Technologyies

| Max Plate Thickness: | 6mm |

| Max Plate Length: | 4200mm |

| Operating Voltage: | 380V 50Hz |

| CNC System: | SYNTEC |

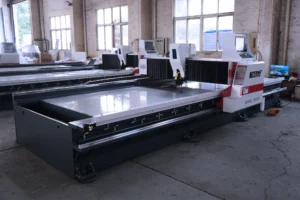

| Length * Width * Height: | 5800mm * 2750mm * 2100mm |

Configurations

Main Feature

KRRASS Vertical V Grooving Machine products provide a reliable, effective and economical solution. Knowledge, ability and experience has been the basis for the development of our mechanical and electronic drive components. Product performance and quality is never compromised while manufacturing HRK Series.

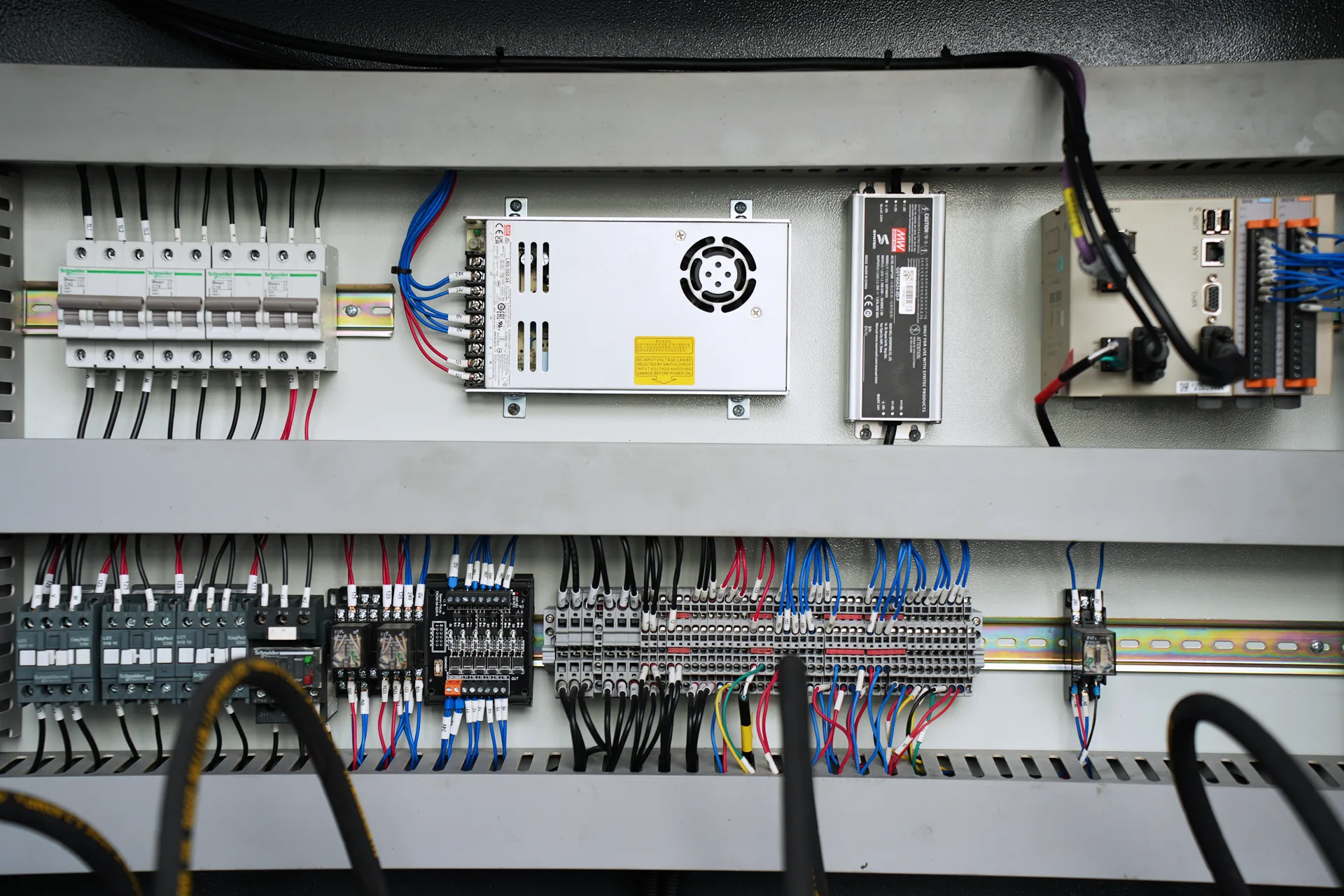

SYNTEC Control

- 15 inch CNC touch display

- Acceleration / deceleration response time: 0.5US

- With fallback function

- PLC interrupt function: scan time is

- Fixed at 10ms

- Avoid collision

Schneider Electric

High quality electric parts can perform well even the electricity is not stable and customers can easily get the replacement anywhere in the word.

