When you choose a laser tube cutting machine in 2026, you want it to be strong, fast, and dependable. The best machines include the KRRASS RAS-B Tube Plate Fiber Laser Cutting Machine, TRUMPF TruLaser Tube Series, BLM GROUP Lasertube, Mazak FG Series, Bystronic ByTube, and LVD Tube Laser. These laser tube cutting machines operate quickly, accurately, and can work autonomously. The table below shows how the top laser cutter models compare for accuracy and important features:

| Rank | Machine Model | Precision (Tolerance) | Key Features |

|---|---|---|---|

| 1 | TruLaser 5030 Fiber | ±0.02mm | BrightLine Fiber, CoolLine |

| 2 | ByStar Fiber | N/A | BeamShaper, ByVision Cutting |

| 3 | OPTIPLEX 3015 NEO | N/A | Intelligent Cutting Head, durability |

| 4 | GHF Series High-Power | N/A | AI-powered autofocus |

| 5 | ENSIS AJ 4kW | N/A | Robotic handling |

You need to select the right fiber laser tube cutting machine for your work. Each laser tube cutting machine offers unique advantages for different jobs and materials.

Table of Contents

Key Takeaways

- Pick a laser tube cutting machine for its strength, speed, and reliability. Make sure it fits what you need to make.

- Think about machines like KRRASS RAS-B and TRUMPF TruLaser Tube Series. These models are known for being precise and having automation features.

- Find machines that can cut many materials, like carbon steel, stainless steel, and aluminum. This will help you do more types of jobs.

- Check the total cost to own the machine, including how much it costs to fix and run. This helps you save money over time.

- Choose machines that have good support and service. This will help you avoid long stops and keep your work going.

- Automation features, like automatic loading and AI systems, can help you work faster. They also mean you do not need as much manual work.

- Make sure your machine can get hardware upgrades and software updates. This will help your machine stay useful as technology changes.

- Doing regular maintenance and having training is important. This helps your laser tube cutting machine work well and last longer.

Top Laser Tube Cutting Machines 2026

KRRASS RAS-B Fiber Laser Tube Cutting Machine

Features

This fiber laser tube cutting machine is strong and cuts well. The KRRASS RAS-B can use power from 1500W up to 20,000W. It cuts round tubes from φ10 to φ10 and square tubes from 10x10mm to 220x220mm. The machine has a welding bed that is very accurate. It can work with sheet production lines. An auto oil-filling system keeps the machine working smoothly. Software like FSCUT3000S and FSCUT2000 helps you cut pipes and plates exactly. Double pneumatic chucks center tubes and spin them, so there is less waste. You only have 50mm of leftover material. You can add automatic loading to make work faster. BOCHU smart cutting heads check and report problems right away.

Applications

You can use the KRRASS RAS-B in metal workshops, car part factories, and building jobs. The machine works with carbon steel, stainless steel, aluminum alloys, and other metals. It can cut I-beams, channel steel, and angle steel easily. Small and medium businesses use this machine to cut tubes and plates quickly and well.

Advantages

The KRRASS RAS-B saves you time and money. It uses less raw material and costs less to buy. The parts come from trusted companies, so the machine lasts longer. You can add it to your work line fast. You get your machine quickly and can pick from many sizes. Automation makes work faster and means you do not need as much help. The machine is safe and easy to take care of.

TRUMPF TruLaser Tube Series

Features

Many companies pick the TRUMPF TruLaser Tube Series. The table below shows its main features and new technology:

| Feature/Advancement | Description |

|---|---|

| Automation and Efficiency | Advanced automation features, including automatic loading and unloading systems. |

| Versatility | Capable of cutting various tube types, including round, square, and rectangular profiles. |

| Flexibility | Quick switching between different tube profiles and materials to adapt to production needs. |

| High-Speed Cutting | Achieves high cutting speeds for shorter production cycles without compromising quality. |

| Precision Cutting | Provides accurate and precise cuts on various tube materials and profiles. |

| Complex Geometries | Handles complex 2D and 3D cuts, including bevel cuts and miters. |

| Reduced Material Waste | Minimizes waste through optimized cutting processes, leading to cost savings. |

| Software Integration | Offers software solutions for CAD/CAM compatibility and remote monitoring. |

| Quality Control | Integrated quality control systems ensure final parts meet specifications and quality standards. |

Applications

You use the TRUMPF TruLaser Tube Series for making lots of parts, custom jobs, and tricky tube shapes. The machine is good for car, furniture, and building work. You can change tube shapes and materials fast, so you can keep up with new orders.

