V-grooving makes the impossible bend possible

Question: I have been working in job shops for many years, but until recently I had never heard of V Grooving Machine for producing sheet metal parts. Everything I’ve read on the topic, which isn’t much, talks about the advantages of V-grooving but not so much about what goes on after these grooves are in the flat part. Do you still need a press brake, or is the part formed by hand? How is the inside radius produced in this type of bend, and how is the bend allowance and bend deduction calculated? When, how, and where would I use V-grooving, and what kind of parts would benefit from it?

Answer: I first came across the concept of grooving back in the 1960s, but that’s another story best left untold. Fast-forward 40 years and grooving now has a much different interpretation, at least when it comes to manufacturing sheet metal and plate parts.

Grooving the Small

I first encountered metal grooving about 10 years ago while producing some extremely small parts in my shop. The materials were thinner than 0.012 inch, with a dimensional tolerance of ±0.0015 in. and an angular tolerance of ±0.5 degree. For those thicknesses and materials, photo etching was the best option for producing the flat. Photo etching did more than just cut the perimeter of the piece. It also gave me the ability to use half-etch lines to establish the bend lines.

In the photo etching process, a laminate is secured to both sides of the sheet. The laminate has cutouts where the laminate is missing, exposing the metal underneath. Sprayed acid eats away at the exposed metal to produce the edges of features and the outer edge of the part. For the half-etch bend lines, only one cut laminate is placed on one side of the workpiece—on the surface of the material that will be the inside of the bend radius, eating away only half of the material thickness while establishing the location and direction of the bend.

For a given work order I received as many pieces as would fit on a 12- by 18-in. sheet. The concept and process worked out well on this small scale. These parts were gold-plated after forming, which left no sign that the half-etch line was even there. Note, the photo etch process does not work with all material types.

Grooving on a Larger Scale

Outside the world of photo etching, we define V-grooving for bending as a method of establishing the bend line and bend angle using grooves cut along the bend line. It’s also known as score-folding, V-cutting, and back-scoring. The grooving process, performed by a separate cutting machine, produces a V-cut located at the bend line. After groove-cutting, the bend can be completed at the press brake or even by hand. At the press brake, the operator can bend the grooved metal into various angles and shapes using off-the-shelf or custom tools.

V Grooving Machine works best in (but is not limited to) material thicknesses from 0.031 to 0.236 in. It works with ferrous and nonferrous metals and other materials, including plastics, aluminum, composite plate, brass, bronze, copper, gold, silver, zinc, PVD-coated colored stainless steel, various stainless steel grades, and mild steel.

Why V-Groove and V Grooving Machine?

