Fiber laser cutting technology revolutionizes precision manufacturing, offering unparalleled speed and accuracy. Whether in manufacturing or advertising, selecting the right fiber laser cutter is critical to your operational success. This guide will help you make an informed decision when buy a fiber laser cutter.

Table of Contents

What is Fiber Laser Cutting?

Fiber laser cutting is a high-precision technology that utilizes a laser beam transmitted via a fiber optic cable to cut through various materials. Known for its speed and precision, this technology is perfect for cutting metals like stainless steel and carbon steel with outstanding edge quality.

How to Buy Fiber Laser Cutter

Choosing the right fiber laser cutter involves understanding various factors that affect its performance and your production needs. Below are the critical elements to consider:

1. Material Thickness

The thickness of the materials you need to cut is a fundamental factor when selecting a laser cutter. Machines vary in their ability to handle different thicknesses. Choosing a laser cutter that aligns with your needs ensures optimal cutting quality, productivity, and cost-efficiency.

2. Part Sizes

The part sizes you intend to produce affect the choice of bed size. Ensure the machine can handle the largest pieces you plan to cut. A larger bed size provides flexibility and precision across a range of projects.

3. Automation Features

Modern fiber laser cutters come equipped with automation features that enhance productivity. Look for options like automated loading and unloading, software integration for optimized cutting, and remote monitoring capabilities.

4. Overall Productivity

Evaluate a machine’s cutting speed, maintenance needs, and energy efficiency. High cutting speeds without sacrificing quality, minimal downtime, and energy-efficient operation are key productivity indicators.

5. Financing Options

Fiber laser cutters are a significant investment. Explore financing options such as leases, loans, and grants. These options can make acquiring a machine more financially manageable.

6. Power Consumption

Power consumption varies based on wattage. Machines range from 500W to 6,000W or more, with higher wattage suitable for thicker materials but using more power. Choose a machine that balances your production needs with energy efficiency.

7. Table Size

The table size directly affects material handling and project flexibility. Larger tables allow for bigger material sheets and fewer repositionings, improving workflow and reducing waste.

8. Versatility

A versatile fiber laser cutter can handle various production tasks without the need for extensive retooling. Machines with adjustable settings and advanced software compatibility are ideal for adapting to different materials and job requirements.

9. Material Compatibility

Fiber lasers excel at cutting metals like aluminum, brass, and stainless steel. Ensure the machine can handle the materials you work with, as some lasers also offer compatibility with non-metal materials.

10. Manufacturer Reputation

Choosing a reputable manufacturer ensures machine reliability and access to after-sales service. Consider brands known for quality, durability, and strong technical support.

