Just like any major investment for your business, selecting the right CNC fiber laser cutting machine demands thorough consideration and research. With the plethora of options available in the market, choosing the perfect machine tailored to your specific needs can be daunting. Whether you're a novice seeking to introduce a CNC fiber laser cutting machine to your workshop or an experienced professional aiming for an upgrade, this comprehensive guide will assist you in understanding the critical factors to consider when selecting the best CNC fiber laser cutting machine for your business.

This guide will take you through the different types of fiber laser cutting technologies and help you assess the machine's power and precision capabilities, ensuring you make an informed decision. We will delve into the significance of bed size, laser wavelength and wattage, cooling systems, software compatibility, and maintenance requirements. These insights will aid you in narrowing down your choices and finding the ideal CNC fiber laser cutting machine that aligns with your production objectives. By the end of this guide, you will possess the knowledge and confidence to invest in a CNC fiber laser cutting machine that will streamline your workflow, boost efficiency, and elevate your business to new heights.

Definition of CNC Fiber Laser Cutting Machine

A CNC fiber laser cutting machine is a device used to laser cut materials in a computerized manufacturing process using G-Code commands and a highly concentrated beam of light to vaporize or melt away a given material. In practice, CNC laser cutter refers to either a cutting laser head tool (a laser head for short) that can be mounted on a CNC machine to perform laser cutting, or a CNC machine on which such a laser head has already been installed. A CNC laser cutter is a user-friendly technologically advanced device that allows reaching much higher manufacturing precision than other CNC processing tools.

Though, the best machines mostly sport lasers of powers ranging from (1500W, 2000W, 3000W, 4000W, 6000W, 8000W). Power is a determining factor of the quality of the work these machine machines can produce. To cut metal sheets like that of stainless steel, electrical steel, aluminum zinc plate, galvanized steel, titanium alloy, iron, brass, copper and other metal of varying thickness; fiber machine with power more than or equal to 1500 W should be used in order to produce distinctive cuts.

How Does It Work

Moving forward, there are many things that many buyers don’t try to learn while buying this fiber laser cutting machine; and, one of them is how this machine works. It is always good to have an extra bit of knowledge, especially of how the machine operates.

The machine operates on a laser that is emitted by a fiber laser generator. This laser is generated through an optical path that focuses the fiber laser beam on the substance in use with a very high power density. This laser beam is then illuminated on the surface of the metal to bring the metal onto its melting or boiling point. During this, the high-pressure gas links with the fiber laser beam and blows away the molten or vaporized material.

While doing all this, the laser beam moves in correspondence with the metal; thus, slitting the material and achieving the purpose of cutting.

Role of CNC Fiber Laser Cutting Machines in a Modern Workshop

Understanding where a fiber laser cutting machine fits in a modern workshop is crucial beyond just evaluating its cost. These machines, which are sizable and sophisticated, must be integrated into a well-organized environment to achieve optimal performance and quality.

Fiber laser cutters are renowned for their versatility and efficiency, regardless of their power rating. For those dealing with a range of material thicknesses, a mid-range fiber laser cutting machine (750W to 1500W) proves to be an invaluable asset. Such machines can handle steel up to 0.70 inches thick, aluminum up to 0.315 inches, stainless steel up to 0.394 inches, and copper and brass up to 0.197 inches, all without requiring lens changes.

Speed and adaptability are key advantages of fiber laser cutting machines, enabling timely completion of tasks and reducing the overall cost of the final product. Although there are considerations such as replacement and downtime costs, these machines offer significant benefits. For instance, a mid-range fiber laser cutting machine can cut twice as fast and at one-sixth the cost of a CO2 laser cutter, with a payback period that is approximately 70% shorter than that of a CO2 laser cutting machine. By incorporating a fiber laser cutting machine into a modern workshop, operators can enjoy enhanced efficiency and cost-effectiveness while maintaining high-quality output.

