You want the best cnc 200t press brake for your shop. Many buyers see electric and hydraulic press brakes work well. Your choice depends on cost, accuracy, speed, flexibility, and the environment. The table below shows important things experts suggest:

| Decision Factor | Description |

|---|---|

| Total Cost of Ownership (TCO) | Look at energy use and maintenance over time to save money. |

| Operational Ecosystem Compatibility | Make sure your press brake works with your tools and process. |

| Scalability | Pick a model that can grow as your business gets bigger. |

| Automation Readiness | Choose a cnc press brake that can be automated later. |

| Avoiding Selection Pitfalls | Do not just look at tonnage and price—service and support are important. |

KRRASS is a top company with electric and hydraulic models. This comparison helps you pick the right one.

Table of Contents

Key Takeaways

- Electric press brakes use much less energy. They use 40% to 70% less power than hydraulic models.

- Pick electric press brakes if you need high precision. They can reach tolerances as close as ±0.01 mm.

- Hydraulic press brakes are best for tough jobs. They work well with thick materials and big batches.

- Think about the total cost over time. Electric models may cost more at first. But they cost less to run in the long term.

- Electric press brakes work faster. They can do up to 20 cycles each minute. Hydraulic models do about 15 cycles per minute.

- Electric press brakes are easier to take care of. You only need to add lubrication. Hydraulic models need oil changes often.

- Look at what your shop needs. Electric models are good for fast and precise jobs. Hydraulic models are better for strong, heavy work.

- KRRASS gives expert help and a good warranty. This helps you feel sure about your press brake choice.

Direct Comparison: Electric vs Hydraulic Press Brakes

Key Differences

When you compare electric and hydraulic press brakes, you notice they work differently. Electric press brakes use servo motors to move the ram. Hydraulic press brakes use oil and pumps instead. This difference changes how they perform, how much they cost, and how they work in production.

You might wonder which press brake uses less energy. Electric models can save a lot of energy, between 40% and 70%. Hydraulic press brakes use more power, even when not working. The table below shows how much energy each type saves:

| Type of Press Brake | Energy Savings |

|---|---|

| Electric | 40%–70% |

| Hydraulic | Higher standby energy consumption |

Precision is important in every shop. Electric press brakes can be very accurate, up to ±0.01 mm. Hydraulic press brakes are less accurate, at ±0.1 mm. Electric models help you make parts with tighter tolerances.

| Type of Press Brake | Accuracy |

|---|---|

| Electric | ±0.01 mm |

| Hydraulic | ±0.1 mm |

Maintenance is another thing to think about. Electric press brakes need less care. You only need to lubricate the guide rails. Hydraulic press brakes need oil changes and regular checks. This can make them cost more over time.

| Type of Press Brake | Maintenance Requirements |

|---|---|

| Electric | Low, lubricate guide rails |

| Hydraulic | High, regular oil replacement and inspections |

Speed matters for your work. Electric press brakes speed up quickly. Their idle speed can be over 200 mm/s. Hydraulic press brakes move slower because they are heavier. Faster speed helps you finish jobs faster.

| Type of Press Brake | Operational Speed |

|---|---|

| Electric | Fast acceleration, idle speed over 200 mm/s |

| Hydraulic | Slower due to large inertia |

KRRASS sells both electric and hydraulic press brakes. You can pick the one that fits your shop. The brand has options for every shop size and production need.

Which Suits Your Needs

You want the best cnc 200t press brake for your business. Electric and hydraulic press brakes each have good points. Electric press brakes are great for high precision, fast speed, and easy care. These models help you save energy and work more efficiently. You get steady results and quick cycles.

Hydraulic press brakes are good for heavy-duty jobs. These machines are strong and work well with thick materials and big batches. You get strong bending force and reliable performance. Hydraulic press brakes are best for tough jobs.

If you want more flexibility, electric press brakes can handle tricky bends and automation. Hydraulic press brakes are strong for hard tasks. Your choice depends on your workflow, the materials you use, and how much you need to produce.

