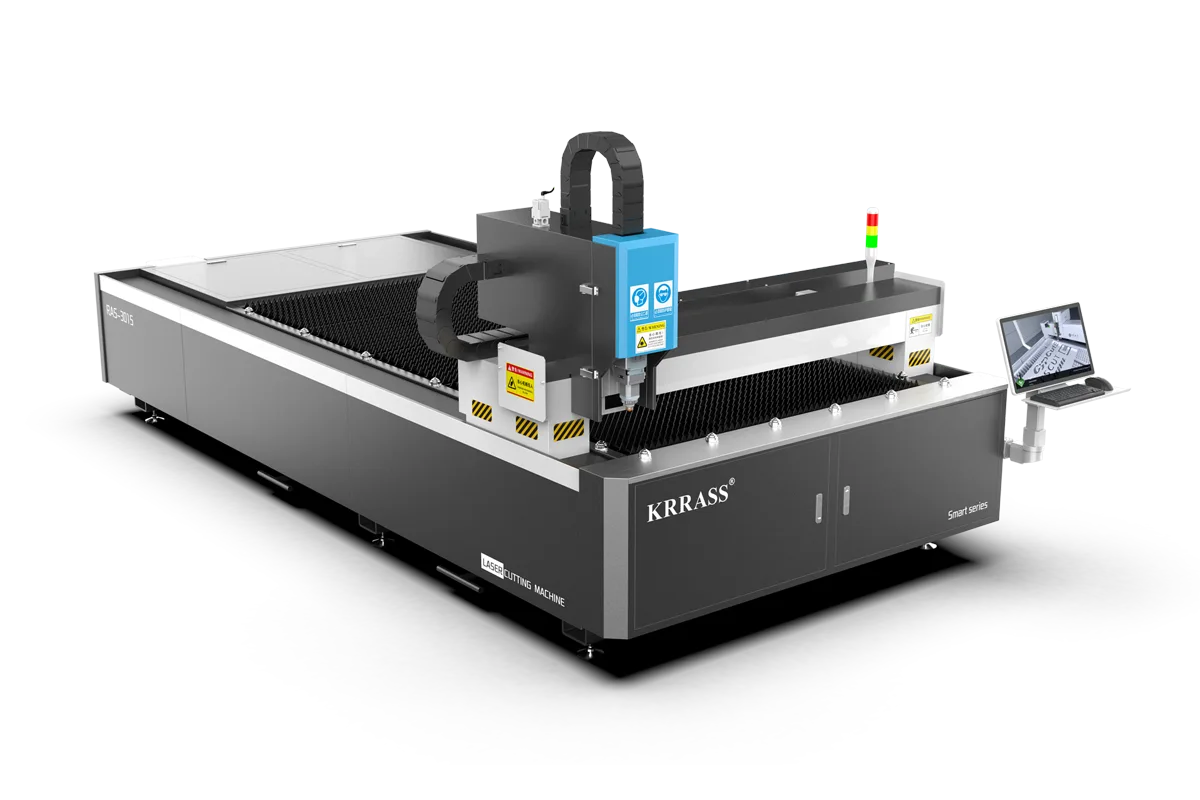

CNC Fiber Laser Cutting Machine

Fiber Laser Cutter Machine Smart Series

Smart Series top-rated Steel Laser Cutting Machine is for metal fabrication, including steel designed, aluminum, titanium, alloy, brass, copper, and iron, with different laser powers (1500W, 2000W, 3000W, 6000W, 12000W, 20KW, 30KW, 40KW). The affordable CNC Fiber Laser cutting Machine is for sale at a low price, with the best fiber laser-cutting system service and support.

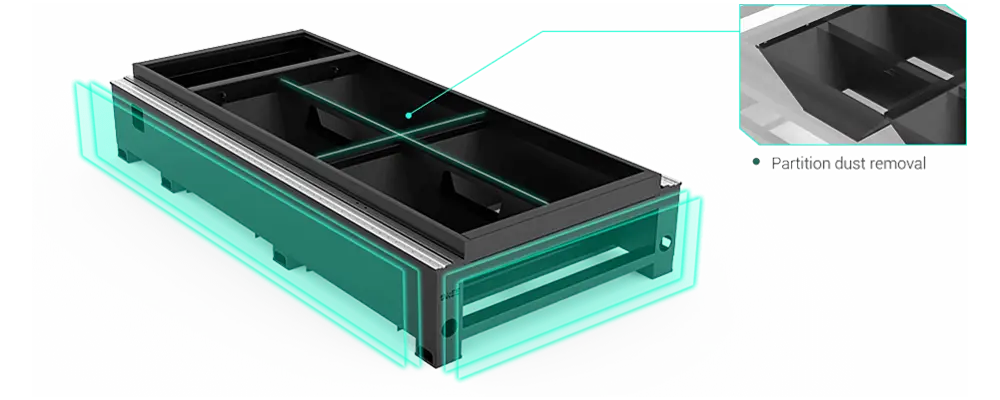

High Precision Welding Bed

Integrated bed with sheet production line, self-sufficiency, shorter delivery, various working size optional

