You want your fiber laser cutting machine to be very accurate. You also want it to have tight tolerances. In 2026, industry data shows some laser cutting machines are very precise. The Fiber Laser Cutting Machine FOL-3015AJ and the CX-CC6050L High Precision Laser Cutting Machine can repeat positions within ±0.01 mm. Laser cutting precision is important for professionals and manufacturers. They need results they can trust. KRRASS is a leader in metalworking. The RAS-3015-Smart 3000W fiber laser cutter is known for its great precision. You should pick a laser cutter that fits your needs.

| Machine Model | Repeatable Positioning Accuracy | Minimum Line Width | Cutting Precision |

|---|---|---|---|

| Fiber Laser Cutting Machine FOL-3015AJ | ±0.01 mm | N/A | N/A |

| CX-CC6050L High Precision Laser Cutting Machine | ±0.01 mm | ±0.01 mm | N/A |

| Hindcam 6KW Laser Cutting Machine | 0.03 mm | N/A | 0.1 mm |

Table of Contents

Key Takeaways

- Pick a laser cutter with high precision, like the KRRASS RAS-3015-Smart 3000W. It can repeat its position within ±0.01 mm.

- Know why tolerances matter. Tight tolerances help parts fit together well. This is important in aerospace and automotive work.

- Keep your laser cutting machine clean and calibrated. This helps it stay accurate and work well.

- Think about the material type and thickness before you choose a laser cutter. Fiber lasers are best for metals. CO₂ lasers are good for non-metals.

- Check the machine’s features, like automation and control systems. These can help you work faster and need less fixing after cutting.

- Pick brands that give good after-sales support, training, and ways to customize. This helps you get what you need.

- Compare different laser cutting technologies. Find the one that fits your project best. Laser cutting is great for precision and smooth finishes.

- Make sure the machine can do what your project needs. This helps you avoid mistakes and work faster.

Top Laser Cutting Machines 2026

KRRASS RAS-3015-Smart 3000W Overview

Key Features

You want a machine that gives steady results. The KRRASS RAS-3015-Smart 3000W is special in laser cutting. It uses a Max China MFSC 3000W fiber laser source. The BLT310 laser head has smart sensors to watch the cutting. The FSCUT2000E control system uses EtherCAT bus for quick and stable work. The working area is 3000mm by 1500mm, so most sheets fit. Fast servo motors move with speed and accuracy. The water cooler keeps the temperature right. You can cut steel, aluminum, titanium, brass, copper, and iron. The machine uses different gases for different metals. You get a 2-year warranty and a 30-day money-back promise.

Performance Highlights

You need a machine that works well every time. The RAS-3015-Smart 3000W cuts fast and keeps tight tolerances. It can repeat positions within ±0.01 mm. The control system helps you make each cut better. The machine works for thin and thick materials. You save time because the edges are smooth. You do not need much extra work after cutting. The modular design lets you add automation or robots. You get good energy use and less upkeep. The machine is quick and keeps the quality high.

Other Leading Brands

Bystronic

Bystronic makes the ByStar Fiber model. It uses BeamShaper technology and is easy to use. Bystronic machines help you get great cuts. The ByVision Cutting system makes setup simple. You can use these machines for hard jobs and big batches.

TRUMPF

TRUMPF is known for the TruLaser 5030 Fiber. It has BrightLine Fiber and CoolLine features. These help you cut thin and thick metal with high precision. TRUMPF machines work with Industry 4.0 systems. You can watch and control your work from anywhere.

Amada

Amada has the ENSIS AJ 4kW. It uses robots to handle materials. You do not need to worry about the optical path because it needs no upkeep. Amada machines are good for making lots of parts. You get steady performance and good results.

Tip: Compare the features and performance of each brand before you pick a machine.