KRRASS gives you many cnc press brake choices. You can choose electric or hydraulic models for your shop. The brand’s experience and support help you pick the best one. This comparison helps you learn more about power, efficiency, speed, and value in the next sections.

Power & Efficiency in CNC 200T Press Brake

Hydraulic Press Brake Energy Use

Hydraulic press brakes have helped metal shops for years. Many factories use these machines for hard jobs. Hydraulic press brakes move the ram with oil and pumps. This needs a lot of energy. A hydraulic CNC 200t press brake uses about 4.5 kW each hour. You pay for this energy every time you use the machine.

Operating Costs

You should think about costs when picking a press brake. Hydraulic models usually cost more to run. The pumps keep working even when not bending metal. This means you spend more on electricity during long jobs. Hydraulic press brakes are great for tough work, but you pay more for energy.

Standby Power

Hydraulic press brakes use power even when not working. The system keeps oil ready for the next job. This standby power makes your bills higher each month. If your shop works many hours, you see extra costs. You need to add this cost when comparing electric and hydraulic press brakes.

Electric Press Brake Efficiency

Electric press brakes use servo motors, not pumps. You get quick control and fast action. Electric models are very efficient in every shop. You save energy because motors run only when bending. This design helps you spend less and be more green.

Energy Savings

Electric press brakes save a lot of energy. The KRRASS MB8-210T6000 uses hybrid technology. You can save 55% to 78% on energy compared to hydraulic models. You spend less on electricity and help the planet. Electric models are smart for shops that want to save money and be more green.

Cost Over Time

Electric press brakes help you save money over time. You pay less for energy and repairs. The motors need less care than hydraulic systems. You also get better accuracy, which means less waste. Electric press brakes give you lower costs, better efficiency, and faster work.

KRRASS MB8-210T6000 Example

The KRRASS MB8-210T6000 shows how new technology helps efficiency. This cnc press brake uses hybrid technology for great results. You get fast cycles and steady production. The machine helps you save energy and money. You also get advanced controls for better accuracy. The MB8-210T6000 is better than hydraulic models in many ways. You see clear wins in efficiency, being green, and speed. If you want a press brake that works well, this model gives you power and accuracy.

Tip: When picking a cnc press brake, always think about energy use and costs. Electric models like the MB8-210T6000 help you get better results and spend less.

Speed & Productivity Comparison

Hydraulic Cycle Times

Hydraulic press brakes have helped metal shops for years. Many factories use them for hard jobs. These machines use oil and pumps to move the ram. This system gives strong bending force. But it makes the machine slower. Hydraulic press brakes do less than 15 cycles each minute. This speed is good for thick materials and tough jobs.

High-Volume Performance

Hydraulic press brakes are strong for big batches. You can bend many parts without stopping. These machines work well with thick steel and wide sheets. You get steady results for lots of parts. But slower cycles mean fewer parts each hour. If your shop does big jobs, hydraulic press brakes help you meet demand.

Electric Press Brake Speed

Electric press brakes use servo motors for quick moves. You control the ram with speed and accuracy. Electric models can do up to 20 cycles each minute. The ram can go down at 200 mm/s. The backgauge can move at 400 mm/s. You finish jobs faster and keep working. Electric press brakes help you save time on every part.

Setup & Changeover

You set up electric press brakes fast. The control system lets you change jobs in seconds. You switch tasks without waiting long. This makes you more efficient. You spend less time waiting and more time working. Electric press brakes help with tricky bends and short jobs.

Impact on Workflow

Speed and productivity affect your shop’s workflow. Electric models are faster and more productive. You can make two or three times more parts than hydraulic models. The table below shows how electric and hydraulic press brakes compare:

| Feature | Electric Press Brake | Hydraulic Press Brake |

|---|---|---|

| Cycle Speed | 15-20 cycles per minute | Slower than electric |

| Descent Speed | Up to 200 mm/s | Typically lower than electric |

| Backgauge Speed | Up to 400 mm/s | Generally slower |

| Efficiency Improvement | 30-50% more parts made | Not as good for big batches |

| Output Comparison | Can make two or three times more parts | Standard output |

Electric press brakes help you finish more jobs each day. You save money and help the environment. Electric models give you better accuracy and more parts. Hydraulic models are strong for hard jobs. But electric models are faster and more efficient. This helps you pick the best cnc 200t press brake for your shop.

