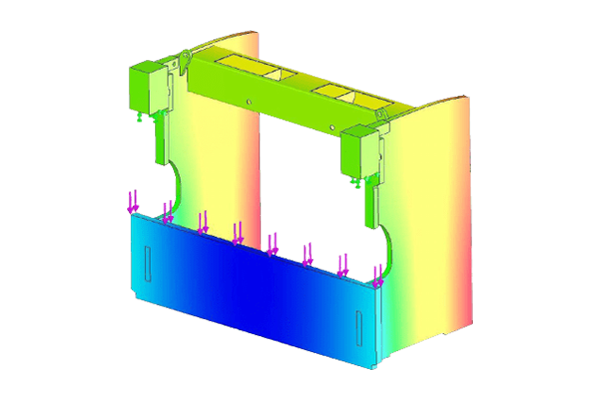

FEA & Stress Analysis

Stress Analysis & Finite Element Analysis

The CAE software SOLIDWORKS used as the method to analyze the linear static construction, stress and deformation for press break and laser cutting machine frames. So for complicated structures, highly complex loading’s, transient modelling and combination of the above, FEA makes sense.

DELEM CNC Control System

DELEM DA-53T Control

- "Hot-key” touch navigation

- 10.1" high resolution colour TFT

- Up to 4 axes (Y1, Y2 + 2 aux. axes)

- Tool / material / product library

- Servo and frequency inverter control

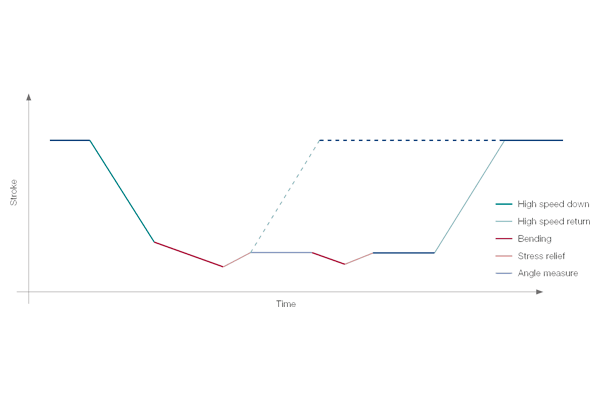

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- TandemLink (option)

- USB memory stick interfacing

- Profile-T offline software

DELEM CNC Control System

DELEM DA-58Tx Control

- 2D graphical touch screen programming

- 18.5" high resolution colour TFT

- Bend sequence calculation

- Crowning control

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- USB, peripheral interfacing

- Profile-T offline software

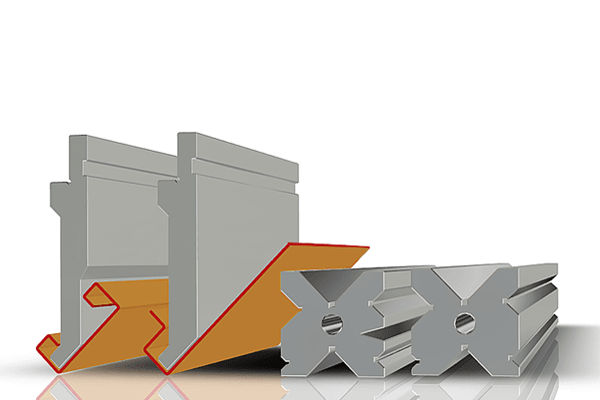

Manual Upper Tool Clamping

KRRASS CNC press brake use all Raw material is provided by qualified suppliers and chemical composition corresponds to international standards. Therefore, raw material yield and tensile strength are guaranteed, are standardized with a 8.4 x 3.5 mm safety groove, which keeps the tool from falling out.