Top Five Laser Cutting Machines by Precision and Tolerances

| Rank | Machine Model | Type | Precision (Tolerance) | Key Features |

|---|---|---|---|---|

| 1 | TruLaser 5030 Fiber | Fiber | ±0.02mm | BrightLine Fiber, CoolLine, Industry 4.0 integration |

| 2 | ByStar Fiber | Fiber | N/A | BeamShaper, ByVision Cutting, user-friendly interface |

| 3 | OPTIPLEX 3015 NEO | CO2/Fiber Hybrid | N/A | Intelligent Cutting Head, MCT technology, durability |

| 4 | GHF Series High-Power | Fiber | N/A | AI-powered autofocus, Swiss reliability |

| 5 | ENSIS AJ 4kW | Fiber | N/A | Robotic handling, zero maintenance optical path |

Real-World Applications

You can use the KRRASS RAS-3015-Smart 3000W in many places. Here are some common uses:

- Sheet metal shops

- OEM part making

- Car and steel furniture industries

- Cutting thick plates with stronger models

You see these machines in factories and workshops everywhere. You can make car parts, furniture frames, and custom metal pieces. You can also cut thick steel plates for building or machines.

Note: Keep your laser cutting machine in good shape with regular care and checks.

Laser Cutting Precision Explained

What Is Laser Cutting Precision?

It is important to know what laser cutting precision means. Laser cutting precision shows how close a laser cutter follows your design. It tells you how well the machine cuts shapes and lines. You want your parts to fit together just right. Laser cutting precision helps you get perfect fits.

- Laser cutters can be accurate to tiny amounts.

- This accuracy matters a lot in aerospace, cars, and medical devices.

- Making detailed cuts is a big advantage over older ways.

Laser cutting precision is special because the laser beam is very focused. You can get seams as thin as 0.1 mm. The surface stays smooth without rough edges. You get sharp, clean edges every time.

Laser cutting is more accurate than other cutting methods. The process depends on how thick and strong the material is. You also need to think about kerf width, kerf deviation, kerf taper, heat affected zone, dross, and surface roughness. All these things change the final cut quality.

Tolerances in Laser Cutting

Tolerances show how much a finished part can change from your design. You want tight tolerances for parts that must fit or move well. In laser cutting, tolerances are the biggest allowed difference between the cut part and your drawing.

Tolerances are written as plus or minus a number, like ±0.05 mm. This means the part can be a little bigger or smaller, but not much. The best laser cutters keep these differences very small.

| Laser Type | Typical Tolerance Range |

|---|---|

| Standard Lasers | 0.1 mm to 0.5 mm |

| CO₂ Lasers | ±0.1 mm to ±0.5 mm |

| Fiber Lasers | ±0.05 mm to ±0.2 mm |

| Ultra-Precision Lasers | ±0.005 mm to ±0.025 mm |

Fiber lasers and ultra-precision lasers give the tightest tolerances. You need these machines for jobs in aerospace, cars, and medical fields. These jobs need exact sizes and high-quality parts.

Minimum Achievable Tolerances

You should know the smallest tolerances before you start a project. This number tells you the smallest difference between your design and the finished part. The best laser cutters in 2026 can reach tolerances as tight as ±0.005 mm. Most top fiber laser machines keep tolerances between ±0.05 mm and ±0.2 mm.

Always check the machine’s specs and test samples before you begin. The minimum tolerances depend on the machine, the material, and the thickness. If you need very tight tolerances, pick a machine that fits your needs.

Tip: Always match your machine’s precision to your project’s needs. This helps you avoid mistakes and wasting materials.

Laser cutting precision and minimum tolerances help you make parts that fit, work, and last. You get better results and higher quality when you know these numbers.

Why Precision and Tolerances Matter

You may ask why precision and tolerances are so important. In laser cutting and metalworking, every detail matters. If you want metal parts to fit together, you must control each cut. Precision helps you get the right shape. Tolerances show how much a part can change and still work.

Using tight tolerances makes sure parts fit and work well. This is needed in cars, planes, and electronics. If a part is too loose or tight, it causes trouble. For example, car engines need parts that fit exactly. Even small mistakes can cause breakdowns or safety problems.

Focusing on precision and tolerances helps your production. Here are some ways it helps:

- Reliable fit and function: You stop gaps or overlaps.

- Process repeatability: Each part works the same way.

- Reduced post-processing: You fix fewer parts after cutting.

- Lower failure rates: Machines last longer and cost less to repair.

Let’s see how different tolerance levels change your work:

| Tolerance Level | Common Use | Production Impact |

|---|---|---|

| ±.005″ | General industrial parts | Normal cost and cycle time |

| ±.001″ | Moving assemblies, fixtures | More setup, slower feeds |

| ±.0001″ | Aerospace, medical, lab-grade | Special tools, strict checks |

Tighter tolerances often mean more time and special tools. You may need to check parts more often. This can slow down work, but you get better and safer products.