Tip: If you want faster cycles and more parts, pick electric press brakes. You get better efficiency, quick setup, and higher output. Hydraulic press brakes are good for tough jobs, but electric models help you work faster and more accurately.

Precision & Accuracy in CNC Press Brake

Hydraulic System Tolerances

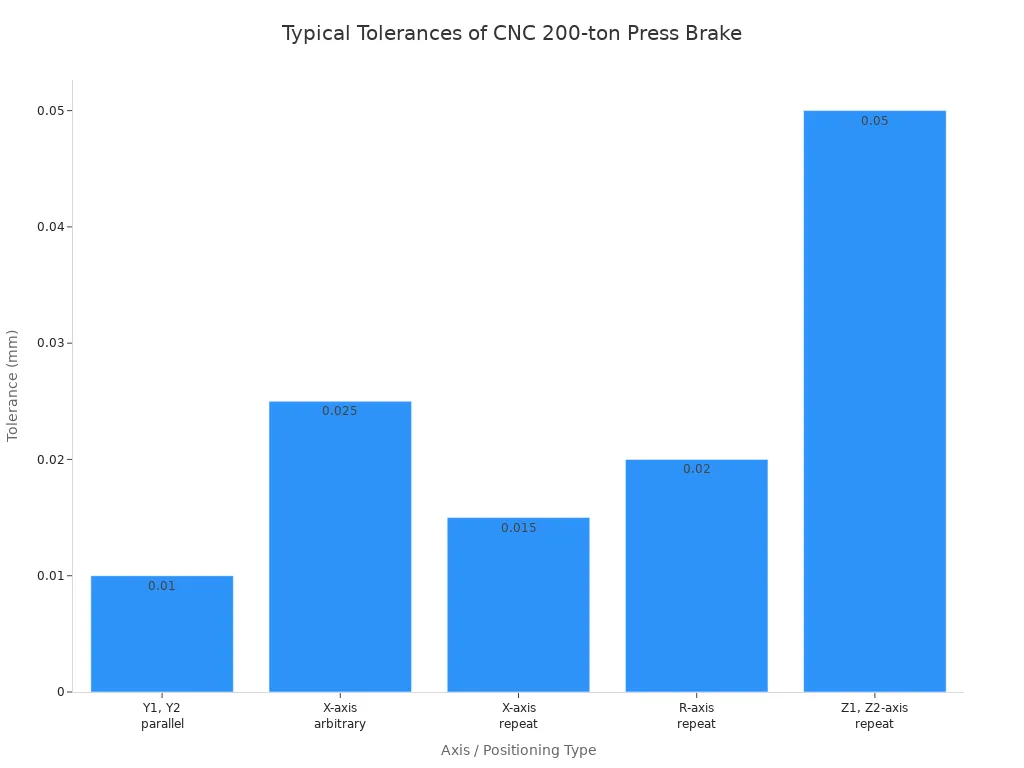

Hydraulic press brakes have helped metal shops for many years. These machines give steady results for tough bending jobs. The tolerances you get depend on the design and controls. Most hydraulic models meet the standards needed for production. You can check the usual tolerances in the table below:

| Axis | Tolerance (mm) |

|---|---|

| Y1, Y2 parallel tolerance | ±0.01 |

| X-axis arbitrary positioning precision | ±0.025 |

| X-axis repeat positioning precision | ±0.015 |

| R-axis repeat positioning precision | ±0.02 |

| Z1, Z2-axis repeat positioning precision | ±0.05 |

Consistency

Hydraulic press brakes keep working well for many cycles. You get good results with thick materials and big batches. The system stays accurate even during long runs. You can see the axis tolerances in the chart below:

Electric System Precision

Electric press brakes use servo motors and smart controls. These machines give you better precision and work faster. Electric models can reach tight tolerances like ±0.01 mm. You can make quick changes and get the same results every time. The electric system reacts fast, so it is good for tricky bends and short jobs.

