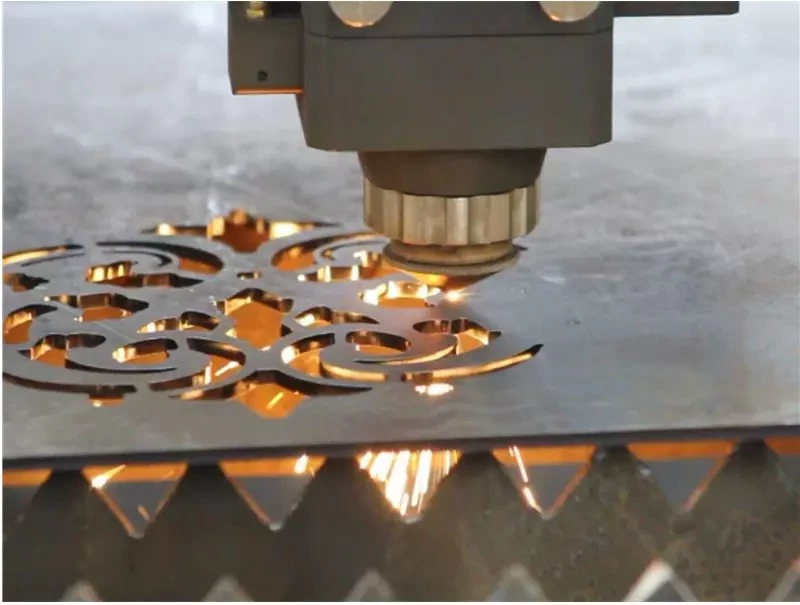

Fiber laser cutting machines are powerful CNC devices designed to precisely cut sheets of metals and other materials. It is a commonly used technology for many industries, including aircraft manufacturing, electronics, tool and die making, automotive parts manufacture, furniture production, and more. The maintenance of a fiber laser cutting machine must be done regularly to ensure excellent performance and efficiency in its operations. This article will explain the key considerations for successful maintenance operations of a fiber laser cutting machine.

Understanding the Nature Of Laser Cutting

Before diving into the details of fibre laser cutting machine maintenance, it's important to understand how laser cutting works. Lasers use optically stimulated effects to cut metal and other substance. The effects can create clean cuts and precise shapes which can be achieved with a high degree of accuracy.

The most efficient method of laser cutting operations is by using a fiber laser cutting machine. They are capable of cutting metal up to twice as fast as CO2 lasers that are common in metal fabrication shops. Furthermore, their compact size and fewer moving parts help lower their cost drastically.

Maintenance Tasks

Using a fiber laser cutting machine requires regular maintenance tasks. To ensure the longevity and accuracy of your machine, there are certain tasks that must be performed on a regular basis:

Cleaning

To keep the lens and optics of the machine clean for maximum efficiency, it is essential to use an approved cleaning agent on the components. This helps to maintain the optics to its factory-fresh condition and extends its life span.

Alignment

By regularly checking and adjusting the alignment of the optical components, you can ensure that the optimum level of accuracy is maintained throughout the machine's usage. Poor alignment may lead to incorrect cutting results and should be checked every few months or depending on the usage of the machine.

Calibration

Calibrating the machine ensures that the cutting results are consistent. Calibration adjustments should be made after any cleaning of physical parts or any replacements of parts within the machine.

Lubrication

Any movable parts of the machine should have adequate amounts of lubricant applied to them. This helps reduce friction and improves the performance of the machine over a longer period of time.

Electrical Checks

The electrical components should also be regularly checked for damage or signs of wear. Any worn out wires or loose connections should be replaced in order to sustain the machine's optimal operation.

Coolant Check

The coolant level in the water tank should also be checked regularly as this helps to avoid any potential problems that can occur.

Suppression Systems

Regular inspection and maintenance of suppression systems such as filters, sprays or dust collectors should be done to make sure they are working properly and efficiently.

Conclusion

Fiber laser cutting machines are powerful tools that require regular maintenance to ensure proper functioning and long life. Cleaning, alignment, calibration, lubrication, electrical checks, coolant check and suppression system maintenance are all necessary upkeep tasks that should be completed regularly in order to get the most out of your fiber laser cutter. Following these practices will help ensure your machine is running at its best and provide you with reliable results.

KRRASS: the best choice for

all sheet metal processing manufacturers

When considering the overall costs of purchasing, maintaining, and operating a sheet metal equipment setup, a sheet metal fabrication service: KRRASS brand is your best choice. KRRASS has a tremendous reputation in the market due to its focus on consistency and quality at the most competitive price. Whether it's Fiber laser cutting machine or any other application equipment, our team of experts has the right combination of industry knowledge and the latest tool to provide you with the best products and services on the market. Moreover, we set ourselves apart with our advanced system that is completely online. Just let us know what your product needs, request a quote, and start the process.

Make a request and Get Started Today

Get Instant Quote

Learn more about our products, please visit and subscribe to our Youtube channel