Types of Fiber Laser Cutters

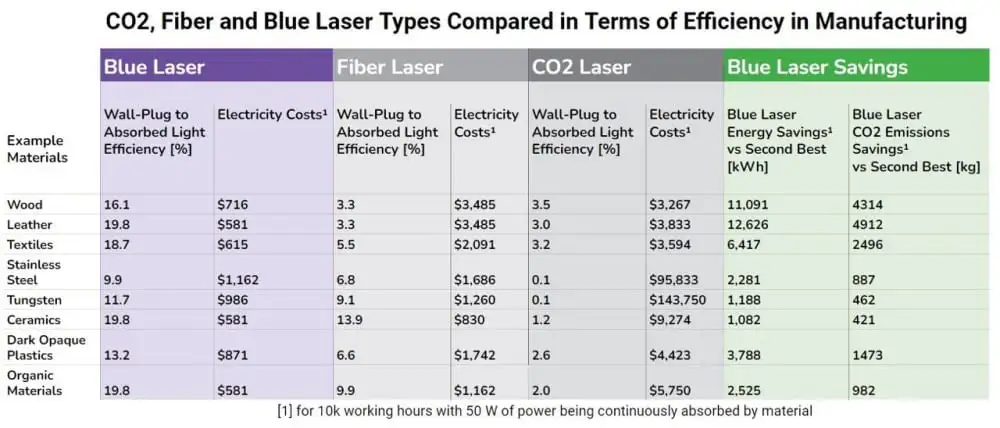

There are three types of lasers commonly used in CNC laser cutter machines, each with its own unique properties and applications. Understanding the differences between these lasers can help you determine which type is best suited for your specific cutting needs.

Diode Laser

A diode laser cutting machine is powered by diode modules that emit laser beams having a wavelength of 450-455nm. It is also called blue laser because of its color. The best thing about these machines is that they are available at an affordable price. You can easily find a desktop diode laser for $500 to $1,000, depending on the features. These machines are great for DIY purposes, professional work, and small businesses. They can easily cut the non-metals we have discussed in the previous section.

The desktop diode cutting lasers can cut 5-20mm in only one pass. If you want to cut wood and acrylic, it is an excellent option. But keep in mind these lasers cannot cut transparent and blue acrylic.

CO2 Laser

A CO2 laser cutter is the next option after diode laser machines. It is a bit expensive due to its technology and immense power. It uses a CO2 laser tube that emits laser beams. These machines are more powerful than diode lasers. Due to high power, the cutting speed is exceptional. They are ideal for cutting a wide range of non-metals. CO2 lasers are easily available in desktop and industrial sizes. The cost of a desktop CO2 laser machine can be $3,000 to $6,000, depending on the features. In contrast, industrial or large CNC laser cutters are over $10,000. For small businesses, home use, hobbyists, and DIY purposes, a desktop laser machine is more than enough.

Fiber Laser

If you want to cut metals, you need to get a fiber laser machine that is designed for metal cutting. Fiber laser machines are quite powerful. For metal cutting, the power should be high, around 1000W or more. They can cut steel, copper, brass, and various other metals. But they are quite expensive. The cost is usually above $30,000.

| Laser Type | Laser Type's Advantages | Laser Type's Drawbacks | Materials That It Can Cut |

|---|---|---|---|

| Blue Diode CNC Laser Cutters | Highly energy-efficient, fast and precise. Low upfront cost, negligible upkeep/maintenance. | Lower laser power blue CNC lasers will struggle with cutting blue or white materials. As of 2024, they also cannot cut metals. | Blue CNC laser can cut wood, leather, textiles, marble, and plastics as well as almost any other material apart from metals. |

| Fiber CNC Laser Cutters | High energy efficiency. As of 2024, the best laser type for cutting metals. | High upfront cost and space-consuming. | Fiber lasers can cut sheet metal including aluminum, carbon steel, stainless steel, brass, copper, and titanium. |

| CO2 Laser Cutters | Readily available in different laser power ratings. | CO2 lasers are an obsolete technology since the advent of high-power blue cnc lasers in 2024. CO2 lasers waste 95-96% of supplied electrical energy (including chiller), leading to noticeably high energy bills. They are also large in size, and require frequent and difficult calibrations. | CO2 lasers are the best for cutting bones, but they also perform well in cutting thermosoftening plastics. CO2 lasers can also be used for cutting wood and leather, although with worse results than high-power blue lasers. |

Factors for Choosing Best CNC Fiber Laser Cutting Machine

Determining Your Needs

Before purchasing a CNC laser cutter, it's crucial to clarify its intended purpose to select the appropriate machine size. Understanding your specific needs will guide you in choosing a machine that aligns with your requirements and budget.

For small-scale applications, such as DIY projects, custom parts for products, or starting a small business, a compact or desktop CNC laser cutter may be ideal. These machines offer a cost-effective solution for home use and small workshops, providing the versatility and precision needed for limited-scale tasks.

On the other hand, if your goals include large-scale industrial applications or bulk production, investing in an industrial CNC laser cutter is essential. These machines are designed for high-volume operations and can handle larger materials and more demanding tasks. By assessing the purpose behind acquiring the CNC laser cutter, you can make an informed decision on the size and type of machine that best suits your needs.

Type of the Laser Machine

We have explored three distinct types of laser machines, each with its own technology and application. If you're looking to start a small craft business or work on DIY projects, a diode laser is a suitable choice. It is affordable and easy to use, making it ideal for personal or small-scale tasks.

