News

Record and deliver news and events related to KRRASS and its products. Welcome to follow and subscribe to KRRASS news to get the latest information.

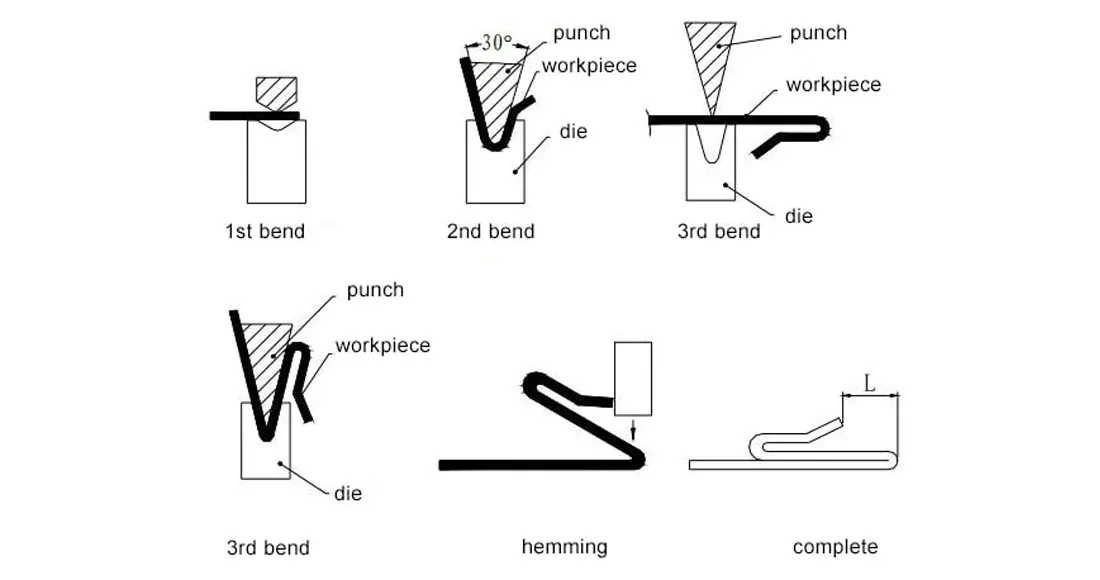

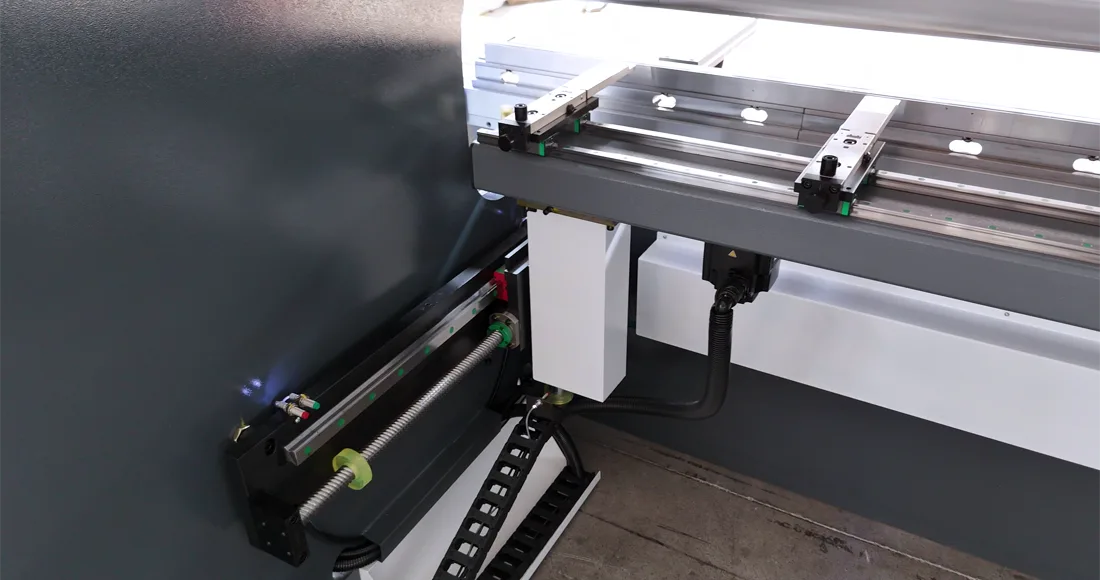

Press Brake Backgauge Calibration: A Complete Step-by-Step Guide

Are you looking to achieve precision in metal bending? Correct calibration of the press brake backgauge is essential. This guide walks you through detailed steps ... Read more