Note: When picking a laser cutting machine, think about the tolerances you need. The right mix of precision and speed saves time and money. It also keeps your products safe and reliable.

Precision and tolerances decide the quality of what you make. They help you earn trust and keep your business strong.

Laser Cutting vs. Other Technologies

Tolerance Comparison Table

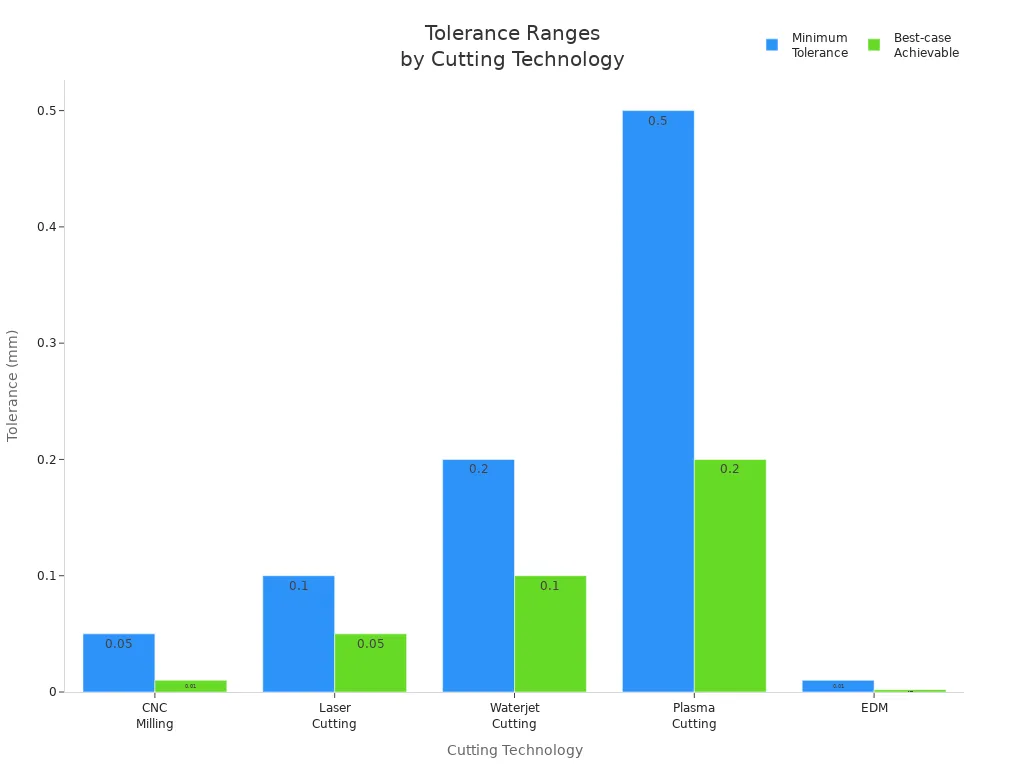

You might wonder how laser cutting compares to other methods. Tolerance levels show how close a machine cuts to your design. Laser cutting gives tight tolerances. Some other technologies can be even more exact. Look at this table to see the differences:

| Cutting Technology | Typical Minimum Tolerance | Best-case Achievable |

|---|---|---|

| CNC Milling | ±0.05 mm | ±0.01 mm |

| Laser Cutting | ±0.1 mm | ±0.05 mm |

| Waterjet Cutting | ±0.2 mm | ±0.1 mm |

| Plasma Cutting | ±0.5 mm | ±0.2 mm |

| EDM (Electrical Discharge Machining) | ±0.01 mm | ±0.002 mm |

Laser cutting works well for most jobs. EDM is the most precise, but you may not need that much accuracy. CNC milling is also very good for tricky shapes.

Finish Quality Differences

You want your parts to look nice and fit right. Laser cutting makes smooth edges and sharp corners. You usually do not need extra finishing. Plasma cutting leaves rough edges and more dross, so you clean up more. Waterjet cutting is good for thick or soft materials, but the finish is not as smooth as laser cutting. EDM makes very exact cuts, but it takes longer.