Auto Oil-filling

Intelligent system for auto oil filling, oil cut-off avoided

Cost-Effective

Low waste of raw materials, low investment with a short payoff period

Introduction to Configuration

Super heavy Steel Welding Machine Bed

The laser cutter machine’s bed adopts 12mm super-thick monolithic steel plate laser blanking. The groove welding method makes the plates reach equal strength butt. Then it undergoes stress annealing and natural aging treatment to eliminate internal stress and maintain the bed’s extremely high stability and cutting accuracy.

The Fifth-generation Aviation Aluminum Alloy Beam

The T6 heat treatment process processes the laser cutter machine’s full beam to make the shaft obtain the highest strength. Solution treatment improves the strength and plasticity of the beam, optimizes and reduces its weight, and speeds up the movement.

Intelligent Control System

“CypCut plane cutting” software is a set of software specially developed for the deep customization of the laser cutter machine industry. Easy to use, rich in functions, and suitable for various processing occasions.

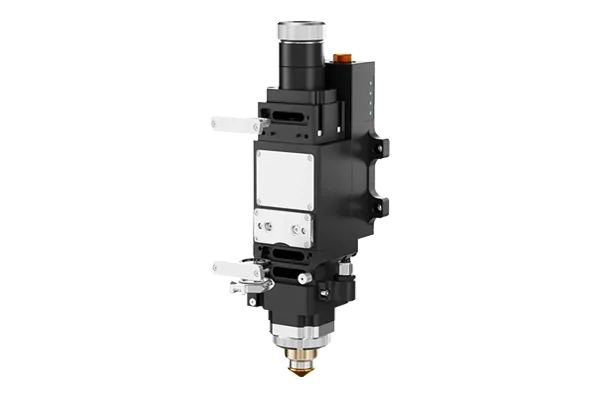

BOCHU Smart Cutting Heads

BOCHU smart cutting heads are quite cost-effective smart cutting heads designed for the laser cutting. Being impact and lightweight, it still integrates multiple sets of intelligent sensors, which ensure real-time closed-loop monitoring to give rapid diagnosis and instant warning.

What is this Machine Used for?

The Steel Laser Cutting Machine is to cut mild steel used, stainless steel, aluminum alloy, brass, and other steel; Application in the automobile industry, sheet metal industry, furniture industry, advertising industry, Etc.

Parameter of laser cutter machine for Steel

| Model | Smart Series 3015,4015,6015,4020,6020,6025 metal laser cutting machine |

|---|---|

| Working Area | 3050*1525/4050*1525/4050*2020/6050*1525/6050*2020 |

| Laser Power(kw) | 1500W,2000W,3000W,6000W,12000W,15000W,20000W |

| Maximum Speed(m/min) | 110 |

| Maximum acceleration(g) | 1.4 |

| X/Y Axis positioning accuracy(mm/m) | ±0.03 |

| X/Y Axis repeated positioning accuracy(mm) | ± 0.02 |

What is the Maximum Cutting Thickness?

| Material | 1KW | 1.5KW | 2KW | 3KW | 4KW | 6KW | 8kw | 12000W |

|---|---|---|---|---|---|---|---|---|

| Carbon Steel(mm) | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-20 | 0.4-25 | 0.4-25 | 0.4-25 | 0.4-45 |

| Stainless Steel(mm) | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 | 0.4-12 | 0.4-20 | 0.4-28 | 0.4-40 |

| Aluminum (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-22 |

| Brass (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-6 | 0.4-8 | 0.4-14 | 0.4-16 | 0.4-20 |

Reviewed by 25 users

my RAS3015-3KW is good. Actually, I just need 2m*1.5m cutting bed, but bigger is better

my 3KW 3015 model is realy good. The support is good

Super yenilməz və lazer kəsici maşın istifadə etmək asan, çox, çox tövsiyə olunur istifadə etmək üçün

A máquina de corte a laser KRRASS é realmente fácil de utilizar.

my 2KW laser machine is really good. Thanks to KRRASS. Merry Christmas and Happy New year