One of the benefits of many types of metals is the fact that they are relatively ductile; ductility ensures that metals bend before they break. This ductility allows them to be formed to be a certain shape and size. This makes metals versatile, since oftentimes flat pieces of sheet metal must have their shape altered to be useful. Many pieces of forming equipment can be used to do this, but one of the most common is the press brake machine.

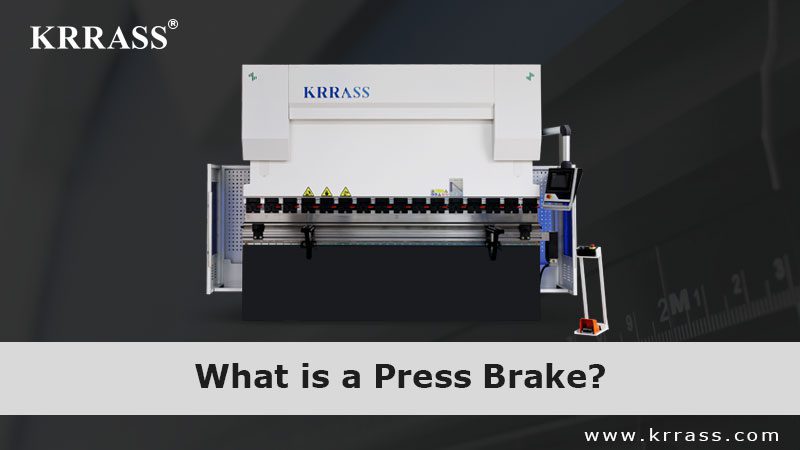

What is a Press Brake?

A press brake is a piece of manufacturing equipment that is used to bend sheet metal. A press brake is typically narrow and long so that large pieces of sheet metal can be bent by it. A press brake bends sheet metal by lowering a punch onto sheet metal that has been positioned on top of a die. The metal may be bent several times by a press brake until the desired form has been achieved.

What types of press brakes are there?

Bending sheet metal requires a large amount of force, and to achieve and deliver this force, the punch is lowered onto the sheet metal through several different methods. The methods of force application can be hydraulic, pneumatic, electric, or mechanical. The method of force application is often included in the name of a press brake (e.g. hydraulic press brake, servo electric press brake).

Press brakes also vary in the amount of force they can provide. On a press brake this is known as tonnage; it is a measure of tons of force that the press brake can deliver. Typically, hydraulic presses are used to achieve very high amounts of force, and pneumatic and servo electric presses provide lesser amounts of force.

The different types of press brakes also have different speeds and accuracies as well. A servo electric press brake will generally have the highest degree of accuracy. Pneumatic and servo electric press brakes are also typically faster than hydraulic and mechanical press brakes as well.

What needs to be considered when bending a metal using a press brake?

Press brakes can make a variety of different bends on many different types of metals. When setting up a bending process, it is important to consider the metal type being bent, the die, the punch, and the bending force.

The metal type is important to understand because of the differing physical properties among metals. For instance, a high carbon steel will generally be less bendable by a press brake than many aluminum alloys because of the differences in ductility and strength. Metals typically have a recommended minimum bend radius that the material can be bent to without damaging it.

The die and the punch used on the press brake both have a large impact on the bending process. The die is hollow material that the metal is placed on top of prior to bending. It is a very hard and strong material that is near in shape to the desired shape of the metal being bent. The punch is a solid material that is lowered down onto the metal. Since the pressing action of the punch onto the metal and the die are what causes the metal to bend, both shapes must be accurately suited to the bending job. The correct metal shape following a press brake operation is dependent on the size and shape of the punches and dies. The dies and the punches are typically designed in such a way that they can be interchanged easily to accommodate a wide array of jobs.

Common press brake applications:

- Automotive panels

- Airframes

- Metal artwork

- Furniture

- Metal containers

- Many other sheet metal forming applications

Reviewed by 1 user

press brake

good press brake from krrass ,i will like