Laser cutting is best for thin sheets and detailed designs. You get a thin kerf and high accuracy. The heat from laser cutting does not bend thin materials much. Plasma cutting uses more heat and can warp your parts. Waterjet-guided laser cutting helps make surfaces smoother by lowering burrs and distortion.

Tip: If you want sharp details and smooth edges, laser cutting is a good choice.

When to Choose Laser Cutting

Pick laser cutting when you need high precision and tight tolerances. Laser cutting is great for electronics, signs, and detailed designs. You can cut thin or medium materials with good accuracy. CNC milling is good for general machining. Plasma cutting is fast for thick materials, but less precise. Waterjet cutting is best for thick or soft materials. EDM is best for very exact cuts in hard materials.

Here is a quick guide:

| Cutting Technology | Preferred Scenarios | Material Thickness | Precision Level |

|---|---|---|---|

| Laser Cutting | High precision, intricate designs, electronics, signage | Thin to medium | High |

| CNC | General machining tasks | Varies | Medium |

| Plasma Cutting | Thick materials, faster cuts | Thick | Medium |

| Waterjet Cutting | Thick materials, softer materials | Thick | Medium |

| EDM | Very precise cuts, hard materials | Varies | Very High |

Laser cutting is best when you need parts to fit together perfectly. You get steady results and save time on finishing. You also get fast production and repeatable quality.

Note: Always pick the cutting technology that fits your project. Laser cutting gives you speed, smooth finish, and tight tolerances for many jobs.

Factors Affecting Laser Cutting Precision

Beam Quality and Focus

You want your cuts to look sharp and smooth. The laser beam’s quality is very important. If you focus the beam tightly, it makes a small spot. This spot has lots of energy. It helps you cut metal easily. Good beam quality means the light stays strong and steady. You get smooth edges and quick cuts. You can change the focus or use special lenses. This lets you work with different thicknesses. You can get the finish you want. This makes it easy to get high precision every time.

- A focused beam gives more energy for better cutting.

- Beam quality changes how smooth and fast you cut.

- Changing the focus helps you work with many materials.

Tip: Always check your beam settings before you start. This helps you avoid mistakes and keeps your cuts neat.

Machine Build and Control

How your machine is made and controlled is very important. Strong frames and good motors help you keep tight tolerances. Laser cutting does not touch the metal. This means you do not bend or warp the part. You get better results than with other cutting methods. Dimensional accuracy depends on beam alignment and head movement. If you set up your machine well, your parts will fit perfectly. Watch out for heat or shaking, as these can change your results. A good control system helps you fix problems fast and keeps your work smooth.

- Non-contact cutting stops bending and keeps tolerances tight.

- Good alignment and motion control make accurate parts.

- Regular checks help you keep precision for a long time.

| Cutting Method | Tolerance Level | Heat Distortion | Detail Quality |

|---|---|---|---|

| Mechanical Cutting | Wider | High | Lower |

| Plasma Cutting | Wider | High | Lower |

| Laser Cutting | Tightest | Minimal | Highest |

Material and Thickness

The kind and thickness of your material change how precise you can cut. Thin sheets let you get very tight tolerances, even ±0.005 inches. You can make small features and fit parts close together. Thick materials soak up more heat. This can cause warping or color changes near the cut. The beam may get wider as it goes deeper. This can make the edge slant. You might see more dross on thick cuts, so you need extra cleaning. Tolerances for thick materials are usually ±0.01 to ±0.02 inches. If you want less warping, make bigger features in thick metal. Kerf width gets bigger with thickness, so plan your designs well.

- Thick materials can warp or change color from heat.

- Thin materials let you make small details and tight fits.

- Kerf width grows with thickness and changes how parts fit.

Note: When you pick materials, think about thickness. It affects how close you can match your design. This is a key factor for laser cutting tolerance.

Speed and Power Settings

You can change how your laser cuts by adjusting speed and power. These two things control how deep and clean your cuts are. If you use high power and slow speed, you can cut thick metals easily. For engraving, you use less power and go faster to make small details. To get the best cuts, you need to balance both settings. This helps you avoid burning or rough edges.

Here is a table that shows how different settings work for different jobs:

| Application Type | Power Setting | Speed Setting |

|---|---|---|

| Thick Materials (e.g., metals) | High (80-100%) | Low (0.1-2 mm/s) |

| Engraving Applications | Low to Moderate (10-40%) | High (100-300 mm/s) |

| High-Quality Cutting | Medium (50-80%) | Moderate |

Thick materials need more power and slower speed. Engraving needs less power and faster speed. High-quality cutting uses settings in the middle. If you go too fast, you might lose accuracy. If the power is too low, the laser may not cut through. You should test and change these settings for each job.

