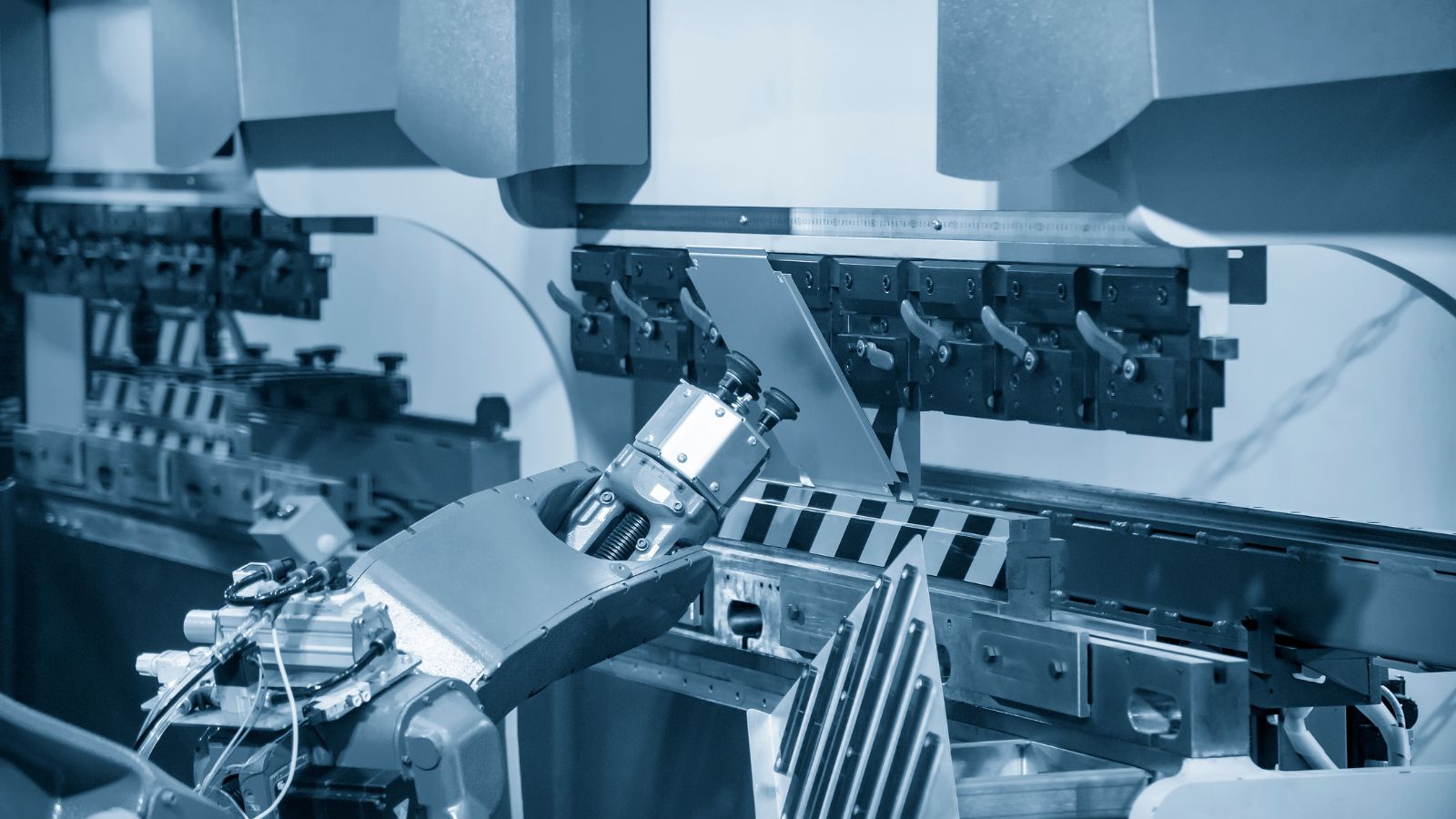

Hydraulic Press Brake Introduction

A hydraulic press brake is a machine tool that uses the force generated by a hydraulic cylinder to bend metal sheets. It has a simple structure, convenient operation, and high efficiency, and is widely used in the sheet metal processing industry.