Advantages

TRUMPF machines are fast and flexible. Automation means less lifting and more work done. You get exact cuts, even on hard shapes. The software lets you watch your work from far away and works with CAD/CAM. You waste less material and have good quality checks.

BLM GROUP Lasertube

Features

BLM GROUP Lasertube machines bring new tech to your shop. The table below lists their best features:

| Feature/Innovation | Description |

|---|---|

| 3D Cutting Head | Enables aesthetic couplings and preparation for welding with inclined cuts for better finishes. |

| Tube Range | Capable of cutting tubes from 0.5″ to 6″ in diameter, accommodating various sizes. |

| Automatic Adjustments | The LT6 is ready for the next cut without manual intervention, enhancing efficiency. |

| Smart Templates | Manually adjusted templates provide additional precision for small and lightweight tubes. |

| Programmable Unloading Positions | Allows for pre-separated parts at the exit, improving workflow efficiency. |

| BLMelements Software Suite | Offers CAD/CAM design, batch time estimates, and real-time monitoring to optimize laser cutting. |

Applications

BLM GROUP Lasertube machines are used in many factories. The table below shows main uses:

| Use Case | Description |

|---|---|

| Chassis Components | Used in the production of chassis parts for various industrial vehicles. |

| Exhaust Pipes | Essential for manufacturing exhaust systems in vehicles. |

| Bodywork Tubular Components | Facilitates the creation of tubular structures for vehicle bodywork. |

| Accessories | Supports the production of various vehicle accessories and interior components. |

| Production Flexibility | Allows for quick adjustments to production processes to meet changing demands. |

| Streamlined Processes | Reduces the need for secondary operations, enhancing overall efficiency. |

| Variety of Profiles and Materials | Capable of cutting different shapes and materials, increasing versatility in manufacturing. |

Advantages

BLM GROUP Lasertube machines are flexible and work fast. Automatic changes and smart templates help you switch jobs quickly. The 3D cutting head lets you make cool and tricky cuts. You can set where finished parts go, which helps your work flow better. The BLMelements software helps you design, plan time, and check your work as you go. You can cut many tube sizes and shapes, so your shop can do more jobs.

