1500W fiber laser cutting machine is a high-power industrial equipment, mainly used for precision cutting various metal materials, including carbon steel, stainless steel, and aluminum. It uses a fiber laser generator as the cutting source, and the laser emits a highly focused beam that is directly irradiated on the material to be cut. What can 1500W fiber laser cut, what the maximum thickness can reach, and what materials are applied?

Overview of Fiber Laser Cutting

Over the last two decades, fiber laser systems have steadily grown in popularity across numerous industries. Used to mark industrial product quantities, etch codes into parts and components, and cut diverse materials, fiber lasers are versatile machines that can complete today’s most demanding applications.

Fiber laser technology was first developed in the 1960s, but it wasn’t until the early 2000s that fiber laser systems became viable options for manufacturing and packaging operations. As fiber laser technology became more cost-effective, large-scale operations began using fiber systems to cut materials and mark their goods with durable text and sharp images. Today, fiber laser technology is becoming increasingly accessible to companies of different sizes and specialties, causing many operations to consider adopting fiber laser systems.

What Power Should Be Adopted

Laser power has a large influence on what applications a fiber laser system can complete, what materials it can work with, and how quickly it can process products.

Given that laser applications have so many variables, it is difficult to definitively state whether a machine can complete specific tasks by looking at laser power alone. A more helpful practice is to examine your application needs, understand the general power range required to complete them, and then search for systems within that range.

The following table is a good starting point:

| Fiber Laser Application | Required Laser Power Range |

| Marking/Engraving Thin Plastic Sheets | 10W-20W |

| Marking/Engraving Rigid Plastic | 30W-50W |

| Marking/Engraving Plastic at High Speeds | 50W |

| Marking/Engraving Soft Metal | 20W |

| Marking/Engraving Stainless Steel | 30W-50W |

| Marking/Engraving Metal at High Speeds | 50W |

| Cutting Plastic Sheets | 40-80W |

| Cutting Rigid Plastic | 50W-100W |

| Cutting Metal Sheets | 500W |

| Cutting Metal Parts | 1,500W |

Introduction to 1500W Fiber Lasers

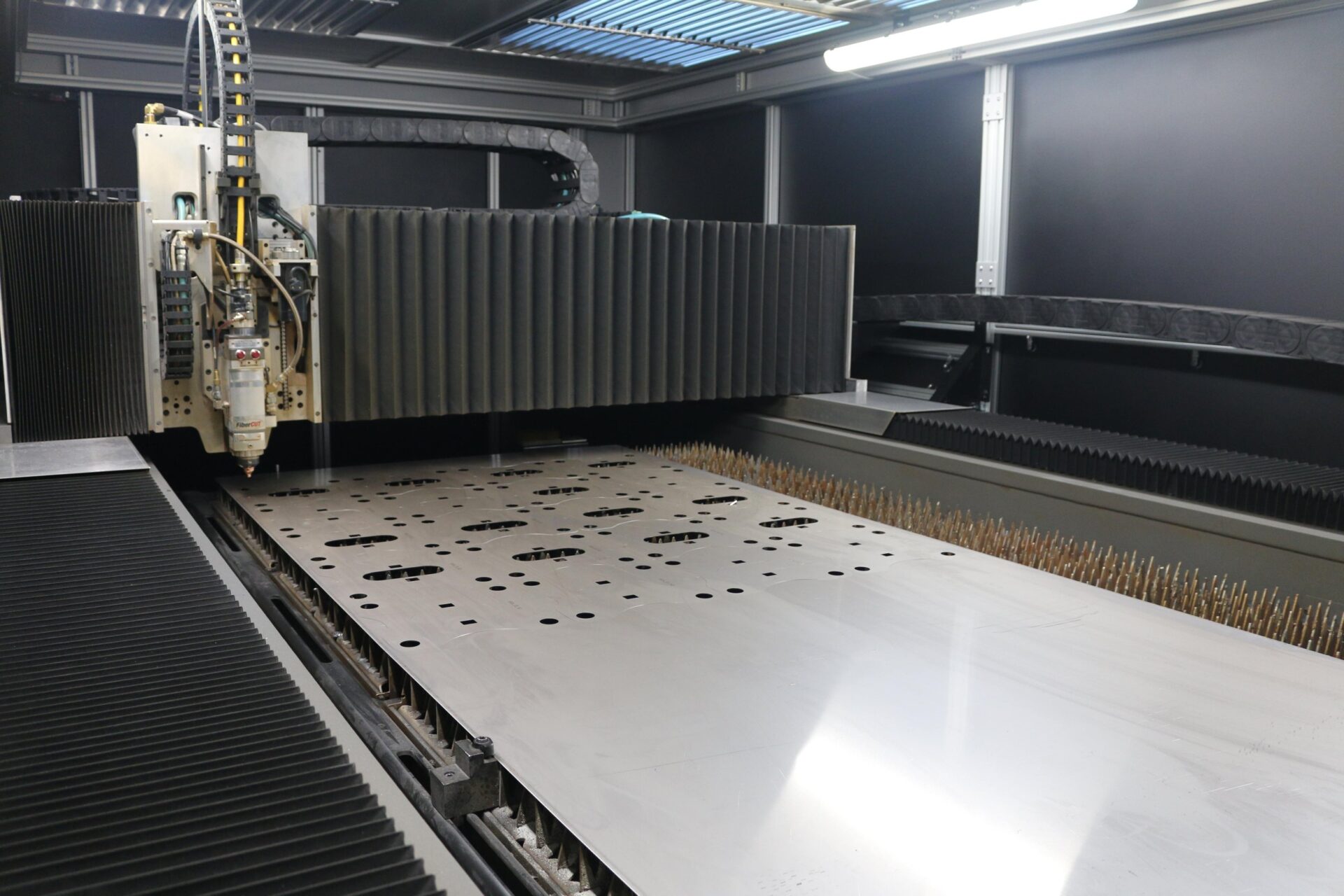

In recent years, 1500 fiber lasers are more and more popular in the market due to their high cost performance. The machine body is manufactured with a high-strength steel frame and is coated with a material that resists scratches and abrasion. The bed provides a stable surface for the cutting material and is able to withstand the heat and pressure generated during the cutting process. Advanced CNC control software that allows the operator to program the machine to complete a specific design or shape.

Features

High Precision Welding Body:

The high precision welding body features an integrated design with a sheet production line, enabling self-sufficiency and faster delivery times. It offers a range of customizable working sizes to meet various needs.

Auto Oil-Filling System:

Equipped with an intelligent auto oil-filling system, this feature ensures precise oil levels while preventing overflow or spillage.

Cost-Effective Solution:

This solution is designed to minimize raw material waste and offers a low investment cost with a short return on investment period.

Open Type Fiber Laser Cutting Machine for Metal Sheet

1500W Fiber Laser Cutting Capacity (Metal Cutting Thickness)

| Material | Cutting Limit | Clean Cut |

| Carbon steel | 14mm | 12mm |

| Stainless steel | 6mm | 5mm |

| Aluminum | 5mm | 4mm |

| Brass | 5mm | 4mm |

| Copper | 4mm | 3mm |

| Galvanized steel | 5mm | 4mm |

How thick can a 1.5 kw fiber laser cut?

Fiber laser 1500W cutting maximum thickness 14mm mild steel, 6mm stainless steel, 5mm aluminum, 5mm brass, 4mm copper, 5mm galvanized steel (Large format cutting area 2m × 4m, 2m × 6m ).

For a 1000W fiber laser cutter, the maximum cutting thicknesses are as follows: it can cut up to 10mm of carbon steel, 5mm of stainless steel, and 3mm of both aluminum and brass. This machine is suitable for applications requiring precision on thinner materials.