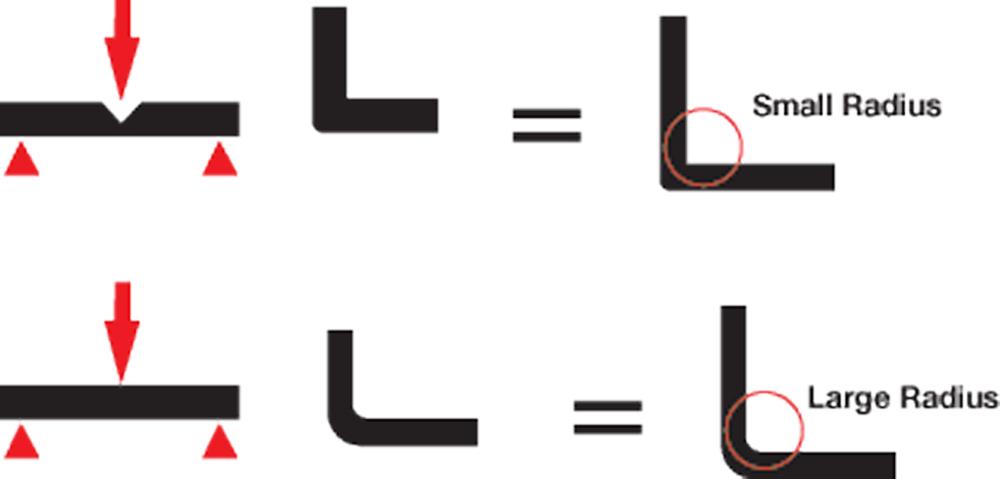

Some parts have features that traditional press brake bending methods simply cannot produce. When air forming sheet metal on a press brake, the punch pushes material into the die space. During forming, the sheet goes from the elastic state to its plastic state, where the sheet stays bent. The bend angle is set as a function of the depth of penetration into the die space, with the inside bend radius nearly equal to the material thickness, depending on the die width.

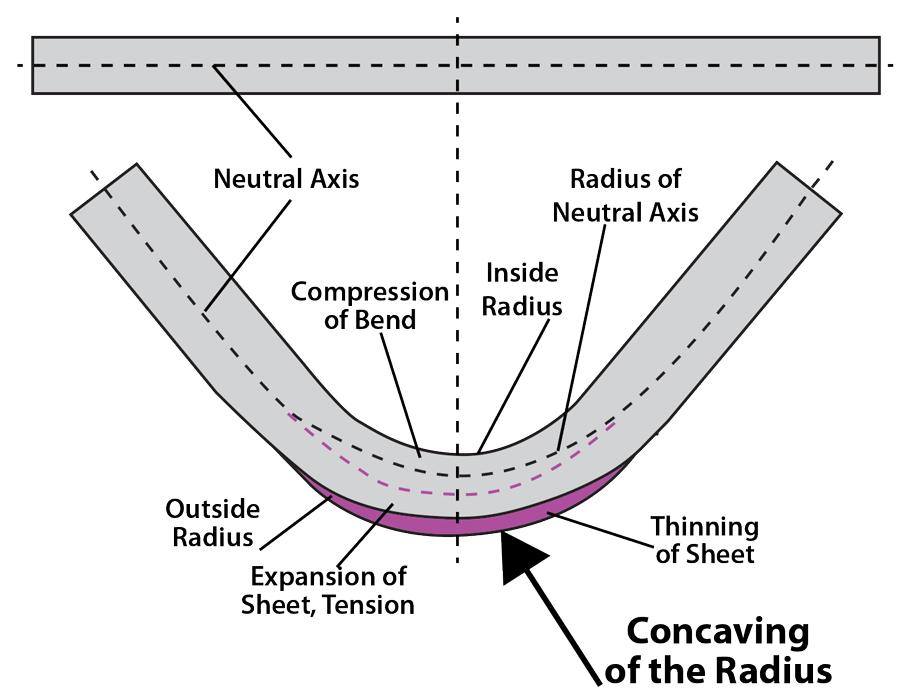

The behavior of the neutral axis is central to sheet metal bending. In the flat condition, the neutral axis is in the middle of the material thickness. During bending, compressive stresses occur on the inside of the bend, toward the inside bend radius, while expansion occurs toward the outside radius. These stresses shift the neutral axis toward the inside surface of the bend.

That shifting of the neutral axis produces the elongation we see when a sheet metal or plate part is bent. Remember that the flat is always smaller than the sum total of the outside dimensions of the finished piece.

Shortcomings of Traditional Bending

Lateral tensile stress on the outside bend radius often leads to discoloration seen on the outside of the bend—something unacceptable for an architectural application. V-grooving the sheet or plate reduces thickness at the bend line, which in turn reduces elongation and subsequent deformation caused by the lateral tensile force during bending.

When long, narrow flanges are bent on a press brake, deformation occurs from the applied compressive forces across the width of the bend. This deformation forces the material to elongate lengthwise (parallel to the bend line), convexing the edge of the bend at both ends.

At the same time, the outside bend radius, under tensile stress, causes the part to elongate slightly in the width direction (perpendicular to the bend line). This causes the outside bend radius to “pull in” somewhat, creating a center-concave condition. The larger the deformation, the more pronounced the center-concave condition becomes on the outside radius. For most parts this concaved area is of no consequence, but in an architectural application, it’s a big issue as it changes the look of the finished piece.

