Metal bending machines, such as hydraulic press brakes, servo-electro press brakes, and CNC press brakes, are widely used in the contemporary sheet metal industry. However, finger brakes, which are special-purpose bending machines, continue to be popular.

While both press brakes and finger brakes serve similar functions, they differ significantly in terms of operating principles and bending methods.

What is a Finger Brake?

Finger brakes, also known as box and pan brakes, are commonly used for bending thin metal plates made of materials with high tensile strength, including stainless steel, aluminum, and other alloys. These brakes work by utilizing a clamping rod with removable steel fingers of varying widths.

Finger brakes are primarily used for forming objects like boxes and pans. The fingers are secured in place by thumbscrews, and any unused fingers can be removed before bending. It is essential to tighten all thumbscrews and secure the fingers before using box and pan brakes to avoid unwanted bending or deformation.

In summary, finger brakes, or box and pan brakes, are specifically designed to bend thin metal plates into objects like boxes and pans. They employ removable steel fingers and clamping rods for this purpose.

What is a Press Brake?

A press brake is a machine widely used in the sheet metal industry for bending metal sheets. The history of bending machines dates back to the simple cornice brake and has evolved over time to include hydraulic press brakes, and eventually CNC press brakes.

The CNC press brake, known for its accuracy and efficiency in bending, utilizes programming for precise control. This machine is versatile and can bend complex workpieces, making it widely used in industries such as automotive, construction, and aviation.

Press brakes come with varying bending capacities and can handle plates of different lengths and thicknesses.

Differences: Press Brake vs Finger Brake

Functions

Finger Brake:

Finger brakes are primarily used for creating boxes, pans, channels, angles, and similar objects of varying depths and sizes. They can also create hemming, processing both open and closed hems, as well as lighter gauge hems.

Press Brake:

In comparison, Press Brake offer a more advanced range of functions. With various types available, press brakes consist of a frame, workbench, ram, tooling, and driving device. The driving device can be manual, mechanical, hydraulic, servo motor, or pneumatic, resulting in different bending forces exerted on the workpiece. This tonnage range enables press brakes to bend plates of varying thicknesses without damaging the machine. The length of the press brake's worktable determines the length of the sheet that can be bent.

Structures and Working Principles

Finger Brake:

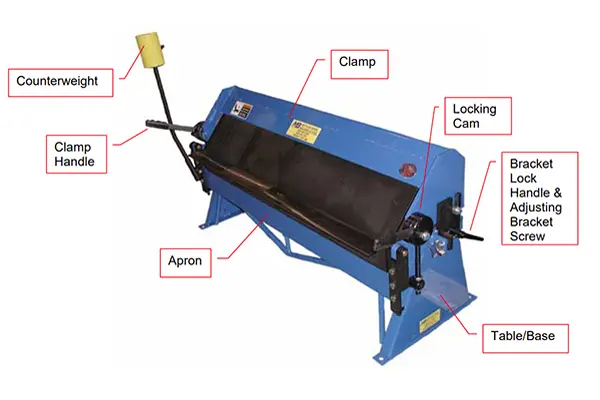

A finger brake is primarily composed of a frame, a forming rod, and a clamping mechanism. It is manually operated, with a heavy steel body that ensures the bending angle remains unaffected even under full load. The clamping rod of the finger brake is equipped with removable fingers, which can be disassembled or rearranged for bending or modifying a workpiece.

Press Brake:

Press brakes, though available in various types, have similar structures consisting of a frame, worktable, ram, toolings, electrical control box, and power system. CNC press brakes have additional features such as a controller, backgauge, light curtain protection, and crowning device. The press brake operates through the combined efforts of the controller and the operator, with the upper die pressing the metal sheet onto the lower die, driven by the ram.

Conclusion

In conclusion, this article highlights the comparison between press brakes and finger brakes, outlining their respective strengths and weaknesses. Despite advancements in press brake technology, finger brakes continue to be widely utilized in the sheet metal industry.

If you are seeking a high-performance press brake to enhance productivity, consider KRRASS press brake. KRRASS specializes in manufacturing machines for the sheet metal industry. For more information, feel free to reach out to our sales team.

FAQs

Box and pan brakes, also known as finger brakes, are a type of leaf brake primarily used for forming boxes, pans, and other objects. They consist of a frame, a clamping rod, and steel fingers that act as clamps. These brakes offer interchangeable finger parts for various specifications and inner radii.

Which is better, a Press Brake or a Finger Brake?

Press brakes offer more advanced technology compared to finger brakes. While finger brakes are suitable for simple bending operations, press brakes can perform various complex bending operations. However, press brakes are more expensive than finger brakes. Therefore, if simple bending is sufficient, a finger brake is a cost-effective choice. However, for complex and multi-functional batch bending operations, a press brake is the ideal machine. It is important to note that finger brakes have a simpler operation but lower safety compared to press brakes, so caution must be exercised when using them.

KRRASS: the best choice for

all sheet metal processing manufacturers

When considering the overall costs of purchasing, maintaining, and operating a sheet metal equipment setup, a sheet metal fabrication service: KRRASS brand is your best choice. KRRASS has a tremendous reputation in the market due to its focus on consistency and quality at the most competitive price. Whether it's press brake or any other application equipment, our team of experts has the right combination of industry knowledge and the latest tool to provide you with the best products and services on the market. Moreover, we set ourselves apart with our advanced system that is completely online. Just let us know what your product needs, request a quote, and start the process.

Make a request and Get Started Today

Get Instant Quote

Learn more about our products, please visit and subscribe to our Youtube channel