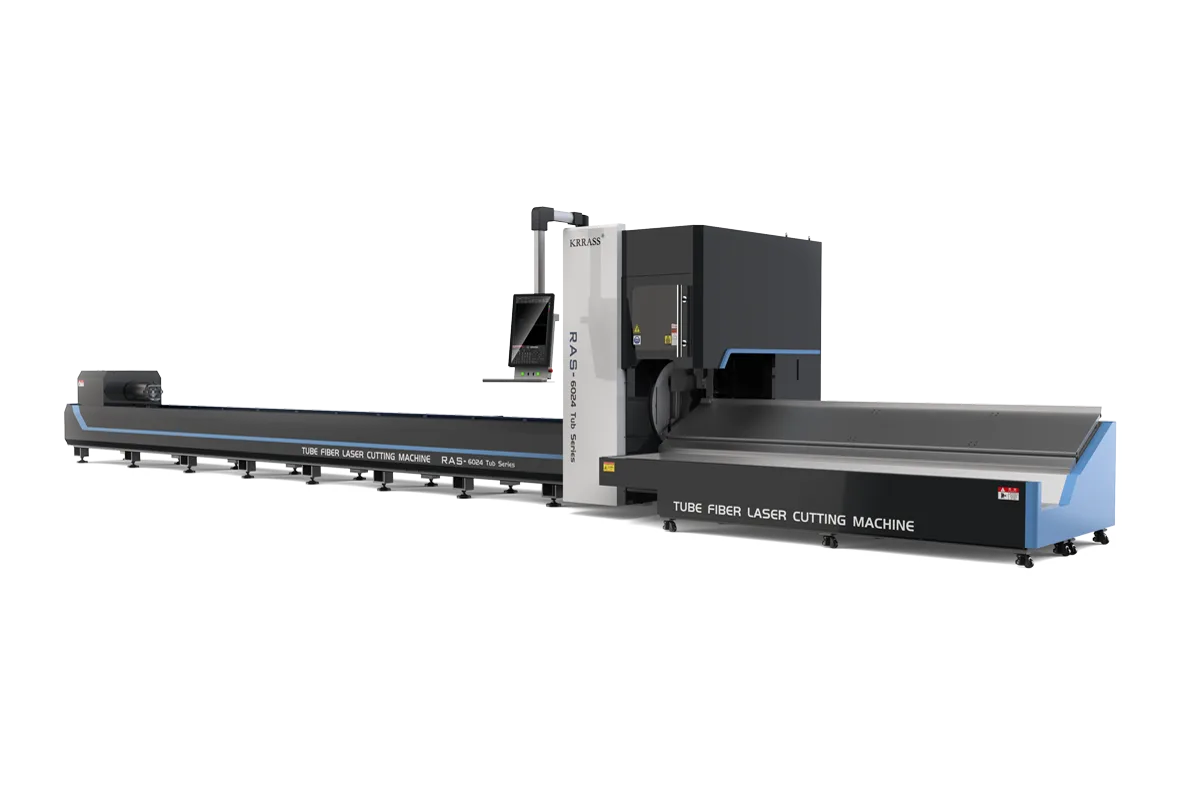

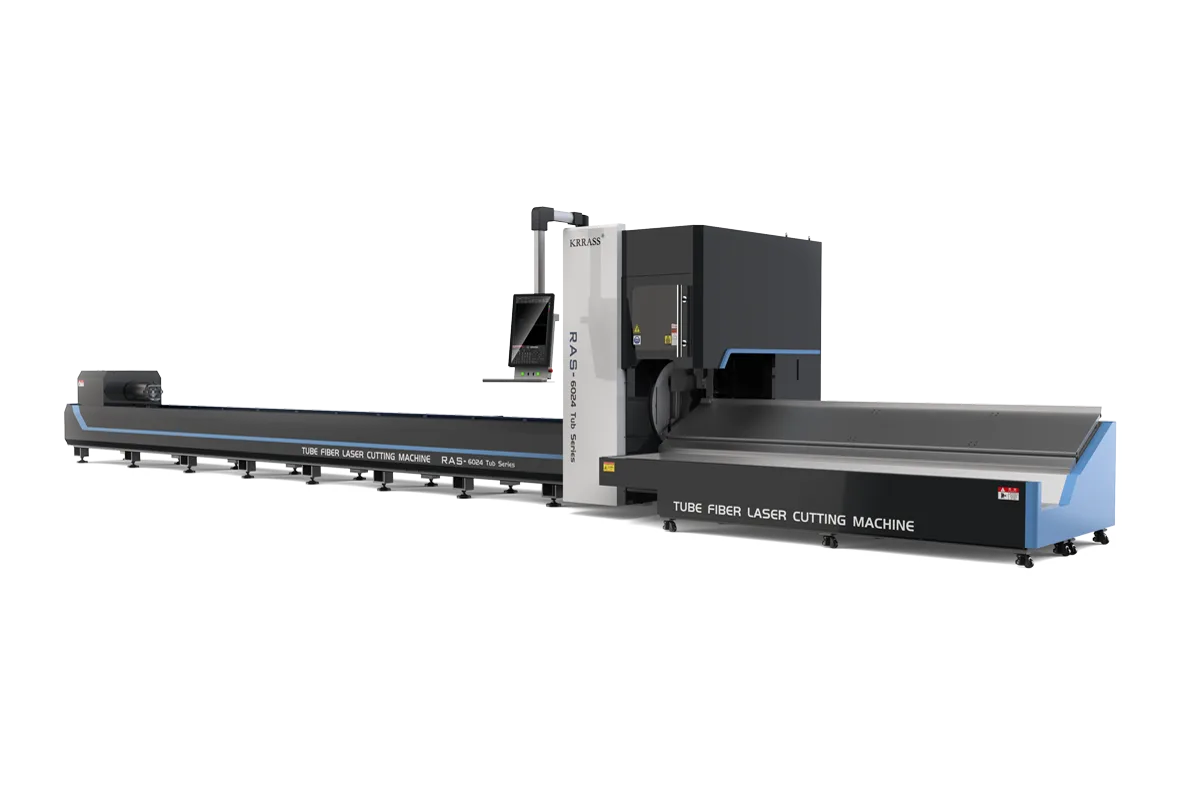

Tube Fiber Laser Cutting Machine

Tube Fiber Laser Cutting Machine

Tube Fiber Laser Cutting Machine RAS-6000 is a new equipment for laser cutting tubes. This Tube Fiber Laser Cutting Machine, specially developed by us after re-imagining the traditional tube cutting process, can provide a complete solution for complex industrial needs, designed to give high cutting accuracy, productivity, and product quality. The device uses a mechanical structure specially designed by the KRRASS research team, combined with its proprietary laser technology. KRRASS hopes to achieve excellent results in the tube processing industry with this dedicated Tube Fiber Laser Cutting Machine.