The working principle of a hydraulic press brake is to use the thrust generated by the hydraulic cylinder to push the slide block down, thereby bending the metal sheet into shape. The thrust of the hydraulic cylinder is provided by the hydraulic system, which consists of a tank, pump, filter, directional control valve, relief valve, pressure gauge, and other components.

Common faults

The following common faults may occur during the use of a hydraulic press brake:

Hydraulic system faults

- Leakage: Leakage in the hydraulic cylinder, seals, and pipes of the hydraulic system will cause the hydraulic system pressure to drop and make it impossible to work normally.

- Symptoms: Low hydraulic system pressure, weak work, and slow movement.

- Causes: Damage to the cylinder seals, loose pipe connections, and low oil level in the tank.

- Troubleshooting methods: Check the cylinder seals and replace the damaged seals; tighten the pipe connections; add hydraulic oil.

- Pollution: The oil in the hydraulic system is polluted, which will cause wear and corrosion of the hydraulic components and reduce the work efficiency.

- Symptoms: The hydraulic system is unstable and noisy.

- Causes: Air, impurities, or water are mixed into the oil.

- Troubleshooting methods: Replace the hydraulic oil and clean the hydraulic system.

- Noise: Air or other impurities exist in the hydraulic system, which will cause the hydraulic system to generate noise.

- Symptoms: The hydraulic system is noisy when working.

- Causes: Air is mixed into the hydraulic system, and the oil filter is blocked.

- Troubleshooting methods: Exhaust air and replace the filter.

Electrical system faults

- Motor overheating: Motor overload or poor heat dissipation will cause the motor to overheat and even burn out.

- Symptoms: The motor temperature is too high, and it makes a buzzing sound.

- Causes: Motor overload, fan failure.

- Troubleshooting methods: Reduce motor load and check fan.

- Poor contact: Poor contact of the terminal lugs or contacts in the electrical wiring can lead to circuit faults.

- Symptoms: The motor cannot start, and the indicator light is not lit.

- Causes: Loose terminal lugs, oxidized contacts.

- Troubleshooting methods: Tighten terminal lugs, clean contacts.

- Component damage: Damage to components in the electrical system can lead to control system failure.

- Symptoms: The control system malfunctions and cannot work normally.

- Causes: Damage to contactors, relays, fuses, and other components.

- Troubleshooting methods: Replace damaged components.