Because V Grooving Machine reduces the thickness of the material at the bend line, you will see less of this concaving that results in straightness errors; often the outside radius becomes so small, concaving just isn’t an issue.

In conventional air bending, you’ll achieve the best results when you get as close as you can to having a one-to-one relationship between the inside bend radius and the material thickness—a perfect bend. However, depending on the material type and temper, you might need what’s effectively a zero-radius bend. And you still need to leave a smooth outside surface on the finished piece.

Sometimes a part might call for a radius that’s producible with a traditional air form, and a skilled operator could certainly produce these kinds of bends. But there are so many thicknesses and tensile variations within the tolerance zone for a particular gauge of sheets. Achieving consistent parts over time isn’t easy, and material inconsistencies at the press brake can result in variations in the bend angle, inside radius, and dimension.

Hence the advantage of thinning the material at the bend line with V-grooving and the subsequent reduction in the bend radius. Thinning the material at the bend line does weaken the bend, but if the resulting (lower) bend strength meets the job requirements, then it should be a viable technique for producing crisp, clean, and consistent bend dimensions and angles. V-grooving also will improve notch accuracy and the look of the finished part.

Architectural Advantages

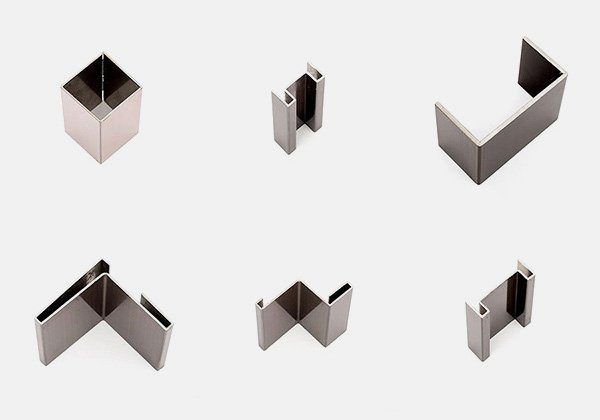

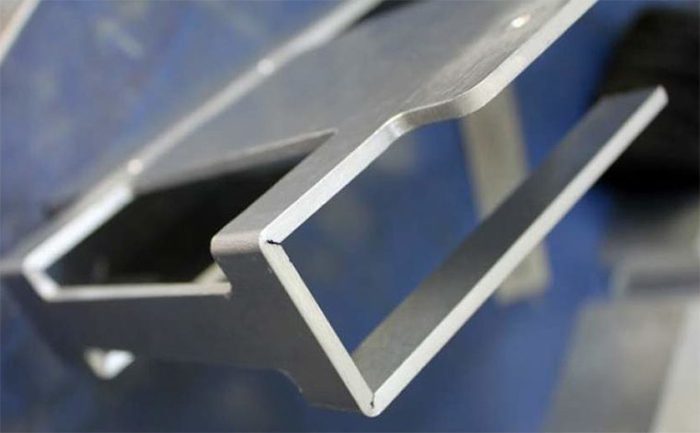

The method works well for architectural fabrications. It can make decorative surfaces easy to manufacture for projects such as bank lobbies, hotels, airports, restaurants, shopping malls, and even kitchen equipment where finish and overall look are the primary goals. Manufacturers of sheet metal parts for decorative architectural panels, wall systems, and other aesthetic components often use V-grooving to produce sharp corners in panels that, once interlocked and mounted, give the appearance of being a seamless unit.

The process produces a very small bend radius that meets demands for specific jobs. The small bend radius also will lack excessive die marks that you would have from a traditional coining or bottoming operation.

In large or thick panels, V Grooving Machine tends to reduce oil canning (waviness) in the metal surface, unlike traditional forming methods that introduce or amplify the oil canning and similar conditions like wrinkling and buckling.