For those needing to cut a variety of non-metal materials at a good speed, a CO2 laser machine is an excellent option. This type of machine is versatile and can be used in a home setting, small shop, or garage, handling a range of materials efficiently.

If your focus is on metal cutting, the only viable option is a fiber laser. Fiber lasers are specifically designed for metal processing and are essential for industrial applications. Before proceeding, determine the type of laser machine that fits your needs by considering the materials you plan to cut—whether a diode, CO2, or fiber laser is the best fit for your requirements.

Optical Power and Cutting Speed

Two crucial specifications that indicate the performance of a laser machine are its optical power and cutting speed. The optical power reflects the strength of the laser beam, which directly influences its cutting capabilities. While other power ratings like Machine Power and Electric Power are listed, the Optical Power specifically denotes the laser's effectiveness.

Diode Lasers: These typically range from 10 to 40 watts. For effective cutting, especially of various materials, a diode laser with 20 watts or more is recommended. Higher power results in better cutting performance.

CO2 Lasers: Generally more powerful than diode lasers, desktop CO2 machines usually offer between 30 to 60 watts. These lasers are suitable for cutting different materials at good speeds. For industrial applications, more powerful CO2 lasers are available, which can handle a wider range of materials and thicknesses.

Fiber Lasers: Fiber lasers come in various power levels, but for efficient metal cutting, a power rating of over 1,000 watts is ideal. The required power may vary depending on the material's thickness. Always check the optical power to understand what thickness and type of material the machine can cut effectively in a single pass.

Additionally, the cutting speed of a laser machine plays a significant role in productivity. A faster machine increases efficiency by reducing cutting times. Therefore, when selecting a CNC laser cutting machine, consider both its optical power and cutting speed to ensure it meets your operational needs and productivity goals.

Accuracy

CNC laser cutters are celebrated for their precision, but accuracy can vary between machines. It’s essential to verify the accuracy of the machine, which is typically measured in fractions of a millimeter. Ensure the machine has a robust construction to maintain stability and consistent accuracy. Additionally, the quality of the motors used in the machine is crucial, as high-quality motors contribute significantly to reliable and precise performance.

Working Area

The working area of a CNC laser cutter determines the maximum size of the objects it can handle. Desktop CNC laser cutters typically have a smaller working area, which is adequate for various applications, including hobby projects and small-scale production. On the other hand, industrial laser cutters feature a larger working area, capable of cutting large sheets of materials like plywood.

When selecting a machine, always check the specifications for the working area. This information is crucial for ensuring that the laser cutter meets your needs based on the size of the objects you plan to cut. By considering the working area, you can choose a machine that aligns with your project requirements and production scale.

Air Assist and Exhaust System

Air assist is a critical feature in laser cutting operations. It provides a steady stream of air that clears away smoke and debris from the cutting area, facilitating deeper and more precise cuts. Additionally, air assist helps prevent smoke and burn marks on the material, resulting in a cleaner surface post-cutting.

Equally important is the exhaust system, which manages the removal of smoke, debris, and gases generated during the cutting process. An effective exhaust fan expels air from the machine, and an optional air purifier can further enhance air quality. When selecting a CNC laser cutter, ensure it includes an air assist system and a robust exhaust setup. This will not only improve cutting performance but also maintain a cleaner and safer working environment.

Essential Safety Features

Safety features are crucial for any laser machine to ensure safe operation. When evaluating a CNC laser cutter, it's important to check for the following safety mechanisms:

Fire Detection System: This feature is essential for preventing and managing potential fires. A fire detection system will automatically stop the machine and alert the user if any fire or flame is detected, addressing the risks associated with the high temperatures of the laser.

Automatic Shutdown: The machine should have an automatic shutdown feature that activates in the event of tilting or impact. This safety measure helps protect users, including children and pets, from accidental harm.

Enclosure: A proper enclosure is necessary to prevent harmful laser beams from escaping. Laser beams can be damaging to the human eye, so a well-designed enclosure is crucial for ensuring safety during operation.

Additional Safety Features: Look for other safety elements such as warning systems and air purification to enhance overall safety and maintain a clean working environment.

Ensure that your CNC laser cutter is equipped with these safety features to provide a secure and efficient working environment.

Budget Considerations

The cost of CNC laser cutting machines varies depending on their size, features, and specifications. Here is a general breakdown of the price ranges:

Desktop Diode Lasers: These are the most affordable option, generally costing between $500 and $1,000. They are suitable for small projects and personal use.

CO2 Lasers: These machines are priced between $3,000 and $6,000. They offer a good balance of performance and cost, making them ideal for a range of non-metal cutting applications.