Advantage:

- Safe and fast tool change

- Can be used without modifying Europe type punches

- Front clamp - vertical tool change

- Rear clamp - horizontal tool change

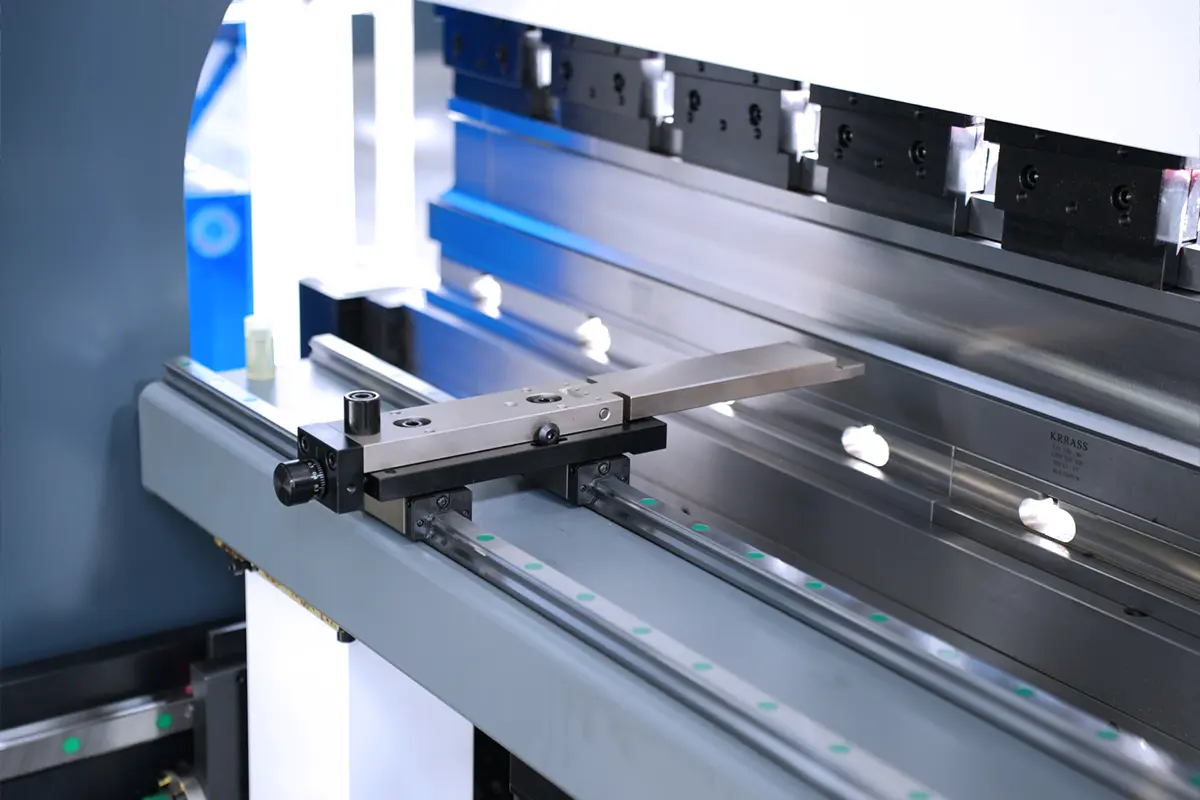

KRRASS® BGA-2 BackGauge

Sheet Metal Press Brake 2-Axis CNC BackGauge with X, R-Axis

- Hiwin Ball screws and linear guide on X, R-axis

- Axis X speed 500 mm/s

- Manual Z1, Z2-axis with HIWIN linear guide

- Mechanical accuracy ± 0.01 mm

- Fingers with double stop and micrometric adjustment

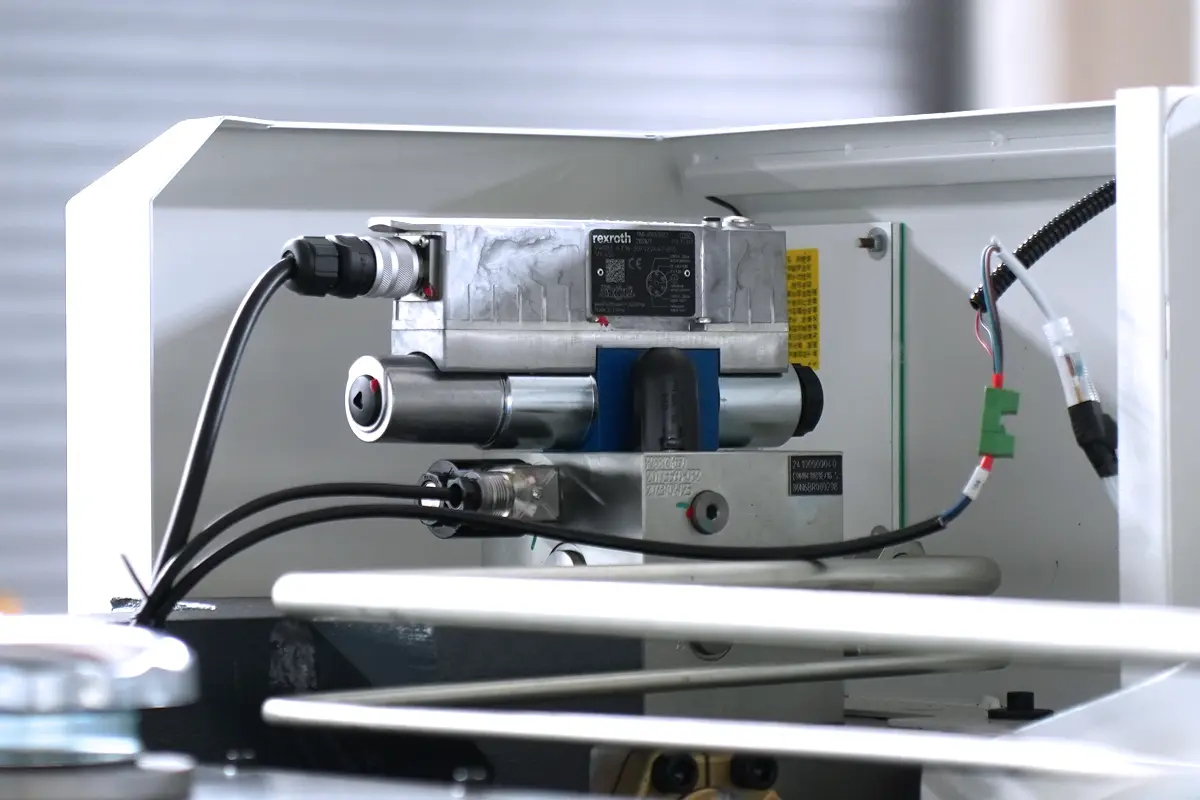

Proportional Valve

The German Rexroth fully closed-loop electro-hydraulic servo high-frequency synchronous control system is adopted to ensure that the machine tool has high stability and high precision in the process of high-speed operation.

Advantage:

- The frequency response (response frequency) is higher and can be as high as 200Hz.

- It can continuously and proportionally control the pressure and flow of the hydraulic system, control the position, speed, and force, and reduce the impact of pressure changes.

- Closed-loop control, signal feedback.

- Original German imported products, longer service life.