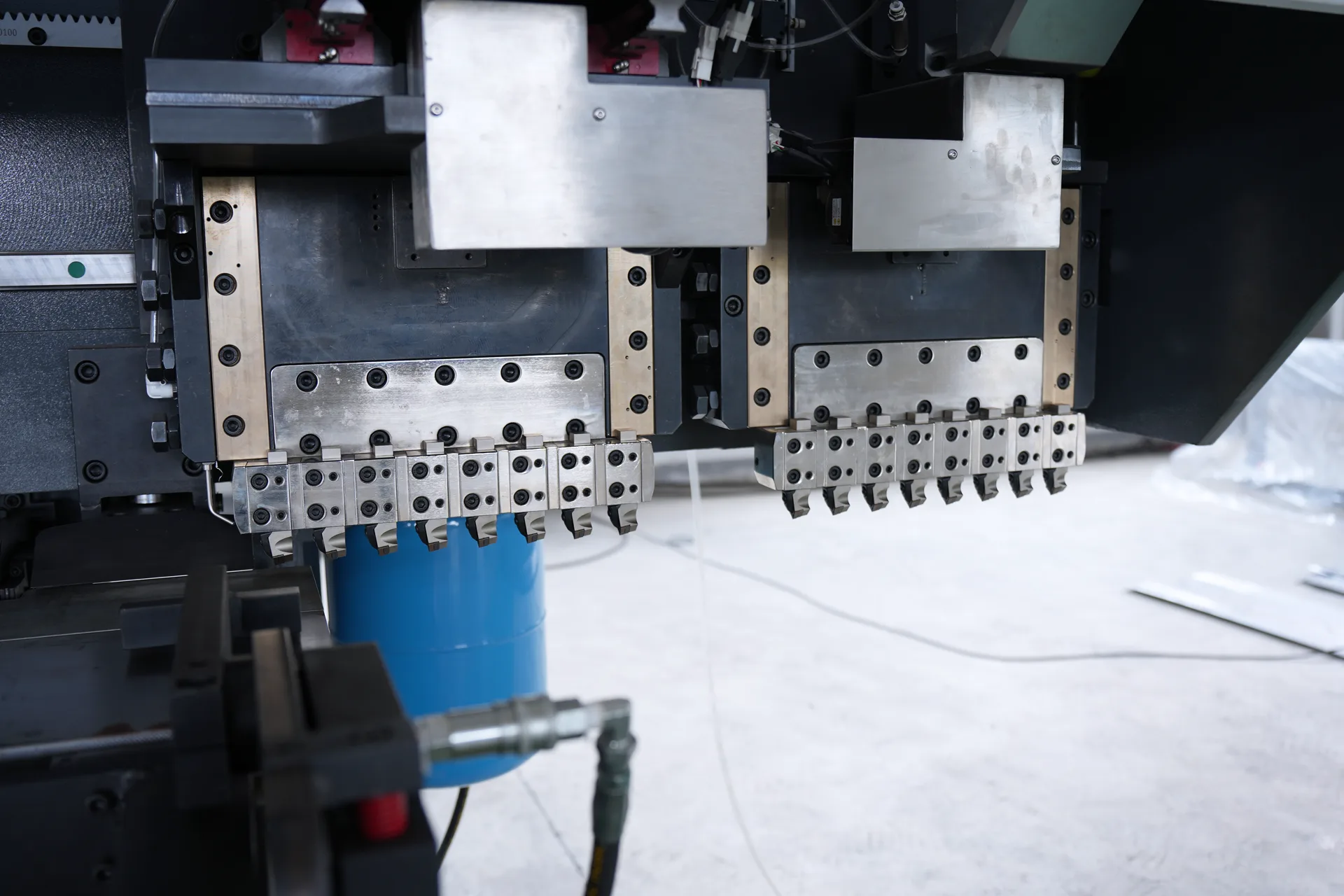

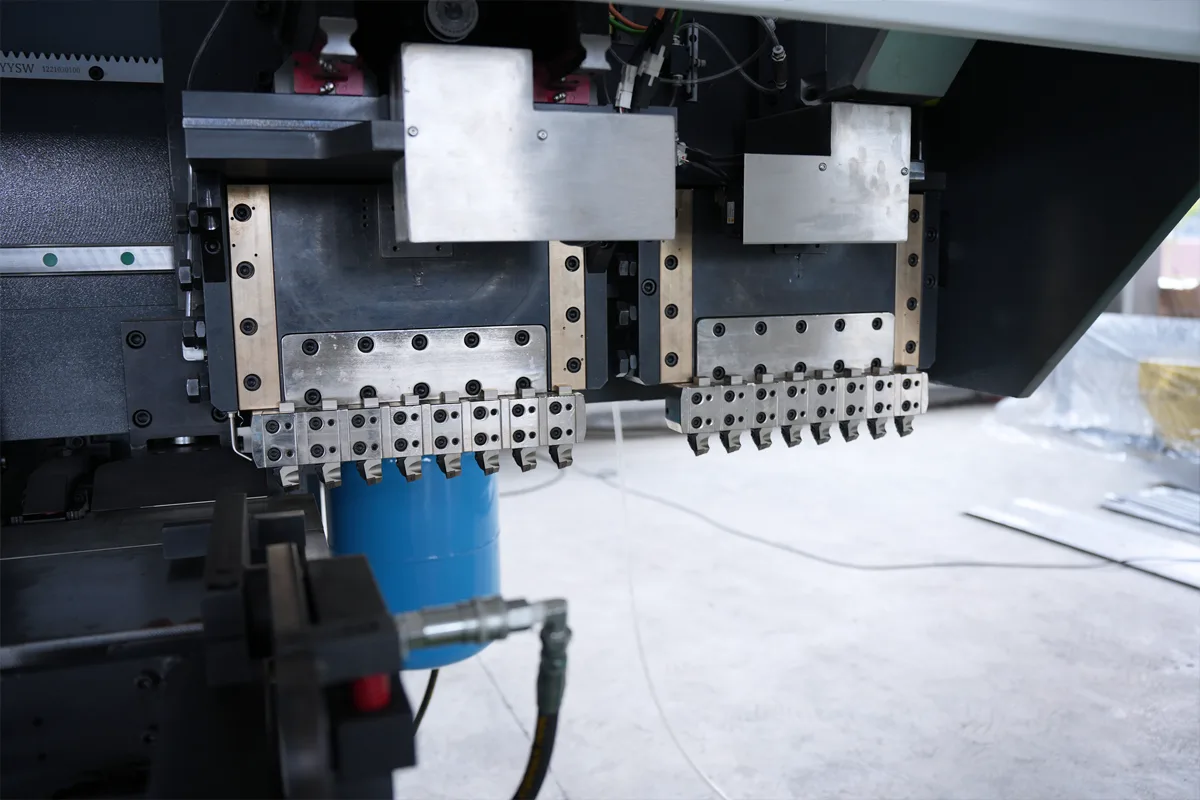

High-Precision V Grooving with Double Rails

Double guide rail precision V-groove, perfect cutting of the plate. Advanced technology ensures the accuracy of each V-groove cut, providing ideal pre-treatment for bending. Each set has 8 cutter heads, a total of 16 cutter heads, making you more efficient.

High-precision Front Clamps

Two high-precision front clamps are installed at the front of the Vertical V Grooving Machine body, which can ensure that the plate will not move randomly when you are slotting the plate, making the operation more accurate. These two high-precision front clamps can move forward and backward automatically with the CNC system, and can also be moved left and right manually according to the length of the slotted plate.

Quick-change Front Support

The front support of Vertical V Grooving Machine is strong, wear-resistant, and can be quickly retracted and switched, which is helpful when you need to groove large plates.

High-precision Rear Clamp

The Vertical V Grooving Machine is also equipped with a very high-precision rear clamp, which is driven by a high-precision servo motor to move forward and backward, and is clamped and released by a hydraulic system.

Hydraulic Station

The hydraulic system is controlled by a CNC controller, which can effectively provide powerful hydraulic power for the front and rear clamps, ensuring that the clamps can firmly clamp the metal plate during operation and ensure the grooving accuracy.

Accurate Back Support Device

The plate is fed into the Vertical V Grooving Machine through the rear clamp on the rear support device, which is driven by a servo motor to ensure that the feeding tolerance is ≤±0.03mm. The surface of the support plate has been reinforced to be more wear-resistant.