Mazak FG Series

Features

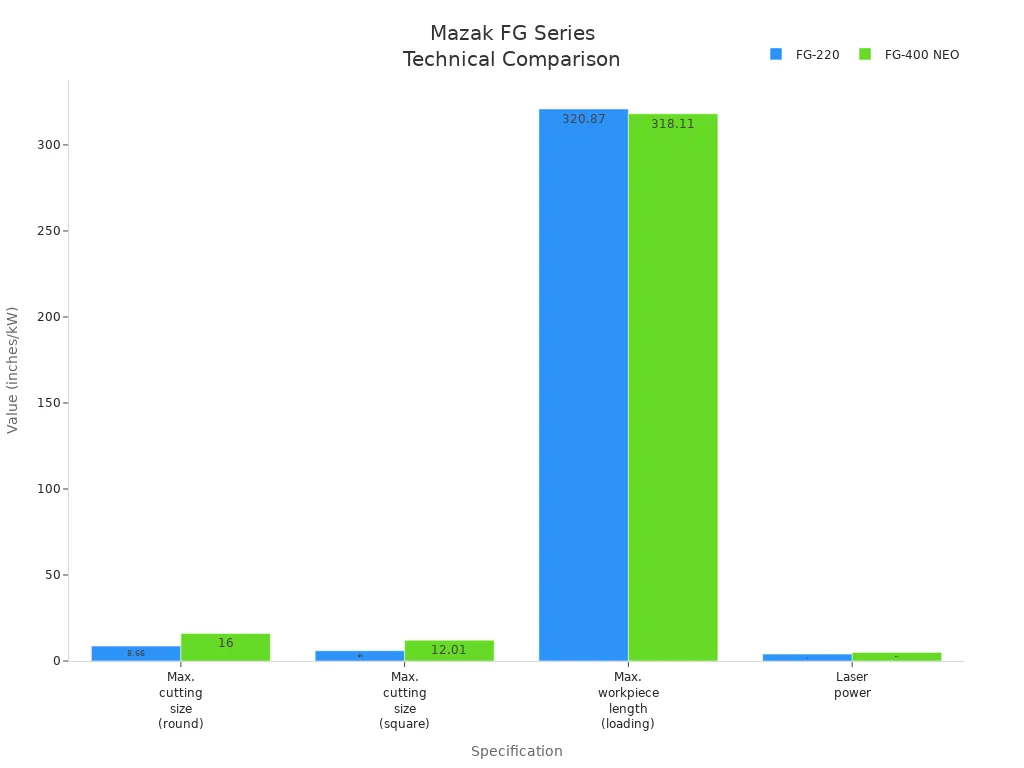

You can trust the Mazak FG Series for strong tube cutting. The FG-220 and FG-400 NEO are built with new technology. The FG-220 has a 3D cutting head with A-axis and B-axis. This lets you cut tubes at many angles and shapes. The FG-400 NEO uses Beam Shaping Technology. This means you get faster cuts and smoother edges. Both models let you cut, drill, and tap in one setup. This saves you time and helps you work faster.

Here is a quick look at the technical specifications:

| Specification | FG-220 | FG-400 NEO |

|---|---|---|

| Max. cutting size (round) | Φ8.66″ | Φ16″ |

| Max. cutting size (square) | 6″ × 6″ | 12.01″ × 12.01″ |

| Max. workpiece length | 320.87″ | 318.11″ |

| Laser power | 4.0 kW | 5.0 kW |

| Workpiece shape | round, square, L beam, H beam, I beam, channel | round, square, rectangular, structural |

| Workpiece material | mild steel, stainless steel, copper, brass, aluminum | mild steel, stainless steel, copper, brass, aluminum |

| Max. workpiece weight | 360 kg | N/A |

| Machine weight | 33,200 kg | N/A |

Applications

You can use the Mazak FG Series in many places. These machines cut round, square, and structural tubes. You can make parts for buildings, cars, and big machines. You can cut, drill, and tap all at once. This helps you finish jobs faster. The FG Series works with mild steel, stainless steel, copper, brass, and aluminum. You can do many kinds of projects.

Advantages

The Mazak FG Series gives you lots of options. The 3D cutting head helps you make hard shapes and angles. Beam Shaping Technology makes cuts clean and quick. You can work with long and heavy tubes. This is good for big jobs. Cutting, drilling, and tapping in one setup saves time. You do not need to move the tube again. These machines work well and give strong results.

Fiber Laser Tube Cutting Machine Performance

Speed and Precision

You want your fiber laser tube cutting machine to be quick and accurate. Fast machines help you finish lots of jobs in less time. Precision means your cuts look neat and have the right shape. Machines like the KRRASS RAS-B and TRUMPF TruLaser Tube Series do both jobs well. You can cut thin or thick tubes and still get good results. The double pneumatic chucks on the KRRASS RAS-B hold tubes tight, so you waste less material and get better cuts. These machines have strong cutting power and always give high-quality work. This helps you finish jobs on time and keeps your customers happy.

Automation Features

Automation makes working with laser tube cutters easier. You do not have to move tubes by hand as much. Automatic loading machines, like the KRRASS RAS-B, let you load and unload tubes fast. This saves you time and energy. Many top machines use smart systems that find problems and fix them before work stops. Some use AI to cut faster and more accurately. Others use IoT to check for wear and plan repairs before something breaks. Robotic arms can move tubes and help with hard cuts. By 2025, over 60% of factories want these features for better speed and fewer mistakes.

Here is a table showing how automation features help you work better:

| Automation Feature | Impact on Productivity |

|---|---|

| Integration of AI for real-time optimization | Makes cutting faster and reduces downtime. |

| Role of IoT in predictive maintenance | Stops surprise breakdowns and keeps work smooth. |

| Adoption of robotic systems | Makes hard cuts quicker and more exact. |

| Expected automation adoption by 2025 | Over 60% of factories will use these features. |

More companies use smart machines because the market is growing fast. New technology lets you do more work with less effort.