Software and Automation

Modern laser cutters use smart software and automation to be more accurate. Real-time monitoring helps you see problems right away. This keeps your cuts sharp and saves material. Predictive maintenance tells you when to fix your machine. This stops mistakes and keeps your cuts exact. Automatic focusing helps you get the right depth every time. This can lower mistakes by up to 30 percent.

Manufacturers who use real-time monitoring spend less on materials and work faster. You can trust your machine to make tiny changes and keep every cut sharp. Automation lets you do the same job over and over with good results, even for hard designs.

- Real-time monitoring finds problems fast and makes cuts better.

- Predictive maintenance keeps your machine working and stops errors.

- Automatic focusing lowers mistakes and makes cuts more exact.

- You save money on materials and work more efficiently.

KRRASS Innovation in Precision

KRRASS is a leader in new laser cutting ideas. The RAS-3015-Smart 3000W model cuts very fast. This means you finish jobs quicker and with better accuracy. You can cut many types of materials, like shiny metals and thick mild steel. This helps you make tiny features and detailed designs easily.

KRRASS machines are small and can be changed for new jobs. You keep good results even if your needs change. The RAS-3015-Smart 3000W works with automation and smart controls. This gives you the same good results every time. You can trust KRRASS for tiny, exact cuts in cars, electronics, and planes.

- Ultra-high speed cutting helps you work faster and more accurately.

- The flexible design works with many materials and small features.

- Small and changeable machines fit your new projects.

Tip: Pick a machine that fits what you need. KRRASS helps you get great laser cutting results every time.

Choosing the Right Laser Cutter

Matching Precision to Application

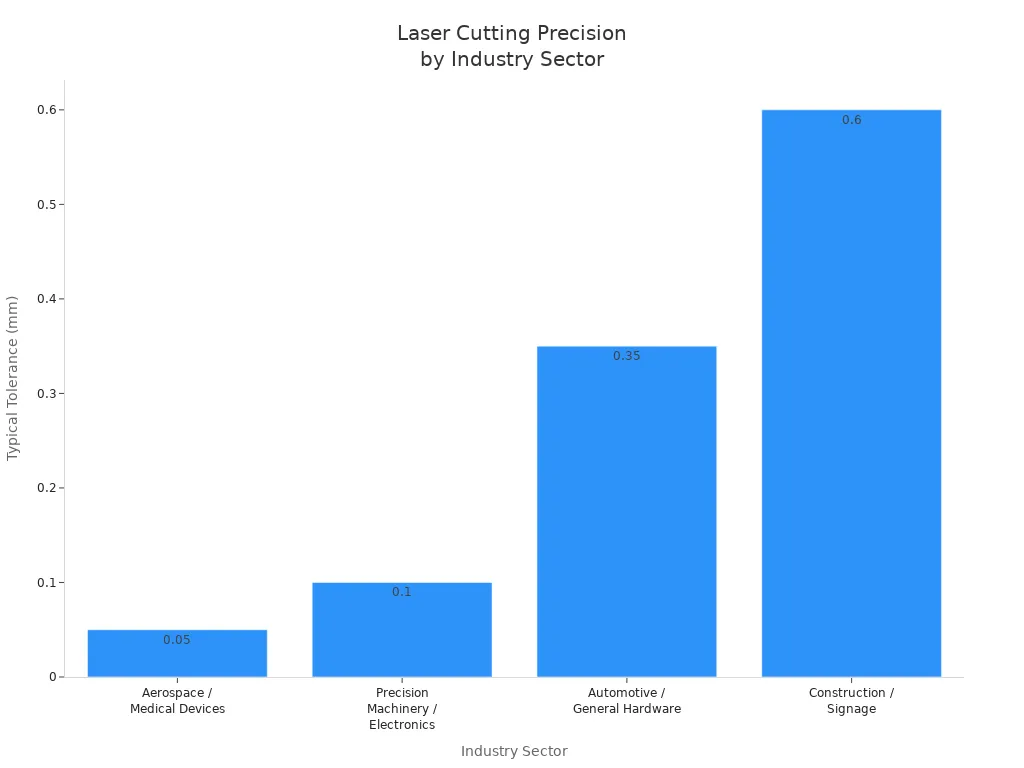

You need to pick a laser cutter that matches your project. Different jobs need different levels of accuracy. Some industries want very tight tolerances. If you work in aerospace or medical devices, you need super high precision. Electronics and machinery also need parts that fit closely. Car parts and hardware can have a bigger range. Construction and signs do not need as much accuracy.

