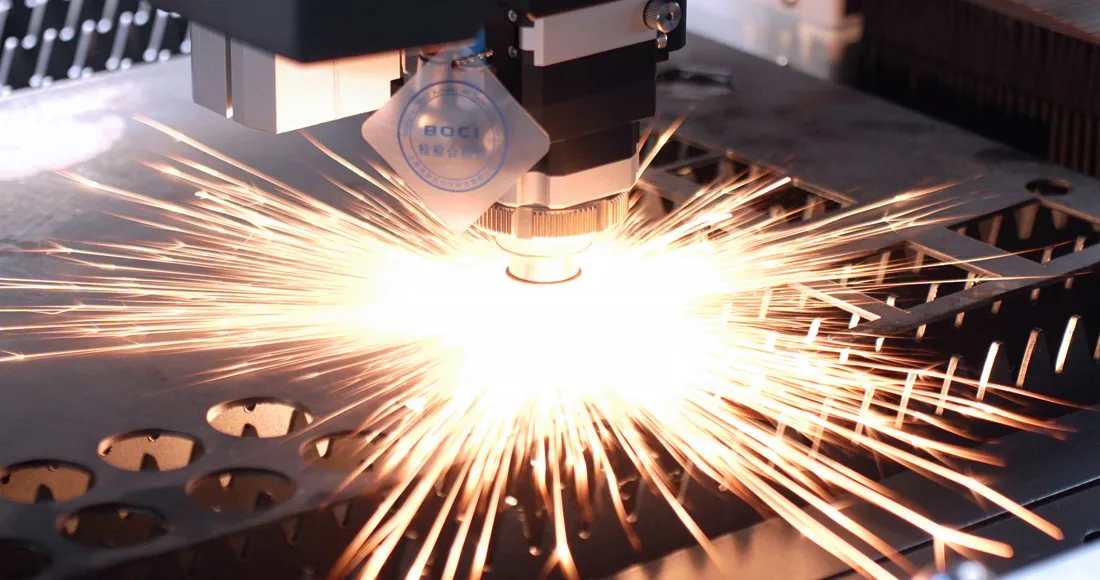

Discover the innovative features of our sheet metal laser cutter. Cut stainless steel, mild steel, aluminum, copper, and brass with unmatched precision. Learn how our advanced laser systems ensure high-quality and efficient metal cutting.

Sheet Metal Laser Cutter

The KRRASS's laser systems come with some really cool metal cutting tech. You can cut all kinds of sheet metal like stainless steel, mild steel, aluminum, copper, and brass super accurately.

We've got this nifty Automatic Focusing Height Follower that we developed. It's a key part for getting the best metal cuts. There's a cutting nozzle controlled by a capacitance sensor and z-axis motor. It adjusts the gap between the metal and the nozzle until the beam is focused just right. And during cutting, it tracks the metal surface and keeps the nozzle in the perfect position.

Inside the lens assembly, there's a protective cover lens. These are cheap and sacrificial optics that keep the focusing lenses safe from reflected laser energy, dust, and debris.

The metal cutting table is made of tough steel grid work. It reduces the contact with the bottom of the sheet metal. We save a CAD cut file for the slats on the computer, so if you need to replace a slat, it's easy to do.

Both fiber and CO2 lasers are great for cutting metal. If you want to know more about how they're different, check out this blog post: Fiber Laser vs CO2 Laser: Which is Right for You.

LASER SOFTWARE

Our CypCutE 2D Cutting Software has some advanced metal cutting features that give you total control. You can set a laser pierce delay to make sure the laser pierces the metal before it starts cutting. The nozzle air pressure can be set differently for the laser dwell, normal cutting, and moving between parts. You can also adjust the laser's modulation frequency from 500 to 50,000 Hz to get a cut without dross, so you don't need to deburr later.

METAL CUTTING TECHNOLOGY

Our metal cutting technology is super popular. It lets you cut sheet metal with precision.

ADVANCED FEATURES

A good metal cutting machine isn't just about a powerful laser resonator. The mechanics and software are designed for metal cutting. Here's what makes us stand out:

Programmable Air

You can connect three gas types to the laser system at the same time with our programmable air assist. You set the gas type for each job in the CypCutE software. No more messing around with gas tanks and lines all the time.