Advanced Controls

Electric press brakes let you control more things. The DELEM DA53T controller in the KRRASS MB8-210T6000 has special features. You can manage up to four axes, like Y1, Y2, and two extra axes. The controller uses smart algorithms for exact movement. CNC crowning control keeps bending angles the same. The electric crowning system makes angles more accurate. The Fagor grating ruler gives feedback, so you can change the slider position right away. The Rexroth proportional valve keeps everything steady and exact, even when working fast.

| Feature | Description |

|---|---|

| Up to 4 axes (Y1,Y2 + 2 aux. axes) | Lets you do complex bends with better control. |

| Advanced Y-axis control algorithms | Uses smart valves for exact control. |

| CNC Crowning control | Keeps bending angles the same for different materials. |

| Electric Crowning System | Makes bending angles very accurate. |

| Fagor Grating Ruler | Shows slider position, so you can adjust in real time. |

| Rexroth Proportional Valve | Keeps things stable and exact during fast work. |

KRRASS Technology

KRRASS mixes hydraulic and electric benefits in its cnc press brake line. The MB8-210T6000 is great for precision and efficiency. You get smart controls and steady performance every time you use it. The DELEM DA53T controller helps you get tight tolerances and steady results. You spend less and get better accuracy with each job. Comparing electric and hydraulic press brakes shows electric models are better for precision and efficiency. You get fewer problems and more output with KRRASS technology.

Note: You help your shop make better parts and get more accurate results when you pick a press brake with smart controls and tight tolerances.

Flexibility & Application Range

Hydraulic Versatility

Hydraulic press brakes are strong. They bend thick materials easily. You can shape steel plates and heavy aluminum. Wide sheets are no problem for these machines. Many shops use hydraulic press brakes for big jobs. They work in construction and shipbuilding. Industrial equipment makers also use them. These machines handle tough tasks well. They keep working for long cycles. You get steady performance with large parts. Hydraulic press brakes work with high-strength metals.

Thick Material Handling

Hydraulic press brakes are good for thick materials. The system uses oil and pumps for steady pressure. You can bend heavy plates and keep precision. This helps with steel beams and bridge parts. Large machinery parts are easy to bend. Hydraulic press brakes keep your work moving. They do well with hard jobs.

Electric Adaptability

Electric press brakes are flexible. They help with complex bends and many jobs. You control the ram with servo motors. Advanced programming makes things easier. You get high precision and fast cycles. You can switch jobs quickly. Small batches and big orders are easy to handle. Electric press brakes are great for custom work. They help industries that need tight tolerances.

Complex Bends

Electric press brakes do well with tricky bends. The 4+1 axis control system helps make detailed shapes. You get the same precision every time. You can bend electrical cabinets and car parts. Aerospace components are easy to shape. Digital controls let you change settings for each job. You see fewer mistakes and better workflow.

| Feature | Description |

|---|---|

| Axis Control | 4+1 axis control system for great bending accuracy and flexibility. |

| Precision | Handles hard sheet metal bends with steady precision. |

| Applications | Used in automotive, aerospace, and custom fabrication. |

- Electrical cabinets and enclosures

- Automotive and aerospace parts

- Appliances and furniture sheet metal

- Construction and HVAC equipment

- Custom fabrication workshops

Electric CNC press brakes use digital programming. They have smart compensation. You can bend many materials and shapes. You keep accuracy every time. This helps you save money and work better.

Industry Suitability

You need the right press brake for your job. Hydraulic press brakes are best for heavy-duty work. Shipbuilding and construction use them a lot. Industrial factories need them for thick plates. You get strong force and steady results.

Electric press brakes are good for jobs needing precision. Automotive and aerospace shops use them for tricky bends. Custom fabrication shops like fast cycles. Electric models help with electronics and furniture. HVAC makers also use them. You get high quality parts with electric press brakes.

KRRASS has many press brake choices. You can pick hydraulic for thick materials. Electric models are good for advanced bends. The brand helps your shop with strong machines and expert support. This guide helps you choose the best press brake for your work.