Here is a table that shows what each industry needs:

| Industry Sector | Precision Requirement Description | Typical Tolerance Range |

|---|---|---|

| Aerospace / Medical Devices | Extremely high precision | Within ±0.05 mm |

| Precision Machinery / Electronics | High precision | Around ±0.1 mm |

| Automotive / General Hardware | Wider tolerance range | ±0.2 mm ~ ±0.5 mm |

| Construction / Signage | Relatively low precision needed | Above ±0.5 mm acceptable |

When you pick a laser cutter, follow these steps:

- Figure out what materials you will cut.

- Use a CO₂ laser for non-metals. Use a fiber laser for metals.

- Think about how thick your materials are and how much you will cut.

Industry-Specific Needs

Automotive and Aerospace

Fiber laser cutting is changing how cars are made. It helps factories work up to 30% faster. In aerospace, fiber lasers cut parts with less waste. This makes things better for the environment by 20%. You need high accuracy for light and strong parts. This is important for electric and self-driving cars. Fiber laser technology helps you meet these tough rules.

Electronics and Medical

Electronics and medical devices need very tight fits. Small parts must go together just right. Fiber lasers make smooth edges and cut the same way every time. You can make circuit boards, connectors, and tools for surgery. High accuracy keeps people safe and makes sure things work well.

Metal Fabrication

Fabrication shops use many kinds of metal. You need a machine that works with thick and thin pieces. Fiber laser cutters help you make custom parts and furniture frames. You also make industrial parts. You get smooth edges and steady quality. This means you finish jobs faster and do not need much extra work.

Budget vs. Performance

You have to think about how much money you can spend. Machines that cut with high accuracy cost more at first. If you have a bigger budget, you can buy a better machine. These machines work faster and save money later. You should look at the price and how much you will get back. If you choose well, you work better and spend less over time.

Tip: Always pick a machine that matches your needs and your budget. This helps you get good results and save money.

KRRASS Value Proposition

When you choose a laser cutting machine, you want more than just high precision. You want a partner who supports your business and helps you succeed. KRRASS gives you that support. You get advanced technology, strong service, and a focus on your needs.

KRRASS has over 30 years of experience in metalworking. The company leads the way in innovation and quality. You see this in the RAS-3015-Smart 3000W. This machine gives you fast, accurate cuts for many types of metal. You can use it for steel, aluminum, brass, copper, and more. The machine works well for both thin sheets and thick plates. You get smooth edges and tight tolerances every time.

KRRASS stands out because you get more than just a machine. You get a full package of value-added services. These services help you use your machine well and keep your business running smoothly.

Here is what you receive when you buy the RAS-3015-Smart 3000W:

| Service Type | Description |

|---|---|

| Training | KRRASS provides training to ensure optimal use of the machine. |

| Warranty | A two-year limited warranty is offered for peace of mind. |

| After-sales support | Strong support team and local helpers are available. |

| Customization options | Options for customization are available to meet specific needs. |

| Global delivery | Assistance with installation and global delivery is provided. |

You do not have to worry about setup or learning how to use the machine. KRRASS trains you and your team. If you have a problem, you can call the support team. Local helpers can visit your site if you need hands-on help. You also get a two-year warranty. This gives you peace of mind.

You can ask for custom features. KRRASS listens to your needs and builds the machine that fits your work. The company ships machines all over the world. You get help with installation, no matter where you are.

KRRASS offers factory direct sales. You save money because you do not pay extra fees to middlemen. The company also provides OEM and ODM services. If you want your own brand or special features, KRRASS can make it happen.

You get a machine that works hard and lasts long. You also get a partner who cares about your success. KRRASS helps you grow your business with reliable machines, strong support, and real value.

Tip: When you choose KRRASS, you choose a brand that stands by you from the first cut to the last.

