If you want to learn to drive, you can go to a nearby parking lot and practice pulling into parking spaces, turning, reversing, different speeds, and emergency braking. If you want to learn to drive a race car, you're going to need more practice, the right equipment, the right track, and a team behind you. The same idea applies to operating a plate bending machine. Anyone can load material into the machine and press a button on the CNC controller to start it. However, that doesn't mean things are going smoothly. Even in the age of advanced CNC, plate rolling remains an art form. Plate rolling is not a simple mechanical operation, but a craft that combines rich experience and deep understanding. From material selection and pretreatment, to adjustment and control during the rolling process, to final quality inspection and optimization, every step requires careful design and strict execution. Through the explanation of this guide, readers will understand the subtleties behind plate rolling and how to use scientific principles and technical means to achieve efficient and precise production.

Table of contents

I. Basic knowledge of plate rolling

II. Tips for plate rolling precision and accuracy

III. Technology and innovation in plate rolling

IV. Quality control and inspection during plate rolling

V.Training and skills development in plate rolling

VI. Choose a good plate rolling machine provider

I. Basic knowledge of plate rolling

Plate rolling is a precise and complex process that requires operators to master the material's properties to achieve the desired forming effect. In the process of plate rolling, it is necessary to fully understand the physical and mechanical properties of the material.

Force balance in plate rolling

During the plate rolling process, various forces interact to form a delicate balance. The operator needs to accurately grasp the adjustment parameters of the rolling machine to ensure that the material is subject to appropriate pressure and deformation to achieve the desired forming effect. For example, in the plate rolling workshop of a steel plant, operators must adjust the roller pressure and transmission speed of the rolling machine according to steel plates of different thicknesses and hardness to ensure that each plate can meet customer requirements.

Understanding of material behavior

Different types of metallic materials exhibit different behavioral characteristics during rolling. Understand the plastic deformation rules, strain hardening characteristics and grain structure of the material on the rolling process, so as to adjust the rolling parameters and achieve the ideal forming effect. For example, in a shipbuilding plant, when rolling hull plates, operators need to consider the characteristics of different types of aluminum alloy materials and their corrosiveness in seawater environments, so as to adjust the rolling parameters to ensure that the hull plates have Sufficient strength and corrosion resistance.

Pre-bending, rolling and back-bending stages

Plate rolling consists of three main stages: pre-bending, rolling and back-bending. In the pre-bending stage, appropriate force is applied to the edge of the plate to produce a slight curvature in preparation for the subsequent rolling operation. The rolling stage is the heart of the entire process, with rolling machinery exerting pressure on the plate to gradually shape it into the desired shape. The back-bending stage is the final fine-tuning and trimming of the formed sheet to ensure it meets specifications. For example, at a building structure manufacturing company, when operators roll steel beams and beam-column plates, they need to back-bend the plates to ensure that they achieve the curvature and geometry required by the design.

II. Tips for plate rolling precision and accuracy

A blend of experience and skill is crucial in ensuring plate rolling with precision and accuracy. Professional operators employ a variety of strategies to ensure stable molding results, finely adjusting parameters to meet precise specifications.

Refinement of parameter adjustment

Achieving precision and accuracy relies on the operator's precise adjustment of rolling machinery parameters. By adjusting parameters such as roller pressure, transmission speed, and roller diameter, operators can precisely control the deformation and forming process of the sheet to ensure that the final product meets strict specifications.

III. Technology and innovation in plate rolling

Innovations in plate rolling technology have completely changed the landscape of the manufacturing industry. As we have discussed, the integration of technology increases efficiency and quality, paving the way for future growth in this field. From traditional three-high mills to modern four-high configurations, the evolution of plate rolling machines reflects the industry's relentless pursuit of innovation.