For a 2000W fiber laser cutter, the maximum cutting capacities are significantly higher. It can handle up to 20mm of carbon steel, 8mm of stainless steel, 6mm of aluminum, and 5mm of brass. This higher power machine is ideal for thicker materials and more demanding cutting tasks.

What Materials Can 1500W Fiber Laser Cut

The 1500W fiber laser cutting machine is versatile and capable of cutting various metals, including stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium, galvanized sheets, iron sheets, inox sheets, aluminum, copper, and brass. It can handle a range of materials such as metal sheets, plates, and tubes.

What Materials Can't Be Cut By Fiber Lasers

While fiber lasers are highly effective for cutting a wide range of metals, they are not suitable for non-metallic materials, highly reflective thick metals, transparent materials, organic and flammable substances, certain composites, and fiberglass. For these materials, alternative cutting methods or laser types may be required.

For entire 1500w fiber laser cutting parameters, pls visit here.

What are the Benefits of Metal Laser Cutter to Your Project?

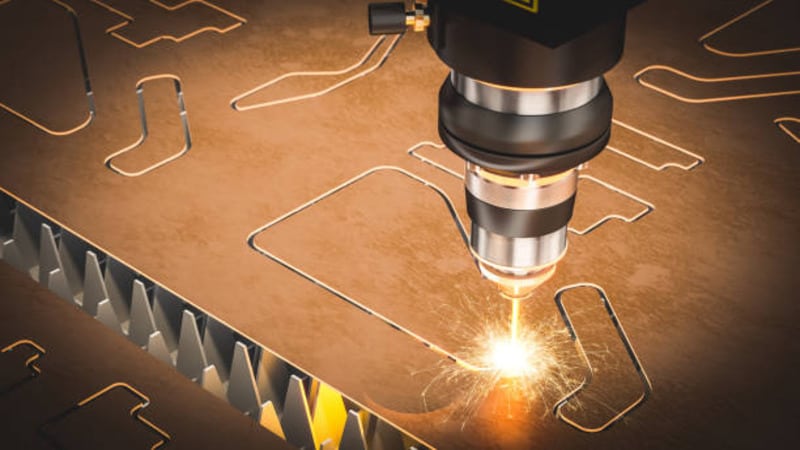

Metal laser cutters are increasingly gaining popularity in the manufacturing industry due to their ability to produce high-precision parts with minimal waste. Laser cutting technology is a versatile tool that can be used for a variety of applications, including automotive, aerospace and electronics.

Benefits include:

- Precision: Metal laser cutters provide precision cuts with extremely accurate tolerances, allowing manufacturers to quickly create high-quality components without wasting materials or time.

- Versatility: The versatility of this technology allows it to be applied to almost any material, from thin sheet metals up to thick plates and even hardwoods like oak. It can also be used for creating complex shapes and delicate features.

- Speed: Laser cutting is much faster than traditional methods of cutting, allowing manufacturers and fabricators to quickly create and manipulate parts in a fraction of the time, without sacrificing quality or accuracy.

- Cost-Effectiveness: Metal laser cutters are also highly cost-effective due to their low operating costs and minimal material waste. The speed at which they can produce parts also helps reduce overall manufacturing times, resulting in lower costs and higher profits.

- Safety: The lasers used in metal laser cutters are powerful but do not produce any excess heat, smoke or sparks during operation, making them safe to use in many work environments where other

Can Fiber Laser Cut Through Thick Steel?

Laser cutting is a powerful tool for fabricating and manufacturing steel components, but it does have its limitations. While this technology excels in producing precise cuts, there are certain thicknesses that it may struggle with, potentially resulting in a compromised finish.

In this article, Krrass Machinery explores the limitations of laser cutting, focusing on how factors such as wattage and metal type affect the maximum thickness that can be effectively cut.

Laser Cutting Thickness Limitations

Laser cutters are precision tools capable of slicing through various thicknesses of steel, but their cutting capabilities are not without constraints. The maximum thickness of steel that a laser cutter can handle largely depends on the power of the laser and the specific type of steel being cut.