High Precision Welding Bed

Integrated bed with sheet production line, self-sufficiency, shorter delivery, various working size optional

Auto Oil-filling

Intelligent system for auto oil filling, oil cut-off avoided

Cost-Effective

Low waste of raw materials, low investment with a short payoff period

Introduction to Configuration

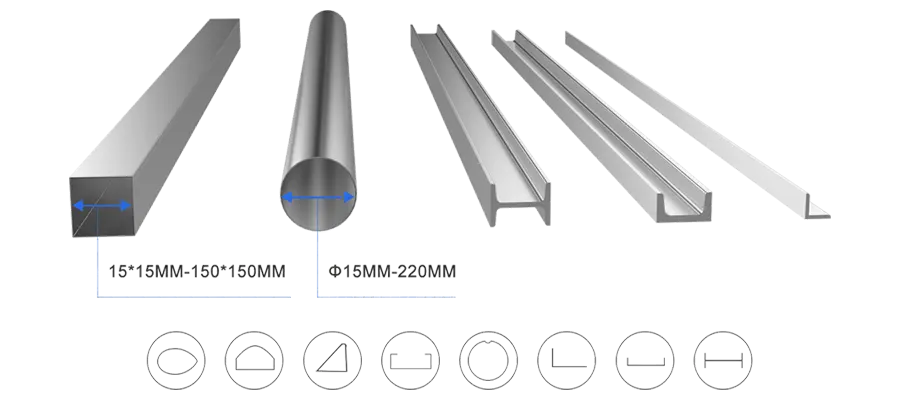

The Pipe Clamping Range is Wide

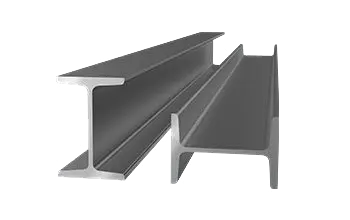

The pipe clamping range of the Laser Tube Cutting Machine is vast, the Round tube is φ10-φ10, and the square tube side length is 10 * 10mm-220mm * 220mm. Support the cutting of various shapes of pipe materials, such as I-beam, channel steel, angle steel, elliptical pipe, waste pipe, multi-deformed pipe, Etc.