Top Advantages of Hydraulic Bending Machines: Efficiency, Accuracy, and Safety

The adoption of high-power, large-torque servo motors and drive technology has led to the increasing use of electric servo drive systems in CNC bending machines. ... Read more

How to Buy a Fiber Laser Cutter: 11 Essential Tips for Making the Right Choice

Looking to buy a fiber laser cutter? Our guide covers 11 essential tips to help you choose the best fiber laser cutter for your needs, ensuring precision, efficiency, and long-term value.

Top 4 DELEM CNC Controllers for High Precision CNC Bending Machines: How to Choose the Best One

In the world of high precision CNC bending machines, the choice of the right CNC controller is crucial. The CNC controller acts as the brain ... Read more

Can a Laser Cutter Cut Metal: Complete Guide

In today’s diverse and advanced manufacturing landscape, laser cutting technology has become essential across various industries due to its unique advantages and wide-ranging applications. Whether ... Read more

What Is Robotic Press Brake Bending? Comprehensive Guide

Our current economy is facing challenges, with rising material costs and freight expenses causing issues for manufacturers. As a result, many metal fabrication companies are ... Read more

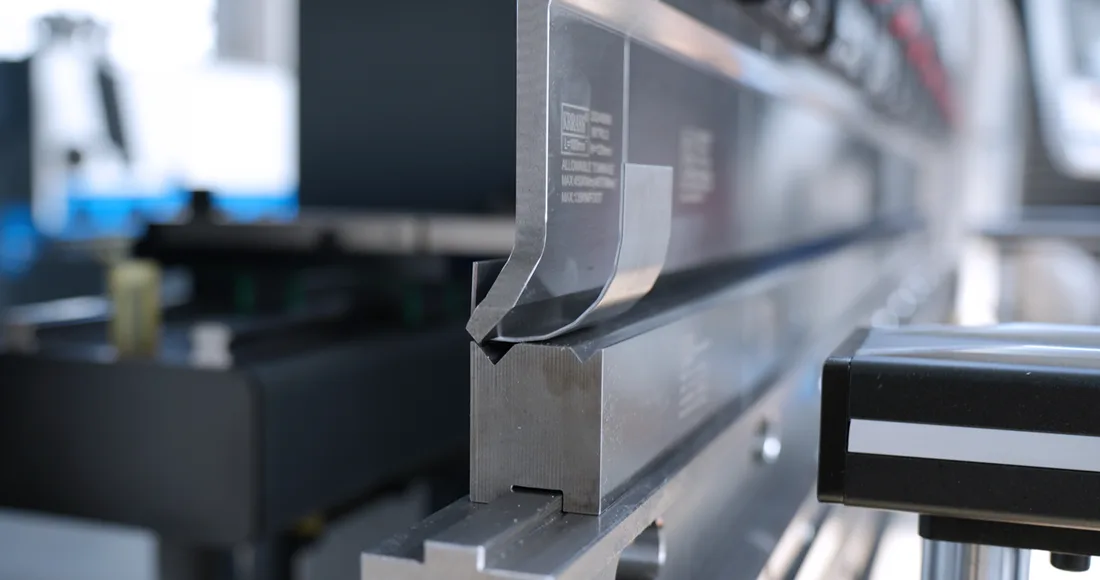

Types of Sheet Metal Bending Machines: Ultimate Guide

Bending machines are integral to the manufacturing industry and come in various types and sizes. With further classification based on features, characteristics, and applications, choosing ... Read more

