1.What is a Fiber Lasre Cutting Machine?

3.Laser cutting machine varieties?

4.Application of laser cutting machine?

5.The cost of laser cutting machine?

1.What is fiber laser cutting machine?

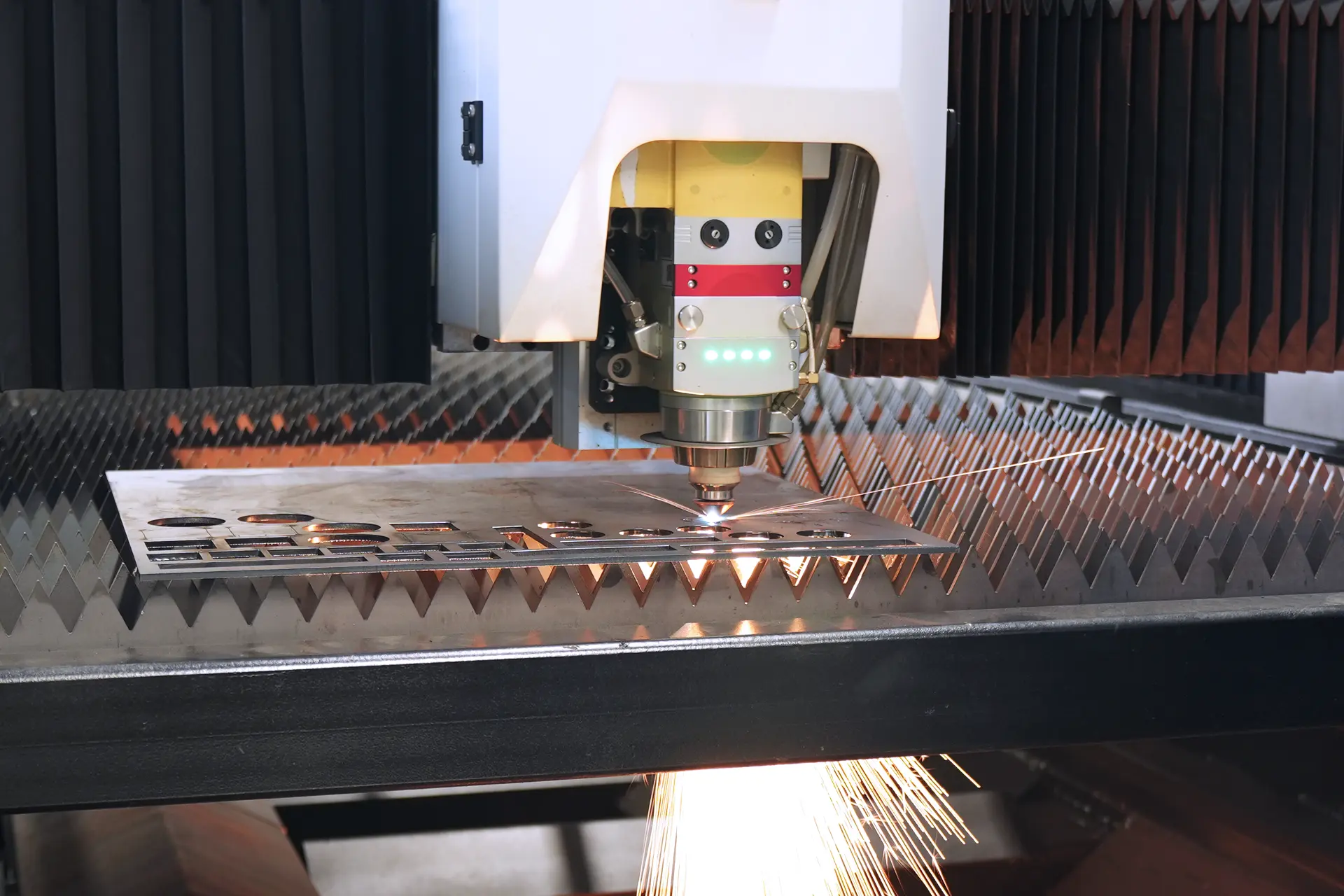

A fiber laser cutting machine is a type of industrial laser cutting equipment that uses a fiber laser source to cut materials. It operates by focusing a high-power laser beam onto the surface of the material, causing it to melt, burn, or vaporize, thereby creating a precise and clean cut.