Pierce Control

Before you start cutting metal, the laser has to pierce the sheet. CypCutE has lots of pierce parameters. You can set the power, dwell time, gas type, gas pressure, and focus gap. This gives you small and efficient pierces and makes your optics last longer.

Fine Adjustments

Cutting metal can be tricky, especially with really thin or thick sheets. The CypCutE 2D Cutting Software can adjust the power and speed for lead-ins and corners. So, you get the same great cut quality even with big, detailed files.

MILD STEEL / COLD ROLLED STEEL

High-powered fiber lasers (1 - 3kW) are perfect for cutting mild steel. They're strong and precise. At these power levels, the laser makes a concentrated beam that cuts through mild steel easily. Mild steel is strong and flexible, and these lasers can handle different thicknesses. The higher the power, the thicker the steel they can cut. You get a clean cut with a small kerf and smooth edges, which is important for precision work. These lasers are also efficient and fast, saving you time and money, especially in factories where quality and quantity matter. They use the material well and give you a great cut every time. We use our laser systems to make electrical panel enclosures, for example.

Our 1500-watt fiber lasers can cut mild steel up to 16mm thick. And our most powerful fiber lasers with 12kW can cut mild steel as thick as 40mm.

ALSO KNOWN AS

- Carbon Steel

- Steel

- Cold Rolled Steel

- Hot Rolled Steel

COMMON USES

- Signage

- Sign Letters

- Manufactured Parts

- Art and Design

- Privacy Panels

- Brackets

- Gears

- Covers or Enclosures

STAINLESS STEEL

Our fiber laser systems can cut stainless steel accurately with our metal cutting option. You get a clean, dross-free edge. Our biggest 12KW fiber laser can handle stainless steel up to 40mm thick. For even thicker stainless steel, our high-power laser cutting machine with a 20kW laser can cut up to 100mm.

You can also etch directly onto the stainless steel surface or use a marking spray to leave a lasting mark.

COMMON USES

- Signage

- Control Panels

- Architecture

- Custom Car Parts

- Aerospace Parts

- Stainless Steel Cut Letters

- Tags and Labels

ALUMINUM

Cutting aluminum with a laser needs power and precision. A 1500W fiber laser is usually the minimum for a good cut, but most of our customers who cut aluminum use 3000W or more.

Many aluminum nameplate makers use 1500W laser systems to cut thin aluminum tags and labels really well. Fiber lasers are better for cutting aluminum labels with adhesive because of their longer wavelength. The laser cuts through the aluminum and adhesive without damaging the material too much. The beam quality and control of the fiber laser also give you a cleaner edge and less chance of burning or warping the aluminum or adhesive.

Our fiber lasers have wavelengths that let them cut aluminum cleanly and precisely. We have lasers from 1.5kW to 12kW.

You can also mark aluminum with our CypCutE 2D Cutting Software. Just use a laser marking spray to leave a dark, lasting mark on the metal.