Material Versatility

You need a machine that can cut many materials. The best fiber laser tube cutting machines work with metals like carbon steel, stainless steel, aluminum, and titanium. Some can even cut non-metals like wood, plastic, and styrofoam. This high adaptability means you can do many jobs without changing machines. You must watch the laser power. Most tube cutters use up to 5 kW. Too much power can hurt the tube. Careful control keeps your cuts clean and safe.

Here is a table showing what materials you can cut:

| Material Type | Processable | Limitations |

|---|---|---|

| Metals | Yes | Must watch thickness and weld seams |

| Carbon Steel | Yes | |

| Aluminum | Yes | |

| Stainless Steel | Yes | |

| Titanium | Yes | |

| Non-metals | Yes | |

| Wood | Yes | |

| Plastic | Yes | |

| Styrofoam | Yes |

When you use a machine with metal tube laser performance, you can switch jobs easily. You do not need a new machine for every project. This flexibility helps your business grow and keeps customers coming back.

Reliability and Maintenance

When you pick a fiber laser tube cutting machine, you want it to work well every day. Reliability means your machine keeps working, even if you use it a lot. Maintenance means you can fix small problems fast, so you do not waste time.

Look for machines with strong parts from trusted brands. The KRRASS RAS-B uses parts from top suppliers. This helps the machine last longer and work better. You do not want broken parts to stop your work. Machines like the TRUMPF TruLaser Tube Series and Mazak FG Series use high-quality materials. These machines can do hard jobs and last for years.

Many top machines have smart systems to help you take care of them. The KRRASS RAS-B has an auto oil-filling system. This keeps the machine running smoothly. You do not need to remember to add oil. The BOCHU smart cutting heads check the machine and tell you if something needs fixing. You can fix problems before they get worse.

Here is a table that shows how the top machines help with reliability and maintenance:

| Machine Model | Key Reliability Feature | Maintenance Support |

|---|---|---|

| KRRASS RAS-B | Auto oil-filling, smart heads | Real-time diagnostics |

| TRUMPF TruLaser Tube | Quality control sensors | Remote monitoring |

| BLM GROUP Lasertube | Automatic adjustments | Software alerts |

| Mazak FG Series | Beam Shaping, strong build | Easy-access components |

| Bystronic ByTube | Predictive maintenance | IoT-based alerts |

| LVD Tube Laser | Durable frame | Simple part replacement |

Check if the machine lets you reach parts easily. Some machines let you change filters or nozzles without tools. This saves you time. You can start working again faster. Many brands offer remote support. You can call or message a technician if you need help. Some machines send alerts to your phone or computer.

Tip: Always follow the maintenance schedule in your machine’s manual. Regular checks keep your machine working well and stop big problems.

Think about the warranty and service plans too. A good warranty helps you feel safe. Service plans can give you regular check-ups and quick repairs. This means you do not worry if something breaks.

Reliable machines help you finish jobs on time. Easy maintenance means you fix things quickly and work more. When you choose a fiber laser tube cutting machine, always ask about reliability and maintenance. This helps your business grow and keeps your customers happy.

Metal Tube Laser Cutting Machine Comparison

Production Volume Needs

If your shop is busy, you need a metal tube laser cutting machine that can keep up. Some machines are better for big jobs, while others are good for smaller batches. The table below shows how the top machines handle lots of work:

| Machine Model | High-Speed Cutting | Automation | Memory/Control System | Best For |

|---|---|---|---|---|

| KRRASS RAS-B | Yes | Yes | FSCUT3000S/2000 | Small to medium shops |

| TRUMPF TruLaser Tube | Yes | Yes | Advanced software | High-volume factories |

| BLM GROUP Lasertube | Yes | Yes | BLMelements | Flexible production |

| Mazak FG Series | Yes | Yes | Smart controls | Large-scale production |

| Bystronic ByTube | Yes | Yes | ByVision | Fast-paced environments |

| LVD Tube Laser | Yes | Yes | Touch-L control | Mixed production |

All these machines use fast cutting heads and smart controls. They help you finish big jobs fast. Some, like the TRUMPF TruLaser Tube, have advanced memory and automation. This helps with hard designs and big batches. The KRRASS RAS-B is good for small and medium shops. It helps you make more parts without spending too much money.