Industrial Laser Cutting Machines: For larger-scale operations requiring heavy-duty performance, these machines typically cost over $10,000. They are designed for high-volume and industrial applications.

Fiber Lasers: The most expensive type, fiber lasers start at around $30,000 and can be higher. They are renowned for their precision and efficiency in cutting metals, making them a significant investment for industrial use.

When planning your budget, consider the machine’s intended use and required features to ensure you choose the best option for your needs and investment.

CNC Laser Cutter Projects Introduction

Customized Jewelry

A CNC laser cuter can make incredible customized jewelry items. It is possible to make any kind of pattern or design on a wide range of materials. Wooden and laser cut acrylic earrings are quite trending, and they can be customized with any shape, name, pattern, etc. It is possible to engrave and cut earrings, pendants, bracelets, rings, etc. You can make these customized jewelry items for you or friends or sell them in online stores.

Wall Art

Through laser cutting, intricate wall art pieces can be made in no time. Whether you want to make Mandala art, nature art, or anything else, the laser machine cuts the material with fine details and perfection. Wooden and acrylic wall art pieces of single or multiple layers can be easily made through these machines. Other than wooden wall art, you can make a wide range of home décor items using the machine and start your own business of customized and unique décor items.

Personalized Gifts

A CNC laser cutting machine can personalize gifts and objects. There are endless items you can make and personalize with it, you can engrave any name, design, date, pattern, or anything else. It can even engrave photos on a piece of wood, which is a hot-selling item.

Customized Cutting Boards

Customized cutting boards are trending these days, and people love to have them in their kitchens. These can be used for cutting as well as a décor piece. Any pattern, quote, or design can be made through the CNC laser machine. These are also preferred for gifting.

Personalized Signs

A CNC laser machine can cut a wide range of materials. It is possible to make personalized signs on acrylic, plywood, and leather. These signs are great for businesses, shops, and advertisements. People look for personalized signs for their businesses and special occasions.

China’s Dominance in the Fiber Laser Cutting Machine Market

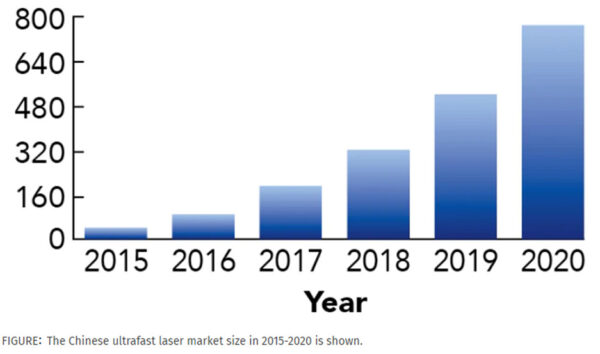

CNC Fiber laser cutting machines have become a leading force in material processing, with China at the forefront of this market. According to Industrial Laser Solutions, China commands over 60% of the global laser processing market. This dominance is partly due to the significant reduction in laser prices, which has led to rapid adoption of laser technologies for applications such as metal cutting, cleaning, and marking. The affordability has made it possible to cater to specifications that are sensitive to user requirements.

In 2018, China saw substantial sales in laser systems, with 30,000 units of mid-power and 6,000 units of high-power laser cutting systems sold. Additionally, 130,000 laser markers were sold in the country. The growth extends beyond traditional applications, with increasing interest in UV and ultrafast lasers. Specifically, China sold approximately 15,000 UV lasers last year, with a forecast of 20,000 units for this year.

The evolution of the laser market in China since 2015 reflects a significant economic transformation and growth in traditional industries. This progress underscores China's role as a key player in the global laser technology market.

Top 10 Fiber Laser Cutting Machine Manufacturers:The Definite Summary in 2024

| Rank | Company | Headquarter |

| 1 | Avonisys AG | Switzerland |

| 2 | Bystronic | Butzberg |

| 3 | Amada Weld Tech | USA |

| 4 | Epilog Laser | USA |

| 5 | Krrass | China |

| 6 | IPG Photonics | USA |

| 7 | Accurl TechnoligiesU | Italy |

| 8 | Prima Power | Italy |

| 9 | HG Tech | Germany |

| 10 | Alpha Laaser | Germany |

Conclusion

In today’s fast-paced industrial landscape, achieving higher production rates in less time is a top priority for many businesses.

When looking for the best fiber laser cutting machine, it’s important to consider the evolving advancements in the Chinese market. For top performance and reliability, KRRASS stands out as a superior choice. Why? KRRASS integrates leading brand components to ensure exceptional quality and high efficiency in their machines.

Eager to learn more about how KRRASS can enhance your production? Contact us today for more information!