Fiber lasers use optical fibers as the medium for delivering the laser beam to the cutting head. These fibers are doped with rare earth elements such as erbium, ytterbium, or thulium, which enable them to produce high-intensity laser light efficiently.

Fiber laser cutting machines are known for their high precision, speed, and versatility. They can cut through a wide range of materials including metals like steel, aluminum, brass, copper, and titanium, as well as various non-metal materials like plastics, ceramics, and composites. They are widely used in industries such as automotive, aerospace, electronics, manufacturing, and signage for applications such as metal fabrication, parts manufacturing, prototyping, and engraving.

2.Laser cutting machine type?

There are several types of laser cutting machines, each with its own advantages and applications. Some of the common types include:

- CO2 Laser Cutting Machines: These machines use a carbon dioxide laser to cut materials. They are well-suited for cutting non-metal materials like wood, acrylic, plastic, fabric, and leather. CO2 lasers are known for their versatility and ability to produce intricate designs with high precision.

- Fiber Laser Cutting Machines: As mentioned earlier, fiber laser cutting machines use fiber lasers to cut materials, primarily metals. They are highly efficient and capable of cutting through various metals with high speed and precision. Fiber lasers are particularly well-suited for thin to medium thickness metals.

- Nd:YAG Laser Cutting Machines: Nd:YAG (neodymium-doped yttrium aluminum garnet) lasers are used in these machines. They are suitable for cutting thicker metals and are often used in industries such as aerospace and automotive for cutting materials like stainless steel and aluminum.

- Solid-State Laser Cutting Machines: These machines use solid-state lasers, which can be based on different materials like crystal or glass. They offer high power and precision, making them suitable for a wide range of materials and applications.

- Disk Laser Cutting Machines: Disk lasers utilize a thin disk as the laser medium. They offer high power efficiency and beam quality, making them suitable for high-speed cutting of various materials, including metals and composites.

The choice of laser cutting machine depends on factors such as the type and thickness of materials to be cut, desired cutting speed, precision requirements, and budget constraints. Each type of laser cutting machine has its own advantages and limitations, so it's essential to select the one that best fits the specific needs of the application.

3.Laser cutting machine varieties?

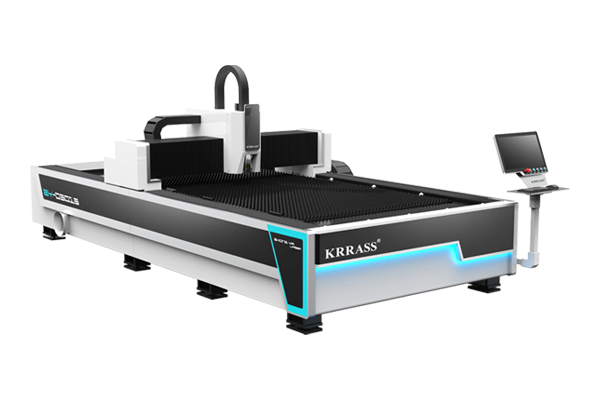

1)Plate Fiber Laser Cutting Machine.

A Plate Fiber Laser Cutting Machine is a specific type of fiber laser cutting machine designed primarily for cutting metal plates. These machines are capable of cutting through various types of metal plates with high precision and speed, making them widely used in industries such as automotive, aerospace, construction, and metal fabrication.

Plate fiber laser cutting machines typically feature a sturdy structure to support the weight of large metal plates and ensure stability during the cutting process. They use a high-power fiber laser source to generate the laser beam, which is then directed onto the surface of the metal plate through a cutting head equipped with focusing optics.

One of the key advantages of plate fiber laser cutting machines is their ability to cut through thick metal plates with exceptional accuracy and efficiency. They can handle a wide range of metals, including stainless steel, carbon steel, aluminum, brass, and copper. Additionally, these machines are known for their fast cutting speeds, which help improve productivity in manufacturing processes.

Plate fiber laser cutting machines are often equipped with advanced features such as CNC (Computer Numerical Control) systems for precise control of cutting parameters, automatic material feeding systems for continuous operation, and integrated software for designing and nesting parts efficiently. These features contribute to increased automation, reduced setup times, and improved overall cutting quality.

Overall, plate fiber laser cutting machines are versatile tools that provide manufacturers with a cost-effective solution for producing high-quality metal parts and components with complex shapes and tight tolerances.