Tip: Pick a press brake that fits your material thickness, bend type, and job size. KRRASS gives you choices for every need. You get good efficiency and precision.

Environmental Impact Comparison

Hydraulic Fluid & Waste

Hydraulic press brakes use oil to bend metal. You need to change the oil often. Old oil can leak or spill. This can hurt the environment. Shops must collect waste oil and throw it away safely. If you do not follow the rules, water and soil can get dirty. Hydraulic systems use filters and hoses. You replace these parts during maintenance. These things add more waste to your shop.

Maintenance

You spend time and money to keep hydraulic press brakes working. You need to change oil and check the machine often. You must look for leaks and change old parts. These jobs help stop accidents and protect nature. Good care lowers the chance of spills. It keeps your shop safe. You also follow rules for dangerous waste. Hydraulic press brakes need more care than electric ones.

Electric Sustainability

Electric press brakes use servo motors, not oil. You do not need hydraulic fluid. This means no spills or leaks. Electric machines help keep your shop clean. They use less energy each time you bend metal. This saves money and helps the earth. Electric press brakes help shops be more green. You meet world rules for emissions. You also make less pollution.

Emissions & Noise

Electric press brakes are quiet. You hear less noise in your shop. This makes work safer and nicer. These machines do not make smoke or bad gases. You help your team stay healthy. You also protect nature. Electric models match green goals. They show you care about the planet. You meet strict emission rules in many places.

- Electric CNC press brakes give you:

- Better energy use

- Lower carbon pollution

- Follow world emission rules

- Quieter work for everyone

Energy Ratings

You can check energy ratings to pick the best press brake. Electric press brakes usually have higher ratings. You save money on power and help the earth. KRRASS hybrid and electric models use smart technology. They can cut energy use by up to 78%. You get strong machines and help the planet. If you choose a CNC press brake with high ratings, you show customers you care about being green.

Tip: If you want to save money and help the environment, look at electric or hybrid press brakes from KRRASS. You get good machines and help make the world better.

Cost & Maintenance of CNC Press Brake

Hydraulic Maintenance

Hydraulic press brakes need regular care to keep working well. You must check and clean the machine often. You also need to watch for leaks and keep the oil at the right level. Shops that use a hydraulic press brake follow a set schedule for maintenance. This helps you avoid problems and keep your machine running smoothly.

Here is a simple table that shows how often you should do each task:

| Frequency | Maintenance Tasks |

|---|---|

| Daily | Inspect while cleaning, lubricate parts, clean touch screen controls. |

| Weekly | Lubricate moving parts, apply rust protectant, clean hydraulic pump motor. |

| Monthly | Check hydraulic oil levels, clean filters, check for leaks, tighten bolts and connections. |

| Bi-Monthly | Lubricate grease fittings, back up CNC control programming. |

| Annual | Change hydraulic oil and filters, check electrical connections, perform preventative maintenance with a technician. |

Common Repairs

You may need to fix leaks or replace worn seals on a hydraulic press brake. Sometimes, you must change the hydraulic oil or clean the filters. If you hear strange noises, you should check the pump and hoses. Regular checks help you find small problems before they become big repairs. This keeps your press brake working through every cycle.

Electric Maintenance

Electric press brakes need less care than hydraulic models. You do not have to change oil or worry about leaks. Most of your work involves checking the guide rails and keeping the machine clean. You should also look at the control system and make sure all wires stay tight.

Reliability

Electric press brakes give you steady performance. The servo motors last a long time and need little attention. You can trust your electric press brake to run many cycles without stopping. This means you spend less time on repairs and more time making parts. Shops that use electric models see fewer breakdowns and lower maintenance costs.

Total Cost of Ownership

When you look at the total cost of owning a press brake, you must think about more than just the price tag. Hydraulic press brakes often cost less to buy at first. Over time, you pay more for oil, filters, and repairs. Electric press brakes may cost more at the start, but you save money on energy and maintenance. You also get better performance and more cycles before you need service.

KRRASS gives you strong support and a good warranty for every cnc press brake. You can count on help if you have questions or need service. This support lowers your long-term costs and keeps your machine running well. When you compare electric and hydraulic press brakes, you see that electric models help you save money and time in the long run. This comparison shows why many shops choose electric press brakes for better value and reliability.