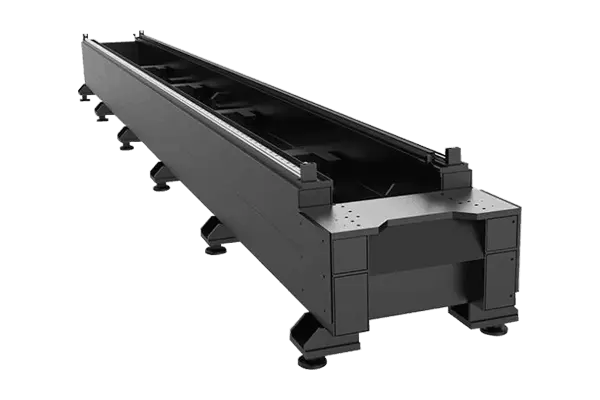

Integrated Machine Bed

The unique industrial structure design gives sheet metal laser cutting machines maximum stability, higher vibration resistance, and damping quality. The compact spacing of 650mm ensures the agility of the chuck and stability during high-speed driving.

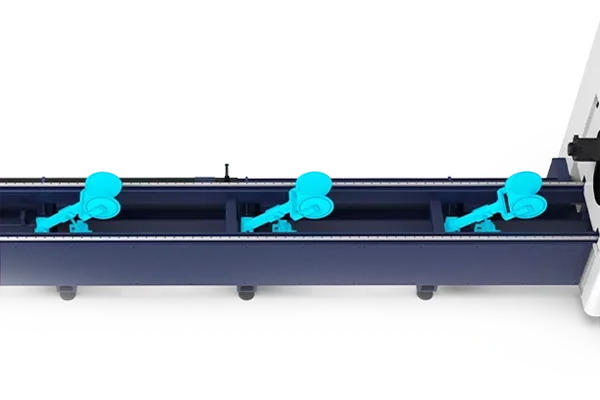

Pneumatic roller support

When the Tube Plate Fiber Laser Cutting Machine works, it can fix the pipe and effectively solves the deformation problem in the cutting operation of the long line.

Tubepro tube cutting and Plate Cutter software

RAS-B Tube Plate Fiber Laser Cutting Machine equipped with FSCUT3000S pipe cutting system, and FSCUT2000 Plate Cutting System, which supports high-precision and high-efficiency cutting of square pipes, round pipes, racetrack-shaped and oval-shaped stretched lines, as well as angle steel and channel steel.

Wide Processing Range, Can Cut a Variety of Tubes

Tube Plate Fiber Laser Cutting Machine can process a wide range of tube sizes: round tube diameter ø15mm-ø220mm, square tube side length 15*15-150*150mm; With a 3D laser cutting head, it can easily cut H steel, I-beam, and angle steel, channel steel, and other profiles, as well as drop-shaped and concave shaped tubes.

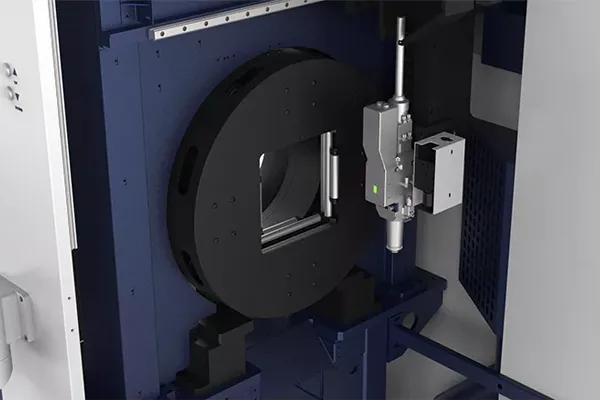

Double Pneumatic Chucks, Ultra-short Tailing

The front and rear of Pipe Fiber Laser Cutting Machine chucks are featured by automatic centering and dual-driven rotation, keeping them synchronous. The front chuck is full-stroke, and cutting tailing is further shortened to 50mm by front chuck avoidance cutting.