KRRASS® family Electric Crowning

- Very precise bending angles

- Europe type dies with 60 mm and 90 mm

- Base can be clamped as well as single dies with 13 mm tang

- Electric crowning with a controller

- Precise positioning and alignment of the crowning table

- Easy and fast usage

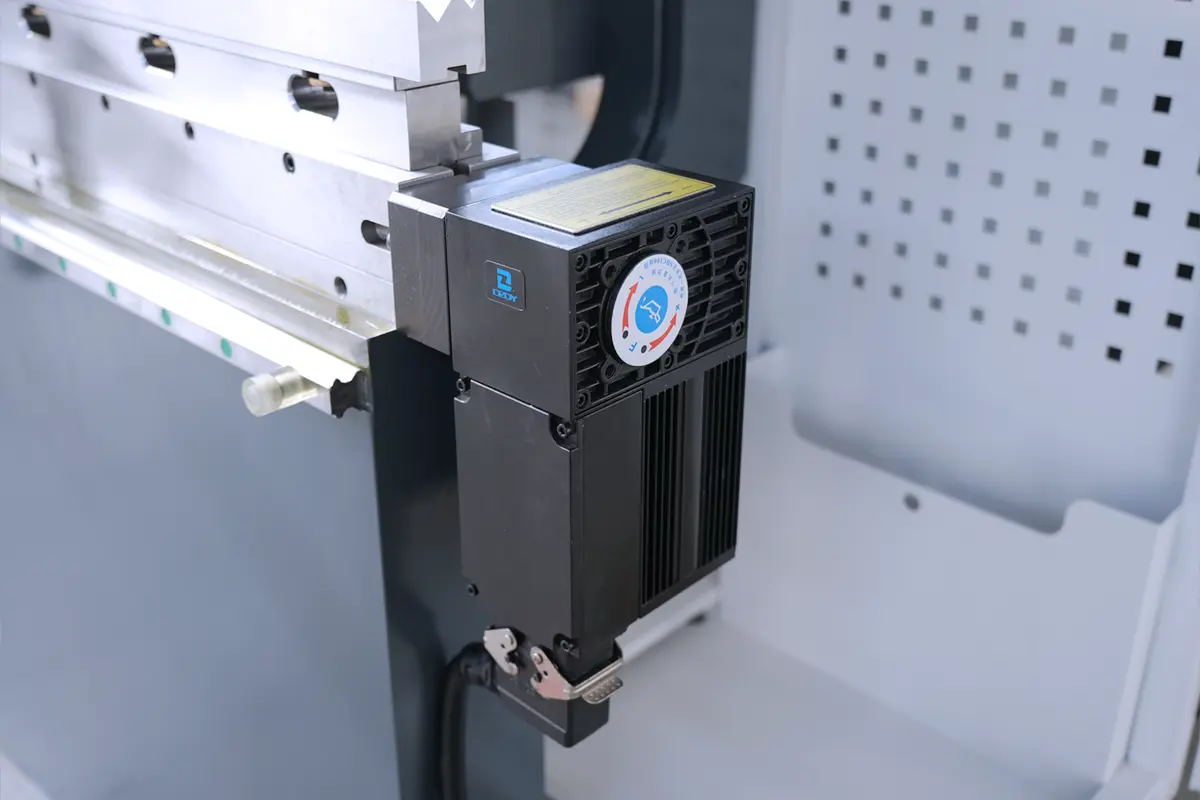

Italy DSP Laser Protection (Optional)

DSP® laser protection will be necessary if you have a high requirement for the safety.

Advantage:

- Laser protection, Multi beam Receiver

- Pretective areas, Front, center and rear

- The safety level is CAT.4 and SIL3

- Detection Case protection degree: IP 65

- Laser classification: class 1 M

- Response time: 5 ms

- Change Speed Point : 5mm + Stopping Space

- The maximum protective distance is up to 15M

- LED indicators show various states

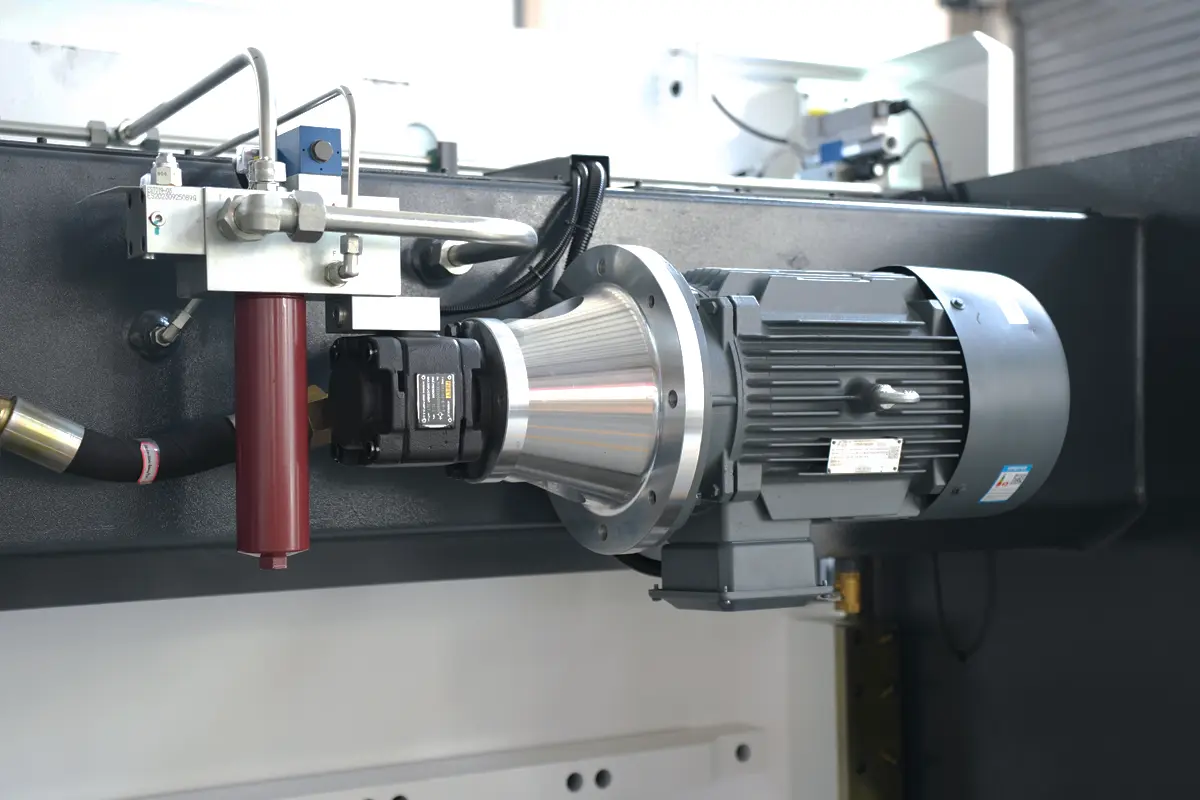

German Siemens Main Motor

The German famous brand motor increases the service life of the machine and keeps the machine working in a low-noise environment.