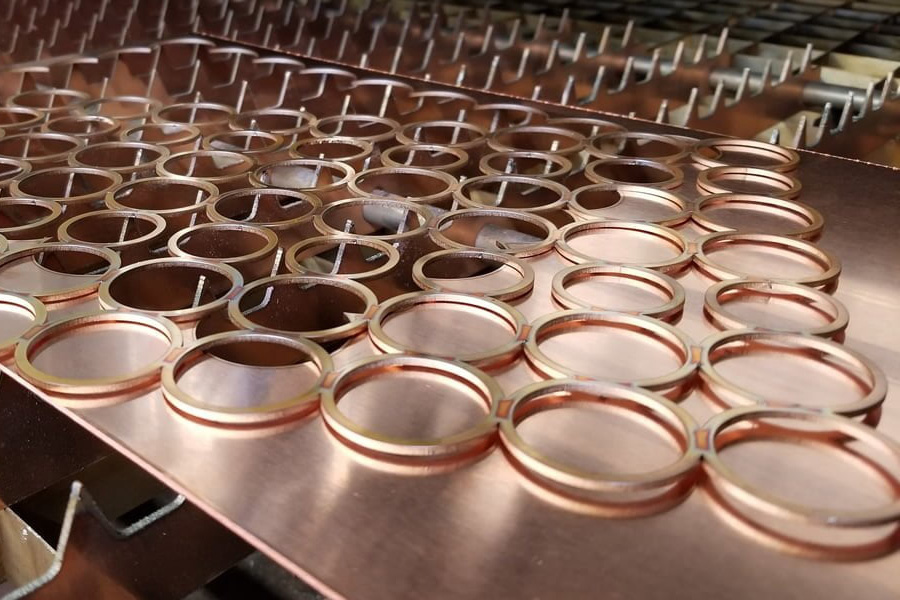

COPPER

Fiber lasers are great for cutting copper. Their short wavelength is absorbed well by copper's reflective surface, so they cut efficiently and precisely. You get clean cuts with a small kerf width, which is perfect for detailed copper designs. Fiber lasers are also more energy-efficient and faster than other lasers when cutting conductive materials like copper.