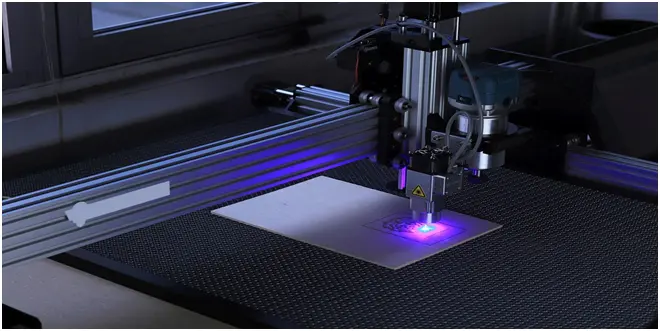

Laser Engraving Machine For Beginners: Ultimate Guide

Surface engraving dates back to the Middle Stone Age, where people with remarkable knowledge etched symbols and writings onto bones, ivory, and stones. Over time, ... Read more

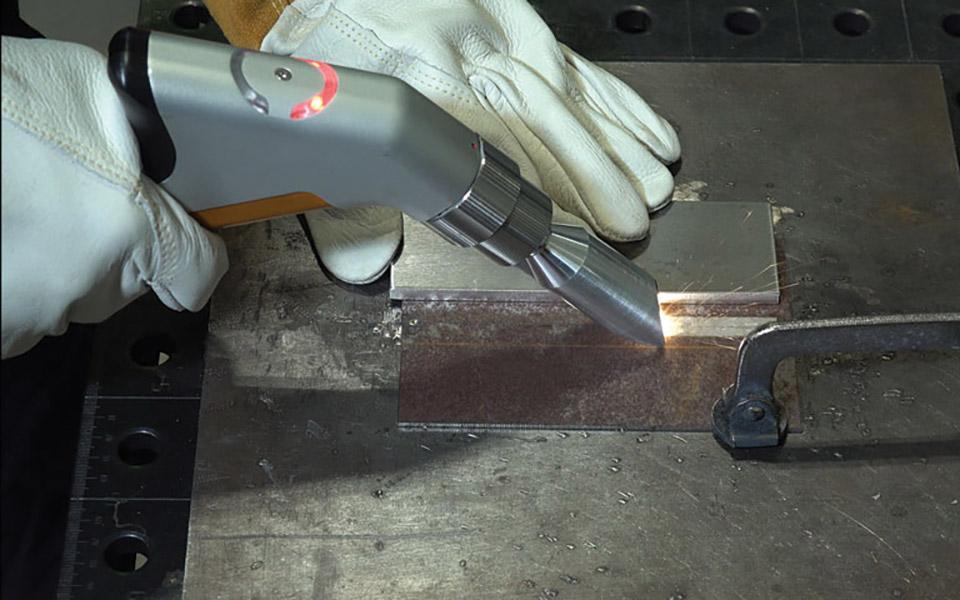

Laser Welding Machine: A Complete Guide for Beginners

Laser welding machines have revolutionized the way metal is joined in industries ranging from automotive to aerospace. Unlike traditional welding methods, a welding laser machine ... Read more

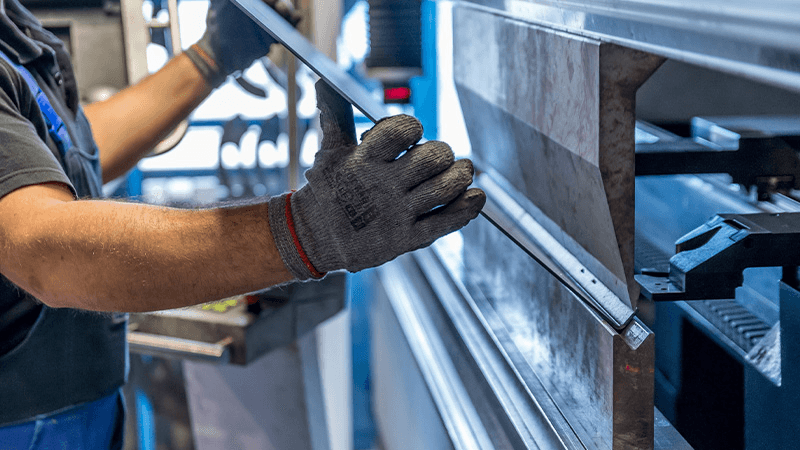

How to Buy Hydraulic Press Brake? Ultimate Guide

When it comes to metal fabrication, investing in the right equipment, such as when you buy hydraulic press brake, can significantly boost productivity, precision, and ... Read more