Metal laser cutting machine is equipped with different fiber laser sources, such as Raycus and IPG, which will affect the cutting accuracy, in addition, different thickness and different hardness of metal materials can also affect the precision of fiber laser cutting machine.

When we want to cut the metals with more accuracy by a metal laser cutting machine, we must understand which aspects will affect the accuracy of the cutting, we will briefly introduce you to the following:

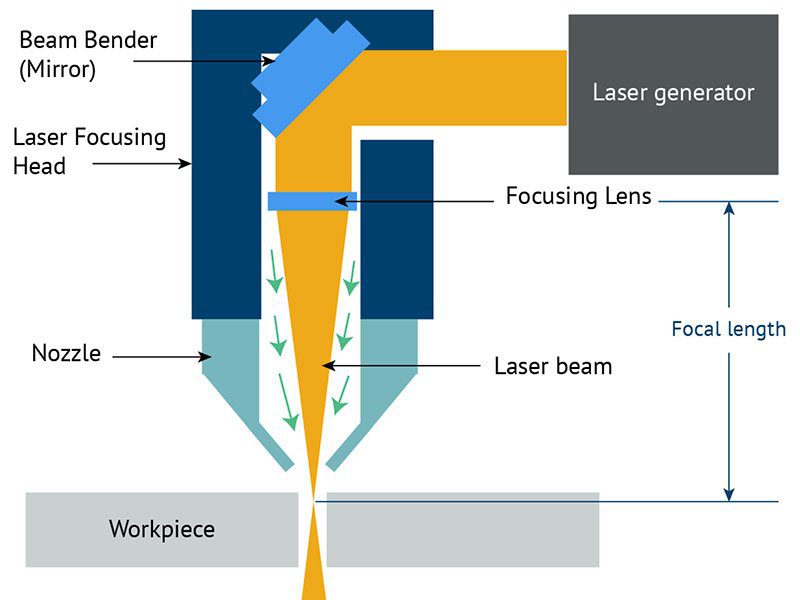

- The laser beam emitted is tapered, so the cutting slit is also tapered, in this case, the slit of 1mm stainless steel will be much smaller than the 4mm thickness.Therefore, the shape of the laser beam is a major element to affect the cutting accuracy. Under such a cone-shaped laser beam, the thicker of the workpiece, the lower accurate it will be and the larger of the cutting slit.

When the cone-shaped laser beams focus on together, the laser point is smaller at this time, The laser cutting precision becomes higher and higher, especially the width of the slit becomes smaller. At this time the smallest spot can reach 0.01mm. This is also one of the factors that affect the cutting accuracy of laser cutting machines.

- In this case, the cutting accuracy of different materials is slightly different. Even with the same material, the precision of the cut will vary if the composition of the material is different. Therefore, the workpiece material also has a certain influence on the laser cutting accuracy.

- The accuracy of the workbench, if the workbench is not accurate or other reasons, it will lead to high-precision laser cutting effect.

Under the same conditions, high precision cutting of stainless steel than aluminum, copper and brass.

Learn more about our products, please visit and subscribe to our Youtube channel