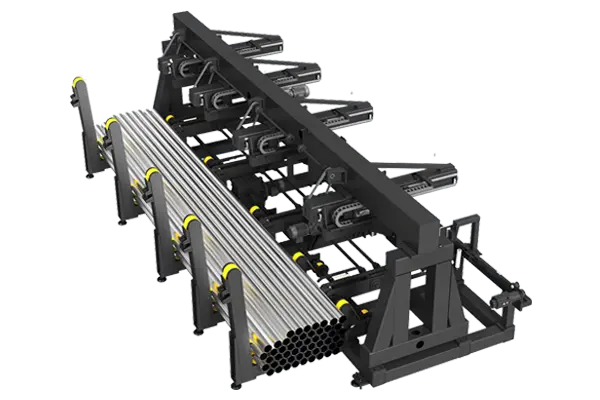

Automatic Loading Equipment (Optional)

- Tubes are usually loaded to material laying area by transmission mechanism of which limiting device can make tubes in order.

- Tubes are clamped by 6 loading rollers that need no reset in a loading cycle, resulting in less waiting time and high cutting efficiency.

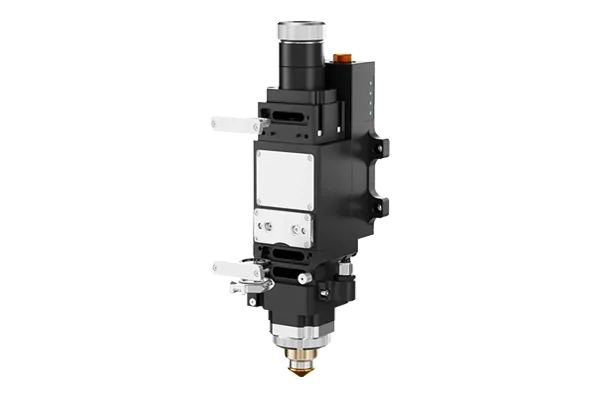

BOCHU Smart Cutting Heads

BOCHU smart cutting heads are quite cost-effective smart cutting heads designed for the laser cutting. Being impact and lightweight, it still integrates multiple sets of intelligent sensors, which ensure real-time closed-loop monitoring to give rapid diagnosis and instant warning.

What is this Machine Used for?

RAS-6000 sheet metal laser cutting machine can cut carbon steel, stainless steel, aluminum alloy, galvanized sheet, titanium alloy, manganese alloy, Etc. The device is widely used in metal tube processing, auto parts manufacturing, electrical manufacturing, elevator manufacturing, petroleum machinery, food machinery, and decorative advertisements.

Parameter of laser cutter machine for Steel

| Model | RAS-6000 |

|---|---|

| Pipe processing range(mm) | 6000* φ20~220 |

| (Square tube: 20*20~150*150) | |

| Laser Power(kw) | 1.5/2/3/4/6 |

| Maximum Speed(m/min) | 100 |

| Positioning Accuracy(mm) | ±0.05 |

| Repeated Positioning Accuracy(mm) | ±0.02 |

| Maximum Rotational Speed(r/min) | 100 |

| Maximum acceleration(G) | 0.8 |

| Table Maximum Load(KG) | 150 |

What is the Maximum Cutting Thickness?

| Material | 1KW | 1.5KW | 2KW | 3KW | 4KW | 6KW | 8kw | 12000W |

|---|---|---|---|---|---|---|---|---|

| Carbon Steel(mm) | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-20 | 0.4-25 | 0.4-25 | 0.4-25 | 0.4-45 |

| Stainless Steel(mm) | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 | 0.4-12 | 0.4-20 | 0.4-28 | 0.4-40 |

| Aluminum (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-22 |

| Brass (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-6 | 0.4-8 | 0.4-14 | 0.4-16 | 0.4-20 |

Reviewed by 3 users

12000w fiber laser cutting machine cut very nice!

Hemos tenido muy buena experiencia con la máquina de corte por láser de fibra de tubo RAS-6000-2000W hasta ahora.

He comprobado las piezas, la marca real Design.

The machine is very good! And the after-sell service is nice too!!