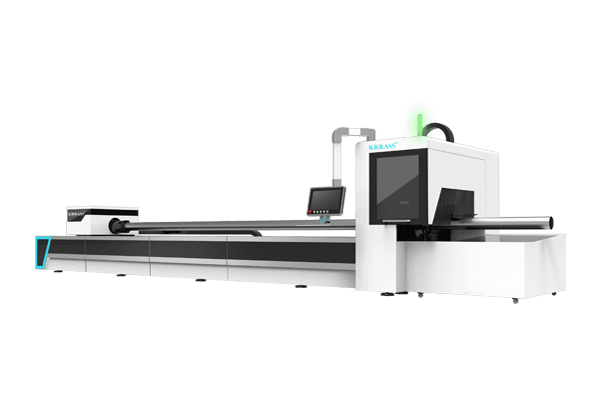

2)Tube Fiber Laser Cutting Machine.

A Tube Fiber Laser Cutting Machine is a specialized type of fiber laser cutting machine designed specifically for cutting tubes, pipes, and other cylindrical or tubular metal structures. These machines utilize fiber laser technology to deliver high precision and efficiency in cutting various types of metal tubes, including steel, stainless steel, aluminum, brass, and copper.

The operation of a tube fiber laser cutting machine involves feeding the metal tube through the machine's cutting area while the laser beam is directed onto the surface of the tube to perform the cutting. The machine can rotate and move the tube along its axis, allowing for precise cuts in different orientations and angles.

Here are some key features and advantages of tube fiber laser cutting machines:

- Versatility: Tube fiber laser cutting machines can cut a wide range of tube shapes, sizes, and materials. They can handle round, square, rectangular, and oval tubes, as well as various thicknesses and diameters.

- High precision: These machines offer exceptional cutting accuracy and repeatability, ensuring consistent results even for complex geometries and tight tolerances.

- Efficient processing: Tube fiber laser cutting machines can achieve high cutting speeds, resulting in improved productivity and reduced production lead times.

- Automation capabilities: Many tube fiber laser cutting machines come equipped with automatic loading and unloading systems, as well as advanced CNC control features for efficient and hands-free operation.

- Minimal material waste: The precise nature of fiber laser cutting minimizes material waste, optimizing material utilization and reducing production costs.

Tube fiber laser cutting machines find applications in various industries such as automotive, aerospace, construction, furniture, and metal fabrication. They are used for cutting tubes and pipes to produce components for structures, frames, exhaust systems, handrails, furniture, and other products requiring tubular metal parts with precise dimensions and shapes.

4.Application of laser cutting machine?

Laser cutting machines have a wide range of applications across various industries due to their versatility, precision, and efficiency. Some common applications of laser cutting machines include:

Laser cutting machines have a wide range of applications across various industries due to their versatility, precision, and efficiency. Some common applications of laser cutting machines include:

- Metal Fabrication: Laser cutting machines are extensively used in metal fabrication industries for cutting various types of metals, including stainless steel, carbon steel, aluminum, brass, and copper. They are employed in the production of sheet metal components, structural parts, chassis, brackets, gears, and other metal parts with precise shapes and sizes.

- Automotive Industry: Laser cutting machines play a vital role in the automotive industry for cutting metal sheets and tubes to manufacture vehicle components such as body panels, frames, exhaust systems, engine parts, and intricate automotive parts with complex geometries.

- Aerospace Industry: Laser cutting technology is widely used in the aerospace sector for cutting lightweight metals like aluminum and titanium to produce aircraft components, turbine blades, fuselage panels, structural parts, and other aerospace components requiring high precision and quality.

- Electronics Manufacturing: Laser cutting machines are utilized in the electronics industry for cutting thin metal sheets and PCBs (Printed Circuit Boards) with intricate patterns and fine details. They are used for manufacturing electronic enclosures, casings, connectors, and other electronic components.

- Signage and Advertising: Laser cutting machines are popularly used in the signage and advertising industry for cutting various materials such as acrylic, plastic, wood, and metal to create custom signs, displays, logos, letters, and decorative elements with high precision and intricate designs.

- Architectural and Interior Design: Laser cutting technology is employed in architectural and interior design applications for cutting materials like wood, acrylic, and metal to produce decorative panels, partitions, screens, wall art, furniture, and custom architectural elements with intricate patterns and designs.

- Packaging Industry: Laser cutting machines are used in the packaging industry for cutting cardboard, paperboard, and other packaging materials to create custom packaging solutions, prototypes, displays, and promotional materials with precise cuts and creases.