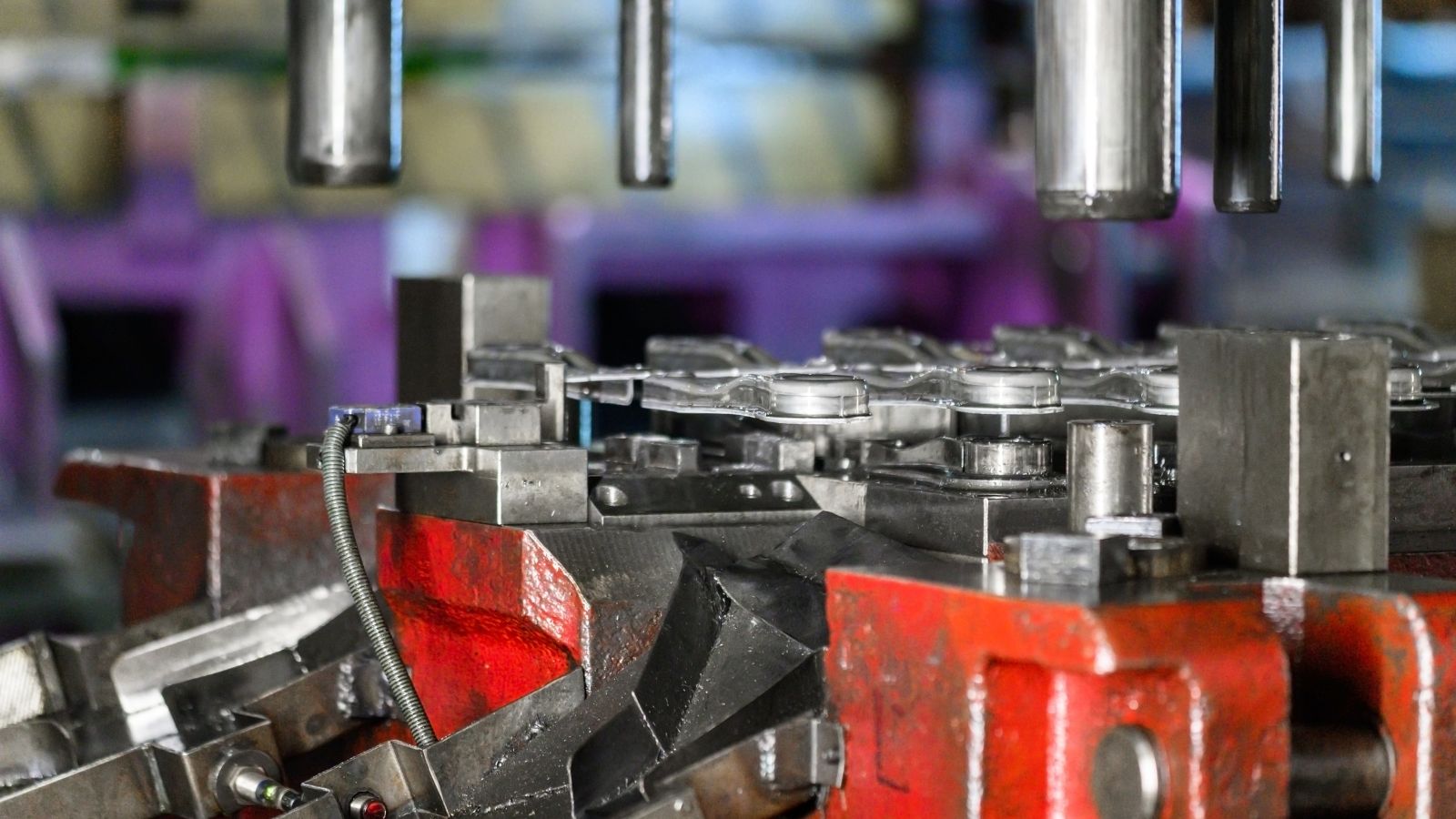

Mechanical faults

- Tool wear: Tool wear or breakage will lead to a decrease in bending quality.

- Symptoms: Scratches and burrs appear on the surface of the bent part.

- Causes: Tool wear and breakage.

- Troubleshooting methods: Inspect tools and replace damaged ones.

- Machine bed deformation: The machine bed can become deformed due to overload or impact, affecting accuracy.

- Symptoms: The dimensions of the bent part are inaccurate, and the bending angles are inconsistent.

- Causes: The machine bed is overloaded or impacted, causing deformation of the machine bed components.

- Troubleshooting methods: Repair machine bed deformation and replace damaged parts.

- Insufficient lubrication: Insufficient lubrication of the machine parts will increase friction and reduce work efficiency.

- Symptoms: The machine is slow and noisy.

- Causes: Insufficient or poor-quality lubricant.

- Troubleshooting methods: Add lubricant and replace lubricant.

Hydraulic System Maintenanc

The hydraulic system is a crucial part of a hydraulic press brake, and its maintenance directly affects the machine's performance and lifespan. To extend the lifespan of the hydraulic system, it's recommended to take the following maintenance measures:

- Regularly replace the hydraulic oil: The hydraulic oil gradually deteriorates over time, losing its lubricating and cooling properties. Replace the hydraulic oil according to usage frequency and ambient temperature, typically every 12 months or 2500 working hours.

- Clean the hydraulic oil tank: Dirt and impurities accumulate at the bottom of the hydraulic oil tank. Regularly clean the tank (e.g., every 6 months) to prevent impurities from entering the hydraulic system, extending the lifespan of the components.

- Inspect the hydraulic filters: The function of the hydraulic filters is to filter impurities from the hydraulic oil, protecting the hydraulic components from wear. Regularly inspect and replace the hydraulic filters (e.g., every 3 months) based on usage conditions.

- Check the hydraulic lines: Regularly check the hydraulic lines for looseness, leaks, or damage. Replace damaged lines promptly and tighten loose connections.

