Why choose Stainless Steel Fiber Laser Cutting Machine RAS series

Simple and efficient

1. Stainless Steel Fiber Laser Cutting Machine RAS series is a perfect standard plane fiber laser cutting machine, which is popular in the industry. It has the highest speedamong those with the same level and may cut 400 small circles per minute. With the maximum speed of 140m and maximum acceleration of 1.5G, it has the highest accuracy among those with the same level and may cut the bicycle with the size of 1/5 of coin.

Pioneered

2. Simple and integrated integration design all over the world. 2.The cast-aluminum beam is die-cast and molded with 10t of steel mould for the first time in the industry, with good rigidity and high strength, whose weight is 1/2 of that of the traditional welded iron beam.

Fiber Laser Cutting Machine Equipment Configuration List:

[wptm id=21]

Notes:

1. The above-mentioned devices is our standard , if have some other requiremenmt or options , please let us know.

2.Two years warranty for whole machine except fiber cable, lens, mirror and other consumable parts. Force majeure clause like natural disaster, war, human factor are also excluded.

Fiber Laser Cutting Machine Technical Parameters And Specification

[wptm id=22]

6000W Fiber Laser Cutting Machine Capacity

[wptm id=23]

Spare Parts And Special Tools

[wptm id=24]

List Of Accompanying Documents

[wptm id=25]

CypCut sheet cutting software

CypCut sheet cutting software is an in-depth design for fiber laser cutting industry. It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks.

Auto Optimize Imported Drawing

CypCut will automatically optimize the errors when import drawing, delete duplicates and invisible graphic, smooth curve and join line segments etc.

Graphical Cutting Technique Setting

Graphical design of technique setting, quick and easy to finish setting of lead line, micro-joint and kerf width compensation etc. of single or large quantity parts.

Flexible Production Mode

CypCut provides floating and workpiece coordinates for small and large quantity production.

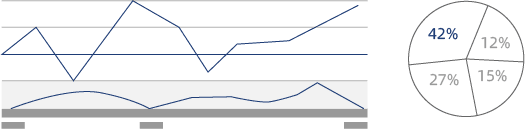

Statistic of Production

Stainless Steel Fiber Laser Cutting Machine have thorough and timely statistic of machine production to help you manage the task schedule.

Precise Edge Finding

Support capacitance and photo-electric sensing to find workpiece edge and offset sheet placement angle.

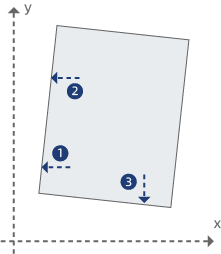

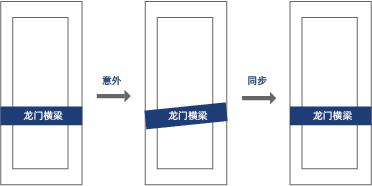

Dual-Drive Error Offset

Auto correct the dual-drive position error each time after machine axes return origin.

Learn more about our products, please visit and subscribe to our Youtube channel