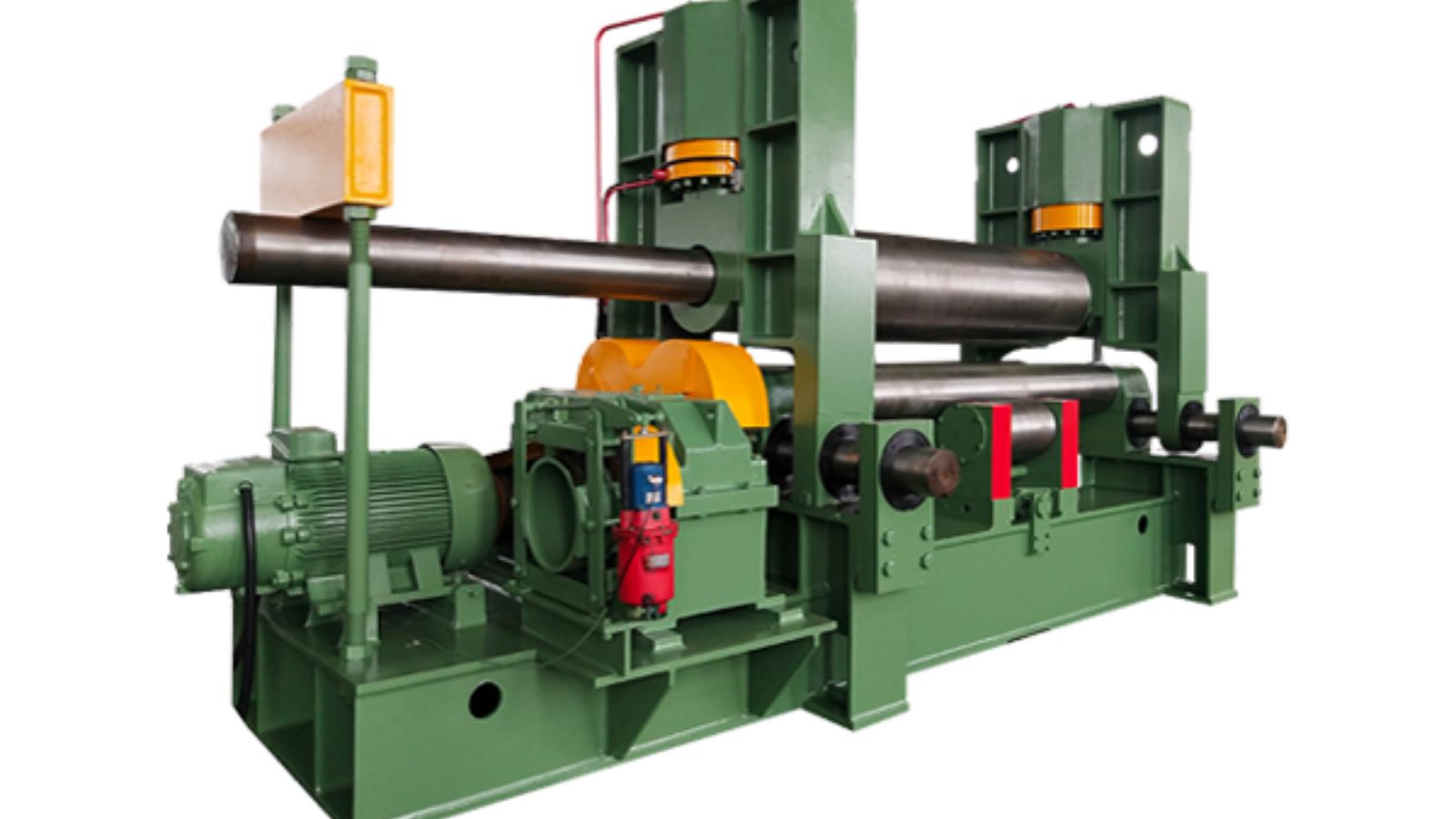

Advanced machinery and equipment

With the continuous advancement of science and technology, a series of advanced mechanical equipment have emerged in the field of plate rolling, such as CNC rolling mills, four-roller plate rolling machines, etc. These equipment adopt the latest control technology and precision transmission system, which can achieve precise control and monitoring of the plate rolling process, greatly improving production efficiency and product quality.

Application of automation technology

Automation technology is also increasingly used in the plate rolling process. By introducing automated control systems and intelligent sensing equipment, automated management and monitoring of the entire rolling process is achieved, reducing interference from human operations and improving production efficiency and yield. For example, in the plate rolling workshop of an automobile manufacturing plant, operators can monitor and control the operating status of the rolling machine in real time through the remote monitoring system, and adjust parameters in a timely manner to ensure the stability and reliability of the production process.