COMMON USES

- Jewelry

- Architectural Panels

- Electrical Components

- Stills

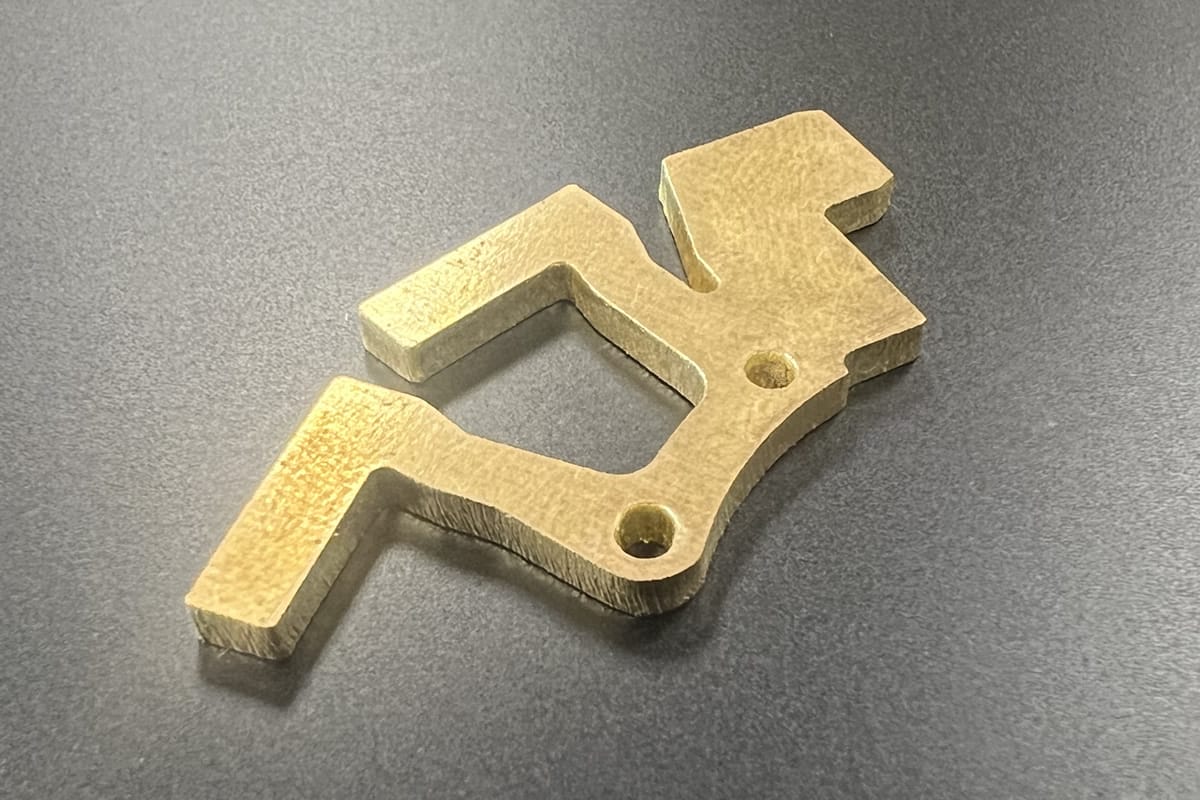

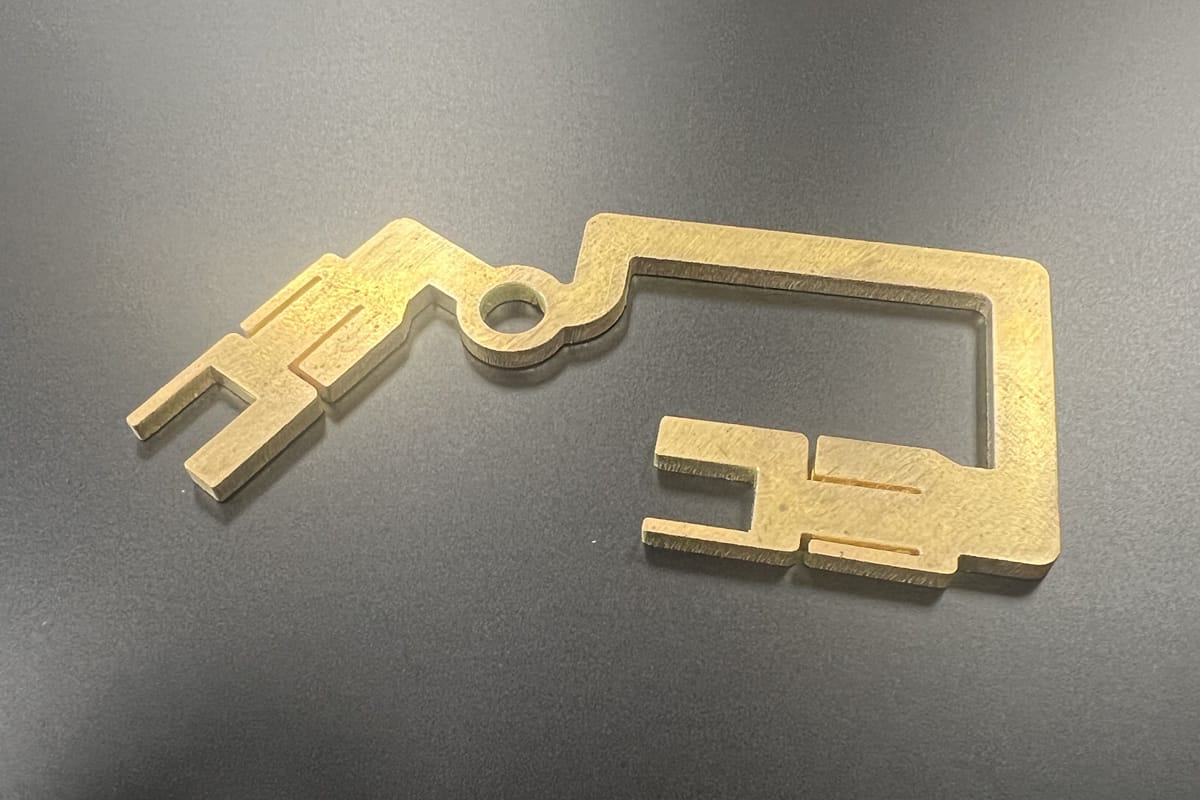

BRASS

Brass is an alloy of zinc and copper. Cutting brass with a fiber laser needs careful power and speed adjustments because it's so reflective. But fiber lasers are still a good choice because they're intense and have a short wavelength, which gives you precise cuts for detailed designs. Our laser systems cut brass sheets with high yield, using the material well and cutting cleanly with air assist.

Our 1500 and 3000 watt metal cutting systems can cut most brass alloys up to 3mm and 6mm, respectively. The CypCutE 3kW system can cut up to 6mm brass.

COMMON USES

- Architectural Panels

- Aerospace Applications

- Jewelry Making

- Arts and Crafts

- Musical Instruments

- Electronic Components

TITANIUM

Titanium is a light, strong, shiny, and corrosion-resistant metal. It's called the "space age metal" and is used in lots of industries. You can etch a dark, even mark on its surface with a marking spray or oxygen assist gas.