Ordinarily, if you go too small with the inside radius for a forming operation, you’ll end up with cracking on the outside surface of the bend. But V-grooving allows the manufacturer of an architectural workpiece to meet critical requirements of a small inside radius while producing parts without the bend marks of traditional forming. Dimensional accuracy is spot-on, the look of the finished piece is topnotch, and bend angle accuracy is excellent.

Bending with V-grooving also reduces the straightness deviations of the radius edge on long and narrow pieces. The best part is, even complicated shapes can be produced at the press brake using standard acute tools.

In a standard air form, the bending process produces a concaving effect on the outside radius. A nonissue for most parts, this can be a problem for certain architectural applications.

Bending & V-Grooving

V-grooving is extremely useful in precision works and bending of corners to maintain the edges. Bending of metals and alloys utilizing V-grooving machines allow for it to be folded to a tight radius or sharp corners. Depending on the thickness of the material and the type of fold required, the V-groove machine cutting head will run a programmed number of times along the sheet material.

At KRRASS we employ precision Bending and V-grooving machines which aid in the improvement of precision; providing sharp bends, radii and corners, while additionally reducing material, transportation and installation costs.

Process Description:

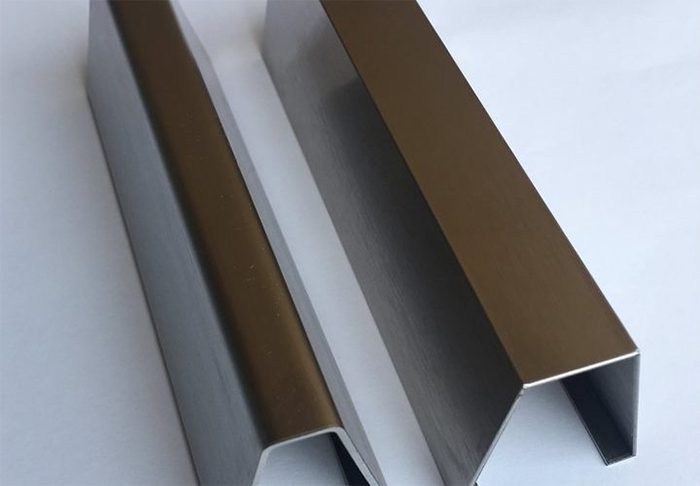

Bending metal using a V-Grooving machine allows it to be folded to a tight radius, or sharp corner. This enables folded metal to mimic solid bar material at around a tenth of the cost and also avoids wastage. V-Grooved profiles look just like solid bar material but are light in weight and easier to transport and install.

Depending on the thickness of the material and the type of fold required, the V-Groove machine cutting head will run a programmed number of times along the sheet material.

Depending on the thickness of the material and the type of fold required, the V-Groove machine cutting head will run a programmed number of times along the sheet material.

V-Grooving allows for sharp bends to be created from sheet material creating profiles that give the appearance of a solid material.

Solid, or bar, metal is both more expensive to purchase and creates wastage once shaped. Bending sheet material is a more cost-effective alternative.

Benefits of V-Grooving – a summary:

Speed – a V-Groover can machine more grooves in one hour than a traditional milling machine or router can perform in eight hours. This means it is cheaper in the cost of labour and large volumes can be handled in relatively quick timescales.

Accuracy – the V-Groover is set to a highly accurate measurement – so much so that a grooved sheet could be put through a second time with no deviation or alteration to the first groove. This means very precise and small profiles can be fabricated.

Bending Detail – channeling out solid bar material creates waste from an expensive commodity. V-Grooving and folding creates minimum waste and is on average a tenth of the cost of working with solid bar metals.

Precision folding – V-Grooving allows for folding to a tight radius, creating sharp bends.

Groove shape options – V-Grooving can be created not just in one shape of V. Wider V, semi-circular and square grooving is also possible allowing for a range of design variations.

Aesthetic – V-Grooved and folded profiles in appearance look as if they are cold-drawn or extruded metal.

Learn more about our products, please visit and subscribe to our Youtube channel