Innovative materials and processes

In addition to innovations in mechanical equipment and automation technology, a series of innovative materials and processes have emerged in the field of plate rolling. New plate materials and surface treatment technologies make plate rolling applications more extensive and product quality more stable and reliable. For example, the use of advanced surface coating technology and anti-corrosion treatment processes can greatly improve the corrosion resistance and weather resistance of plates and meet the high-quality needs of plate products in different industries.

IV. Quality control and inspection during plate rolling

Quality control is at the core of plate rolling, ensuring the integrity and reliability of rolled plate products. Skilled operators utilize specialized tools and techniques to maintain strict quality standards, conduct meticulous inspections, and promptly identify and correct any defects.

Operator skills and experience

During the quality control and inspection process, the operator's skill level and experience are crucial. They need to accurately grasp the adjustment parameters of the rolling machinery and skillfully use various testing tools and equipment to ensure that each rolled plate meets strict specifications.

Advanced testing equipment

With the advancement of science and technology, the plate rolling industry has introduced a series of advanced testing equipment, such as ultrasonic detectors, magnetic particle flaw detectors, etc. These equipment can comprehensively inspect the interior and surface of the board, detect hidden flaws and defects in a timely manner, and ensure the quality and reliability of the product.

Establishment of quality management system

In order to ensure the effective implementation of quality control and inspection work, plate rolling enterprises need to establish a complete quality management system. This includes developing detailed quality control processes and standard operating procedures, training operators in quality awareness and skills, establishing a sound quality record and traceability system, and conducting regular internal and external quality audits and certifications. By establishing a sound quality management system, companies can continuously improve product quality and enhance market competitiveness.

V.Training and skills development in plate rolling

The art and science of plate rolling requires dedicated training and skill development. Experienced mentors play a vital role in nurturing new talent and can impart valuable knowledge and techniques. And students are required to practice and continue learning.

Role of mentor

In the plate rolling industry, experienced instructors play an important role in teaching knowledge and solving doubts. They not only have deep professional knowledge and rich experience, but also have good guidance and communication skills, and can effectively teach technology and guide students to improve their skills in practice. For example, in the plate rolling workshop of a large steel company, teachers have gone through strict selection and training and become mentors and helpful friends to apprentices, passing on the essence and skills of the industry.

The importance of practice

In the learning process of plate rolling, practical operation is crucial. By personally operating rolling machinery and participating in the actual production process, students can better understand theoretical knowledge, master operating skills and the ability to deal with practical problems.

The importance of continuous learning

With the continuous development of technology and continuous changes in the industry, continuous learning has become an essential quality for plate rolling workers. Continuously update knowledge and learn the latest technologies and processes by participating in training courses, seminars and industry exchange activities to maintain industry sensitivity and competitiveness.

VI. Choose a good plate rolling machine provider

As the saying goes, a good horse deserves a good saddle, and a good machine can better serve the victory, so it is crucial to choose a good plate rolling machine provider. Here are specific suggestions:

- Technology and Equipment: Choose a supplier with advanced technology and equipment. They should have an experienced team of engineers and advanced manufacturing facilities that can provide efficient and reliable plate rolling solutions.

- Quality and Reliability: Focus on supplier quality control standards and product quality. They should have a strict quality management system to ensure that the boards they produce meet international standards and customer requirements.

- Customer Service: Pay attention to your suppliers’ customer service levels. Excellent suppliers should be able to respond to customer needs and questions in a timely manner and provide comprehensive pre-sales consultation and after-sales service support.

- Cost-Effectiveness: Consider price and performance and choose a provider that matches your budget and needs. Don't just look at the price and ignore the quality and service.

- References and evaluations: Check out a vendor's customer reviews and case studies to learn about their performance and reputation. Connect with their existing customers to learn about their satisfaction and experience with them.

As a company with leading technology and a belief in quality, we strongly recommend KRRASS, a company committed to providing excellent plate rolling mill solutions. KRRASS has a team of experienced and skilled engineers, as well as advanced production equipment and a strict quality management system to ensure that it provides customers with efficient and reliable products and services. KRRASS always pays attention to the needs of customers and provides comprehensive pre-sales consultation and after-sales service support to help customers achieve production goals. By cooperating with KRRASS, you can choose a high-quality plate rolling machine with confidence, bringing stable benefits and excellent quality to your production.