Thicker steel necessitates higher laser power, which can slow down cutting speeds and increase heat generation. This added heat may affect the quality of the cut, leading to potential warping or melting of the steel. To manage these issues, specialized cutting techniques and cooling systems might be required.

Additionally, the reflective nature of certain steel types, such as stainless steel, can present challenges. The reflective surface can cause the laser beam to bounce off, complicating the cutting process for thicker stainless steel sheets.

General Laser Cutting Thickness Limits Based on Wattage

Laser cutting capabilities are influenced by the power of the laser, which determines how much heat is generated to melt or vaporize the material being cut. Higher wattage lasers produce more intense beams, allowing them to cut through thicker materials. The appropriate wattage for cutting various materials depends on the type of metal and its thickness.

For instance, a lower-wattage laser may struggle with cutting thicker stainless steel sheets. As a general guide, the maximum cutting thickness for different metals based on laser wattage is as follows:

| Type of Laser Cutting Machine | Maximum Thickness of Carbon Steel | Maximum Thickness of Stainless Steel | Maximum Thickness of Aluminium Plate | Maximum Thickness of Copper Plate |

| 500W | 6mm | 3mm | 2mm | 2mm |

| 1000W | 10mm | 5mm | 3mm | 3mm |

| 2000W | 16mm | 8mm | 5mm | 5mm |

| 3000W | 20mm | 10mm | 8mm | 8mm |

3 Terms in Fiber Laser Cutting

Marking Area

The term "marking area" refers to the space within which a fiber laser system can etch codes, images, and markings. Similar to the "print height" in continuous inkjet and thermal inkjet printers, the marking area defines the maximum size of the code or image that a laser system can create.

In addition to determining the maximum size of the markings, the marking area is crucial for applications where multiple substrates need to be processed in a single operation. For instance, when applying lot codes to food cans, having a large marking area combined with an appropriate production line setup allows for efficient marking of several cans at once.

Marking areas vary widely among different fiber laser systems, ranging from a few square millimeters to several hundred square millimeters. There is no one-size-fits-all standard, so it is advisable to consult with an expert to select a marking area that best suits your specific needs.

Marking Speed

When selecting a fiber laser system for marking and engraving, it is crucial to choose one that aligns with your production demands.

For high-volume operations, such as bottling lines, the marking system must keep pace with the speed of your production line. Fiber laser systems come with varying speed capabilities to accommodate different production setups. The fastest systems available can handle line speeds exceeding 900 meters per minute (m/min). However, most manufacturing and packaging facilities find that a system with a speed range of 200-600 m/min suffices for their needs.

Another key performance metric is characters per second (CPS), which indicates the number of numbers, letters, and symbols a fiber laser system can produce in one second. This metric is especially important for applications involving extensive text or alphanumeric codes, as it determines whether the system can handle your coding requirements efficiently.

Typically, industrial fiber laser systems are rated at around 2,000 characters per second. Keep in mind that this figure can vary based on factors such as code complexity and the material of the substrate. To ensure the chosen system fits your specific needs, consult with the manufacturer or supplier to discuss how their laser system will integrate with your production processes.

Marking Precision

Marking precision refers to how accurately a fiber laser system can create marks on substrates, ensuring that the codes or designs match the intended size, position, and shape without deviation. High precision ensures that markings are clear, correctly aligned, and consistently produced, while lower precision can lead to issues such as distorted characters, misplaced markings, and uneven coloring.

Unlike metrics such as marking speed or marking area, marking precision does not have a standardized measurement. Instead, it is influenced by several factors:

- Optical System Quality: The performance of lenses, mirrors, and other optical components affects precision.

- Motion Control System Quality: The accuracy of motors and controllers that guide the laser also plays a crucial role.

- Software Sophistication: Advanced software can enhance precision by providing more accurate control over marking parameters.