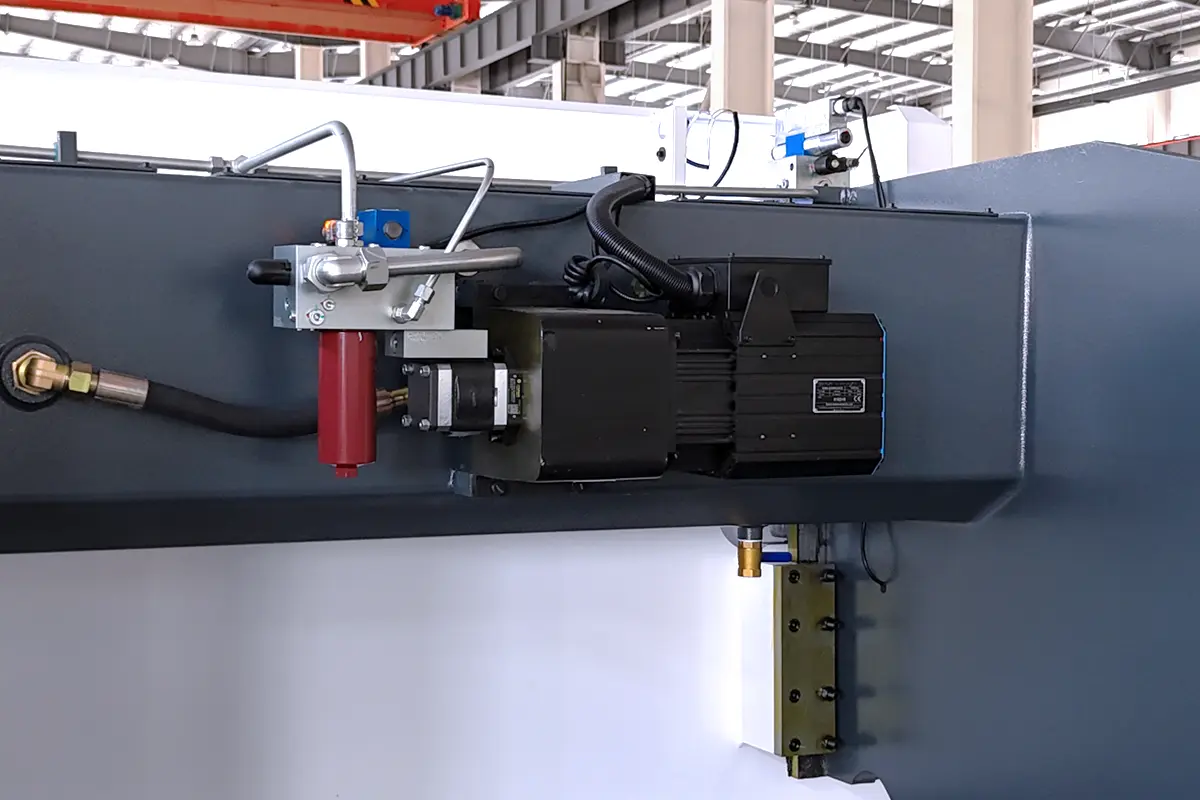

Hybrid Servo ECO Function

KRRASS® New Hybrid Servo ECO Function (Optional)

KRRASS® promotes a friendly environmental policy, and as such all our equipment features the Hybrid ECO Function. Our hybrid servo-drive positioning system provides accuracy at any position.

Advantage:

- Operating cost is min due to low energy consumption. Thus, it gives advantages to the user with high efficiency & low operation cost.

- High dynamic for a higher productivity of the machine.

- Compliance with EU Directives.

- Lower energy for a green Machine.

- Lowered sound pressure level at 50 dB.

- The servo-motor, with closed loop speed control.

- Energy efficiency of up to 35 % compared to conventional systems.

Punches & Dies

Sheet Metal Press Brake punches and dies will be one of the most important topics we discuss before you place the order. Any bending shape will be completed by a suitable set of punch and die. We can provide appropriate toolings according to different bending requirements of customers.

Sheet Metal Press Brake Technical Parameter

| Model | Bending Pressure (kn) | Bending Length (mm) | Column Distance (mm) | Throat Depth (mm) | Slider Stroke (mm) | Max. Opening Height (mm) | Y1,Y2-axis Down Speed (mm/sec) | Y1,Y2-axis Back Stroke Speed (mm/sec) | X-axis Max.Distance (mm) | Main Motor (kw) |