Complex Shapes and Profiles

Sometimes you need to cut tubes into special shapes for custom work. A good metal tube laser cutting machine can do these jobs. Many top machines use strong lasers and smart motors. They can cut curves, angles, and even 3D shapes. Here are some features you should look for:

- Special laser cutting heads for hard shapes

- Automation for loading and moving tubes

- Support for many graphic formats, so you can use your favorite design software

- Systems that let you skip extra steps, saving you time

Machines like the BLM GROUP Lasertube and Mazak FG Series can cut many shapes. You can make parts for cars, furniture, or buildings. These machines help you finish more jobs with fewer steps.

Tip: If your machine supports many formats, you can switch projects faster. This keeps your shop working well.

Cost Efficiency

You want a machine that saves you money over time. Some machines use less power and need fewer repairs. Others help you waste less material. The KRRASS RAS-B is known for low running costs. It uses smart oil systems and strong parts, so you spend less on repairs. Many machines now use motors that save energy and smart sensors. These features help you save money and are better for the environment.

Here is a quick look at what makes a machine cost-efficient:

- Uses less electricity

- Needs fewer repairs

- Wastes less material

- Offers automation to lower labor costs

If you have a small or medium business, you want a metal tube laser cutting machine that fits your budget and keeps costs low. Big factories may buy machines with more automation to save money on large jobs.

Support and Service

When you buy a metal tube laser cutting machine, you need more than just strong cutting. You also need good support and service. Good support helps you fix problems fast. This keeps your machine working and your business running.

Many top brands give strong support services. The table below shows how some big brands compare:

| Manufacturer | Support Services Offered | Technological Advancements |

|---|---|---|

| IPG | Comprehensive global support, installation, maintenance | Fiber lasers for many materials, vertical integration for cost |

| Mazak | Installation, training, maintenance, remote diagnostics | High-power beam shaping, cloud-based support platform |

Trusted brands help you with installation and training. You learn to use your metal tube laser cutting machine the right way from the start. Many companies offer remote diagnostics. If something goes wrong, a technician can check your machine from far away. This saves time and gets you back to work faster.

Some brands, like Mazak, use cloud-based support. You can check your machine’s health and get updates online. This helps you plan maintenance and stop sudden breakdowns. IPG gives global support, so you can get help anywhere. You do not have to worry if something breaks.

Look for companies that offer regular maintenance plans. These plans help keep your machine in good shape. Regular check-ups can find small problems before they get big. You save money and avoid long stops at work.

Tip: Always ask about support and service before you buy. Good support can help your machine work better for a long time.

When you look at different machines, think about more than price or features. Strong support and service help you get the most from your metal tube laser cutting machine. You can work with confidence, knowing help is always there.

Choosing the Right Laser Tube Cutting Machine

Assessing Requirements

You need to know what your business needs from a laser tube cutting machine. Every shop wants different things, so you should think about a few key points:

- Precision and accuracy help you make good cuts for important jobs.

- Productivity and efficiency let you finish more work faster.

- Cost-effectiveness means you save money over time.

- Reliability and durability keep your machine working with less downtime.

- Safety features protect you and your team from harm.

- Versatility and flexibility let you cut many tube sizes and materials.

- Checking production needs helps you know how many cuts you need.

- Knowing material types makes sure your machine works with carbon steel, aluminum, and other metals.

- Setting your budget helps you balance what you spend now and later.

If you want a top metal tube laser cutting machine, match these points to your daily work. Some machines are very adaptable, so you can switch jobs and materials quickly.

Tip: Make a list of your most common jobs and materials before you shop. This will help you pick the best machine.

Total Cost of Ownership

When you look at the price of a laser tube cutting machine, think about more than just the price tag. The total cost of ownership includes maintenance, energy use, and how much value the machine loses over time. You need to plan for regular care to keep your machine working well. Energy costs depend on the machine’s power and how much you use it. Most machines lose 60–80% of their value in six to twelve years. If you pick a model with low running costs, you can save money each month. Knowing these costs helps you make a smart choice for your budget.