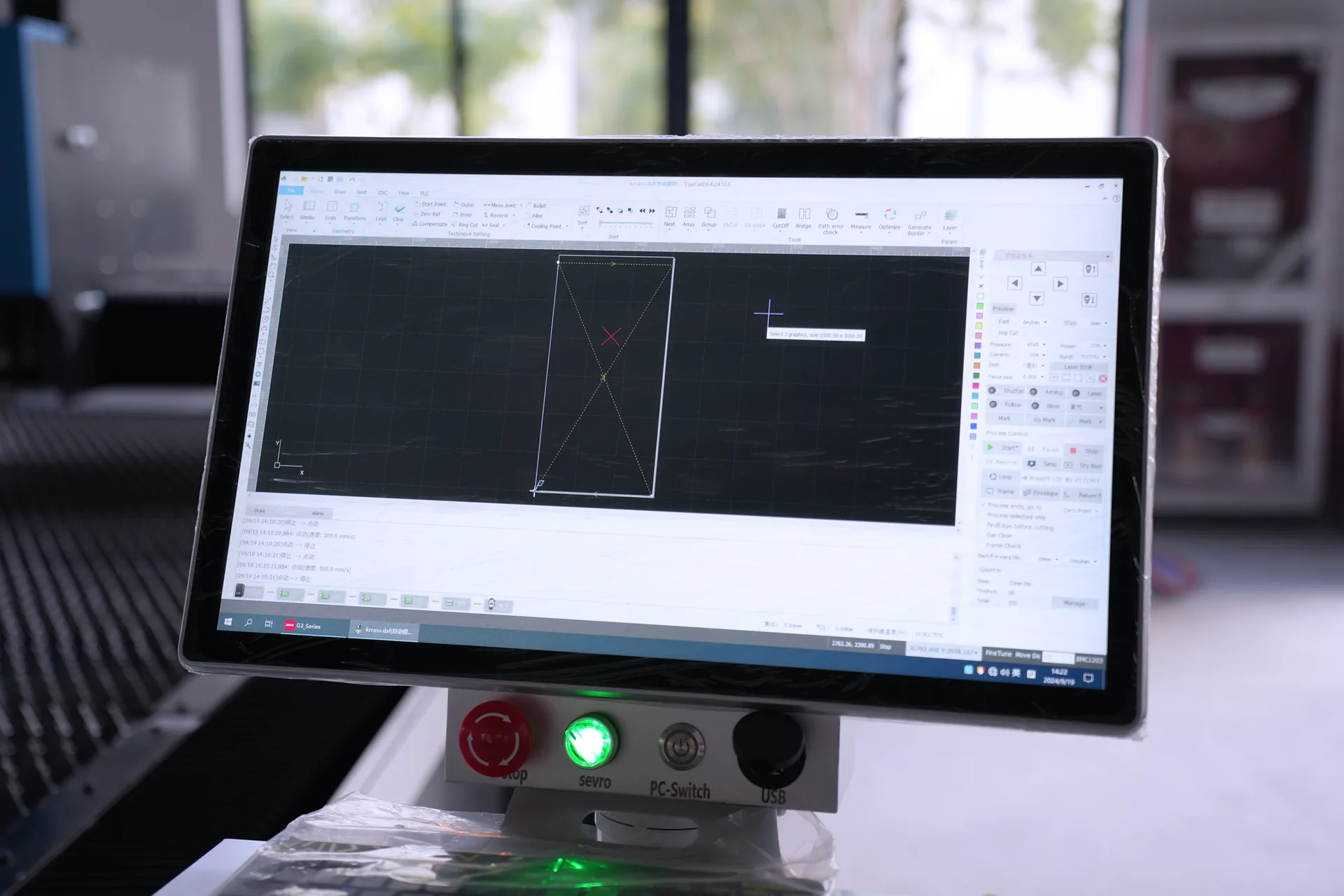

11. Software Integration

Software plays a crucial role in enhancing machine functionality. Look for user-friendly software that automates cutting processes, improves accuracy, and integrates well with your existing design tools.

Case Studies: Choosing the Right Fiber Laser Cutter

- Small Custom Jewelry Shop

- Requirements: Precision for thin metals (0.5mm to 3mm).

- Recommended Machine: A compact, low-power fiber laser cutter (500W–1kW) for detailed cutting.

- Medium-Sized Automotive Parts Manufacturer

- Requirements: Cutting metals up to 12mm thick with high productivity.

- Recommended Machine: A 3kW to 5kW laser cutter with automation features for efficient production.

- Large-Scale Metal Fabrication Facility

- Requirements: Cutting thick steel (over 20mm) with scalability.

- Recommended Machine: A 10kW+ fiber laser cutter with a large table size for heavy-duty tasks.

Conclusion

When buying a fiber laser cutter, consider your material types, production demands, and long-term business goals. By focusing on technical specifications, software compatibility, and reliable after-sales support, you can select a machine that will enhance your manufacturing capabilities.

KRRASS offers a range of high-performance fiber laser cutters designed for diverse industrial applications. Contact us to find the perfect solution for your needs.

Reviewed by 1 user

One of my friend high recommend Krrass, and we will take the laser machine