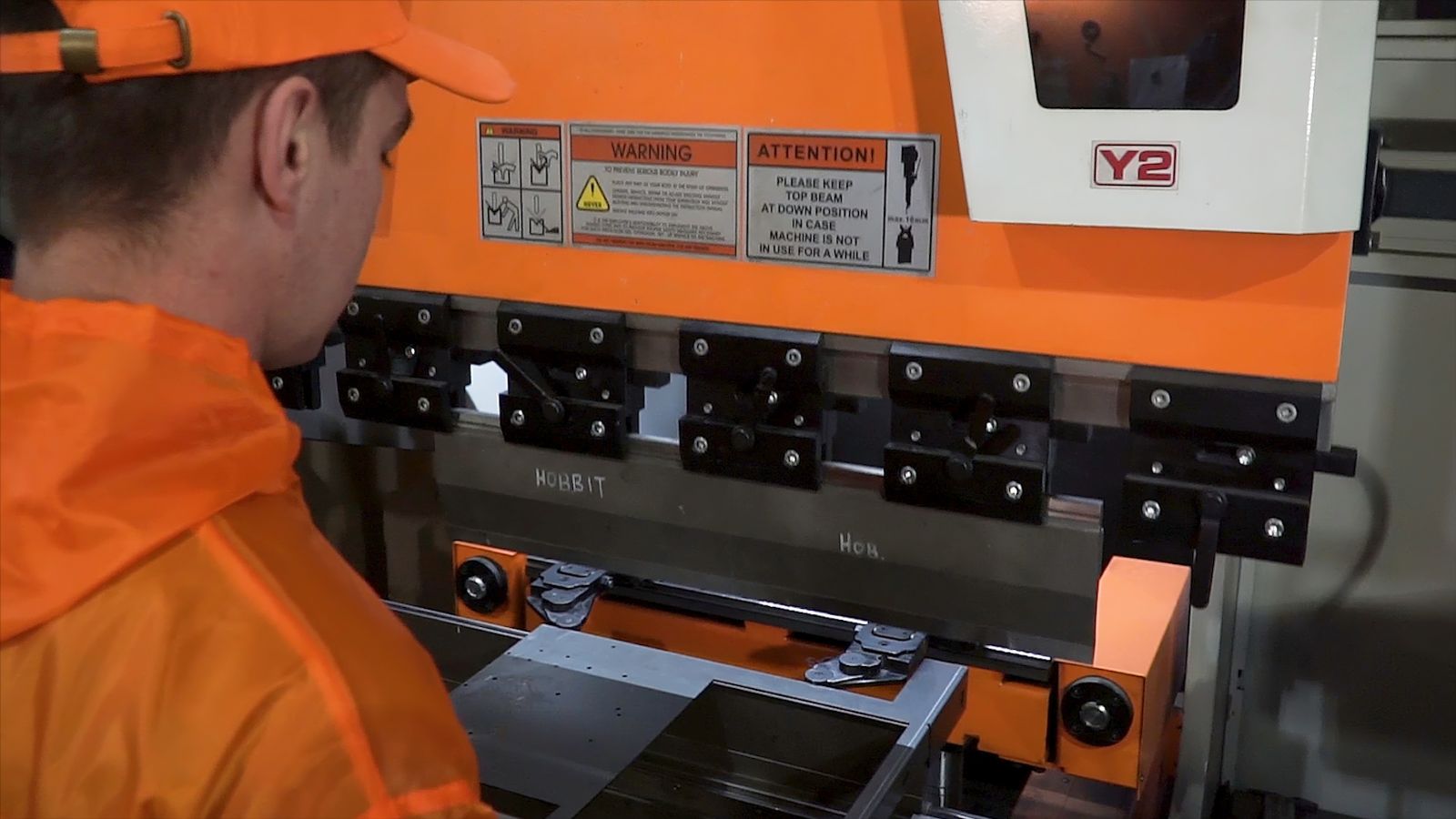

Safety Precautions

A hydraulic press brake is a high-pressure device. Therefore, adhere to the following safety precautions while operating it:

- Operators must undergo proper training and be familiar with the operating procedures and safety precautions for the hydraulic press brake.

- Before starting work, carefully inspect the hydraulic system for leaks to ensure the machine is in good condition.

- Strictly prohibit placing hands or other objects in the working area during operation to avoid being pinched.

- After work is completed, turn off the power and perform cleaning and maintenance following the prescribed procedures.

Conclusion

A hydraulic press brake is an essential piece of equipment in sheet metal processing. Understanding its common faults, troubleshooting methods, and maintenance practices empowers users to better maintain and operate the machine, improving production efficiency and product quality. Additionally, adhering to safety precautions helps prevent accidents.