Tip: Always check the warranty and support when you buy a cnc press brake. KRRASS offers expert help and fast service, so you can focus on your work.

Value & Investment: KRRASS CNC Press Brake

Hydraulic Press Brake Value

What You Get

If you pick a hydraulic press brake from KRRASS, you get more than a machine. You get smart features that help you work better and faster. The hydraulic system gives strong bending force for thick materials. You can do hard jobs without worry. KRRASS hydraulic press brakes have smart controls and automatic functions. These features make your work easier and more exact.

Here is a table that shows what makes KRRASS hydraulic press brakes special:

| Feature | Description |

|---|---|

| R-Axis | Changes the backgauge fingers’ height for different thicknesses. |

| Z-Axis | Controls how far the backgauge fingers go into the material. |

| CNC Crowning | Fixes ram bending, so bends stay exact even with heavy loads. |

| Delem Controller | Lets you set angles, positions, and depths for each cycle. |

| Advanced Features | Figures out settings and fixes angles by itself, saving time and stopping mistakes. |

You get steady results every time you use the machine. The hydraulic press brake helps you save money by making fewer mistakes and working better.

Electric Press Brake Value

ROI

Electric press brakes from KRRASS help you get your money’s worth. You save on energy and maintenance. The electric system uses servo motors that need less care and last longer. You finish each job faster and with better accuracy. This means you make more parts in less time.

You also spend less because electric press brakes use less power. You do not need hydraulic oil or new filters. You pay less for repairs and have less downtime. The electric press brake helps you work faster and make better parts. You see your savings grow as you make more parts and waste less.

Tip: Electric press brakes help you make more parts and save money. You get fast jobs, high accuracy, and lower costs.

KRRASS MB8-210T6000 Features

The KRRASS MB8-210T6000 is a top cnc press brake. It uses hybrid technology that mixes hydraulic and electric systems. The machine has smart controls for every job. You can bend hard shapes with high accuracy. The DELEM DA53T controller lets you control up to four axes. You get CNC crowning for perfect angles and steady work.

Key features include:

- Hybrid drive saves energy and gives strong bending force

- DELEM DA53T controller makes programming and setup easy

- CNC crowning system keeps results the same every time

- European clamping system lets you change tools quickly

- KRRASS gives you good support and a strong warranty

You get a press brake that works hard and lasts a long time. KRRASS gives expert help and quick service. You can trust your cnc press brake to keep your shop working well. The MB8-210T6000 gives you great results, lower costs, and good value.

Hybrid & Advanced Press Brake Options

What Is Hybrid Technology

Hybrid press brake technology mixes electric and hydraulic systems. Hybrid models use servo drives to run hydraulic pumps. This design gives strong power for thick materials. It also keeps energy use low. You get both electric and hydraulic benefits. The servo system controls the hydraulic fluid flow. You only use energy when bending metal. Hybrid press brakes turn off when not working, like electric machines. This helps you save money and protect the environment.

- Hybrid press brakes mix electric and hydraulic benefits.

- Servo drives run hydraulic pumps for better efficiency.

- You get strong bending power for thick materials.

- Hybrid models work well for shops needing up to 250 metric tons of force.

Pros & Cons of Hybrid

Hybrid press brakes have many good points for your shop. You get precision, energy savings, and less maintenance. The system gives power and flexibility for tough jobs. Hybrid models help you lower your impact on the environment. You see steady pressure, which means high precision for every bend.

Pros of Hybrid Press Brakes:

- Mix hydraulic and electric strengths for better performance.

- Give high precision and energy efficiency.

- Need less maintenance than regular hydraulic models.

- Give strong force for thick materials.

- Lower your shop’s impact on the environment.

Cons of Hybrid Press Brakes:

- Cost more at first than regular hydraulic or electric models.

Hybrid press brakes use a servo-drive system, not gear pumps. You save energy because the machine turns off when idle. This matches the efficiency of electric press brakes. Hybrid models are great for shops that need power and smart energy use.