|---|---|---|---|---|---|---|---|---|---|---|

| 50T1600 | 500 | 1600 | 1250 | 205 | 160 | 540 | 230 | 140 | 600 | 4 |

| 80T/2500 | 800 | 2500 | 2000 | 350 | 170 | 570 | 230 | 140 | 600 | 7.5 |

| 110T/2500 | 100 | 2500 | 2000 | 410 | 200 | 570 | 220 | 140 | 600 | 7.5 |

| 110T/3200 | 1100 | 3200 | 2700 | 410 | 200 | 570 | 220 | 140 | 600 | 7.5 |

| 110T/4000 | 1100 | 4000 | 3500 | 410 | 200 | 570 | 220 | 140 | 600 | 7.5 |

| 135T/2500 | 1350 | 2500 | 2000 | 410 | 200 | 570 | 200 | 140 | 600 | 11 |

| 135T/3200 | 1350 | 3200 | 2700 | 410 | 200 | 570 | 200 | 140 | 600 | 11 |

| 135T/4000 | 1350 | 4000 | 3500 | 410 | 200 | 570 | 200 | 140 | 600 | 11 |

| 175T/3200 | 1750 | 3200 | 2700 | 410 | 200 | 570 | 160 | 140 | 600 | 11 |

| 175T/4000 | 1750 | 4000 | 3500 | 410 | 200 | 570 | 160 | 140 | 600 | 11 |

| 175T/5000 | 1600 | 5000 | 4100 | 410 | 200 | 570 | 160 | 90 | 600 | 11 |

| 175T/6000 | 1600 | 6000 | 5100 | 410 | 200 | 570 | 160 | 90 | 600 | 15 |

| 210T/3200 | 2100 | 3200 | 2700 | 410 | 200 | 570 | 160 | 140 | 600 | 15 |

| 210T/4000 | 2100 | 4000 | 3500 | 410 | 200 | 570 | 160 | 140 | 600 | 15 |

| 210T/5000 | 2100 | 5000 | 4100 | 410 | 200 | 570 | 130 | 90 | 600 | 15 |

| 210T/6000 | 2100 | 6000 | 5100 | 410 | 200 | 570 | 130 | 90 | 600 | 15 |

| 250T/3200 | 2500 | 3200 | 2700 | 410 | 250 | 420 | 160 | 140 | 600 | 18.5 |

| 250T/4000 | 2500 | 4000 | 3500 | 410 | 250 | 620 | 160 | 140 | 600 | 18.5 |

| 250T/5000 | 2500 | 5000 | 4100 | 410 | 250 | 620 | 130 | 90 | 600 | 18.5 |

| 250T/6000 | 2500 | 6000 | 5100 | 410 | 250 | 620 | 130 | 90 | 600 | 18.5 |

| 320T/3200 | 3200 | 3200 | 2700 | 450 | 300 | 670 | 150 | 130 | 600 | 22 |

| 320T/4000 | 3200 | 4000 | 3500 | 450 | 300 | 670 | 150 | 130 | 600 | 22 |

| 320T/5000 | 3200 | 5000 | 4100 | 450 | 300 | 670 | 130 | 90 | 600 | 22 |

| 320T/6000 | 3200 | 6000 | 5100 | 450 | 300 | 670 | 130 | 90 | 600 | 22 |

| 400T/3200 | 4000 | 3200 | 2700 | 500 | 300 | 670 | 150 | 130 | 600 | 30 |

| 400T/4000 | 4000 | 4000 | 3500 | 500 | 300 | 670 | 150 | 130 | 600 | 30 |

| 400T/5000 | 4000 | 5000 | 4100 | 500 | 300 | 670 | 130 | 90 | 600 | 30 |

| 400T/6000 | 5000 | 6000 | 5100 | 500 | 300 | 670 | 130 | 90 | 600 | 30 |

| 500T/4000 | 5000 | 4000 | 3500 | 500 | 300 | 670 | 150 | 130 | 600 | 30 |

| 500T/5000 | 5000 | 5000 | 4100 | 500 | 300 | 670 | 130 | 90 | 600 | 30 |

| 500T/6000 | 5000 | 6000 | 5100 | 500 | 300 | 670 | 130 | 90 | 600 | 30 |

Reviewed by 69 users

I had bought a 250T/4000 CNC press brake of DA66T. That’s good. I like the 3D function, very usefull

i bought 110t 2500mm, good performance

plegadora de chapa MB8-210/4000MM es bueno. Funciona bien

Máquina de plegado de alto rendimiento, precisa y robusta. Interfaz intuitiva, rápida configuración y excelente durabilidad. Ideal para trabajos exigentes, mejora la productividad y garantiza seguridad en operación

i have bought the RAS-3015T fiber laser cutting machine from krrass