- Medical Device Manufacturing: Laser cutting technology is utilized in the medical device industry for cutting various materials such as stainless steel, titanium, and polymers to produce surgical instruments, implants, medical devices, and components with complex geometries and high precision.

These are just a few examples of the diverse applications of laser cutting machines across different industries. With advancements in laser technology and machine capabilities, the range of applications continues to expand, driving innovation and efficiency in manufacturing processes.

5.The cost of laser cutting machine?

The cost of a laser cutting machine can vary widely depending on several factors, including the machine's size, power, capabilities, brand, and additional features. Here's a breakdown of some general price ranges based on different types of laser cutting machines:

Entry-level CO2 Laser Cutting Machines: These machines are typically more affordable and suitable for cutting non-metal materials like wood, acrylic, and plastics. Prices for entry-level CO2 laser cutting machines can range from $2,000 to $10,000 USD for small desktop models, while larger machines may cost between $10,000 to $50,000 USD.

Fiber Laser Cutting Machines: Fiber laser cutting machines are primarily used for cutting metals and offer higher precision and cutting speeds compared to CO2 lasers. The cost of fiber laser cutting machines can range from $30,000 to $500,000 USD or more, depending on the machine's size, power output, and additional features such as automatic loading/unloading systems and CNC controls.

Tube Laser Cutting Machines: Tube laser cutting machines, designed specifically for cutting metal tubes and pipes, generally come at a higher price point due to their specialized capabilities. Prices for tube laser cutting machines can range from $100,000 to $1,000,000 USD or more, depending on the machine's size, power, and automation features.

High-End Laser Cutting Systems: High-end laser cutting systems with advanced features, large working areas, high power outputs, and automation capabilities can cost several hundred thousand to millions of dollars. These systems are typically used in industrial manufacturing settings for high-volume production and precision cutting applications.

It's essential to consider not only the upfront cost of the laser cutting machine but also factors such as operating costs, maintenance requirements, software compatibility, and technical support when evaluating the total cost of ownership. Additionally, some manufacturers offer leasing or financing options to help businesses acquire laser cutting machines with manageable payment plans.

6.The brand of laser source?

Laser cutting machines can use various brands of laser sources, with each brand offering different specifications and performance characteristics. Some of the prominent brands of laser sources commonly used in laser cutting machines include:

- IPG Photonics: IPG Photonics is a leading manufacturer of high-power fiber lasers, including continuous wave (CW) and pulsed fiber lasers. Their lasers are known for their reliability, efficiency, and high beam quality, making them popular choices for industrial laser cutting applications.

- Trumpf: Trumpf is a well-known manufacturer of laser cutting systems and laser sources. They offer a range of laser sources, including CO2 lasers and solid-state lasers, known for their high power output, precision, and durability.

- Coherent: Coherent is a global provider of laser technology solutions, offering a wide range of laser sources for various industrial applications. Their lasers include CO2 lasers, fiber lasers, and diode-pumped solid-state lasers, known for their performance, reliability, and versatility.

- nLIGHT: nLIGHT is a manufacturer of high-power semiconductor lasers and fiber lasers used in laser cutting, welding, and other industrial applications. Their lasers are known for their compact design, high efficiency, and reliability.

- Raycus: Raycus is a Chinese manufacturer specializing in fiber laser sources for laser cutting, welding, marking, and other industrial applications. They offer a range of fiber lasers known for their stability, affordability, and high cutting performance.

- SPI Lasers: SPI Lasers is a UK-based manufacturer of fiber lasers used in laser cutting, welding, and marking applications. Their lasers are known for their high beam quality, reliability, and efficiency.

7.Max laser:It is a laser manufacturer specializing in the research and development, production and sales of fiber lasers and their core devices, and is also the first high-tech enterprise in China to realize the localization and vertical integration of two core technologies of lasers and optical passive devices.

These are just a few examples of the many brands of laser sources available in the market. When choosing a laser cutting machine, it's essential to consider factors such as the brand and type of laser source, power output, beam quality, and suitability for specific cutting applications. Additionally, factors such as service and support, warranty, and long-term reliability should also be taken into account when selecting a laser cutting machine.

Reviewed by 1 user

6000W fiber laser cutting machine

Very excellent fiber laser cutting machine manufacturers, just purchased 6000W fiber laser cutting machine, KRRASS workers for on-site debugging and training. Hope to cooperate next time.