Maximizing Laser Cutting Precision

Calibration and Maintenance

You want your laser cutting machine to be very accurate. You need to check and fix it often. Follow the manufacturer’s rules for calibration. Look at your machine regularly to stop damage. Clean and oil the moving parts so they work well. Write down your settings and changes to see what works best. Try your machine on different materials to make sure it is accurate.

Check the optics, keep the chiller working, and line up the parts right. This helps your laser cutting machine work better and cut more precisely.

You should also clean the mirrors and lenses. This keeps the laser beam strong and clear. Change the filters to keep the air clean. Make sure the alignment is correct for good cuts. Update the software and firmware to help your machine do its best. These steps help you set up your machine right and get great results.

Operator Training

Operator training is very important for good laser cutting. You need to know how your machine works. You also need to know how different materials change the way you cut. Trained operators can change the settings for better accuracy. This is helpful with hard materials or tricky designs. Learn how to get materials ready and keep your machine in shape. This helps you make better cuts and reach tight tolerances.

- Operator training helps laser cutting machines work better.

- Trained operators can change settings for better accuracy and tolerances, even with tough jobs.

- Knowing how to care for the machine and prepare materials makes cuts better.

You should make special tolerance rules for each material and cutting method. This helps you meet your quality and speed goals.

Quality Control Methods

Quality control helps you keep your cuts accurate and tight. Check new materials for thickness, flatness, and surface. After the first cut, measure the part to see if it is right. Watch the laser while it works to catch problems fast. At the end, use tools like CMM or scanners to check the size.

| Quality Control Method | Description |

|---|---|

| Optimized Laser Parameters | Adjust beam strength, pulse speed, and gas to lower heat damage. |

| Material-Specific Adjustments | Change settings for different material types and thickness. |

| High-Resolution Inspections | Use OGP systems to measure parts without touching them. |

| GD&T Principles | Use special rules to show how much a part can change. |

| Statistical Process Control (SPC) | Watch for changes to keep cuts within good limits. |

Keep your laser cutting area at the right temperature and humidity. This stops heat from changing your results. Clean the lenses and check your machine often to keep cuts steady. These steps help you get the best from your machine and make high-quality parts.

Tip: If you want the best accuracy, always calibrate, train your operators, and use strong quality checks.

You want your projects to be very accurate. You also want parts to fit together well. The KRRASS RAS-3015-Smart 3000W is a top machine in 2026. You should pick a machine that matches what you need. Think about things like the laser source, how fast it cuts, and if it has automation. Also look at the brand, support, power, size, and price.

| Factor | Description |

|---|---|

| Laser Source Type | Choose fiber for metal, CO₂ for non-metal |

| Cutting Speed | Faster machines boost productivity |

| Automation and Features | Advanced options improve workflow |

| Brand and Reputation | Trusted brands offer better support |

| Support and Training | Good support keeps machines running |

| Power and Capability | Pick power for your material and job |

| Machine Size | Fit the machine to your workspace |

| Additional Costs | Plan for maintenance and consumables |

You get the most for your money when you balance features with how the machine works in real life.

FAQ

What materials can you cut with the KRRASS RAS-3015-Smart 3000W?

You can cut steel, aluminum, titanium, brass, copper, and iron. The machine works well with different thicknesses. You get clean edges on every material.

How precise is the KRRASS RAS-3015-Smart 3000W?

You achieve repeatable positioning accuracy within ±0.01 mm. This lets you create parts that fit together perfectly. You get reliable results every time.

Does the machine come with a warranty?

You receive a two-year limited warranty. This covers the main parts and gives you peace of mind. You also get strong after-sales support.

Can you customize the machine for special needs?

You can request custom features or options. KRRASS offers OEM and ODM services. You get a machine that matches your project requirements.

What is the working area of the RAS-3015-Smart 3000W?

You get a working area of 3000mm by 1500mm. This size fits most sheet metal jobs. You can handle large and small projects.

How do you keep the machine cutting accurately?

You should calibrate the machine often. Clean the optics and check alignment. Regular maintenance helps you keep high precision.

What support does KRRASS offer after purchase?

You get training, installation help, and technical support. Local helpers can visit your site. You can contact the support team anytime.

Is there a return policy for the machine?

You have a 30-day money-back guarantee with certain conditions. You can try the machine and return it if it does not meet your needs.