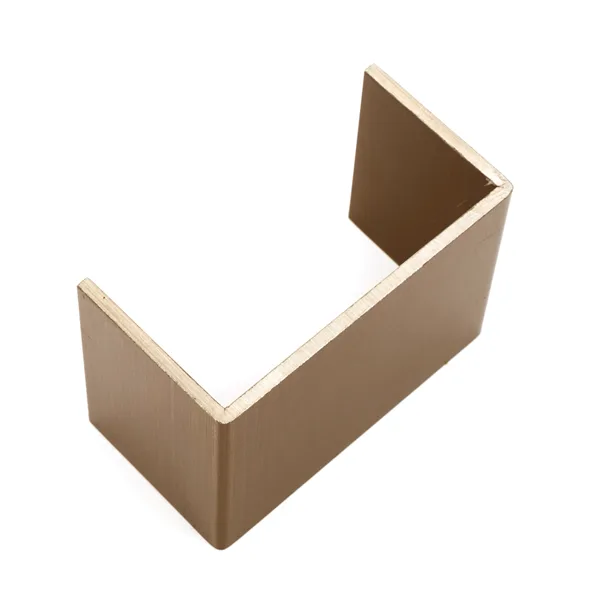

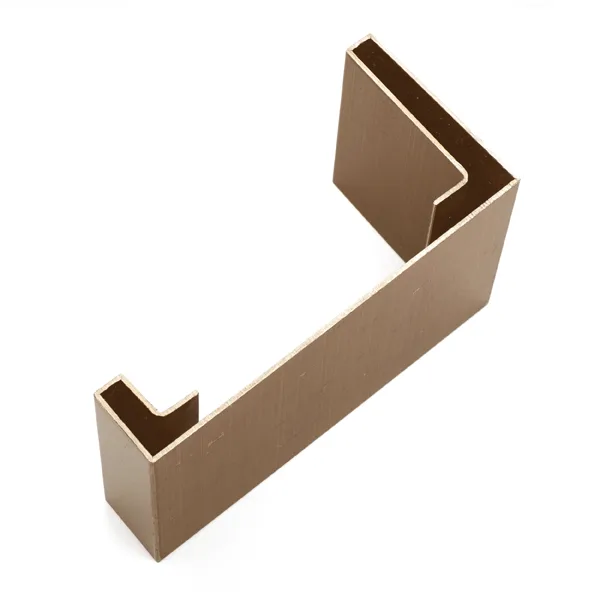

What is this Machine Used for?

Warranty

30-DAY MONEY BACK GUARANTEE

You should feel completely satisfied with your KRRASS V Grooving Machine purchase, and your peace of mind is a significant part of that process. We want you to feel the same confidence in your new KRRASS machine that we do, which is why every Press Brake purchase includes our Hassle-Free KRRASS 30-Day Return option in order to fully experience and evaluate their new KRRASS machine. It allows you to return or exchange your KRRASS purchase, for any reason, within 30 days of initial purchase. Refunds are simple and are issued once the original machine and all accompanying accessories have been returned. The refund or exchange will be issued minus the 15% restocking fee for items & accessories, 25% KRRASS V Grooving Machine Series customization fee, and shipping or handling costs are not included. Click here for details

2-YEAR LIMITED MACHINE WARRANTY

2 years Bumper to Bumper machine warranty for all machine mechanical and electrical components. (Except consumables parts) The Company represents and warrants that the KRRASS All Series of products will perform according to the warranty policy stated above from date of invoice. Products will be free from defects in materials and workmanship under normal use and service for the stated period. KRRASS has the responsibility to offer a timely solution and/or repair if deemed inoperable or defective by KRRASS Repair & Support Specialists. Clients are obligated to show proof of any such claims of machine parts or operational defects. Click here for details

Reviewed by 9 users

Related products

Related products

-

Sale!

Sale!

V Grooving Machine for Sheet Metal, Horizontal V Grooving Machine, RAS-1250X3200

5.00 out of 5$19,800.00Original price was: $19,800.00.$17,600.00Current price is: $17,600.00. Add to cart -

Sale!

Sale!

V Grooving Sheet Metal, Horizontal V Grooving Machine, RAS-1500X4000

5.00 out of 5$29,800.00Original price was: $29,800.00.$27,600.00Current price is: $27,600.00. Add to cart -

Sale!

Sale!

V Groover For Sale, Vertical V Grooving Machine HRK-1250X3200

5.00 out of 5$28,500.00Original price was: $28,500.00.$25,300.00Current price is: $25,300.00. Add to cart

Leave feedback about this