After-Sales Support

After you buy your machine, good support is very important. You want your machine running and your team working. Here are some support options to look for:

| Support Option | Description |

|---|---|

| Ongoing Support | You get help when you need it to keep up with work. |

| Training | You learn how to use the machine for the best results. |

| Just-in-Time Service | You get repairs or help right away, so you do not wait long. |

| Expert Guidance | You can ask experts for advice to make your work easier and faster. |

Strong after-sales service helps you stay happy with your machine. Companies with great support get more repeat customers and referrals. This support keeps your machine working and helps your business grow.

Note: Always ask about training and service plans before you buy. Good support can save you time and money later.

Future-Proofing

You want your laser tube cutting machine to last for many years. Future-proofing helps you protect your investment and keep your business strong. When you choose a machine, you should look for features that let you grow and change with new technology.

Many machines in 2026 offer upgradeable hardware. You can add new tools or parts when your needs change. This means you do not have to buy a new machine every time you want better performance. Software updates also play a big role. You can install new programs that improve cutting speed or add new functions. These updates help your machine stay current and work with the latest designs.

Automation support gives you more options for your shop. Machines with automation features let you work faster and handle more jobs. You can add robotic arms or smart sensors to help with loading and cutting. This makes your work easier and helps you finish projects on time.

Material flexibility is important for future-proofing. You want a machine that can cut many types of metal and even new materials as they come out. If you work with carbon steel today, you might need to cut aluminum or titanium tomorrow. A flexible machine lets you take on new jobs without buying extra equipment.

Training resources help you and your team learn new skills. Good manufacturers offer guides, videos, and online help. You can learn how to use new features and get the most from your machine. This keeps your shop ready for changes in the industry.

Here is a table that shows what to look for when you want to future-proof your laser tube cutting machine:

| Feature | Why It Matters |

|---|---|

| Upgradeable hardware | Lets you add new tools and improve performance. |

| Software updates | Keeps your machine current and adds new functions. |

| Automation support | Boosts efficiency and helps with bigger jobs. |

| Material flexibility | Adapts to new metals and materials. |

| Training resources | Teaches you how to use new features. |

Tip: Always ask about upgrade options and training when you talk to manufacturers. This helps you plan for growth and keeps your machine working well for years.

You should think about your business goals and how your needs might change. If you plan to grow, pick a machine that can grow with you. Future-proofing gives you peace of mind and helps you stay ahead in the market.

There are many strong choices for laser tube cutting in 2026. Some machines, like the KRRASS RAS-B, are known for being precise and reliable. They also have good automation features. To pick the best machine, think about what materials you use most. You should also consider how fast you need to work and your plans to grow.

Next steps for you:

- Talk to manufacturers about your needs and budget

- Try out machines to see how well and fast they cut

- Check what kind of support and reviews the machines have

- Follow setup and care tips to avoid mistakes

Making smart choices now will help your business do better in the future.

FAQ

What materials can you cut with a fiber laser tube cutting machine?

You can cut metals like carbon steel, stainless steel, aluminum, and titanium. Some machines also cut things like plastic or wood. Always check your machine to see what materials it can handle.

How do you choose the right laser power for your needs?

Pick the laser power based on the thickness and type of material. Thicker metals need more power. Most jobs work well with 1500W to 6000W.

Is it hard to maintain a laser tube cutting machine?

You can keep your machine working by cleaning it and checking the oil often. Many machines have smart systems that remind you when to do maintenance.

Can you automate loading and unloading tubes?

Yes, lots of new machines can load and unload tubes by themselves. This saves time and means you do not have to do as much manual work.

How safe are fiber laser tube cutting machines?

Manufacturers make these machines with safety features. You get covers, emergency stop buttons, and warning lights. Always follow the safety rules.

What software do you need for laser tube cutting?

You use CAD/CAM software to design parts and run the machine. Many machines come with their own software to make things easier.

How long does it take to learn to use a laser tube cutter?

You can learn the basics in a few days if you get good training. Most companies give guides and support to help you start.