KRRASS Hybrid Solutions

KRRASS offers advanced hybrid press brake choices. The brand makes machines that mix electric and hydraulic technology for top results. You get models like the PBE and PBA Series. These use less hydraulic oil and give strong bending force. Hybrid press brakes help you save up to 78% on energy compared to older machines. You also get better accuracy and faster cycles. KRRASS hybrid press brakes fit shops that want high performance and lower costs. You get reliable machines, expert help, and a warranty that keeps your business running well.

Tip: If you want a press brake with power, efficiency, and precision, look at KRRASS hybrid models. You get the benefits of electric and hydraulic systems in one smart solution.

Choosing Your CNC 200T Press Brake

Buyer Checklist

You want to make a smart choice when you buy a press brake. Use this checklist to help you compare options:

- Decide if you need electric or hydraulic power for your jobs.

- Check the bending force and working length for your materials.

- Look at the control system. See if it is easy to use and program.

- Ask about energy savings and maintenance needs.

- Review the warranty and after-sales support from KRRASS.

- Think about future upgrades or automation.

Tip: Write down your needs before you talk to a supplier. This helps you ask better questions and get the right press brake.

Matching to Your Shop

You need a press brake that fits your shop’s workflow. Electric models work well for shops that want fast cycles and high precision. You can finish small batches quickly and switch jobs with ease. Hydraulic models suit shops that bend thick plates or run heavy-duty jobs. You get strong force and steady performance for big projects.

Here is a table to help you match the right press brake to your shop:

| Shop Type | Best Choice | Why It Works |

|---|---|---|

| Custom Fabrication | Electric | Fast setup, tight tolerances |

| High-Volume Factory | Hydraulic | Strong force, handles thick material |

| Mixed Production | Hybrid/Electric | Flexibility, energy savings |

KRRASS offers many press brake models. You can choose electric, hydraulic, or hybrid machines. The team helps you pick the best fit for your workflow and production goals.

Future-Proofing

You want your press brake to last for years. Think about how your shop might grow. Electric models make it easy to add automation or advanced controls. You can upgrade software and add new features. Hydraulic models give you strong power for expanding into bigger jobs. Hybrid models offer a balance of force and efficiency.

Note: KRRASS supports you with training, upgrades, and expert advice. You can reach out for help as your needs change.

Plan for the future by choosing a press brake that can grow with your business. Ask about options for automation, smart controls, and remote support. KRRASS helps you stay ahead with reliable machines and strong service.

You can easily tell electric and hydraulic press brakes apart. Electric press brakes work fast and use less energy. They also make very accurate bends. Hydraulic press brakes are strong for thick metal. They do well with hard jobs and big tasks. Electric press brakes help you save money over time. Hydraulic press brakes are good for heavy-duty work. KRRASS gives you press brakes you can trust. You can ask KRRASS experts for help picking a press brake. Choose the press brake that matches your shop’s needs. Make your choice with confidence.

FAQ

What is the main difference between electric and hydraulic CNC press brakes?

Electric press brakes move with servo motors. Hydraulic press brakes use oil and pumps to move. Electric models work faster and are more accurate.

How do I choose the right press brake for my shop?

Think about how thick your materials are. Look at how big your jobs are. Decide if you need speed or high accuracy. KRRASS experts can help you pick the best model for your work.

Are electric press brakes more energy efficient?

Yes. Electric press brakes save energy because motors only run when bending. You pay less for power and help the planet.

What maintenance does a hydraulic press brake need?

You need to check oil often and change filters. Look for leaks and clean the machine. Regular service keeps your hydraulic press brake working well.

Can I automate my KRRASS CNC press brake later?

Most KRRASS CNC press brakes can add automation. Ask about which controllers and upgrades work for your needs.

What warranty and support does KRRASS offer?

KRRASS gives a strong warranty and quick support. You get help with setup, training, and repairs. Contact KRRASS to learn more about what is covered.

Which industries use CNC 200-ton press brakes?

CNC 200-ton press brakes are used in car, airplane, and building jobs. Custom shops also use them for thick metal and hard bends.