- Overall System Design: The overall construction and design of the laser system impact its ability to maintain precision.

Additionally, the environment of your facility and the type of substrate used can affect the precision of the laser markings. To ensure you select a system that meets your precision requirements, consult with suppliers about the accuracy of their systems and consider how your specific environment and materials might influence performance.

How to Choose the Right Laser Power

When selecting a fiber laser cutting machine, understanding the relationship between laser power and cutting capability is essential. Fiber lasers are primarily used for cutting metal, including materials like stainless steel, carbon steel, aluminum, and brass. The thickness that can be cut increases with the laser power.

The power of fiber laser cutting machines is largely determined by the laser source. In the market, machines with power levels of 4000W and above are classified as high-power, those between 2000W and 4000W as medium-power, and those below 2000W as low-power. Currently, 2000W fiber laser cutting machines are in high demand, as they can handle most cutting tasks efficiently. Although higher power machines (above 2000W) can offer faster cutting speeds, they come at a higher cost. Laser power is one of the main factors that directly impacts the price of a laser cutting machine.

For cutting thinner stainless steel and carbon steel sheets, a low-power fiber laser cutting machine is often sufficient. These machines provide a good cutting effect while maintaining fast speeds, ensuring both work efficiency and cost savings. Therefore, it is crucial to select a laser cutting machine based on the specific metal material and thickness you intend to work with, rather than simply opting for the highest power available. However, if your cutting needs involve both thick and thin plates and you have high production capacity requirements, investing in a high-power laser cutting machine may be a more prudent choice. High-power machines can also achieve good cutting quality by adjusting the cutting speed and changing the auxiliary gas.

For example, a 1000W machine is capable of cutting carbon steel up to 8mm thick, while a 1500W machine can cut up to 12mm. In the case of stainless steel, a 1000W machine can handle thicknesses up to 4mm, while a 1500W machine can cut up to 6mm. From this, it's clear that when comparing 1000W and 1500W fiber laser cutting machines, the 1500W option is often the more sensible choice for a broader range of applications.

How to Choose the Right Laser Power

When selecting a fiber laser cutting machine, understanding the relationship between laser power and cutting capability is essential. Fiber lasers are primarily used for cutting metal, including materials like stainless steel, carbon steel, aluminum, and brass. The thickness that can be cut increases with the laser power.

The power of fiber laser cutting machines is largely determined by the laser source. In the market, machines with power levels of 4000W and above are classified as high-power, those between 2000W and 4000W as medium-power, and those below 2000W as low-power. Currently, 2000W fiber laser cutting machines are in high demand, as they can handle most cutting tasks efficiently. Although higher power machines (above 2000W) can offer faster cutting speeds, they come at a higher cost. Laser power is one of the main factors that directly impacts the price of a laser cutting machine.

For cutting thinner stainless steel and carbon steel sheets, a low-power fiber laser cutting machine is often sufficient. These machines provide a good cutting effect while maintaining fast speeds, ensuring both work efficiency and cost savings. Therefore, it is crucial to select a laser cutting machine based on the specific metal material and thickness you intend to work with, rather than simply opting for the highest power available. However, if your cutting needs involve both thick and thin plates and you have high production capacity requirements, investing in a high-power laser cutting machine may be a more prudent choice. High-power machines can also achieve good cutting quality by adjusting the cutting speed and changing the auxiliary gas.

For example, a 1000W machine is capable of cutting carbon steel up to 8mm thick, while a 1500W machine can cut up to 12mm. In the case of stainless steel, a 1000W machine can handle thicknesses up to 4mm, while a 1500W machine can cut up to 6mm. From this, it's clear that when comparing 1000W and 1500W fiber laser cutting machines, the 1500W option is often the more sensible choice for a broader range of applications

Reviewed by 2 users

this cutting machine cut very smmoth, perfect

This fiber laser cutting machine represents a valuable investment to improve our processes